Title: Reliable Custom Metal Fabrication Solutions with SourcifyChina Factory

Body:

SourcifyChina Factory offers comprehensive custom metal fabrication services, including precision sheet metal, CNC machining, and metal stamping. With a strong focus on quality control, industry certifications, and efficient supply chains, SourcifyChina ensures high standards and quick turnaround times for projects of all sizes【5†source】【7†source】.

Their extensive network of trusted manufacturers in China allows for competitive pricing and adherence to international quality standards. Services range from prototyping to mass production, catering to various industries such as aerospace, automotive, and electronics【6†source】【9†source】. SourcifyChina’s commitment to excellence and customer satisfaction makes it a reliable partner for all your custom metal fabrication needs.

For more information, visit [SourcifyChina’s official website](https://www.sourcifychina.com).

Choosing SourcifyChina Factory for custom fabrication metal purchases from China offers numerous advantages. Their expertise ensures high-quality products tailored to your specifications, backed by rigorous quality control processes. Additionally, they provide competitive pricing without compromising on quality, making them a cost-effective choice for your metal fabrication needs.

Furthermore, SourcifyChina Factory’s commitment to timely delivery ensures your projects stay on schedule. They leverage advanced technology and skilled labor to meet stringent deadlines, reducing downtime and increasing efficiency. Their customer support is also top-notch, offering personalized service to address any concerns or specific requirements.

Moreover, SourcifyChina Factory is known for its transparent communication and reliable supply chain management. They provide regular updates and maintain a strong network of suppliers to ensure a steady flow of materials. This reliability minimizes risks associated with supply chain disruptions, ensuring smooth operations for your business.

Finally, SourcifyChina Factory’s sustainable practices and ethical manufacturing processes align with modern business values. By choosing them, you contribute to environmentally friendly initiatives and support ethical labor practices, enhancing your brand’s reputation and appeal to socially conscious consumers.

