SourcifyChina offers unmatched expertise in sourcing automotive CNC machines, ensuring buyers get the best quality and price. Their deep industry knowledge and extensive network streamline the purchasing process.

The company prioritizes rigorous quality control, guaranteeing that every CNC machine meets stringent international standards. This focus on quality fosters trust and reliability.

SourcifyChina provides comprehensive support, from initial inquiry to post-purchase assistance. Their dedicated team assists with logistics, customs, and any technical issues, ensuring a seamless experience.

Choosing SourcifyChina means partnering with a reputable and experienced sourcing agent, ensuring a smooth, cost-effective, and high-quality procurement process for automotive CNC machines.

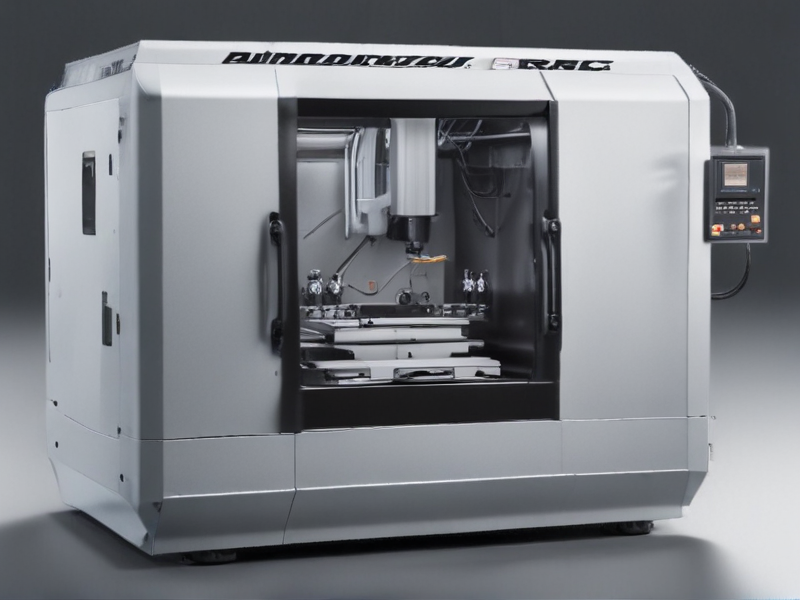

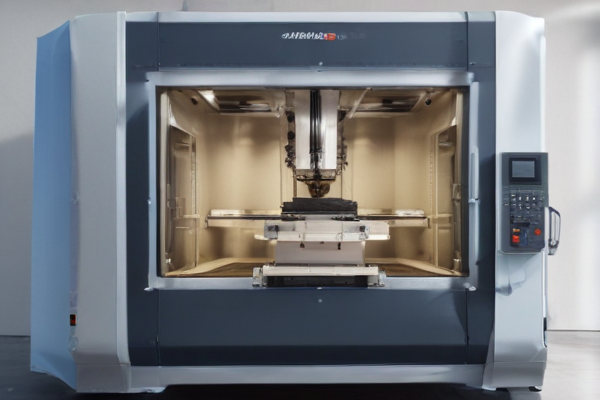

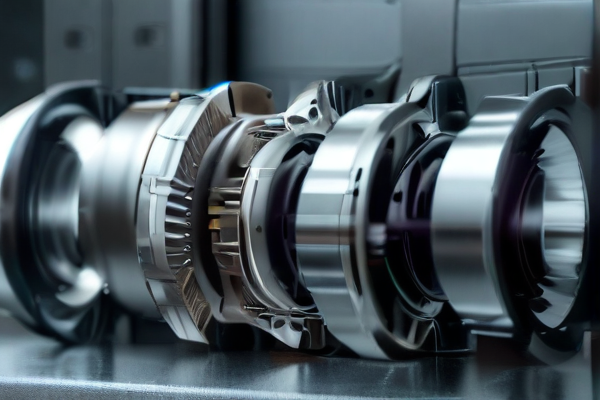

Automotive CNC machines are essential for precision manufacturing in the automotive industry. They include various types such as milling machines, lathes, and multi-axis machines, each offering unique capabilities for producing complex parts.

