Reliable

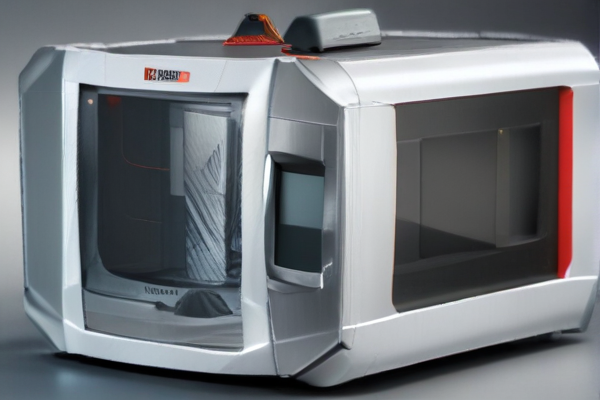

SourcifyChina Factory Metal Cutter Laser Machine: High Precision and Efficiency for Industrial Applications

The SourcifyChina factory metal cutter laser machine stands out in the market for its reliability and precision. Designed for various industrial applications, this machine ensures high efficiency and exceptional accuracy, making it a valuable asset for businesses involved in metal fabrication.

Key Features:

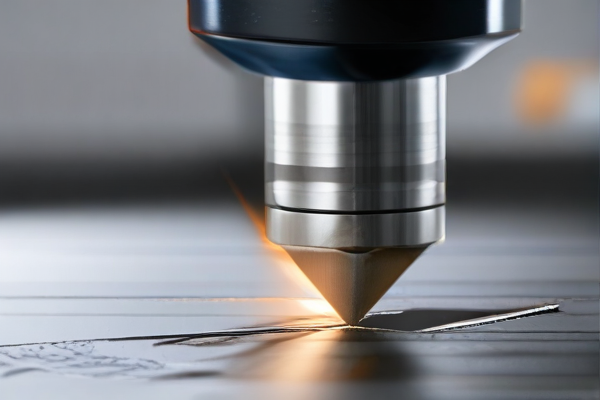

1. High Precision Cutting: The laser cutter delivers precise cuts, minimizing material wastage and ensuring consistent quality.

2. Advanced Technology: Equipped with the latest laser technology, it offers enhanced performance and durability.

3. User-Friendly Interface: The intuitive interface allows for easy operation and quick setup, reducing downtime.

4. Versatile Applications: Suitable for cutting various metals, including steel, aluminum, and copper, making it ideal for diverse industries.

5. Cost-Effective: The machine’s efficiency and low maintenance costs contribute to overall cost savings for manufacturers.

Why Choose SourcifyChina?

– Reliable Supplier: SourcifyChina is known for its dependable products and excellent customer service.

– Quality Assurance: Each machine undergoes rigorous testing to meet international standards.

– After-Sales Support: Comprehensive support services ensure smooth operation and prompt resolution of any issues.

In summary, the SourcifyChina factory metal cutter laser machine offers a combination of reliability, precision, and efficiency, making it an excellent choice for businesses looking to enhance their metal cutting operations.

Why Choose “SourcifyChina” Factory for Purchasing Metal Cutter Laser Machines from China?

“SourcifyChina” offers unparalleled expertise in manufacturing high-quality metal cutter laser machines. Their advanced technology ensures precise and efficient cutting, meeting the diverse needs of various industries. This makes them a top choice for buyers seeking reliable and innovative solutions.

The factory is renowned for its stringent quality control processes. Every machine undergoes rigorous testing to ensure durability and performance. This commitment to quality guarantees that buyers receive products that meet the highest industry standards, ensuring long-term reliability and satisfaction.

Competitive pricing is another significant advantage of choosing “SourcifyChina”. They offer high-quality machines at affordable rates, providing excellent value for money. This cost-effectiveness allows buyers to maximize their budget without compromising on quality or performance.

Customer support at “SourcifyChina” is exceptional. They provide comprehensive after-sales services, including technical support and maintenance. This ensures that buyers have continuous assistance, enhancing their overall experience and satisfaction with the purchase.

The factory’s customization capabilities set them apart. They offer tailored solutions to meet specific requirements, ensuring that each machine perfectly fits the buyer’s needs. This flexibility makes “SourcifyChina” an ideal partner for businesses looking for bespoke metal cutting solutions.

In conclusion, “SourcifyChina” combines advanced technology, stringent quality control, competitive pricing, excellent customer support, and customization capabilities. These factors make them a superior choice for buyers looking to purchase metal cutter laser machines from China.

Metal cutter laser machines are essential for precision cutting in various industries. They offer different types and options based on power, application, and technology. Here’s a detailed overview of the common types and features.

Types of Metal Cutter Laser Machines:

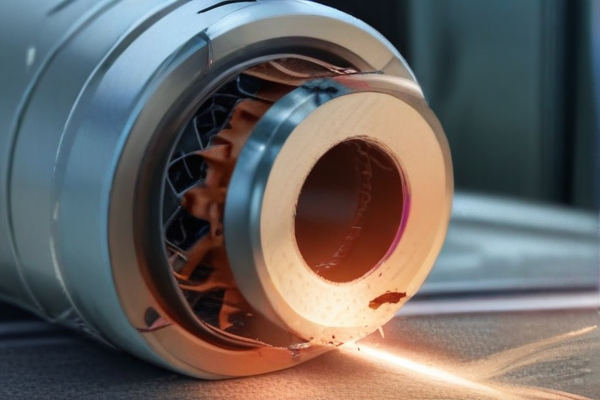

– CO2 Laser Cutters: Utilize CO2 gas to generate the laser beam. Ideal for cutting, engraving, and marking on non-metallic materials and thin metals.