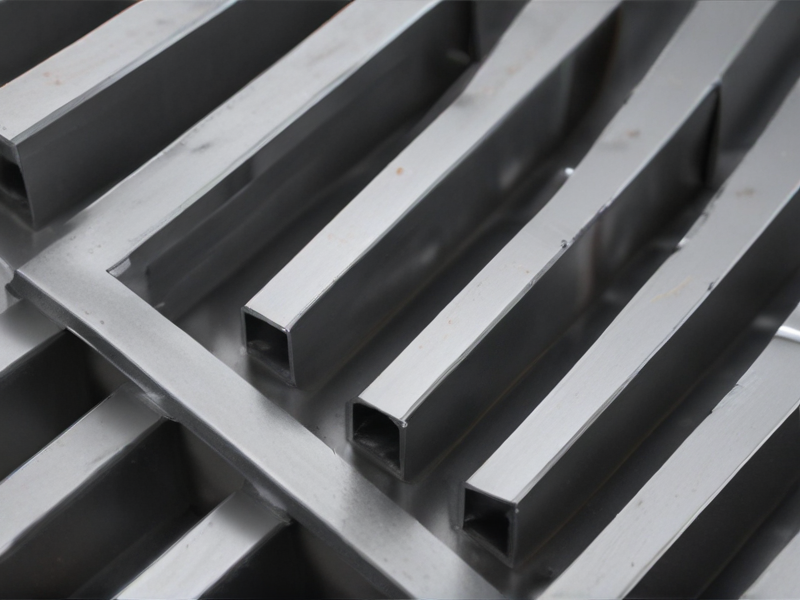

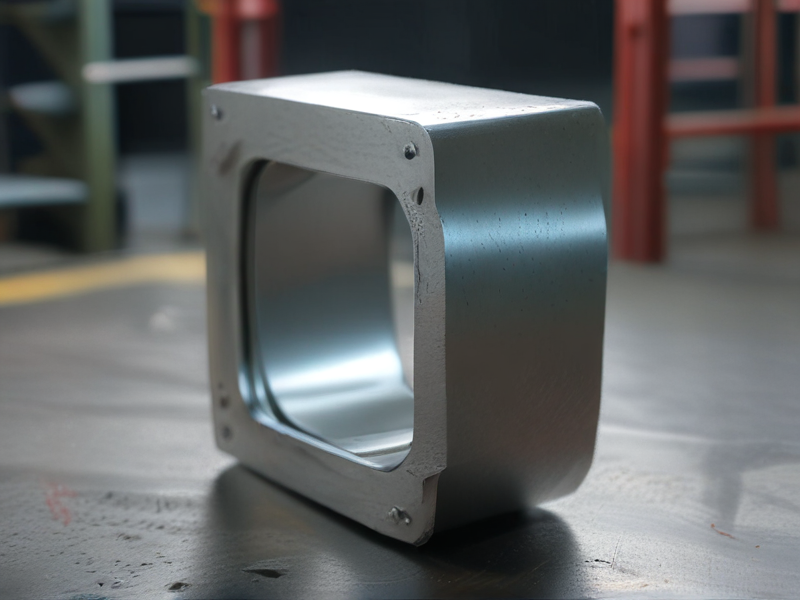

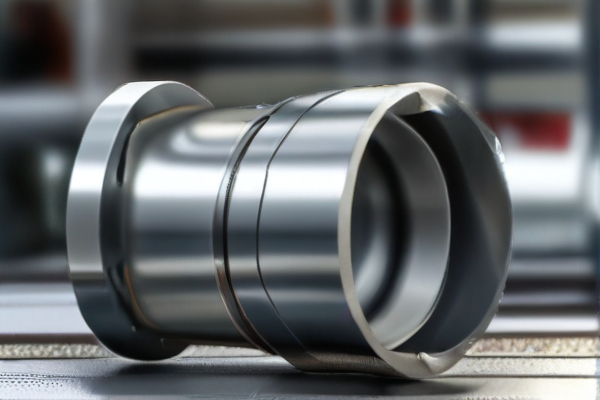

Custom fabrication metal involves creating metal structures tailored to specific requirements. This process includes cutting, bending, and assembling metal components to produce unique designs. Various types and options are available for custom metal fabrication.

– Materials: Steel, aluminum, stainless steel, copper, brass

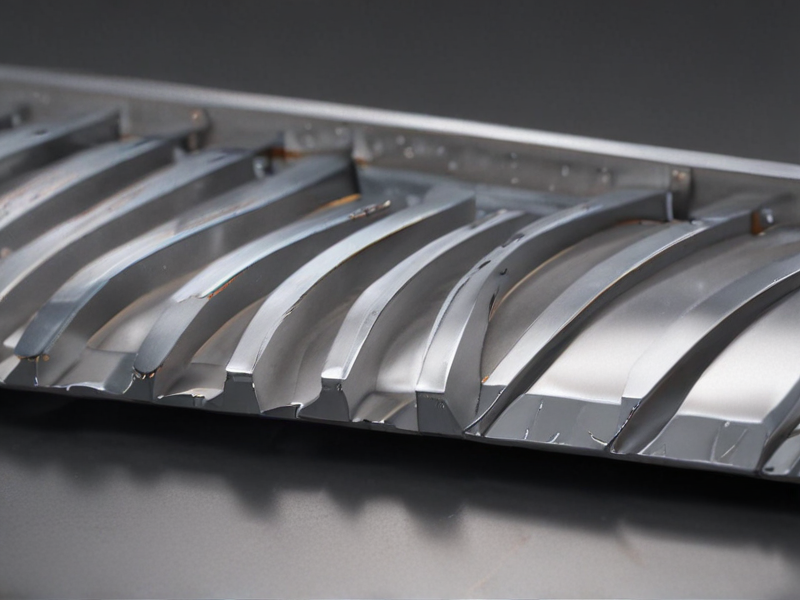

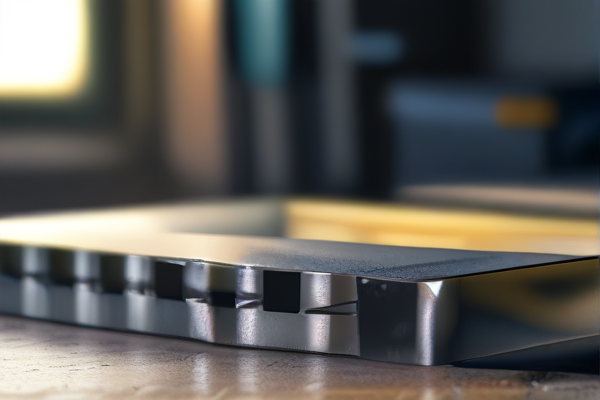

– Processes: Cutting, welding, bending, machining, stamping

– Finishes: Powder coating, painting, anodizing, galvanizing

– Applications: Architectural structures, industrial machinery, automotive parts, custom furniture

– Techniques: CNC machining, laser cutting, water jet cutting, press brake forming

Custom fabrication metal is essential in various industries due to its versatility and precision. It allows for the creation of tailored components and structures, enhancing functionality and performance.

