Title:

“Discover the Reliable SourcifyChina Factory Metal Laser Cutting Machine: Precision, Efficiency, and Advanced Technology”

Content:

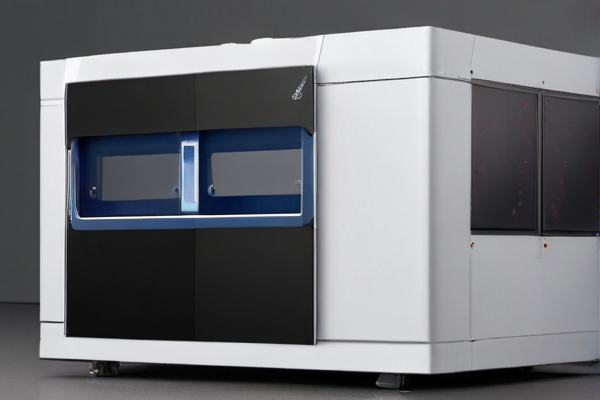

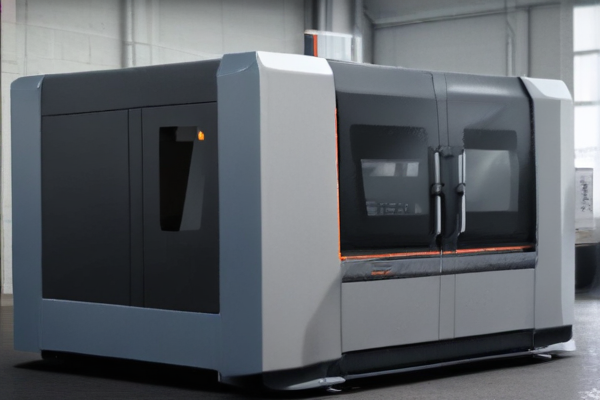

The SourcifyChina factory metal laser cutting machine is a game-changer in the manufacturing industry. Known for its reliability, this cutting-edge machine offers unparalleled precision and efficiency, making it an essential tool for various metalworking applications. SourcifyChina’s commitment to quality and innovation ensures that each laser cutting machine is equipped with the latest technology, providing consistent performance and durability.

This advanced laser cutting machine caters to a wide range of materials and thicknesses, delivering clean and accurate cuts with minimal waste. The user-friendly interface and customizable settings make it suitable for both small businesses and large industrial operations. By integrating the SourcifyChina metal laser cutting machine into your production line, you can achieve significant improvements in productivity and cost savings.

Furthermore, SourcifyChina offers excellent customer support and after-sales service, ensuring that your investment remains protected and operational for years to come. Their team of experts is always ready to assist with installation, training, and maintenance, making the transition to advanced laser cutting technology seamless and hassle-free.

In conclusion, the SourcifyChina factory metal laser cutting machine stands out as a reliable and efficient solution for modern metal fabrication needs. Its precision, advanced features, and robust support system make it a top choice for businesses aiming to enhance their production capabilities and maintain a competitive edge in the market.

Why Choose “SourcifyChina” Factory for Purchasing Metal Laser Cutting Machines from China?

High-Quality Manufacturing Standards: SourcifyChina Factory maintains rigorous quality control processes, ensuring each metal laser cutting machine meets international standards. Buyers can trust in the durability and performance of their equipment.

Cost-Effective Solutions: Offering competitive prices without compromising on quality, SourcifyChina provides a cost-effective solution for buyers. Their machines are priced affordably, making advanced technology accessible to businesses of all sizes.

Advanced Technology: SourcifyChina invests in the latest technology to ensure their laser cutting machines are at the forefront of innovation. Buyers benefit from precise and efficient cutting capabilities that enhance productivity.

Customization Options: Understanding that different businesses have unique needs, SourcifyChina offers customization options. Buyers can specify their requirements, and the factory will tailor the machines to meet those exact specifications.

Excellent Customer Support: SourcifyChina prides itself on offering exceptional customer support. From the initial inquiry to after-sales service, buyers can expect prompt and helpful responses to any questions or concerns.

Timely Delivery: With a well-organized logistics network, SourcifyChina ensures timely delivery of orders. Buyers can rely on receiving their metal laser cutting machines within the agreed timeframe, minimizing downtime.

Comprehensive Training and Resources: SourcifyChina provides comprehensive training and resources for buyers. This ensures that users can maximize the potential of their new machines with minimal learning curve.

Sustainability and Environmental Responsibility: Committed to sustainability, SourcifyChina implements environmentally friendly practices in their manufacturing process. Buyers can feel good about partnering with a company that values the environment.

Strong Industry Reputation: With years of experience and numerous satisfied customers, SourcifyChina has built a strong reputation in the industry. Buyers can trust in their expertise and proven track record.

