Technology and Applications of 12l14 steel

Technology and Applications of 12L14 Steel

12L14 Steel Composition and Properties

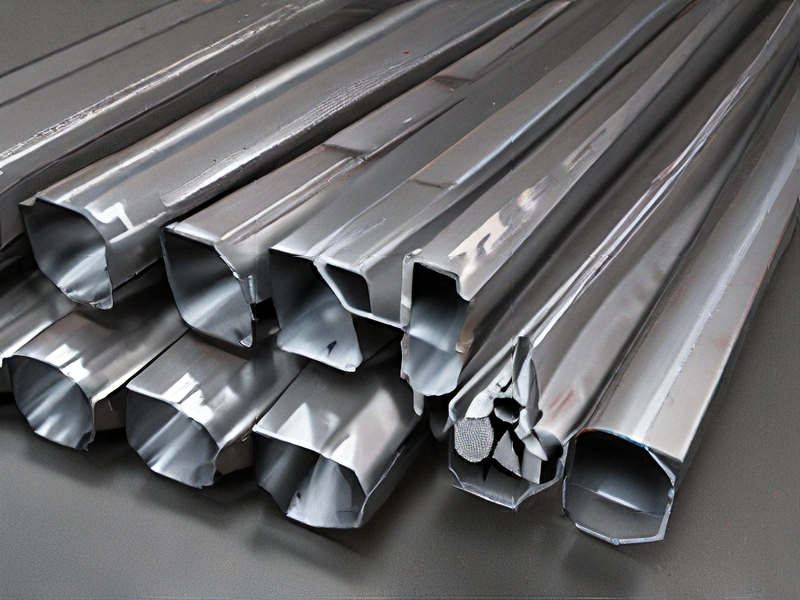

12L14 is a free-machining steel alloy known for its excellent machinability and superior surface finish. This carbon steel contains lead, enhancing its machinability without compromising its mechanical properties. The typical composition includes:

– Carbon: 0.15%

– Manganese: 0.85-1.15%

– Phosphorus: 0.04-0.09%

– Sulfur: 0.26-0.35%

– Lead: 0.15-0.35%

Technological Attributes

1. Machinability: The lead content significantly improves machinability, allowing for high-speed machining with minimal tool wear. This makes it ideal for precision machining applications.

2. Surface Finish: The alloy’s properties facilitate a superior surface finish, which is crucial for components requiring tight tolerances and fine finishes.

3. Formability and Weldability: While 12L14 is easily formed and machined, its weldability is relatively poor due to the lead content, which can cause weld cracking.

Applications

1. Automotive Industry: 12L14 is widely used in manufacturing precision automotive parts like gears, shafts, and fasteners. Its excellent machinability ensures efficient production processes and high-quality parts.

2. Electrical Components: Due to its good surface finish and precise tolerances, it is used for electrical connectors and terminals.

3. Hardware: The alloy is used to produce screws, bolts, and nuts, benefiting from its ease of machining and fine surface finish.

4. Hydraulic Components: The alloy’s properties make it suitable for producing fittings and couplings used in hydraulic systems.

Conclusion

12L14 steel is a versatile alloy, ideal for applications requiring precise machining and a high-quality surface finish. While its lead content enhances machinability, it also poses challenges for welding. Consequently, its applications are focused on industries where machining efficiency and surface integrity are paramount.

Quality Testing Methods for 12l14 steel and how to control quality

Quality testing of 12L14 steel, a leaded free-machining steel, involves several methods to ensure it meets the required specifications:

1. Chemical Composition Analysis: Conducted using spectrometry to confirm the steel contains the proper amounts of carbon, manganese, phosphorus, sulfur, lead, and other elements. This ensures the material meets standards like ASTM A108.

2. Hardness Testing: Rockwell or Brinell hardness tests measure the steel’s hardness, indicating its strength and machinability.

3. Tensile Testing: Determines the tensile strength, yield strength, and elongation of the steel, ensuring it can withstand the expected mechanical stresses.

4. Microscopic Examination: Evaluates the microstructure to detect inclusions, grain size, and distribution, which affect the steel’s mechanical properties and machinability.

5. Dimensional Inspection: Ensures the steel dimensions meet the required tolerances, critical for applications needing precise parts.

6. Surface Finish Inspection: Verifies the surface quality, detecting any defects like cracks or inclusions that could affect performance.