– Automotive Industry: Custom metal parts for engines, frames, and other components.

– Construction: Structural beams, columns, and decorative elements.

– Aerospace: Precision parts for aircraft, satellites, and space exploration equipment.

– Medical Devices: Customized surgical instruments and implants.

– Renewable Energy: Components for wind turbines and solar panel mounts.

– Architecture: Unique designs for buildings and infrastructure.

– Marine Industry: Specialized parts for ships and submarines.

– Agriculture: Custom machinery parts and storage solutions.

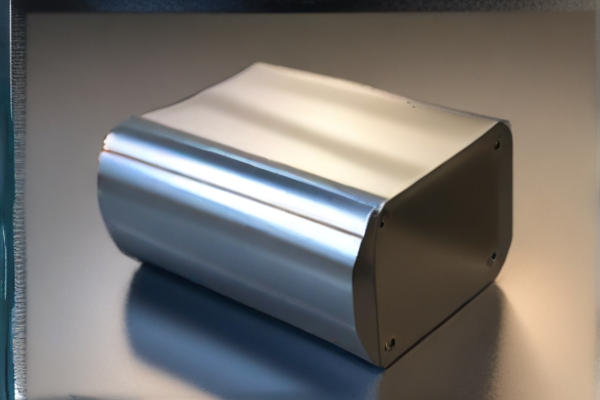

– Electronics: Enclosures and heat sinks for electronic devices.

– Defense: Armored vehicle parts and military equipment.

– Food Processing: Stainless steel components for hygiene and durability.

– Furniture: Custom metal frames and fixtures for durability and design.

– Sports Equipment: Specialized parts for high-performance gear.

– Art and Sculpture: Custom metalwork for artistic projects.

– Tool and Die Making: Precision molds and dies for manufacturing.

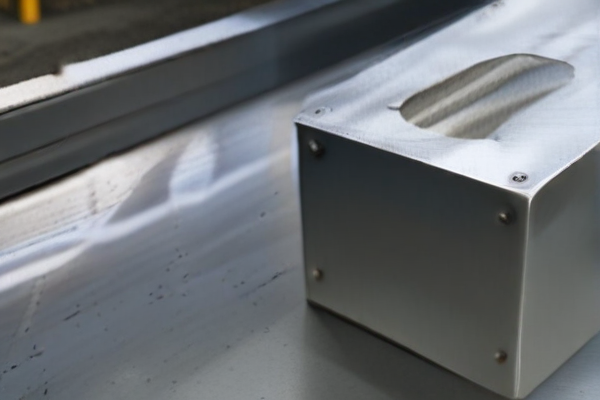

– Telecommunications: Custom racks and enclosures for networking equipment.

– Oil and Gas: Components for drilling rigs and pipelines.

– Robotics: Customized frames and parts for automation systems.

– Signage: Durable and intricate signs for businesses.

– Transportation: Custom parts for trains, buses, and other transport vehicles.

SourcifyChina custom fabrication metal materials encompass a wide range of metals tailored to specific industry needs. They offer stainless steel, aluminum, brass, and copper, ensuring durability and performance. Each material is selected for its unique properties, such as corrosion resistance, strength, and conductivity, catering to diverse applications.

Stainless steel is popular for its excellent corrosion resistance and strength, making it ideal for automotive, construction, and medical industries. Aluminum, known for its lightweight and high conductivity, is widely used in the aerospace and electronics sectors.

Brass and copper are valued for their superior electrical conductivity and malleability. Brass is often used in plumbing and electrical applications, while copper is essential in electrical wiring and thermal applications due to its excellent heat and electrical conductivity.

SourcifyChina’s custom fabrication process ensures precise manufacturing according to client specifications. Advanced technologies like CNC machining, laser cutting, and welding are employed to achieve high-quality finishes and intricate designs. Each product undergoes rigorous quality checks to ensure it meets industry standards and client expectations.

By offering a diverse range of metals and utilizing state-of-the-art fabrication techniques, SourcifyChina provides reliable solutions for various industrial needs. Their commitment to quality and customer satisfaction sets them apart in the custom fabrication industry.