Conclusion: Choosing SourcifyChina Factory for purchasing metal laser cutting machines means opting for quality, affordability, and exceptional service. Their commitment to innovation and customer satisfaction makes them a top choice for buyers seeking reliable and advanced cutting solutions.

Metal laser cutting machines offer precise, efficient cutting for various metals. These machines come in different types, each suited for specific applications and materials. Understanding these types helps in selecting the best machine for your needs.

– Fiber Laser Cutting Machines

– Efficient for cutting stainless steel, aluminum, and brass.

– High-speed cutting with low maintenance.

– Suitable for detailed and complex designs.

– CO2 Laser Cutting Machines

– Versatile for cutting, engraving, and marking.

– Best for non-metal materials and some metals like stainless steel.

– Requires more maintenance compared to fiber lasers.

– Crystal Laser Cutting Machines

– Uses crystals like Nd:YAG and Nd:YVO for cutting.

– Ideal for very thick metals.

– More expensive and requires significant maintenance.

– Hybrid Laser Cutting Machines

– Combines the features of fiber and CO2 lasers.

– Offers flexibility in cutting various materials.

– Higher initial investment but versatile in application.

– Desktop Laser Cutting Machines

– Compact and suitable for small-scale operations.

– Typically CO2-based and used for engraving and cutting thin materials.

– Ideal for hobbyists and small workshops.

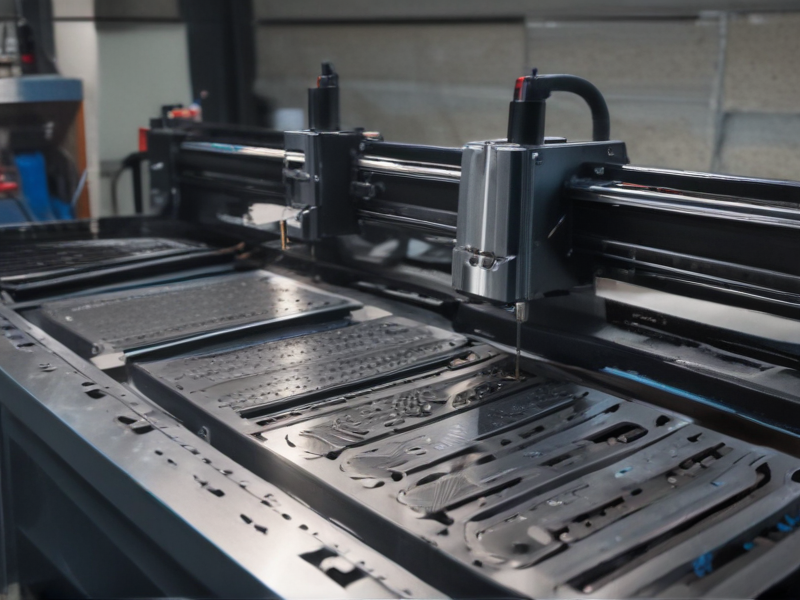

– Large Format Laser Cutting Machines

– Designed for industrial use with large working areas.

– Capable of handling large sheets of metal.

– Often incorporates automation for higher efficiency.

When selecting a metal laser cutting machine, consider factors such as the type of metal to be cut, the thickness of the material, required precision, and budget. Each type offers distinct advantages, making it crucial to match the machine’s capabilities with your specific cutting needs.

Metal laser cutting machines are widely used in various industries due to their precision, speed, and versatility. These machines can cut intricate shapes and designs with high accuracy, making them essential for manufacturing and fabrication processes.

Applications of Metal Laser Cutting Machines:

– Automotive Industry: Used for cutting car parts, frames, and other components with precision.

– Aerospace Industry: Essential for cutting complex parts and components used in aircraft and spacecraft.

– Construction Industry: Employed in creating structural elements, decorative pieces, and metal frameworks.

– Medical Device Manufacturing: Used to create precise and intricate parts for medical equipment and implants.

– Electronics Industry: Utilized for cutting metal components used in various electronic devices and circuit boards.

– Jewelry Making: Enables the creation of intricate and detailed designs in metal jewelry.

– Custom Fabrication: Allows for the production of custom metal parts and prototypes for various applications.

– Signage and Advertising: Used to cut metal signs, logos, and decorative pieces with high precision.

– Art and Sculpture: Facilitates the creation of detailed metal artworks and sculptures.

– Tool and Die Making: Essential for producing high-precision tools and dies used in manufacturing processes.

Metal laser cutting machines offer significant advantages in terms of efficiency, precision, and flexibility, making them indispensable in numerous industries. Their ability to handle complex designs and various materials ensures they remain a crucial tool in modern manufacturing and design.