– Fiber Laser Cutters: Use optical fibers doped with rare earth elements to produce the laser. Known for high efficiency, low maintenance, and excellent cutting speed on metals.

– Nd:YAG Laser Cutters: Employ neodymium-doped yttrium aluminum garnet as the lasing medium. Suitable for both cutting and welding of metals.

Options and Features:

– Power Levels: Available in various power outputs (e.g., 500W, 1000W, 3000W) to cater to different material thicknesses and cutting speeds.

– Cutting Area Size: Machines come in different sizes (e.g., 4×8 feet, 5×10 feet) to accommodate varying sheet metal dimensions.

– Software Integration: Advanced CNC systems with user-friendly interfaces for precise control and automation.

– Cooling Systems: Water or air cooling mechanisms to manage heat dissipation and maintain optimal performance.

– Automatic Loading and Unloading: Automation options to enhance productivity by reducing manual handling.

– Dual-Purpose Machines: Some models combine cutting and engraving capabilities for versatile use.

– Safety Features: Enclosures, emergency stop buttons, and smoke extractors to ensure operator safety.

These types and options allow businesses to choose the right metal cutter laser machine tailored to their specific needs, enhancing efficiency and precision in metalworking tasks.

Metal cutter laser machines are crucial in industrial settings for precise cutting of metals like steel, aluminum, and titanium. They find applications in:

– Manufacturing components for aerospace and automotive industries.

– Creating intricate designs in metal artwork.

– Fabricating precise parts for electronics and medical devices.

– Enabling efficient production in sheet metal fabrication.

– Customizing metal components in architectural projects.

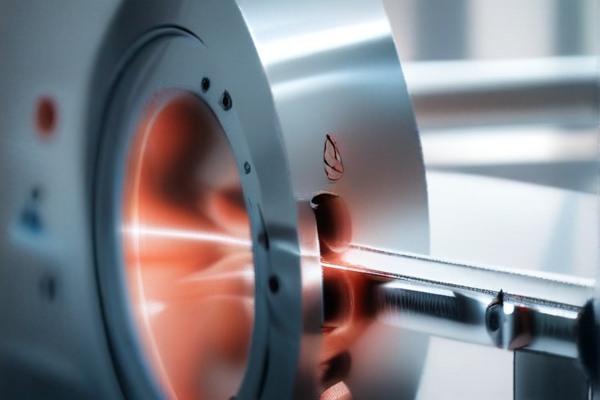

Metal cutter laser machines have become essential tools in the Aerospace, Defense, and Marine industries due to their precision, efficiency, and versatility. These machines use high-powered lasers to cut through various metals with unparalleled accuracy, which is crucial for manufacturing complex components. In the aerospace sector, laser cutters are used to fabricate lightweight yet strong parts, ensuring the structural integrity and performance of aircraft. The ability to cut intricate shapes and designs with minimal waste also makes them ideal for producing specialized components needed in defense applications, where precision and reliability are paramount. Additionally, in the marine industry, laser cutting technology is employed to create durable parts for ships and submarines, enhancing their longevity and performance in harsh marine environments.

The advantages of metal cutter laser machines extend beyond precision cutting. They offer significant improvements in production speed and cost-efficiency, which are critical in industries that demand high standards and fast turnaround times. The non-contact nature of laser cutting reduces the risk of material deformation and eliminates the need for secondary finishing processes, further streamlining production workflows. For defense and aerospace, where material properties and integrity cannot be compromised, laser cutting ensures components meet stringent regulatory standards. Furthermore, the flexibility of laser cutters allows for quick reprogramming and adaptation to different projects, providing a versatile solution for diverse manufacturing needs. In the marine industry, this adaptability is crucial for maintaining and upgrading fleets with custom-fabricated parts, ensuring vessels remain operational and efficient.

In the automotive industry, metal cutter laser machines play a pivotal role in enhancing manufacturing precision and efficiency. These machines utilize high-powered laser beams to cut through various metal components, allowing for the creation of intricate and precise parts used in vehicle production. The precision of laser cutting ensures that each part meets stringent specifications, which is crucial for maintaining the safety and performance standards of automotive components. Additionally, laser cutting reduces the need for subsequent finishing processes, streamlining production and lowering costs. This technology is particularly beneficial for producing complex geometries found in engine components, body panels, and intricate interior parts, enabling automotive manufacturers to innovate and improve vehicle designs rapidly.

In the electronics sector, metal cutter laser machines are indispensable for fabricating small, intricate components required in modern devices. The precision and minimal thermal impact of laser cutting make it ideal for producing delicate parts such as circuit boards, microelectromechanical systems (MEMS), and various connectors. Laser cutting allows for high repeatability and accuracy, essential for mass production in the electronics industry where tolerances are extremely tight. Furthermore, the ability to cut and engrave fine features on metals enhances the design capabilities of electronic devices, contributing to the miniaturization trend prevalent in consumer electronics. The efficiency and precision of metal cutter laser machines thus significantly enhance production capabilities and product quality in the electronics industry.