SourcifyChina custom fabrication metal quality control manufacturing process ensures high standards through meticulous planning and execution. Every project begins with a detailed analysis of client requirements, followed by precise engineering designs.

During the production phase, advanced machinery and skilled technicians work together to fabricate metal components with utmost precision. Regular inspections are conducted to verify dimensional accuracy and material integrity.

Quality control extends to the final stages, where products undergo rigorous testing for durability and performance. Any deviations from specified standards are promptly addressed to maintain consistency.

In summary, SourcifyChina’s comprehensive quality control process guarantees reliable and high-quality custom metal fabrication, meeting client expectations and industry standards.

SourcifyChina specializes in custom fabrication metal services, offering precision engineering and high-quality manufacturing processes. Their capabilities include cutting, bending, welding, and assembling various metal components to meet specific client needs.

They leverage advanced technologies like CNC machining and laser cutting to ensure accuracy and consistency in every project. This ensures that each product meets exact specifications and high standards of quality.

SourcifyChina also provides surface finishing options such as powder coating, anodizing, and plating, which enhance the durability and aesthetics of metal parts. These finishing services cater to a wide range of industries, from automotive to aerospace.

The company’s skilled workforce is adept at handling complex projects, ensuring timely delivery and competitive pricing. Their expertise spans from small-scale prototypes to large production runs, making them a versatile partner in custom metal fabrication.

Furthermore, SourcifyChina emphasizes stringent quality control measures throughout the manufacturing process. This commitment to quality ensures that all products are reliable and meet international standards.

Their customer-centric approach involves close collaboration with clients, from initial design to final production. This ensures that every detail is addressed, resulting in products that precisely match the clients’ requirements.

In summary, SourcifyChina’s custom fabrication metal capabilities combine advanced technology, skilled craftsmanship, and strict quality control to deliver exceptional products. Their comprehensive services and client-focused approach make them a preferred choice for diverse metal fabrication needs.

Custom metal fabrication offers numerous advantages for various industries, providing tailored solutions that meet specific needs and improve overall efficiency.

– Precision and Accuracy: Custom fabrication ensures components fit perfectly, reducing the need for adjustments and rework.

– Durability: High-quality materials and precise fabrication methods lead to longer-lasting products.

– Flexibility in Design: Allows for the creation of unique, complex designs that standard fabrication cannot achieve.

– Cost-Effectiveness: Custom fabrication can be more economical in the long run due to reduced waste and increased efficiency.

– Enhanced Performance: Tailored components often perform better as they are designed specifically for their intended use.

– Material Choice: Ability to choose the best materials for specific applications, enhancing the final product’s quality.

– Speed: Custom fabrication can accelerate project timelines with more efficient production processes.

– Consistency: Ensures uniformity across all fabricated parts, crucial for large-scale projects.

– Integration: Facilitates better integration with existing systems and components.

– Innovation: Supports innovative designs and solutions, pushing the boundaries of what is possible in product development.

Custom fabrication metal is a specialized process that allows for the creation of tailored metal structures and components to meet specific needs and specifications. This technique offers versatility and precision.

Key features of custom fabrication metal include:

– Design Flexibility: Custom fabrication allows for intricate designs and complex shapes that standard manufacturing cannot achieve.

– Material Variety: A wide range of metals such as steel, aluminum, copper, and titanium can be used based on project requirements.

– Precision and Accuracy: Advanced machinery and techniques ensure high precision and accuracy in dimensions and assembly.

– Strength and Durability: Fabricated metal parts are robust, offering long-lasting performance and resilience.

– Customization: Tailored to fit exact specifications, including unique sizes, shapes, and finishes.

– Prototyping and Testing: Ability to create prototypes for testing and validation before full-scale production.

– Cost-Efficiency: Reduces waste and optimizes material usage, potentially lowering overall production costs.

– Enhanced Aesthetics: Custom metal fabrication can provide superior surface finishes and decorative features.

– Quality Control: Rigorous quality control processes ensure the highest standards of workmanship and material integrity.

– Integration Capability: Can be designed to integrate seamlessly with existing systems and components.

– Scalability: Suitable for both small-scale projects and large-scale industrial applications.

– Technical Support: Access to expert technical support and consultation throughout the fabrication process.

These features make custom metal fabrication an essential process in various industries, including construction, automotive, aerospace, and manufacturing.

SourcifyChina specializes in custom fabrication of metal products, offering tailored solutions to meet diverse client needs. Our expertise encompasses a wide range of metals, including steel, aluminum, and brass, ensuring high-quality, durable products.