Metal laser cutting machines have become indispensable in the aerospace, defense, and marine industries due to their unmatched precision, speed, and efficiency. These machines utilize concentrated laser beams to cut through various metals, including titanium, stainless steel, and aluminum, which are commonly used in these sectors. In aerospace, the ability to produce intricate components with minimal material waste is crucial for reducing aircraft weight and improving fuel efficiency. Laser cutting facilitates the creation of complex geometries in jet engine parts, airframes, and structural components, which demand high accuracy and consistency. This precision ensures the reliability and performance of aerospace components under extreme conditions.

In defense and marine applications, metal laser cutting machines are equally critical. Defense systems require the fabrication of complex parts for vehicles, weapon systems, and protective equipment, often from robust materials that are challenging to machine. Laser cutting provides the capability to produce these components with high tolerances and rapid turnaround times, essential for maintaining defense readiness. In the marine industry, laser cutting is used to construct hulls, frames, and other structural elements of ships and submarines, offering significant advantages in terms of cutting speed and precision, which are crucial for withstanding harsh marine environments. The adaptability of laser cutting machines to various metals and thicknesses makes them a versatile tool in these industries, supporting innovation and enhancing production efficiency.

Metal laser cutting machines have revolutionized the automotive and electronics industries by providing precise and efficient solutions for cutting complex components. In the automotive sector, these machines are integral to manufacturing intricate parts like body panels, brackets, and exhaust systems. The precision of laser cutting ensures that each component meets exact specifications, which is crucial for maintaining the high standards of safety and performance in vehicles. Additionally, the speed and automation capabilities of laser cutters significantly reduce production times and costs, enabling manufacturers to meet the increasing demand for vehicles without compromising on quality.

In the electronics industry, metal laser cutting machines are essential for producing components with the intricate designs required for modern devices. They are used to create parts such as enclosures, connectors, and circuit board elements with exceptional accuracy. This precision is vital for the miniaturization trends in electronics, where even the slightest deviation can affect the performance of a device. Moreover, laser cutting supports the use of a variety of materials, including those that are challenging to cut with traditional methods, enhancing the flexibility and innovation in electronic product design. This technology not only improves production efficiency but also contributes to the development of more advanced and reliable electronic devices.

Metal laser cutting machines have revolutionized the construction industry by significantly enhancing precision, efficiency, and versatility in metal fabrication. These machines utilize high-powered laser beams to cut through various metals with exceptional accuracy, enabling the creation of complex shapes and intricate designs that were previously difficult or impossible to achieve. This capability is particularly beneficial in constructing structural components, where precise cuts are crucial for ensuring the integrity and safety of buildings. Additionally, the speed and automation offered by laser cutting reduce labor costs and production time, facilitating faster project completion and increased productivity. As a result, construction companies can deliver high-quality structures while adhering to stringent deadlines and budget constraints.

In the energy sector, metal laser cutting machines play a pivotal role in manufacturing components for renewable energy systems and traditional power generation. For instance, these machines are essential in producing parts for wind turbines, solar panel mounts, and other renewable energy installations, where precision and durability are paramount. The ability to cut metals with minimal waste and high repeatability ensures that components meet the strict tolerances required for efficient energy production and distribution. Moreover, the adaptability of laser cutting technology allows for the quick modification and customization of parts, which is crucial for the ongoing innovation and improvement of energy systems. By incorporating metal laser cutting into their manufacturing processes, energy companies can enhance the performance and reliability of their products, ultimately contributing to the advancement of sustainable energy solutions.