– Milling Machines: Ideal for cutting and shaping metal parts.

– Lathes: Perfect for creating cylindrical parts with high precision.

– Multi-Axis Machines: Enable complex machining with multiple axes for intricate designs.

– Laser Cutters: Provide high precision cutting with minimal material waste.

– Water Jet Cutters: Utilize high-pressure water for cutting without heat distortion.

– EDM (Electrical Discharge Machines): Used for intricate shapes in hard metals.

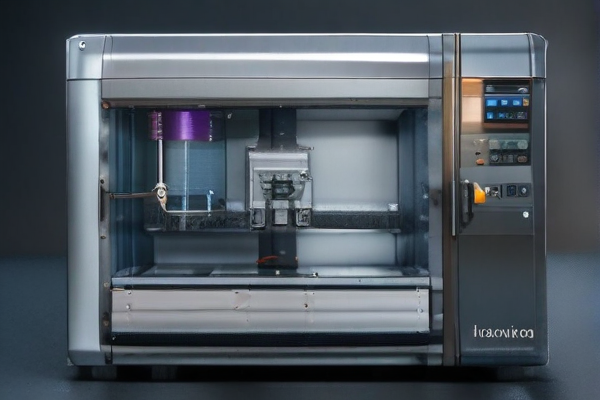

– Hybrid Machines: Combine additive and subtractive processes for advanced manufacturing.

– Robotic CNC Systems: Offer flexibility and automation for high-volume production.

– 5-Axis CNC Machines: Allow for cutting along five different axes simultaneously, ideal for complex geometries.

– Swiss-Type CNC Machines: Specialize in small, precise parts with high complexity.

These options cater to diverse needs in the automotive manufacturing process, ensuring precision, efficiency, and high-quality output.

Automotive CNC machines are integral in manufacturing precision components for vehicles, ensuring high accuracy and repeatability. These machines are essential for producing parts such as engine blocks, transmission cases, and other critical components.

Key applications include:

– Engine Block Machining: CNC machines create complex engine blocks with high precision.

– Transmission Component Production: Accurate machining of gears and shafts for transmissions.

– Suspension Parts Manufacturing: Producing consistent and reliable suspension components.

– Brake System Components: Ensuring the accuracy and safety of brake parts.

– Custom Prototype Parts: Rapid development of prototype components for testing and development.

– Exterior and Interior Trim: Crafting detailed and aesthetic parts for vehicle interiors and exteriors.

– Die and Mold Production: Creating molds for plastic and metal parts.

– Exhaust System Components: Fabricating parts that withstand high temperatures and stress.

– Fuel System Parts: Precision manufacturing of fuel injectors and pumps.

– Electric Vehicle Components: Producing parts specific to electric vehicles, such as battery casings and motor housings.

Automotive CNC machines enhance efficiency, reduce waste, and improve the overall quality of vehicle components, driving innovation and reliability in the automotive industry.