Quality Control Methods:

1. Supplier Quality Assurance: Work with trusted suppliers and ensure they adhere to strict quality standards. Perform regular audits and inspections.

2. In-Process Inspection: Regular inspections during manufacturing to catch defects early. Use statistical process control (SPC) to monitor and control the manufacturing process.

3. Final Inspection: Comprehensive testing of finished products to ensure they meet all specifications before shipping.

4. Documentation and Traceability: Maintain detailed records of all testing and inspections to trace any issues back to their source.

5. Training and Procedures: Ensure all personnel are trained in quality control procedures and understand the importance of maintaining quality standards.

Implementing these methods and controls ensures 12L14 steel meets required quality standards, providing reliable performance in its intended applications.

Tips for Procurement and Considerations when Purchasing from 12l14 steel

When purchasing 12L14 steel, consider several key factors to ensure you make an informed procurement decision:

1. Material Specifications: Verify that 12L14 steel meets your specific requirements in terms of chemical composition, mechanical properties, and dimensional tolerances. This includes ensuring it adheres to ASTM standards or other relevant specifications.

2. Supplier Reputation: Choose a reputable supplier known for quality materials and reliable service. Check reviews, certifications, and their track record in delivering materials on time and as specified.

3. Cost and Budget: Compare prices from different suppliers while considering the overall cost, including shipping, taxes, and any additional fees. Balance cost-effectiveness with the quality and reliability of the supplier.

4. Lead Times: Evaluate the supplier’s lead times to ensure they can meet your project timelines. Consider factors like production capacity and potential delays in sourcing or manufacturing.

5. Quality Assurance: Inquire about the supplier’s quality control processes. Ensure they conduct necessary inspections and tests to guarantee the material’s integrity and compliance with standards.

6. Technical Support: Determine if the supplier offers technical support or guidance regarding the use and properties of 12L14 steel. This can be crucial for selecting the right material for your application.

7. Environmental Considerations: If applicable, assess the supplier’s environmental policies and practices to align with your organization’s sustainability goals.

8. Communication and Customer Service: Opt for a supplier with clear communication channels and responsive customer service. This facilitates smooth transactions and effective resolution of any issues that may arise.

By carefully considering these factors, you can streamline the procurement process and ensure that the 12L14 steel you purchase meets your project’s requirements in terms of quality, cost-effectiveness, and reliability.

FAQs on Sourcing and Manufacturing from 12l14 steel in China

FAQs on Sourcing and Manufacturing from 12L14 Steel in China

#### What is 12L14 Steel?

12L14 steel is a low-carbon steel with added lead for enhanced machinability. It’s widely used for producing precision parts that require extensive machining, like fittings and fasteners.

#### Why Source 12L14 Steel from China?

China offers competitive pricing, a broad range of suppliers, and significant manufacturing capacity. Many Chinese suppliers have experience with international standards and can provide high-quality 12L14 steel.

#### How to Find Reliable Suppliers in China?

1. Research Online: Use platforms like Alibaba, Made-in-China, and Global Sources.

2. Verify Credentials: Check certifications like ISO and customer reviews.

3. Request Samples: Evaluate the quality before placing large orders.

4. Visit Factories: If possible, visit the manufacturing facilities to ensure compliance with standards.

#### What Are the Key Considerations When Sourcing 12L14 Steel?

1. Quality Standards: Ensure the supplier adheres to ASTM, AISI, or other relevant standards.

2. Machinability: Confirm the material’s properties for your specific machining needs.

3. Price: Compare prices from multiple suppliers to get the best deal.

4. Lead Times: Understand the production and delivery timelines.

#### What Are Common Challenges?

1. Quality Control: Maintaining consistent quality can be a challenge. Regular inspections and third-party audits can mitigate this.

2. Communication Barriers: Language and cultural differences may cause misunderstandings. Clear contracts and regular communication are crucial.

3. Logistics: Shipping delays and customs issues can impact delivery times. Working with experienced logistics providers can help.

#### How to Ensure Compliance and Quality?

1. Third-Party Inspections: Use independent inspection services to verify the quality.

2. Regular Audits: Conduct periodic audits of the manufacturing process.

3. Detailed Specifications: Provide clear and detailed product specifications to avoid misunderstandings.

By following these guidelines, you can effectively source and manufacture 12L14 steel products from China, ensuring high quality and reliability.