Metal cutter laser machines have revolutionized the construction industry by providing precise and efficient cutting solutions. These machines use high-powered lasers to cut through various metals, such as steel, aluminum, and titanium, with exceptional accuracy. This precision minimizes material wastage and ensures that components fit perfectly during assembly, reducing the need for further adjustments. In construction, where structural integrity and fit are critical, laser cutters offer unparalleled reliability. Additionally, their ability to handle complex shapes and fine details allows for innovative architectural designs and intricate structural components that would be challenging to achieve with traditional cutting methods.

In the energy sector, metal cutter laser machines play a vital role in the fabrication of components for renewable energy systems, such as wind turbines and solar panels. The precision cutting capabilities ensure that parts are manufactured to exact specifications, which is crucial for the efficiency and performance of energy systems. For instance, the intricate designs of wind turbine blades and solar panel mounts require precise cuts that only laser machines can provide. Moreover, the speed and efficiency of laser cutting reduce production times and costs, making the development of renewable energy technologies more economical. As the demand for clean energy solutions grows, the utilization of laser cutting technology will continue to enhance the quality and performance of energy infrastructure.

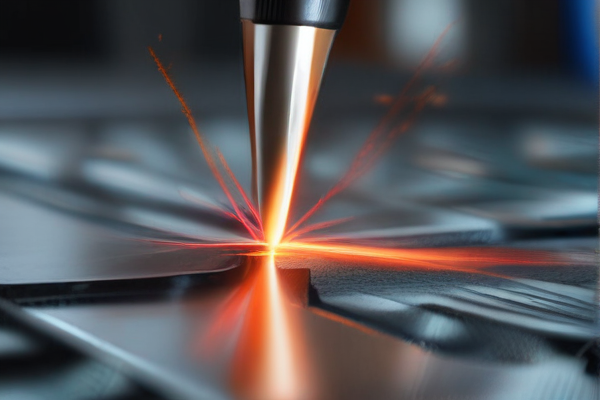

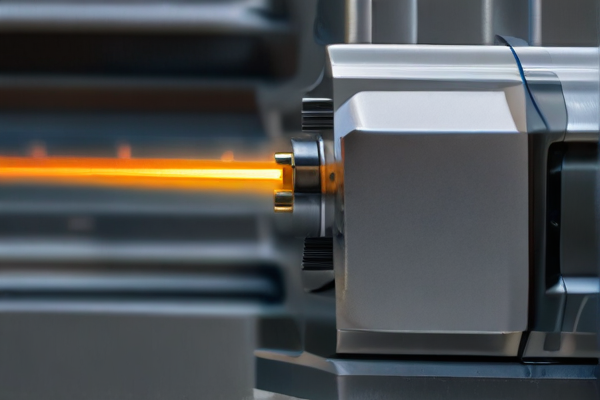

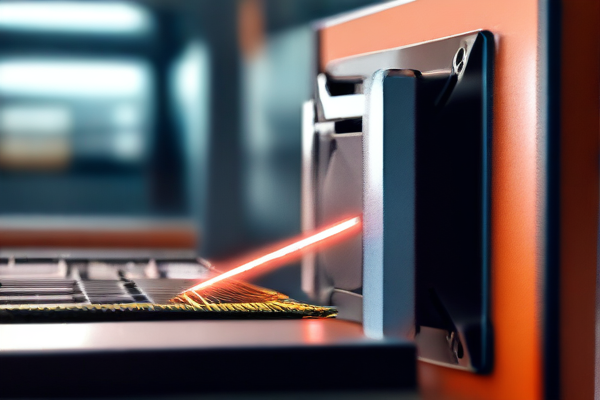

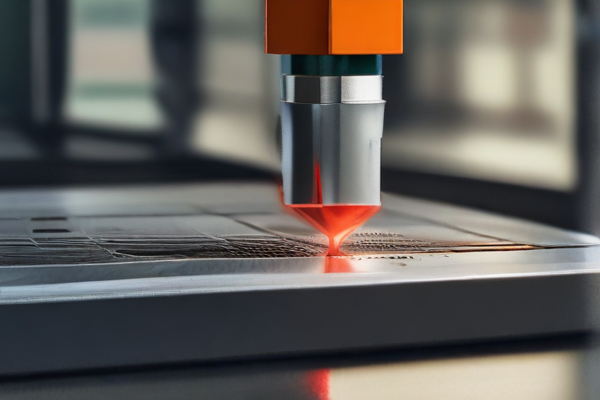

A metal cutter laser machine is a highly advanced piece of industrial equipment designed for precision cutting of various metals. Utilizing the power of a concentrated laser beam, these machines can cut through metals like stainless steel, aluminum, brass, and copper with remarkable accuracy and speed. The technology behind laser cutting involves focusing a high-energy laser onto the metal surface, which melts, burns, or vaporizes the material along a predefined path. This results in clean, sharp edges and intricate designs that would be difficult or impossible to achieve with traditional cutting methods. Additionally, laser cutters often feature computer numerical control (CNC) systems, allowing for automation and repeatability in production processes, thus enhancing efficiency and reducing manual labor.