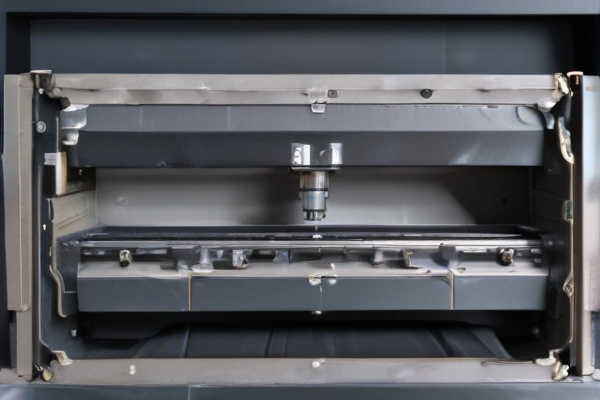

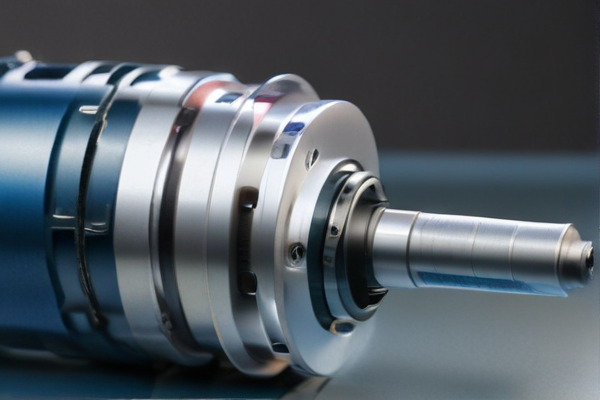

SourcifyChina’s automotive CNC machines are built with high-quality materials to ensure durability and precision. The frames are typically made from cast iron or welded steel, providing stability and reducing vibrations during operation.

The machine components, such as the spindles and gears, are often crafted from hardened steel or specialized alloys. This ensures longevity and high performance under the rigorous demands of automotive manufacturing.

Tool holders and fixtures used in these CNC machines are usually made from materials like stainless steel or titanium. These materials are chosen for their strength and resistance to wear, ensuring consistent accuracy.

Cutting tools used in SourcifyChina’s CNC machines are often made from tungsten carbide or high-speed steel. These materials are selected for their ability to maintain sharp edges and withstand the high temperatures generated during machining processes.

Overall, SourcifyChina focuses on using top-grade materials to enhance the reliability and efficiency of their automotive CNC machines, meeting the exacting standards required in the automotive industry.

SourcifyChina employs a stringent quality control process for its automotive CNC machines. From initial design to final production, each step is meticulously monitored. Advanced CAD software is used to ensure precision in design, followed by rigorous prototyping and testing.

During manufacturing, SourcifyChina implements real-time monitoring systems. These systems track and report any deviations in machine performance or material quality, allowing for immediate corrective actions. This ensures each machine meets stringent industry standards.

Post-production, every CNC machine undergoes comprehensive inspections. Engineers test machines under various operational conditions to guarantee durability and reliability. This phase ensures the machines perform optimally in real-world applications.

Customer feedback is integral to SourcifyChina’s quality control process. The company continuously gathers and analyzes user data to refine its manufacturing techniques. This customer-centric approach fosters ongoing improvements and innovation in CNC machine production.

In summary, SourcifyChina’s robust quality control process for automotive CNC machines emphasizes precision, real-time monitoring, thorough testing, and continuous improvement. This commitment to excellence ensures the delivery of high-performance and reliable CNC machines to the automotive industry.

SourcifyChina’s automotive CNC machines are known for their high precision and efficiency. These machines ensure accurate cutting, drilling, and milling operations essential for automotive part manufacturing. The integration of advanced software allows for complex geometries to be produced with ease.

The machines are equipped with multi-axis capabilities, enabling intricate part designs that meet stringent industry standards. Their robust construction ensures durability and long-term reliability, even under high-volume production demands. The use of high-quality materials in their build contributes to minimal maintenance requirements.

Automation features in SourcifyChina’s CNC machines significantly reduce production time and labor costs. The machines support a range of materials, from aluminum to high-strength steels, making them versatile for various automotive components. Their user-friendly interfaces allow for easy programming and operation, enhancing productivity and reducing the learning curve for operators.

Incorporating state-of-the-art technology, these CNC machines offer real-time monitoring and diagnostics. This capability ensures optimal performance and quick troubleshooting, minimizing downtime. The machines’ precision and consistency improve the quality of finished products, crucial for the competitive automotive industry.

Overall, SourcifyChina’s automotive CNC machines combine precision, efficiency, and durability to meet the demands of modern automotive manufacturing. Their advanced features and robust design make them a valuable asset for any production facility aiming for high-quality and cost-effective output.

Automotive CNC machines revolutionize manufacturing by offering unparalleled precision and efficiency. These machines automate complex tasks, ensuring consistent quality and reduced production time.

– High Precision and Accuracy: CNC machines deliver exact specifications, minimizing errors and enhancing product quality.

– Efficiency and Speed: Automating processes reduces the time needed for production, leading to faster turnaround and increased output.

– Cost-Effective: By reducing manual labor and waste, CNC machining lowers production costs and increases profitability.

