Technology and Applications of 4×8 cnc routers

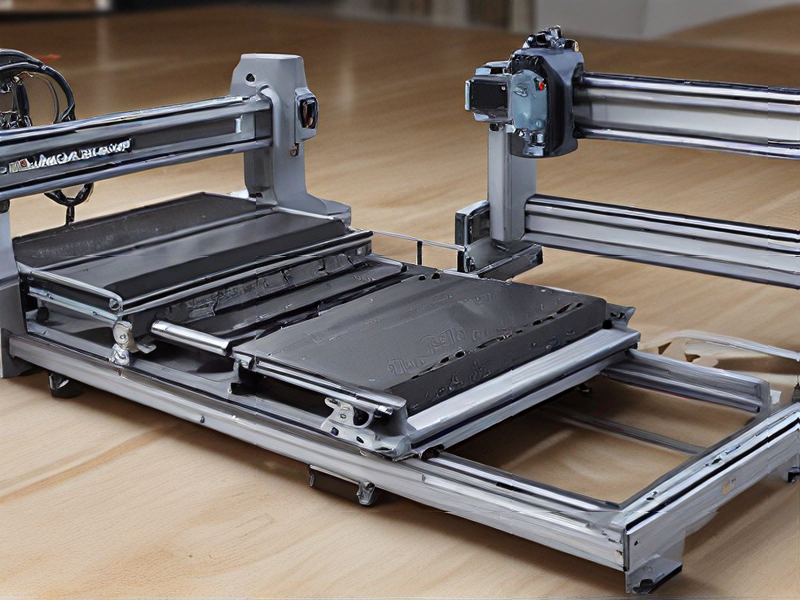

A 4×8 CNC (Computer Numerical Control) router is a versatile machine used extensively in manufacturing and crafting industries. The “4×8” refers to the dimensions of the working area, which is 4 feet by 8 feet. This size is ideal for handling large sheets of material like wood, plastic, and metal.

Technology

CNC routers operate through computer-controlled movements, allowing for high precision and repeatability. Key technological components include:

1. Controller: The brain of the CNC router, it interprets design files (usually G-code) and translates them into movement commands for the machine.

2. Spindle: The cutting tool’s motor, which can rotate at various speeds to cut different materials.

3. Drive System: Typically utilizes stepper or servo motors to move the spindle along the X, Y, and Z axes with precision.

4. Frame and Table: A sturdy structure to support the material and ensure stability during cutting.

5. Software: CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are used to create designs and convert them into instructions for the router.

Applications

1. Woodworking: Ideal for creating furniture, cabinetry, and decorative pieces. CNC routers can perform intricate cuts, engravings, and carvings.

2. Sign Making: Used to cut and engrave signs from various materials, including wood, plastics, and metals.

3. Prototyping and Production: Useful in both rapid prototyping and mass production, allowing for quick turnaround and consistent quality.

4. Aerospace and Automotive: Utilized for producing components and molds due to their precision and ability to handle tough materials.

5. Arts and Crafts: Artists and hobbyists use CNC routers to create detailed sculptures, models, and custom pieces.

Advantages

– Precision and Accuracy: High repeatability and minimal error margins.

– Versatility: Capable of handling a wide range of materials.

– Efficiency: Faster production times compared to manual methods.

– Complex Designs: Ability to produce intricate and complex shapes not feasible by hand.

In summary, 4×8 CNC routers integrate advanced technology to offer precise, versatile, and efficient solutions across various industries, from large-scale manufacturing to detailed artistic creations.

Quality Testing Methods for 4×8 cnc routers and how to control quality

Quality testing methods for 4×8 CNC routers typically involve a combination of the following approaches:

1. Dimensional Accuracy: Measure the dimensions of finished products against design specifications using precision calipers or coordinate measuring machines (CMM). This ensures parts are within tolerances.

2. Surface Finish Evaluation: Use surface roughness testers to assess the smoothness of machined surfaces. This helps maintain consistent quality in aesthetic and functional aspects.

3. Material Inspection: Verify the material properties such as hardness, tensile strength, and composition to ensure they meet required standards for durability and performance.

4. Tooling Inspection: Regularly check the condition and sharpness of cutting tools (end mills, drills) to maintain machining quality and avoid defects like burrs or tear-outs.

5. Performance Testing: Run sample jobs or prototypes through the CNC router to evaluate performance under typical operating conditions. This includes checking for accuracy in cutting profiles, hole drilling, and overall machine stability.