The benefits of using a metal cutter laser machine in an industrial setting are numerous. One of the key advantages is the ability to produce complex shapes and fine details with minimal material waste. The precision of laser cutting also ensures that parts fit together perfectly, which is crucial for industries such as aerospace, automotive, and manufacturing where tolerances are tight. Moreover, the non-contact nature of laser cutting reduces the risk of material deformation or contamination, preserving the integrity of the metals being processed. Furthermore, advancements in laser technology have led to faster cutting speeds and the ability to handle thicker materials, broadening the range of applications. In summary, metal cutter laser machines represent a significant technological advancement in metal fabrication, offering superior accuracy, efficiency, and versatility.

Metal cutter laser machines have revolutionized the manufacturing of medical devices by providing unparalleled precision and efficiency. These machines use highly focused laser beams to cut through metal with extreme accuracy, ensuring that the components meet the stringent specifications required in the medical industry. The ability to produce intricate shapes and designs without physical contact reduces the risk of contamination, a crucial factor in medical device production. Additionally, the laser cutting process minimizes thermal distortion, preserving the integrity and functionality of the metals used in medical implants, surgical instruments, and other critical devices.

In the realm of medical devices, metal cutter laser machines facilitate the production of components with complex geometries and fine details that are difficult to achieve with traditional manufacturing methods. For instance, stents, pacemakers, and orthopedic implants often require precise cuts and smooth finishes to function correctly and ensure patient safety. Laser cutting technology also supports rapid prototyping and customization, enabling manufacturers to quickly develop and test new designs. This flexibility accelerates the innovation cycle and allows for the tailored production of medical devices, enhancing their effectiveness and reliability in medical applications.

A metal cutter laser machine is an advanced tool used extensively in machining and manufacturing for precision cutting of metal materials. It employs a high-powered laser beam to melt, burn, or vaporize metal, creating intricate cuts with exceptional accuracy. The laser cutter’s ability to produce clean edges and minimal material wastage makes it a preferred choice for various applications, from automotive to aerospace industries. Its non-contact cutting method reduces the risk of mechanical deformation, enhancing the overall quality of the finished product. Additionally, the flexibility of laser cutting allows for complex geometries that are difficult to achieve with traditional cutting methods.

The efficiency and versatility of metal cutter laser machines have revolutionized the manufacturing sector. These machines are equipped with computer numerical control (CNC) systems, enabling automated and highly precise operations. This automation not only increases production speed but also ensures consistent quality across large batches. Furthermore, advancements in laser technology, such as fiber lasers, have improved energy efficiency and cutting capabilities, allowing for thicker and more diverse metal types to be processed. Overall, the adoption of laser cutting technology in metalworking has significantly enhanced productivity, reduced production costs, and expanded the potential for innovation in product design.

The SourcifyChina metal cutter laser machine is constructed with high-grade materials to ensure durability and precision. Its frame is made from industrial-strength steel, providing a sturdy base that minimizes vibrations during operation. This steel is treated to resist corrosion, extending the machine’s lifespan.

The laser cutting head features high-quality optics, usually composed of glass or synthetic sapphire, ensuring accurate and clean cuts. These materials are chosen for their ability to withstand high temperatures and maintain clarity over extended use.

The machine’s electronic components, including the laser source and control system, are sourced from reputable manufacturers. This ensures reliable performance and integration with advanced software, allowing for precise control and customization of cutting parameters.

Protective components, such as the safety enclosures and shields, are made from impact-resistant polycarbonate. This material offers clear visibility of the cutting process while providing protection from laser emissions and debris.

In summary, the SourcifyChina metal cutter laser machine is built using robust and reliable materials, ensuring high performance, durability, and safety for various industrial applications.

The quality control manufacturing process for SourcifyChina’s metal cutter laser machine begins with the careful selection of raw materials. Only high-grade metals and components are chosen to ensure durability and performance.

Next, precision machining and assembly are carried out using state-of-the-art equipment. This step involves meticulous attention to detail to guarantee that each part fits perfectly and operates smoothly.

Throughout the production process, rigorous testing is conducted at various stages. This includes laser calibration, cutting accuracy tests, and thermal stability checks to ensure optimal functionality.

Quality assurance teams perform final inspections before the machines are shipped. These inspections include verifying the alignment, laser power consistency, and overall machine integrity.

Moreover, each metal cutter laser machine undergoes a trial run to simulate real-world operating conditions. This step is crucial for identifying any potential issues and making necessary adjustments.

Continuous improvement protocols are in place, incorporating feedback from clients and the latest technological advancements. This ensures that the machines not only meet but exceed industry standards.

Documentation and certification processes are meticulously handled, providing customers with detailed records of the quality control measures implemented. This transparency builds trust and ensures compliance with international standards.

In conclusion, SourcifyChina’s commitment to quality is evident in every step of their metal cutter laser machine manufacturing process. From material selection to final inspections, each stage is designed to ensure the highest level of precision and reliability. This comprehensive approach guarantees that customers receive machines that are not only efficient but also durable and dependable.