We provide comprehensive custom fabrication services, from initial design to final production. Our advanced manufacturing processes and cutting-edge technology guarantee precision and efficiency in every project we undertake.

Our team of skilled engineers and craftsmen work closely with clients to create bespoke metal products. Whether you need custom parts for machinery, architectural elements, or unique decorative pieces, we deliver exceptional results.

At SourcifyChina, we pride ourselves on our ability to handle complex and challenging projects. Our state-of-the-art facilities and commitment to innovation ensure we meet the highest standards of quality and craftsmanship.

We understand the importance of timely delivery and cost-effectiveness. Our streamlined production processes and robust supply chain enable us to complete projects on schedule and within budget, without compromising on quality.

Our portfolio includes a diverse array of projects, from small-scale prototypes to large-scale industrial fabrications. Each project receives the same attention to detail and dedication to excellence, ensuring complete client satisfaction.

In conclusion, SourcifyChina is your trusted partner for custom metal fabrication. Our commitment to quality, precision, and customer service sets us apart in the industry. Whether your project is big or small, simple or complex, we have the expertise and resources to bring your vision to life. Let us help you achieve your goals with our bespoke metal fabrication solutions.

SourcifyChina Custom Fabrication Metal is a premier company specializing in high-quality custom metal fabrication services. Located in China, the company leverages advanced manufacturing technologies and a skilled workforce to deliver precision-crafted metal components and assemblies for a wide range of industries, including automotive, aerospace, construction, and electronics. SourcifyChina’s expertise encompasses various fabrication techniques such as cutting, bending, welding, and machining, ensuring that they can meet the unique specifications and stringent quality standards of their clients. The company prides itself on its ability to handle both small and large production runs with efficiency and reliability, making it a trusted partner for businesses seeking top-notch metal fabrication solutions. With a commitment to innovation, quality, and customer satisfaction, SourcifyChina Custom Fabrication Metal continues to be a leader in the global metal fabrication market, helping companies bring their product visions to life with unmatched precision and excellence.

Custom fabrication metal plays a critical role in the aerospace, defense, and marine industries due to its ability to meet stringent specifications and performance requirements. In aerospace, custom metal fabrication is essential for producing aircraft components such as fuselage parts, landing gear, and engine components, which must withstand extreme temperatures and stresses. The precision and durability of custom-fabricated metals ensure the safety and reliability of aircraft, enabling them to perform optimally under rigorous conditions. Similarly, in defense, custom metal fabrication is crucial for manufacturing robust military equipment, including armored vehicles, weapon systems, and structural components for military infrastructure. The ability to fabricate metals to exacting standards enhances the performance and longevity of these critical assets, providing a strategic advantage in defense operations.

In the marine industry, custom fabrication metal is indispensable for constructing and maintaining ships, submarines, and offshore structures. Marine environments are notoriously harsh, with exposure to saltwater, high pressures, and corrosive conditions. Custom-fabricated metals, such as corrosion-resistant alloys, are designed to withstand these challenges, ensuring the structural integrity and longevity of marine vessels and installations. Additionally, custom fabrication allows for the creation of specialized components that meet the unique requirements of different marine applications, from commercial shipping to naval defense. The ability to produce tailored metal solutions enhances the efficiency, safety, and reliability of marine operations, making custom metal fabrication a cornerstone of innovation and performance in this sector.

Custom fabrication metal plays a crucial role in the automotive industry, offering bespoke solutions for various components and structures. This process enables the creation of unique parts that meet specific design and performance requirements, enhancing the overall functionality and aesthetic appeal of vehicles. For instance, custom metal fabrication is used to produce high-performance exhaust systems, intricate body panels, and reinforced chassis components. These tailored solutions allow for improved aerodynamics, reduced weight, and increased durability, which are essential for both standard and high-performance vehicles. Additionally, custom metal fabrication supports the development of prototypes and concept cars, enabling automakers to experiment with innovative designs and materials before mass production.

In the electronics industry, custom fabrication metal is vital for creating specialized enclosures, heat sinks, and structural components that protect and enhance the performance of various devices. Precision metal fabrication allows for the manufacture of intricate parts that fit perfectly within the compact spaces of modern electronic gadgets, ensuring optimal performance and reliability. For example, custom metal enclosures provide robust protection against electromagnetic interference (EMI) and physical damage, which is critical for sensitive electronic components. Moreover, custom heat sinks made from metals with high thermal conductivity are essential for managing heat dissipation in devices such as computers, smartphones, and industrial equipment. This level of customization ensures that electronic products meet stringent industry standards and consumer expectations for durability and efficiency.