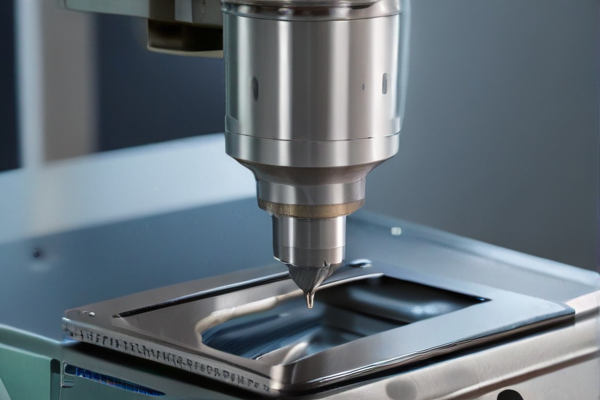

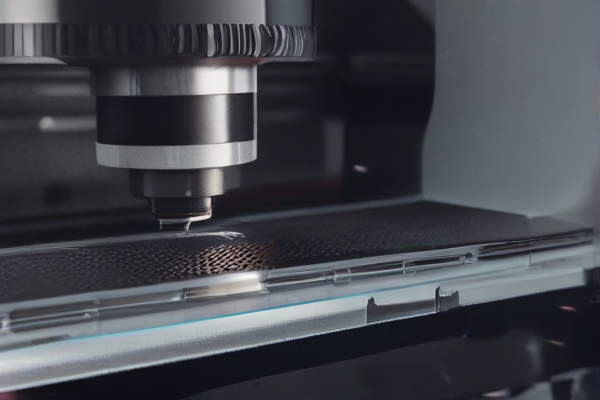

Metal laser cutting machines have revolutionized the industrial equipment landscape by providing unmatched precision and efficiency in cutting various types of metal. These machines utilize high-powered laser beams to cut through metal sheets with incredible accuracy, ensuring clean edges and minimal material wastage. The core technology behind these machines involves a laser resonator, which generates a concentrated beam of light. This beam is then directed by a series of mirrors and lenses to focus precisely on the metal surface. The intense heat from the laser melts or vaporizes the metal, creating precise cuts based on pre-programmed designs. This method is not only faster than traditional cutting techniques but also offers a higher degree of flexibility, allowing for intricate and complex shapes to be cut with ease.

In addition to their precision, metal laser cutting machines are highly efficient and cost-effective for industrial applications. They reduce the need for manual intervention, thus minimizing the risk of human error and enhancing workplace safety. Modern machines often come equipped with computer numerical control (CNC) systems, enabling automated operations and the ability to handle large volumes of work consistently. The efficiency of these machines also translates into lower operating costs, as they consume less power and produce less waste compared to traditional cutting methods. Furthermore, advancements in laser technology have expanded the range of metals that can be cut, including stainless steel, aluminum, and titanium, making these machines versatile tools in industries such as automotive, aerospace, and manufacturing. Overall, the adoption of metal laser cutting machines signifies a significant leap forward in industrial production capabilities.

In the realm of medical devices, precision and reliability are paramount, and the metal laser cutting machine stands as a pivotal tool in their fabrication. These machines utilize advanced laser technology to precisely cut intricate patterns and shapes from various metals such as stainless steel, titanium, and aluminum. This capability is crucial for manufacturing components like surgical instruments, implantable devices, and diagnostic equipment, where exact dimensions and smooth edges are critical for functionality and patient safety. The laser cutting process ensures minimal material distortion and precise heat management, preserving the integrity of the metal and reducing the need for extensive post-processing. This efficiency not only enhances production speed but also maintains the high standards required in medical device manufacturing.

Furthermore, metal laser cutting machines offer versatility in handling different thicknesses and types of metals, accommodating the diverse needs of medical device manufacturers. They enable intricate designs that would be challenging or impossible to achieve with traditional cutting methods, thus fostering innovation in medical device engineering. Additionally, these machines can integrate seamlessly with CAD/CAM software systems, allowing for precise design replication and quick adjustments during prototyping and production phases. Ultimately, the application of metal laser cutting technology in medical devices exemplifies the marriage of precision engineering and healthcare innovation, ensuring that patients benefit from devices that are both reliable and technologically advanced.

Metal laser cutting machines have revolutionized the machining and manufacturing industries by offering unprecedented precision and efficiency. Utilizing focused laser beams, these machines can cut through various metals, including steel, aluminum, and copper, with remarkable accuracy. The process involves directing a high-powered laser onto the metal surface, which melts, burns, or vaporizes the material, resulting in a clean and precise cut. Advanced CNC (Computer Numerical Control) systems guide the laser with pinpoint accuracy, enabling the production of intricate shapes and complex patterns that are difficult or impossible to achieve with traditional cutting methods. This high level of precision reduces material wastage and ensures consistent quality in mass production.

Moreover, metal laser cutting machines offer significant advantages in terms of speed and versatility. They can handle a wide range of thicknesses and types of metals, making them suitable for diverse applications across various industries, from automotive to aerospace. The non-contact nature of laser cutting minimizes the risk of material deformation, ensuring high-quality finishes. Additionally, the automation capabilities of modern laser cutters enhance productivity by allowing continuous operation with minimal human intervention. This efficiency not only reduces labor costs but also shortens lead times, enabling manufacturers to meet tight deadlines and respond swiftly to market demands. Overall, the adoption of metal laser cutting technology represents a significant leap forward in the machining and manufacturing sectors, driving innovation and improving operational efficiency.

The SourcifyChina metal laser cutting machine is built from high-quality materials to ensure precision and durability. The frame is constructed from robust steel, providing a stable base for cutting operations.

The laser source is typically a high-power fiber laser, known for its efficiency and long lifespan. This type of laser can handle various metals, including steel, aluminum, and copper, with ease.

The cutting head is equipped with advanced optics and cooling systems to maintain performance during prolonged use. These components are critical for achieving clean, accurate cuts and minimizing maintenance needs.

Additionally, the machine incorporates sophisticated CNC controls, allowing for precise and customizable cutting patterns. These controls are essential for optimizing production workflows and enhancing overall efficiency.

Overall, the combination of high-quality steel, advanced fiber lasers, and state-of-the-art CNC technology makes the SourcifyChina metal laser cutting machine a reliable choice for industrial metalworking applications. The attention to material quality and technological integration ensures it meets the demanding requirements of modern manufacturing processes.