– Complex Design Capability: CNC machines can handle intricate and detailed designs that would be challenging with traditional methods.

– Consistency: Ensures uniformity across large production runs, maintaining the same high standard for every unit.

– Flexibility: Easy to reprogram for different tasks, making them ideal for custom and small-batch production.

– Safety: Automates potentially hazardous tasks, reducing the risk of injury to workers.

– Material Versatility: Can work with a wide range of materials, from metals to plastics, broadening manufacturing capabilities.

– Reduced Waste: Precision machining minimizes material waste, leading to more sustainable production processes.

– Maintenance and Reliability: Modern CNC machines are built to last, with easy maintenance and high reliability, ensuring long-term operational efficiency.

Automotive CNC machines are crucial for modern manufacturing, combining precision, efficiency, and versatility to meet the demanding standards of the automotive industry.

Automotive CNC machines are pivotal in modern vehicle manufacturing, providing precision, efficiency, and versatility in producing complex components.

Key features of automotive CNC machines include:

– Precision and Accuracy: Achieve tight tolerances essential for automotive parts.

– High-Speed Machining: Rapid production to meet industry demands.

– Versatility: Capable of handling various materials like aluminum, steel, and composites.

– Automation: Reduces human error and increases consistency.

– Multi-Axis Machining: Enables complex geometries and intricate designs.

– CAD/CAM Integration: Seamless transition from design to production.

– Durability: Built to withstand the rigors of continuous, heavy-duty use.

– Quality Control: Integrated inspection tools ensure parts meet strict standards.

SourcifyChina specializes in providing high-quality automotive CNC machines, catering to custom product needs in the automotive industry. Their machines are designed to enhance precision and efficiency in manufacturing processes, ensuring top-notch performance and reliability.

The company offers a wide range of CNC machining services, including milling, turning, and grinding, tailored to meet specific project requirements. These services are essential for creating intricate automotive components with exact specifications, contributing to the overall quality and safety of vehicles.

SourcifyChina’s commitment to innovation is evident in their use of advanced technology and machinery. This ensures that each custom product is manufactured to the highest standards, meeting the rigorous demands of the automotive sector. Their expertise in CNC machining allows for the production of complex parts with tight tolerances, essential for modern automotive applications.

Additionally, SourcifyChina provides comprehensive project management, from initial design to final production. This end-to-end service ensures seamless integration of custom CNC machined parts into larger manufacturing processes, facilitating smoother operations and faster time-to-market for automotive manufacturers.

In summary, SourcifyChina excels in delivering custom automotive CNC machining solutions, leveraging advanced technology and meticulous project management to meet the unique needs of their clients. Their focus on precision, quality, and innovation makes them a trusted partner in the automotive manufacturing industry.

SourcifyChina is a prominent company specializing in the production and supply of CNC machines tailored for the automotive industry. Renowned for its cutting-edge technology and precision engineering, SourcifyChina provides high-quality CNC machining solutions that cater to the complex and exacting standards of automotive manufacturing. The company leverages advanced computer numerical control systems to enhance productivity, efficiency, and accuracy, making it a trusted partner for leading automotive manufacturers worldwide. SourcifyChina’s robust machinery is designed to handle a wide range of automotive components, from engine parts to intricate body structures, ensuring superior performance and reliability. With a commitment to innovation, customer satisfaction, and competitive pricing, SourcifyChina stands out as a leader in the CNC machine market, driving forward the capabilities and progress of the automotive sector.

Aerospace, Defense, and Marine applications of automotive CNC machines are pivotal due to the precision and complexity required in manufacturing components for these sectors. In aerospace, CNC machines are used to produce high-precision parts such as turbine blades, engine components, and structural elements from materials like titanium and aluminum. These machines enable the creation of parts with tight tolerances, essential for ensuring safety and performance at high altitudes and speeds. The ability of CNC machines to operate continuously and consistently also improves production efficiency, which is crucial in the high-demand aerospace industry where delays can have significant financial and operational repercussions.