Custom fabrication metal plays a pivotal role in the construction industry, offering tailored solutions that meet specific structural and aesthetic requirements. In construction, the ability to create custom metal components allows for greater flexibility in design, enabling architects and builders to realize unique and complex structures that standard materials cannot support. For instance, custom metal fabrication is essential in crafting bespoke staircases, railings, and structural beams that must adhere to precise specifications and load-bearing requirements. Additionally, it enhances the durability and longevity of buildings, as fabricated metals can be treated to withstand environmental stressors such as corrosion, weathering, and seismic activity, thereby ensuring the safety and resilience of constructed facilities.

In the energy sector, custom fabrication metal is indispensable for the development and maintenance of critical infrastructure. This includes the production of specialized components for power plants, oil and gas facilities, and renewable energy installations such as wind turbines and solar panels. The precision and customization afforded by metal fabrication ensure that these components meet the stringent standards required for efficient and safe energy production and distribution. Custom-fabricated metal parts are also crucial for creating pipelines, storage tanks, and support structures that must endure extreme conditions and high pressures. Furthermore, in the renewable energy domain, custom metal fabrication supports the innovation of new technologies, such as advanced photovoltaic systems and more efficient wind turbine designs, thereby contributing to the transition towards sustainable energy solutions.

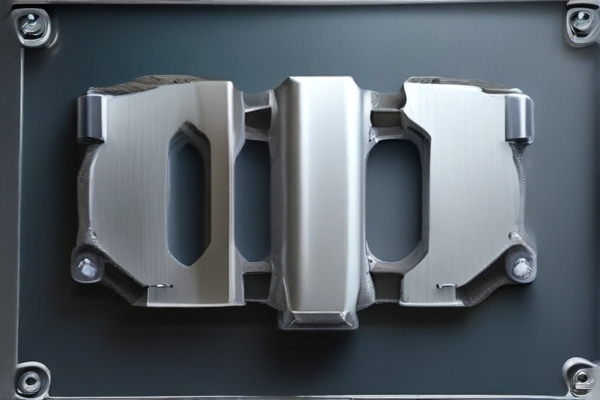

The industrial equipment industry heavily relies on custom fabrication metal to meet specific operational requirements and enhance efficiency. Custom metal fabrication involves creating bespoke metal components tailored to the precise dimensions and specifications needed for specialized equipment. This process allows manufacturers to design parts that perfectly fit their machinery, ensuring optimal performance and durability. For instance, in the production of large-scale machinery used in construction or mining, custom-fabricated metal parts can withstand extreme conditions and heavy loads, providing the necessary strength and resilience that off-the-shelf components might lack. This level of customization is crucial for industries where precision and reliability are paramount, as it minimizes the risk of equipment failure and downtime.

Moreover, custom fabrication metal supports innovation and adaptation in the industrial equipment sector. As technology advances and industry demands evolve, companies often need to modify existing machinery or develop new equipment to stay competitive. Custom fabrication enables the creation of unique solutions, such as specialized fittings, frames, and supports, which can be quickly adjusted or redesigned to incorporate new technologies or improve existing systems. This flexibility not only accelerates the development process but also allows for more cost-effective and sustainable production methods. By leveraging custom metal fabrication, the industrial equipment industry can maintain high standards of quality and performance, while also fostering innovation and adaptability in a rapidly changing market.

Custom fabrication metal plays a crucial role in the development and production of medical devices, offering tailored solutions to meet the stringent demands of the healthcare industry. Through custom fabrication, metals can be precisely engineered to create components that meet specific dimensional, structural, and functional requirements. This precision is vital for medical devices such as implants, surgical instruments, and diagnostic equipment, where even the slightest deviation can impact performance and safety. Metals like titanium, stainless steel, and cobalt-chromium alloys are often used due to their biocompatibility, strength, and resistance to corrosion, ensuring longevity and reliability in medical applications.