The SourcifyChina metal cutter laser machine offers high precision cutting, ensuring intricate designs and accurate results. It can cut various metals, including steel, aluminum, and copper, with exceptional speed and efficiency.

The machine is equipped with advanced laser technology, allowing for clean and smooth edges. This reduces the need for secondary processing, saving time and resources. Its automated features enhance productivity by minimizing manual intervention and maximizing output.

Designed for durability and reliability, the SourcifyChina metal cutter laser machine boasts a robust build quality. It requires minimal maintenance, making it a cost-effective solution for long-term use. The user-friendly interface simplifies operation, making it accessible to both experienced professionals and beginners.

The machine also supports customizable settings, catering to specific project requirements. Its energy-efficient design helps reduce operational costs while maintaining high performance. With safety features integrated, the machine ensures a secure working environment for operators.

In conclusion, the SourcifyChina metal cutter laser machine is a versatile and efficient tool for metal cutting needs. Its advanced features, ease of use, and cost-effectiveness make it an excellent choice for businesses looking to improve their metal fabrication processes.

A metal cutter laser machine offers significant advantages for various industries, enhancing precision, speed, and versatility in metalworking processes.

– Precision and Accuracy: Laser cutting achieves extremely fine and intricate cuts, minimizing material waste and ensuring consistent quality.

– Speed and Efficiency: High cutting speeds reduce production times, enabling faster turnaround for projects.

– Versatility: Suitable for cutting a wide range of metals, including steel, aluminum, and titanium, accommodating diverse industrial needs.

– Automation: Modern laser cutters can be integrated with automated systems, reducing manual labor and increasing production efficiency.

– Cost-Effective: Though the initial investment is high, the reduction in material waste, labor costs, and improved production speed results in long-term savings.

– Minimal Material Distortion: Laser cutting generates minimal heat-affected zones, preserving the integrity of the material.

– Complex Shapes and Designs: Capable of cutting complex geometries that traditional methods struggle with, expanding design possibilities.

– Low Maintenance: Compared to mechanical cutting tools, laser cutters require less maintenance, reducing downtime.

– Environmentally Friendly: Produces fewer emissions and waste, contributing to a greener manufacturing process.

– Consistent Results: Delivers uniform results across large production runs, ensuring high-quality standards are met consistently.

These benefits make metal cutter laser machines an indispensable tool in modern manufacturing, driving efficiency and innovation.

Metal cutter laser machines are highly efficient tools designed for precise cutting of various metals. They offer numerous advantages, making them essential in industrial applications.

Key features include:

– Precision and Accuracy: Capable of cutting metals with high precision, ensuring minimal waste and intricate designs.

– Speed: Laser cutters operate at high speeds, significantly reducing production time compared to traditional methods.

– Versatility: Suitable for cutting a wide range of metals, including steel, aluminum, brass, and titanium.

– Quality Edges: Produces smooth and clean edges, reducing the need for additional finishing processes.

– Automation Compatibility: Can be integrated with CNC systems for automated cutting, improving efficiency.

– Energy Efficiency: Modern laser cutters are designed to be energy-efficient, reducing operational costs.

– Minimal Maintenance: Requires less maintenance compared to other cutting methods, ensuring longer machine life.

– Safety Features: Equipped with safety mechanisms to protect operators, including enclosed cutting areas and automatic shut-off systems.

– Environmental Impact: Generates less waste and emissions, making it an eco-friendly option.

– Cost-Effectiveness: Despite higher initial investment, the efficiency, speed, and reduced waste make it cost-effective in the long run.

These features collectively make metal cutter laser machines a valuable asset in modern manufacturing and metalworking industries.

SourcifyChina Metal Cutter Laser Machines

SourcifyChina offers high-precision metal cutter laser machines tailored to meet specific industrial needs. These machines ensure precise cuts on various metal surfaces, enhancing production efficiency and product quality.

Custom Products

SourcifyChina specializes in creating custom laser cutting solutions. They design and manufacture machines according to client specifications, ensuring that each product meets the exact requirements of the task at hand.

Innovative Technology

Utilizing cutting-edge laser technology, SourcifyChina’s machines provide superior performance. Their advanced features include high-speed cutting, minimal material waste, and enhanced safety measures for operators.

Diverse Applications

These laser machines are versatile, suitable for a wide range of applications including automotive, aerospace, and construction industries. They are capable of cutting different metals like steel, aluminum, and copper with precision.

Cost Efficiency

Investing in SourcifyChina’s metal cutter laser machines can significantly reduce operational costs. Their machines are designed for durability and low maintenance, ensuring long-term savings and high return on investment.

Customer Support

SourcifyChina prides itself on exceptional customer support. They offer comprehensive training, installation, and maintenance services to ensure optimal machine performance and client satisfaction.

Sustainable Practices

Committed to sustainability, SourcifyChina’s laser cutting machines are energy-efficient and environmentally friendly. They minimize waste and reduce the carbon footprint of manufacturing processes.

Completed Projects

SourcifyChina has successfully completed numerous projects worldwide. Their custom metal cutter laser machines have been pivotal in various industries, contributing to advancements in manufacturing technology and product development. With a proven track record, SourcifyChina continues to innovate and lead in the field of laser cutting solutions.