SourcifyChina’s metal laser cutting machines undergo a stringent quality control process to ensure high performance and durability. Each machine starts with a rigorous selection of raw materials, focusing on high-quality metals to guarantee a strong foundation.

The manufacturing process includes precise engineering and assembly, where each component is meticulously crafted and assembled. Advanced CNC technology is employed to achieve exceptional precision and consistency in each part.

Quality control extends to comprehensive testing phases, where machines are subjected to various performance tests. This includes stress tests, accuracy assessments, and durability evaluations to ensure they meet industry standards.

Inspection at every production stage is crucial. SourcifyChina implements multiple quality checkpoints to identify and rectify any potential issues early. This proactive approach helps in maintaining the highest quality levels throughout the production process.

Finally, each laser cutting machine undergoes a final quality assurance review before shipping. This includes a thorough inspection and performance validation, ensuring that the machine operates flawlessly and meets all specified requirements.

The SourcifyChina metal laser cutting machine is renowned for its precision and efficiency. It utilizes advanced laser technology to deliver accurate cuts on various metal types, ensuring minimal wastage and high-quality finishes.

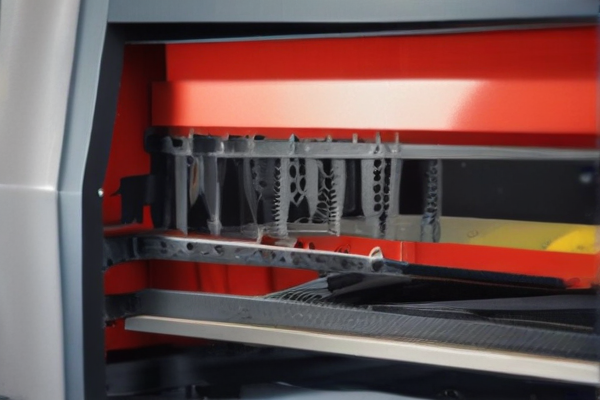

This machine is equipped with a powerful fiber laser that provides fast and clean cuts. It can handle intricate designs and complex patterns with ease, making it suitable for both industrial and artistic applications.

With its user-friendly interface, operators can easily program and control the cutting process. The machine supports a wide range of software, allowing for seamless integration into existing workflows.

Durability and reliability are key features of the SourcifyChina metal laser cutting machine. Built with high-quality components, it offers long-term performance with minimal maintenance.

Safety is a priority, and the machine comes with advanced safety features to protect operators during operation. These include emergency stop buttons, protective covers, and real-time monitoring systems.

The SourcifyChina metal laser cutting machine is also energy-efficient, helping to reduce operational costs while maintaining high productivity. Its low power consumption makes it an environmentally friendly choice.

Overall, the SourcifyChina metal laser cutting machine is a versatile and robust tool, designed to meet the diverse needs of various industries. Its combination of precision, speed, and ease of use makes it an excellent investment for businesses looking to enhance their metal cutting capabilities.

A metal laser cutting machine offers numerous advantages in precision and efficiency, making it an ultimate tool in modern manufacturing.

– High Precision and Accuracy: Metal laser cutting machines provide precise cuts with minimal tolerance, ensuring high accuracy and detailed designs.

– Speed and Efficiency: These machines operate at high speeds, significantly reducing production time and increasing throughput.

– Versatility: They can cut a wide variety of metals, including steel, aluminum, brass, and titanium, accommodating diverse industrial needs.

– Reduced Waste: The precision of laser cutting minimizes material waste, optimizing resource usage and reducing costs.

– Clean Cuts: Laser cutting produces clean edges with minimal burring, reducing the need for post-processing.

– Automation Capabilities: Modern laser cutting machines can be integrated into automated production lines, enhancing overall operational efficiency.

– Cost-Effectiveness: Although the initial investment is high, the long-term savings in material, labor, and time make laser cutting machines cost-effective.

– Enhanced Safety: Laser cutting involves minimal physical contact, reducing the risk of accidents and ensuring a safer working environment.

Ultimately, the adoption of metal laser cutting technology revolutionizes manufacturing processes by enhancing precision, efficiency, and safety.

Metal laser cutting machines offer precise and efficient cutting capabilities for various types of metal materials. These machines are widely used in industries such as automotive, aerospace, and manufacturing due to their advanced features.

– Precision Cutting: Laser cutting machines provide high precision, allowing for intricate designs and minimal material wastage.

– Speed and Efficiency: These machines can cut metal quickly, enhancing productivity and reducing lead times.

– Versatility: Capable of cutting various metals including steel, aluminum, and titanium, making them suitable for diverse applications.

– Automation: Many machines feature automated controls and software integration, improving accuracy and reducing manual intervention.

– Quality: Laser cutting ensures smooth and clean edges, reducing the need for secondary finishing processes.