Furthermore, custom fabrication metal enables the creation of innovative medical devices that are patient-specific. For example, custom implants can be designed to fit a patient’s unique anatomy, enhancing the success rates of surgical procedures and improving patient outcomes. Advanced fabrication techniques, including CNC machining, 3D printing, and laser cutting, allow for the production of complex geometries and intricate designs that would be impossible with traditional manufacturing methods. This level of customization not only improves the functionality and comfort of medical devices but also accelerates the development process, enabling quicker transitions from prototype to market. As a result, custom fabrication metal is pivotal in driving advancements in medical technology and enhancing the overall quality of healthcare.

Custom fabrication metal plays a pivotal role in machining and manufacturing, enabling the creation of bespoke components tailored to specific applications. In machining, custom fabrication involves cutting, shaping, and assembling metal parts to meet precise specifications. This process often utilizes advanced techniques such as CNC (Computer Numerical Control) machining, which ensures high precision and repeatability. Custom fabrication is essential in industries where standard parts cannot meet unique design requirements or where prototypes are developed for new products. The flexibility of custom metal fabrication allows for the production of complex geometries and intricate designs that are critical in sectors like aerospace, automotive, and medical device manufacturing.

In the broader context of manufacturing, custom fabrication metal contributes to the development of specialized equipment, structural components, and machinery that must adhere to stringent performance standards. The ability to customize metal parts enhances the efficiency and effectiveness of manufacturing processes, as it allows for the integration of components that perfectly fit the intended use. This bespoke approach also supports innovation, as manufacturers can rapidly prototype and iterate on new designs. Additionally, custom fabrication often employs various welding, bending, and assembly techniques to produce high-strength, durable parts that meet specific industry standards. Overall, the application of custom fabrication metal in machining and manufacturing is integral to producing high-quality, reliable, and innovative products across diverse industries.

FAQ for Custom Fabrication Metal Quality Work from SourcifyChina Factory

Q1: What types of metal fabrication services does SourcifyChina offer?

A1: SourcifyChina provides a range of metal fabrication services, including cutting, bending, welding, and assembling metal components to meet custom specifications.

Q2: What metals do you work with?

A2: We work with a variety of metals, including stainless steel, aluminum, carbon steel, copper, and brass.

Q3: How do you ensure the quality of your fabricated metal products?

A3: Quality is ensured through rigorous quality control processes, including precision machining, inspection protocols, and adherence to international standards like ISO 9001.

Q4: Can you handle large volume orders?

A4: Yes, SourcifyChina is equipped to handle both small and large volume orders, providing scalable solutions to meet your production needs.

Q5: What is your typical turnaround time for custom metal fabrication?

A5: Turnaround time varies based on project complexity and order size but typically ranges from 2 to 6 weeks. Expedited services are available upon request.

Q6: Do you provide design and engineering support?

A6: Yes, our team offers comprehensive design and engineering support to help transform your concepts into high-quality finished products.

Q7: What industries do you serve?

A7: We serve a wide range of industries, including automotive, aerospace, construction, electronics, and medical equipment manufacturing.

Q8: How can I get a quote for my project?

A8: You can get a quote by contacting us through our website, providing details about your project requirements, materials, and any specific instructions.

Q9: What are your payment terms?

A9: Our payment terms typically include a deposit upon order confirmation and the balance upon completion, but we are flexible and can discuss terms that suit your needs.

Q10: Where is SourcifyChina located, and do you ship internationally?

A10: SourcifyChina is based in China, and we offer international shipping to ensure that our products reach customers worldwide efficiently and on time.

Custom fabrication metal manufacturing from SourcifyChina Factory offers several advantages and considerations for businesses looking to leverage Chinese manufacturing expertise. Here are some key tips:

1. Define Specifications Clearly: Ensure that all design specifications, materials, tolerances, and finishes are clearly communicated. Detailed CAD drawings and technical documents are essential.

2. Quality Control: Implement rigorous quality control processes. SourcifyChina offers on-site quality inspections, but it’s prudent to specify critical checkpoints and inspection criteria.

3. Material Selection: Choose the right materials for your project. SourcifyChina can provide a variety of metals such as stainless steel, aluminum, and carbon steel. Ensure the chosen material meets your project’s durability, strength, and corrosion resistance requirements.

4. Prototype Development: Start with a prototype to evaluate the factory’s capabilities and the feasibility of your design. This helps in identifying potential issues early in the process.

5. Communication: Maintain regular communication with the factory. SourcifyChina typically provides dedicated account managers to facilitate this, ensuring smooth project updates and timely resolution of issues.