SourcifyChina is a prominent company specializing in the production and distribution of metal cutter laser machines. Renowned for their cutting-edge technology and robust engineering, SourcifyChina’s laser machines cater to a wide range of industrial applications, including automotive, aerospace, and construction. Their product lineup features advanced laser cutting systems that offer precision, efficiency, and durability, making them a preferred choice for businesses seeking high-quality metal fabrication solutions. The company emphasizes innovation, incorporating the latest advancements in laser technology to enhance performance and productivity. Additionally, SourcifyChina is committed to providing exceptional customer service, offering comprehensive support and training to ensure clients maximize the potential of their laser cutting equipment. With a strong presence in both domestic and international markets, SourcifyChina continues to set industry standards, driving growth and technological progress in the metal cutting sector.

Metal cutter laser machines play a pivotal role in aerospace, defense, and marine applications due to their precision and versatility. In the aerospace industry, these machines are indispensable for fabricating intricate components like turbine blades and structural elements from high-strength alloys such as titanium and Inconel. The ability to cut with micron-level precision ensures that parts meet stringent aerospace standards for performance and safety. Moreover, laser cutting minimizes material waste and facilitates rapid prototyping, crucial for developing and refining new aircraft designs efficiently.

In defense applications, metal cutter laser machines enable the fabrication of armored vehicle components, weapon systems, and lightweight yet robust armor plating. The precision and speed of laser cutting contribute to maintaining military readiness by ensuring quick turnaround times for repairs and upgrades. Additionally, the ability to cut through thick armor materials efficiently enhances the development of advanced military technologies. In the marine sector, these machines are utilized for crafting ship components like hull structures, propellers, and navigation systems from corrosion-resistant metals such as stainless steel and aluminum alloys. Laser cutting’s accuracy and ability to handle complex geometries support the maritime industry in constructing durable, high-performance vessels capable of withstanding harsh marine environments.

Metal cutter laser machines are revolutionizing the automotive industry by enhancing precision and efficiency in manufacturing processes. These machines are pivotal in creating intricate parts, such as engine components, brackets, and gears, with remarkable accuracy. The high precision of laser cutting reduces material waste and ensures uniformity in parts, which is crucial for vehicle safety and performance. Additionally, laser cutting technology is faster compared to traditional methods, reducing production time and costs. This speed and efficiency are especially beneficial in the automotive sector, where mass production and timely delivery are critical. Furthermore, the ability of laser cutters to handle various metals, including steel and aluminum, makes them versatile tools for producing a wide range of automotive parts.

In the electronics industry, metal cutter laser machines play an ultimate role in manufacturing components with extremely tight tolerances. These machines are used to cut and shape delicate parts for devices such as smartphones, laptops, and other consumer electronics. The precision of laser cutting ensures that components fit perfectly, which is essential for the miniaturization trends in electronics. Laser cutters also allow for the production of complex geometries that are often required in electronic devices, enabling innovative designs and functionalities. Moreover, the clean and burr-free cuts produced by lasers reduce the need for additional finishing processes, saving time and improving overall product quality. The adaptability of laser technology to different materials, including thin metals and alloys, further enhances its application in the dynamic and rapidly evolving electronics industry.

In the construction industry, metal cutter laser machines are revolutionizing the way materials are processed and assembled. These machines utilize high-powered lasers to precisely cut through various metals, allowing for intricate designs and highly accurate dimensions. This precision reduces material waste and ensures that components fit together perfectly, which is essential for structural integrity in buildings and infrastructure projects. The speed and efficiency of laser cutting also help in meeting tight project deadlines, as it significantly cuts down the time required for manual cutting and finishing processes. Additionally, the versatility of laser cutters in handling different metals such as steel, aluminum, and titanium makes them indispensable in modern construction, where a variety of materials are often used.

In the energy sector, metal cutter laser machines play a crucial role in the manufacturing and maintenance of equipment used in power generation and distribution. For instance, in the production of wind turbines, laser cutters are used to fabricate the complex shapes of turbine blades with high precision, ensuring optimal aerodynamic performance. Similarly, in the solar energy industry, laser machines are employed to cut and shape the metal components of solar panels, enhancing their efficiency and durability. The precision and cleanliness of laser cutting also minimize the risk of contamination and defects, which is critical in the high-stakes environment of energy production. Furthermore, the ability to quickly prototype and produce custom parts with laser cutters aids in the rapid advancement and deployment of new technologies within the energy sector.

Metal cutter laser machines are revolutionizing the industrial equipment industry through their precision, efficiency, and versatility. These machines utilize high-powered laser beams to cut and shape metal materials with extreme accuracy, enabling the production of complex and intricate designs that are difficult or impossible to achieve with traditional cutting methods. Industries such as automotive, aerospace, and manufacturing heavily rely on these laser cutters to create components with tight tolerances and fine details. The ability to cut through a variety of metals, including steel, aluminum, and titanium, makes laser cutting machines indispensable for producing high-quality parts that meet stringent industry standards.