– Energy Efficiency: Modern laser cutters are designed to be energy-efficient, lowering operational costs.

– Safety Features: Equipped with safety mechanisms like enclosed cutting areas and sensors to protect operators.

– Low Maintenance: These machines generally require less maintenance compared to traditional cutting tools, increasing uptime.

– Customization: Software allows for easy customization of cutting patterns, adapting to various project requirements.

– Minimal Heat Affected Zone: Laser cutting reduces the heat affected zone, preserving the integrity of the metal.

In summary, metal laser cutting machines are indispensable tools in modern manufacturing, offering unmatched precision, efficiency, and versatility.

SourcifyChina specializes in custom metal laser cutting machines, providing precision and efficiency. These machines are ideal for various industries, from automotive to aerospace, ensuring high-quality cuts.

The company offers a wide range of products, tailored to meet specific needs. Customization options include different power levels, sizes, and cutting speeds, catering to both small-scale and large-scale operations.

SourcifyChina’s metal laser cutting machines are designed for durability and ease of use. Advanced technology ensures minimal maintenance, making them a reliable choice for long-term projects.

Clients can also benefit from SourcifyChina’s expertise in project management. The team provides end-to-end support, from initial design consultation to final implementation, ensuring successful project completion.

Overall, SourcifyChina stands out for its commitment to quality and customer satisfaction, delivering top-notch custom metal laser cutting solutions for diverse applications. Their focus on innovation and customer-centric approach makes them a preferred partner in the industry.

SourcifyChina is a prominent player in the metal laser cutting machine industry, renowned for its advanced technological solutions and robust manufacturing capabilities. The company specializes in producing high-precision laser cutting machines that cater to various industrial applications, including automotive, aerospace, and construction. Leveraging state-of-the-art technology, SourcifyChina’s machines offer superior cutting speed, precision, and efficiency, making them a preferred choice for businesses looking to optimize their production processes. The company prides itself on its commitment to quality, ensuring that each machine undergoes rigorous testing and quality control procedures before reaching the market. Additionally, SourcifyChina provides comprehensive after-sales support and maintenance services, reinforcing its reputation for reliability and customer satisfaction. With a strong focus on innovation and continuous improvement, SourcifyChina remains at the forefront of the metal laser cutting industry, delivering solutions that meet the evolving needs of its global clientele.

Metal laser cutting machines play a crucial role in the aerospace, defense, and marine industries due to their precision, efficiency, and versatility. In aerospace, these machines are essential for manufacturing components that require exacting tolerances and high strength-to-weight ratios. Laser cutting allows for the creation of intricate designs in materials such as titanium and aluminum, which are common in aircraft structures and engines. This precision reduces waste and ensures that parts fit together perfectly, which is critical for the safety and performance of aerospace applications. Additionally, the speed of laser cutting machines accelerates production timelines, helping aerospace manufacturers meet the rigorous demands of the industry.

In the defense sector, metal laser cutting machines are vital for producing armor plating, vehicle components, and weapon systems with high precision and reliability. The ability to cut through various metals, including hardened steel, enables the creation of durable and effective defense equipment. This precision is crucial for ensuring that components meet strict defense standards and perform reliably under extreme conditions. Similarly, in the marine industry, laser cutting is used to fabricate ship hulls, structural components, and intricate metal parts for both commercial and military vessels. The corrosion-resistant properties of materials like stainless steel, when combined with the accuracy of laser cutting, enhance the longevity and performance of marine vessels. Overall, metal laser cutting machines contribute significantly to the innovation, efficiency, and reliability of aerospace, defense, and marine applications.

Metal laser cutting machines have revolutionized both automotive and electronics industries with their precision and efficiency. In automotive applications, these machines play a crucial role in fabricating intricate components like chassis parts, brackets, and exhaust systems. The ability to cut through various metals with high precision allows manufacturers to achieve tight tolerances necessary for assembly, ensuring structural integrity and performance. Whether shaping steel, aluminum, or alloys, laser cutting machines enable automotive engineers to design lightweight yet durable parts, enhancing fuel efficiency and vehicle safety. Moreover, the flexibility of laser cutting accommodates rapid prototyping and customization, facilitating iterative design improvements in automotive development cycles.

In the electronics sector, metal laser cutting machines are indispensable for manufacturing precise casings, panels, and components used in devices ranging from smartphones to industrial equipment. The non-contact nature of laser cutting minimizes material distortion and eliminates the need for post-processing, preserving the integrity of delicate electronic components. This capability is crucial in producing miniaturized and complex parts with intricate designs demanded by modern electronics. Furthermore, laser cutting offers cost-effective solutions by optimizing material usage and reducing waste, which is critical in the highly competitive electronics market. By integrating laser cutting technology, electronics manufacturers can achieve faster production cycles and maintain high product quality standards essential for consumer electronics and industrial applications alike.