To control quality effectively:

– Establish Standard Operating Procedures (SOPs): Document clear procedures for setup, operation, maintenance, and quality checks.

– Implement Regular Maintenance: Schedule routine maintenance for the CNC router and its components to prevent breakdowns and ensure consistent performance.

– Training and Skill Development: Provide training for operators on machine operation, tooling changes, and quality inspection techniques.

– Quality Assurance Checks: Conduct regular audits of the production process and output to identify potential issues early.

– Feedback Loop: Establish a feedback mechanism where operators can report issues encountered during machining processes for continuous improvement.

By integrating these testing methods and quality control measures, manufacturers can ensure consistent, high-quality output from their 4×8 CNC routers.

Tips for Procurement and Considerations when Purchasing from 4×8 cnc routers

When purchasing a 4×8 CNC router for procurement purposes, several key considerations can optimize your decision-making process:

1. Machine Specifications: Evaluate bed size, spindle power, and cutting speed to ensure they meet your production needs. Consider the material compatibility (wood, plastic, aluminum) and the maximum thickness the machine can handle.

2. Precision and Accuracy: Look for CNC routers with robust construction and high-quality components to ensure precise cuts and consistent performance over time. Check reviews and specifications for details on tolerance levels and repeatability.

3. Software Compatibility: Ensure compatibility with your existing CAD/CAM software. Evaluate ease of programming and the availability of updates and support for the software platform.

4. Maintenance and Support: Research the reputation of the manufacturer or supplier for customer support and maintenance services. Consider warranties, availability of spare parts, and technical assistance.

5. User Interface and Ease of Use: User-friendly interfaces and intuitive controls can reduce training time and increase productivity. Look for features like touchscreen controls, remote monitoring capabilities, and compatibility with mobile devices.

6. Safety Features: Prioritize machines with safety features such as emergency stop buttons, protective enclosures, and automatic tool height adjustment to minimize risks in operation.

7. Cost and ROI: Evaluate initial purchase costs against long-term return on investment (ROI). Consider factors like energy efficiency, maintenance costs, and productivity gains when assessing overall value.

8. Reviews and Recommendations: Seek feedback from other users or industry experts. Online reviews and testimonials can provide insights into real-world performance and reliability.

By focusing on these considerations, you can streamline your procurement process and choose a 4×8 CNC router that aligns with your production requirements and business goals effectively.

FAQs on Sourcing and Manufacturing from 4×8 cnc routers in China

Certainly! When sourcing and manufacturing 4×8 CNC routers from China, several frequently asked questions (FAQs) commonly arise:

1. Quality Assurance: How can I ensure the quality of CNC routers from Chinese manufacturers?

– Answer: Research manufacturers thoroughly, request samples, and consider using third-party inspection services to verify quality standards.

2. Cost Considerations: What are the typical costs associated with importing CNC routers from China?

– Answer: Costs include manufacturing, shipping, import duties, and potential customs fees. Get detailed quotes from multiple suppliers to compare.

3. Lead Times: How long does it take to manufacture and deliver 4×8 CNC routers from China?

– Answer: Lead times vary but typically range from a few weeks to a few months. Factor in production schedules and shipping times when planning.

4. Communication and Language: How can I effectively communicate with Chinese manufacturers if there is a language barrier?

– Answer: Many manufacturers have English-speaking staff. Clear communication is crucial; consider using translators or interpreters if necessary.

5. Customization: Can Chinese manufacturers customize CNC routers to specific requirements?

– Answer: Yes, many manufacturers offer customization options. Clearly communicate your specifications and ensure they can be met before finalizing orders.

6. After-Sales Support: What kind of after-sales support can I expect from Chinese manufacturers?

– Answer: Ensure the manufacturer offers warranties and support for troubleshooting and repairs. Clarify terms before finalizing any agreements.

7. Certifications and Compliance: What certifications should I look for when importing CNC routers from China?

– Answer: Look for certifications such as CE, ISO, or UL, depending on your market’s regulatory requirements. Verify authenticity and validity.

8. Payment Terms: What are the typical payment terms when dealing with Chinese manufacturers?

– Answer: Payment terms often involve a deposit upfront and balance upon completion or before shipping. Use secure payment methods and consider payment terms negotiation.

By addressing these FAQs, importers can navigate the sourcing and manufacturing process of 4×8 CNC routers from China more effectively, ensuring smoother transactions and satisfactory outcomes.