Beyond precision, metal cutter laser machines offer significant improvements in production speed and cost-effectiveness. Traditional cutting methods often involve multiple steps and considerable manual labor, but laser cutting streamlines the process by reducing the need for additional tooling and finishing. This efficiency translates into faster turnaround times and lower labor costs, making it a highly attractive option for large-scale production. Furthermore, the non-contact nature of laser cutting minimizes material waste and reduces the risk of contamination, ensuring a cleaner and more sustainable manufacturing process. As a result, the adoption of metal cutter laser machines continues to grow, driving innovation and competitiveness within the industrial equipment sector.

The use of metal cutter laser machines in the medical device industry has revolutionized the manufacturing and precision of medical tools and implants. These machines enable the production of highly intricate and precise components essential for various medical applications. For instance, surgical instruments, such as scalpels and scissors, require sharp, precise edges to ensure clean cuts and reduce tissue damage during procedures. Laser cutting technology allows for the fabrication of these instruments with exceptional accuracy, ensuring they meet stringent medical standards. Additionally, the production of implants, including stents and orthopedic devices, benefits from laser cutting’s ability to create complex geometries and fine details that are critical for proper integration with the human body.

Furthermore, metal cutter laser machines enhance the efficiency and consistency of medical device manufacturing. Traditional manufacturing methods often involve multiple steps and can introduce variability in the final product. Laser cutting, however, offers a single-step process that reduces the likelihood of errors and defects. This reliability is crucial in the medical field, where device failure can have serious consequences. The high level of automation in laser cutting also allows for rapid prototyping and production scaling, enabling faster development and deployment of new medical technologies. Overall, the precision, reliability, and efficiency of metal cutter laser machines make them indispensable in advancing medical device manufacturing, ultimately contributing to better patient outcomes.

Metal cutter laser machines have revolutionized the machining and manufacturing industries by providing high precision and efficiency in cutting various types of metals. These machines utilize concentrated laser beams to slice through metals like stainless steel, aluminum, and titanium with exceptional accuracy. The precision of laser cutting reduces the need for additional machining processes, minimizing material waste and optimizing production costs. Additionally, laser cutters can produce complex geometries and intricate designs that are difficult to achieve with traditional cutting methods. This capability is particularly valuable in industries such as aerospace, automotive, and electronics, where precision and detail are paramount.

In manufacturing applications, metal cutter laser machines enhance production speed and flexibility. They can be programmed to cut different shapes and sizes without the need for custom tooling, enabling quick changes in production lines and reducing downtime. The non-contact nature of laser cutting means there is less mechanical stress on the material, resulting in cleaner cuts and smoother edges. This is beneficial for ensuring high-quality finishes and reducing post-processing work. Furthermore, the automation potential of laser cutting systems allows for integration with computer-aided design (CAD) and computer-aided manufacturing (CAM) software, streamlining the entire manufacturing process from design to final product. This integration not only boosts productivity but also maintains consistency and repeatability in manufacturing operations.

Sure, here’s a concise FAQ on manufacturing “metal cutter laser machine quality work from SourcifyChina factory”:

—

1. What is the quality of metal cutter laser machines from SourcifyChina?

Our metal cutter laser machines are manufactured using high-grade materials and advanced technology to ensure precision, durability, and reliability. Each machine undergoes rigorous quality control checks to meet international standards.

—

2. What types of metals can the laser cutter machines handle?

Our laser cutter machines can handle a variety of metals including stainless steel, carbon steel, aluminum, brass, and copper. The versatility of our machines allows for efficient cutting of different metal thicknesses.

—

3. How precise are the cuts made by SourcifyChina’s laser machines?

The precision of our laser machines is exceptionally high, with cutting tolerances within ±0.1mm. This ensures clean, accurate cuts suitable for intricate designs and detailed work.

—

4. What is the lifespan of the laser source in these machines?

The laser sources in our machines typically have a lifespan of around 100,000 hours, depending on usage and maintenance. We use top-tier laser sources from reputable brands to ensure longevity and performance.

—

5. Do the machines come with a warranty?

Yes, our metal cutter laser machines come with a standard one-year warranty covering parts and labor. Extended warranties are also available upon request.

—

6. How user-friendly are the laser cutter machines?

Our machines are designed with user-friendliness in mind, featuring intuitive interfaces, easy-to-use software, and comprehensive manuals. Training and support are also provided to ensure seamless operation.

—

7. Can SourcifyChina customize laser cutter machines based on specific requirements?

Yes, we offer customization options to meet specific needs, including modifications in machine size, power, and additional features to cater to unique production requirements.

—

8. How does SourcifyChina ensure the quality of its machines?

We implement a strict quality control process, including multiple testing phases, inspections, and adherence to ISO standards. Continuous improvement practices ensure that our machines consistently meet high-quality benchmarks.

—

If you have any other questions, feel free to reach out to us directly.

Sure, here are some tips about metal cutter laser machine manufacturing from SourcifyChina factory:

1. Understand Your Requirements: Determine the specific type of metal you need to cut, the thickness, and the precision required. This will help in selecting the appropriate laser cutter.

2. Evaluate Laser Power: SourcifyChina offers various laser powers. Higher power lasers are suitable for thicker metals but may be overkill for thinner materials. Match the power with your application needs.

3. Check Cutting Speed and Precision: Ensure the machine offers the speed and precision required for your tasks. Higher precision is crucial for detailed work, while speed is important for high-volume production.