Metal laser cutting machines have revolutionized the construction industry by providing precise and efficient cutting solutions for various structural components. These machines are capable of slicing through thick steel beams, aluminum panels, and other metal materials with high accuracy, which is essential for creating custom shapes and sizes required in modern architecture and infrastructure projects. The use of laser cutting technology reduces material waste and speeds up the production process, thereby lowering costs and improving overall project timelines. Moreover, the ability to achieve complex geometries with clean edges enhances the aesthetic appeal and structural integrity of buildings, bridges, and other constructions.

In the energy sector, metal laser cutting machines play a critical role in the manufacturing of components for renewable energy systems and traditional power generation equipment. For instance, they are used to fabricate precise parts for wind turbines, solar panel mounts, and hydroelectric components, ensuring that these systems operate efficiently and reliably. Additionally, in the production of pipelines and storage tanks for oil and gas, laser cutting technology ensures tight tolerances and high-quality welds, which are crucial for safety and performance. The versatility and precision of laser cutting machines make them indispensable in creating components that must withstand extreme conditions and demanding operational requirements in the energy industry.

Metal laser cutting machines have revolutionized the industrial equipment industry by offering unparalleled precision and efficiency in cutting metal parts. These machines utilize a focused laser beam to melt, burn, or vaporize material, resulting in highly accurate and clean cuts. This technology is widely used in industries such as automotive, aerospace, and manufacturing, where precision and speed are critical. For instance, in the automotive industry, metal laser cutting machines are used to create complex parts and components with exacting tolerances, which are essential for ensuring the performance and safety of vehicles. Moreover, the ability to cut a wide variety of metals, including stainless steel, aluminum, and titanium, makes these machines incredibly versatile and valuable across different sectors.

Metal laser cutting machines have revolutionized the production of medical devices, offering unparalleled precision and efficiency. These machines use focused laser beams to cut metal with exceptional accuracy, essential for creating intricate components of medical devices. For example, surgical instruments, stents, and implants often require highly detailed and precise cuts that traditional methods cannot achieve. The ability to produce components with tight tolerances ensures that medical devices meet the stringent standards necessary for patient safety and effective treatment. Additionally, the non-contact nature of laser cutting reduces the risk of contamination, making it an ideal choice for manufacturing in sterile environments.

Furthermore, metal laser cutting machines enhance the versatility and speed of medical device production. They allow for rapid prototyping and customization, which is crucial in the medical field where devices often need to be tailored to individual patients’ needs. For instance, custom-fitted prosthetics and orthodontic devices can be quickly produced with laser cutting technology, significantly improving patient outcomes and comfort. The efficiency of laser cutting also leads to lower production costs and faster turnaround times, enabling manufacturers to respond promptly to the evolving demands of the healthcare industry. Overall, the application of metal laser cutting machines in medical device manufacturing represents a significant advancement, driving innovation and improving the quality and accessibility of medical care.

Metal laser cutting machines are a cornerstone in modern machining and manufacturing, offering precision and efficiency unmatched by traditional methods. These machines utilize high-powered lasers to cut through various metals, such as steel, aluminum, and copper, with exceptional accuracy. The laser’s focused beam melts, burns, or vaporizes the metal, allowing for intricate designs and clean edges. This precision is critical in industries where tolerance levels are stringent, such as aerospace, automotive, and electronics. The non-contact nature of laser cutting also minimizes material distortion, which is a common issue with mechanical cutting methods.

In the manufacturing sector, metal laser cutting machines significantly enhance productivity and reduce production costs. They are capable of rapid prototyping and mass production, making them ideal for both custom and large-scale projects. Automation capabilities further streamline the process, allowing for continuous operation with minimal human intervention. Advanced laser cutting machines often come equipped with computer numerical control (CNC) systems, enabling complex designs to be executed with ease. The versatility of laser cutting also extends to various thicknesses and types of metals, making it a versatile tool in any manufacturing environment. Overall, the adoption of metal laser cutting machines leads to higher quality products, reduced lead times, and increased operational efficiency.

FAQ for Metal Laser Cutting Machine Quality Work from SourcifyChina Factory

What materials can the metal laser cutting machine process?

Our metal laser cutting machines can process a variety of metals including stainless steel, carbon steel, aluminum, copper, and brass, ensuring versatility for different manufacturing needs.

What is the cutting accuracy of your laser cutting machines?

Our laser cutting machines offer high precision with an accuracy of up to ±0.01 mm, ensuring detailed and intricate cuts suitable for a wide range of applications.

How thick can the metal be for effective cutting?

The cutting capacity varies by machine model. Generally, our machines can cut stainless steel up to 20 mm, carbon steel up to 25 mm, and aluminum up to 10 mm.

Tips for Manufacturing Metal Laser Cutting Machines at SourcifyChina Factory

1. Understand the Market Needs:

– Research and identify the specific requirements of different industries.