6. Lead Time and Logistics: Factor in production lead times and shipping durations. SourcifyChina can assist with logistics, but it’s essential to plan for potential delays in international shipping.

7. Cost Considerations: Custom fabrication can be cost-effective, but consider all costs, including production, shipping, tariffs, and potential rework. SourcifyChina’s transparent pricing can help in accurate cost estimation.

8. Compliance and Standards: Ensure that the manufacturing process complies with relevant industry standards and certifications. SourcifyChina can adhere to international standards, but it’s crucial to specify these requirements upfront.

9. Partnership and Trust: Building a strong relationship with your manufacturing partner is key. Visit the factory if possible, and work towards building a partnership based on trust and mutual benefit.

By following these tips, you can effectively utilize SourcifyChina’s custom fabrication metal manufacturing services to achieve high-quality, cost-efficient production.

FAQ for Sourcing Custom Fabrication Metal from SourcifyChina Factory

What types of custom metal fabrication does SourcifyChina offer?

SourcifyChina offers a wide range of custom metal fabrication services including laser cutting, welding, bending, punching, and machining for various metals like steel, aluminum, and stainless steel.

How do I get a quote for my custom metal fabrication project?

You can get a quote by providing detailed drawings or CAD files of your project, specifying the materials, quantities, and any specific finishing requirements. Submit these details through our online form or email them directly to our sales team.

What is the typical lead time for custom metal fabrication orders?

The lead time varies depending on the complexity and size of the project. Generally, it ranges from 2 to 6 weeks. We will provide a more accurate timeline after reviewing your project details.

Can SourcifyChina handle large volume production runs?

Yes, SourcifyChina is equipped to handle both small batch and large volume production runs, ensuring consistent quality and timely delivery.

What quality control measures are in place at SourcifyChina?

SourcifyChina implements stringent quality control measures including material verification, dimensional inspections, and surface finish checks to ensure all products meet your specifications and industry standards.

Do you offer any finishing services for fabricated metal parts?

Yes, we offer a variety of finishing services such as powder coating, painting, anodizing, and galvanizing to enhance the appearance and durability of your metal parts.

How can I track my order status?

You can track your order status through our online customer portal or by contacting our customer service team for regular updates on your project’s progress.

What are the payment terms for orders?

We typically require a 50% deposit upon order confirmation and the remaining 50% before shipment. Payment terms may be adjusted based on the order size and customer relationship.

Can SourcifyChina assist with design and prototyping?

Yes, our experienced engineers can assist with design optimization and prototyping to ensure your project meets all functional and aesthetic requirements.

Is international shipping available?

Yes, we offer international shipping options and can handle all necessary export documentation to ensure your order is delivered smoothly to your location.

Sourcing custom metal fabrication from SourcifyChina factory requires a strategic approach to ensure quality and reliability. Here are some essential tips:

1. Define Your Requirements: Clearly outline your product specifications, including materials, dimensions, tolerances, and any specific finishes. Detailed drawings or CAD files can help avoid misunderstandings.

2. Research the Factory: Investigate SourcifyChina’s capabilities and reputation. Look for reviews, case studies, and client testimonials. Verify their experience with similar projects.

3. Request Samples: Before committing to large orders, request samples to evaluate the quality of their work. This helps in assessing their precision, craftsmanship, and material quality.

4. Quality Control: Ensure the factory has robust quality control processes. Inquire about their inspection procedures, certifications (e.g., ISO), and whether they conduct third-party audits.

5. Communication: Maintain clear and frequent communication. Establish a single point of contact who understands your project requirements and can provide timely updates.

6. Pricing and Payment Terms: Get detailed quotes, including breakdowns of material, labor, and any additional costs. Negotiate favorable payment terms, such as a percentage upfront and the balance upon completion or delivery.

7. Lead Times: Confirm realistic production lead times and factor in shipping durations. Ensure they can meet your deadlines without compromising quality.

8. Logistics: Plan for shipping and customs clearance. Discuss Incoterms (e.g., FOB, CIF) to understand who bears the risks and costs during transportation.

9. Legal Protections: Draft a detailed contract outlining specifications, deadlines, payment terms, and penalties for non-compliance. Consider including a non-disclosure agreement (NDA) to protect your designs.

10. Visit the Factory: If possible, visit SourcifyChina to see their operations firsthand. This can provide insights into their production capabilities and work culture.

By following these steps, you can mitigate risks and ensure a successful partnership with SourcifyChina for your custom metal fabrication needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.