4. Assess Build Quality and Durability: The machine should be robust and durable. Check for features like a solid frame, high-quality laser source, and reliable components to ensure long-term use.

5. Safety Features: Safety is paramount. Look for machines with built-in safety features like protective enclosures, emergency stop buttons, and proper ventilation systems.

6. Software Compatibility: Ensure the laser cutter comes with user-friendly software for design and operation. Compatibility with popular CAD/CAM software can streamline your workflow.

7. Technical Support and Training: SourcifyChina offers technical support and training. Make sure you have access to these services for troubleshooting and to maximize the machine’s potential.

8. Cost and ROI: Consider the total cost of ownership, including maintenance and operational costs. Calculate the return on investment based on your production needs and potential efficiency gains.

9. Customizability: Some applications may require custom solutions. Check if SourcifyChina can tailor the machine to your specific requirements.

10. Reviews and References: Look for customer reviews and ask for references to gauge the machine’s performance in real-world scenarios.

By considering these factors, you can make an informed decision when selecting a metal cutter laser machine from SourcifyChina, ensuring it meets your manufacturing needs efficiently and effectively.

Sure! Here’s a detailed FAQ for sourcing a metal cutter laser machine from SourcifyChina factory:

—

What types of metal cutter laser machines does SourcifyChina offer?

SourcifyChina provides a variety of metal cutter laser machines, including fiber laser cutting machines, CO2 laser cutting machines, and hybrid models. Each type caters to different materials and cutting thicknesses.

What is the lead time for ordering a metal cutter laser machine?

The lead time varies depending on the model and customization requirements. Generally, it ranges from 4 to 8 weeks from the date of order confirmation.

Are there customization options available for the laser machines?

Yes, SourcifyChina offers customization options to meet specific requirements such as power settings, bed size, and additional features like auto-feeding mechanisms.

What is the warranty period for the laser machines?

SourcifyChina provides a standard warranty period of 2 years for their metal cutter laser machines, covering parts and labor for any manufacturing defects.

Do you offer installation and training services?

Yes, SourcifyChina offers comprehensive installation and training services. Technicians are available to set up the machine and provide hands-on training to ensure proper operation.

What after-sales support is available?

SourcifyChina provides robust after-sales support, including online technical support, spare parts supply, and regular maintenance services to ensure optimal machine performance.

Can you provide references or case studies from previous customers?

Yes, upon request, SourcifyChina can provide references and case studies from satisfied customers who have successfully integrated their laser cutting machines into their operations.

What are the payment terms for purchasing a laser cutter?

The payment terms typically include a 30% deposit upon order confirmation, with the remaining 70% due before shipment. Payment can be made via bank transfer or other agreed-upon methods.

Is shipping included in the price?

Shipping costs are not included in the machine price. SourcifyChina can assist with arranging shipping and provide cost estimates based on the destination.

How do I place an order with SourcifyChina?

To place an order, contact SourcifyChina’s sales team via their official website or email. They will guide you through the process, including selecting the right machine, customization options, and payment details.

—

Sourcing a metal cutter laser machine from a factory in China through Sourcify involves several key steps to ensure a successful procurement process. Here are some tips to guide you through:

1. Define Your Requirements: Clearly outline your specifications for the laser machine. Include details like cutting capacity, material compatibility (e.g., stainless steel, aluminum), laser power, and any specific software or feature requirements.

2. Research and Shortlist Suppliers: Utilize platforms like Sourcify or other sourcing websites to identify potential suppliers. Look for manufacturers with a proven track record in producing laser cutting machines. Check reviews, certifications, and years of experience.

3. Request for Quotations (RFQ): Send detailed RFQs to your shortlisted suppliers. Provide clear specifications and ask for quotes that include unit price, shipping costs, lead times, and payment terms. This helps in comparing offers effectively.

4. Evaluate Samples and Quality: If feasible, request samples or visit the factory to inspect the manufacturing process and product quality. Ensure the supplier can meet your quality standards and has adequate production capabilities.

5. Negotiate Terms and Conditions: Negotiate pricing, terms of payment, warranty, and any customization options required. Clarify all details to avoid misunderstandings later.

6. Verify Supplier Credentials: Conduct due diligence on the supplier. Verify business licenses, certifications (ISO, CE, etc.), and check for any past issues or disputes. This step helps in ensuring reliability and credibility.

7. Finalize the Agreement: Once satisfied with a supplier, finalize the agreement with a detailed contract. Include all agreed-upon terms, delivery schedules, penalties for delays, and quality assurance measures.

8. Monitor Production and Delivery: Maintain regular communication with the supplier during production. Monitor progress closely to address any issues promptly. Arrange for inspections if necessary before shipping.

9. Arrange Shipping and Customs Clearance: Coordinate shipping logistics, including transportation, insurance, and customs clearance. Factor in any tariffs or taxes that may apply to imported machinery.

10. Follow-Up and Feedback: After receiving the machine, assess its performance against your expectations. Provide feedback to the supplier for future improvements or as a reference for others.

By following these steps, you can streamline the process of sourcing a metal cutter laser machine from a reliable factory in China, ensuring a smooth procurement experience with Sourcify or similar platforms.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.