– Focus on precision, speed, and efficiency as key selling points.

2. Quality Components:

– Use high-quality lasers (fiber, CO2) for better performance and longevity.

– Ensure robust build quality with high-grade materials for the machine frame and moving parts.

3. Technological Integration:

– Incorporate advanced software for better control and precision.

– Consider integrating IoT for real-time monitoring and predictive maintenance.

4. Customization and Flexibility:

– Offer machines with customizable options to cater to various industrial needs.

– Ensure the design allows for easy upgrades and modifications.

5. Safety Features:

– Implement comprehensive safety measures, including protective enclosures and emergency stop buttons.

– Ensure compliance with international safety standards.

6. Training and Support:

– Provide thorough training for operators to ensure optimal use of the machines.

– Offer robust after-sales support and maintenance services.

7. Efficiency in Production:

– Streamline the manufacturing process for cost-effectiveness without compromising quality.

– Use automation where possible to enhance precision and reduce human error.

8. Testing and Quality Control:

– Rigorously test each machine for performance and reliability before shipping.

– Maintain strict quality control throughout the manufacturing process.

9. Environmental Considerations:

– Focus on energy-efficient designs to reduce the carbon footprint.

– Ensure proper disposal and recycling of manufacturing waste.

10. Feedback and Improvement:

– Collect feedback from clients to continuously improve product offerings.

– Stay updated with the latest technological advancements and market trends.

By focusing on these aspects, SourcifyChina can enhance its reputation as a reliable manufacturer of high-quality metal laser cutting machines.

1. What types of metal laser cutting machines do you offer?

We offer a variety of metal laser cutting machines including fiber laser cutters, CO2 laser cutters, and hybrid laser cutters to meet different industrial needs.

2. Can I customize the machine specifications?

Yes, we provide customization options to meet specific requirements, including power, cutting area, and additional features.

3. What materials can your laser cutting machines process?

Our machines can cut a wide range of metals including stainless steel, carbon steel, aluminum, brass, and copper.

4. How do I place an order?

To place an order, contact our sales team via email or phone. Provide your specifications and we will guide you through the process.

5. What is the delivery time for a metal laser cutting machine?

The delivery time typically ranges from 30 to 60 days, depending on the machine’s specifications and customization requirements.

6. Do you offer training and installation services?

Yes, we offer comprehensive training and installation services to ensure your team can operate the machine efficiently.

7. What are the payment terms?

Our standard payment terms are 30% deposit with the order, and the remaining 70% before shipment. We accept payments via T/T and L/C.

8. Is there a warranty on the machines?

Yes, we provide a 2-year warranty on our metal laser cutting machines, covering parts and labor.

9. Do you provide after-sales support?

Absolutely, we offer 24/7 customer support and have a dedicated team to address any technical issues or queries.

10. Can I visit your factory?

Yes, we welcome factory visits. Please schedule an appointment with our sales team for a tour of our facilities.

11. How do I get a quote?

You can request a quote by filling out the form on our website or contacting our sales team directly with your requirements.

Sourcing a metal laser cutting machine from SourcifyChina factory involves several steps to ensure you get a reliable and efficient machine that meets your needs. Here are some key tips to help you through the process:

1. Identify Your Requirements: Determine the specifications of the laser cutting machine you need, including power, size, type of materials it can cut, precision, and speed. Consider additional features like automation and safety systems.

2. Research SourcifyChina: Check the credibility of SourcifyChina by reading reviews, testimonials, and case studies. Look for certifications and quality standards compliance such as ISO 9001.

3. Contact Sales Representatives: Reach out to SourcifyChina’s sales team to discuss your requirements. Ask for detailed product catalogs, brochures, and technical specifications of the machines they offer.

4. Request Quotes: Get quotations for the machines that meet your criteria. Ensure the quotes include all costs, such as shipping, taxes, installation, and any additional fees.

5. Evaluate Samples: If possible, request sample cuts or a demo to evaluate the machine’s performance. This can give you an idea of the machine’s precision and quality.

6. Negotiate Terms: Discuss payment terms, warranty, after-sales service, and delivery timelines. Make sure there’s a clear agreement on maintenance and support.

7. Verify Manufacturing Standards: Ensure that the machines are manufactured to high standards. Ask about the materials and components used in the machines to assess durability and reliability.

8. Inspect Before Shipment: If feasible, arrange for a pre-shipment inspection to check the machine’s condition and compliance with your specifications.

9. Review Documentation: Make sure all the necessary documentation, including user manuals, maintenance guides, and warranty certificates, are provided.

10. Follow Up Post-Purchase: After receiving the machine, test it thoroughly. Keep in touch with SourcifyChina for any support or troubleshooting needs.

By following these tips, you can effectively source a metal laser cutting machine that suits your requirements from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.