In the defense sector, CNC machining is critical for manufacturing weapon components, vehicle parts, and communication equipment. The high precision and repeatability of CNC machines ensure that each component meets stringent defense standards, enhancing reliability and effectiveness. Similarly, in the marine industry, CNC machines are employed to create parts for ships and submarines, such as propellers, engine components, and hull fittings. The harsh marine environment demands parts that can withstand corrosion and extreme pressures, and CNC machines facilitate the production of such robust components. The adaptability of CNC machines to handle various materials and complex geometries makes them indispensable across these high-stakes industries.

Automotive CNC machines play a pivotal role in the automotive industry by enabling the precise and efficient manufacturing of complex components. These machines are used to produce a wide range of parts, from engine blocks and transmission housings to intricate components like fuel injectors and turbochargers. The precision and repeatability of CNC machining ensure that each part meets stringent quality standards, which is crucial for the performance and safety of vehicles. Additionally, the flexibility of CNC machines allows manufacturers to quickly adapt to new designs and make modifications without significant downtime, supporting the industry’s demand for innovation and rapid development cycles.

In the electronics sector, CNC machines are essential for creating the intricate and miniaturized components required in modern devices. They are used to manufacture printed circuit boards (PCBs), enclosures, and various other parts that require high precision. The ability of CNC machines to handle complex geometries and fine tolerances is critical for ensuring the reliability and performance of electronic products. Moreover, CNC machining allows for the integration of various materials, such as metals and plastics, which is important for the diverse needs of electronic applications. This versatility not only supports the development of cutting-edge technology but also helps in maintaining consistency and quality in mass production.

Construction Applications:

Automotive CNC (Computer Numerical Control) machines have revolutionized the construction industry by enhancing precision and efficiency in manufacturing components. These machines enable the creation of complex, custom parts with high accuracy, essential for constructing durable and reliable structures. In construction, CNC machines are used to fabricate metal and plastic components for machinery, scaffolding, and other structural elements. Their ability to produce identical parts repeatedly ensures consistency and reduces the margin of error, leading to safer and more robust construction projects. Additionally, CNC machines expedite the production process, allowing for faster completion of construction tasks and the ability to meet tight project deadlines.

Energy Applications:

In the energy sector, automotive CNC machines play a critical role in the production of equipment used in renewable energy systems, such as wind turbines, solar panels, and hydroelectric components. Precision machining is vital for creating the intricate parts required in these systems, where even minor deviations can impact efficiency and performance. CNC machines are employed to manufacture turbine blades, generator parts, and structural components that must withstand extreme conditions and stress. By ensuring high precision and durability, CNC machines contribute to the reliability and longevity of energy infrastructure, thereby supporting the shift towards sustainable energy solutions. Moreover, their use in prototyping and developing new energy technologies accelerates innovation and the deployment of advanced energy systems.

The industrial equipment industry has significantly benefited from the application of automotive CNC (Computer Numerical Control) machines, enhancing precision and efficiency in manufacturing processes. Automotive CNC machines are employed to produce complex and high-tolerance components crucial for modern vehicles, such as engine blocks, transmission parts, and intricate body panels. These machines enable manufacturers to achieve superior accuracy and consistency, which are vital for meeting stringent automotive industry standards. The automation and programmability of CNC machines reduce the likelihood of human error, streamline production workflows, and allow for the rapid adaptation of designs, which is essential for staying competitive in a fast-paced market.

Moreover, the integration of automotive CNC machines in the industrial equipment sector supports cost-effective production and scalability. By automating repetitive tasks and minimizing material waste through precise cutting and shaping, CNC machines help lower production costs and improve resource efficiency. This scalability is particularly beneficial for handling large production volumes while maintaining high quality, which is crucial for the automotive industry’s demand for mass production of reliable components. Additionally, the ability of CNC machines to operate continuously with minimal downtime enhances overall productivity, ensuring that manufacturers can meet tight deadlines and customer demands. The use of CNC technology also facilitates innovation, as manufacturers can experiment with new designs and materials with greater ease, pushing the boundaries of automotive engineering and design.

Automotive CNC (Computer Numerical Control) machines, traditionally used for precision manufacturing in the automotive industry, have found significant applications in the medical device sector. These machines offer unparalleled precision and efficiency, essential for producing intricate and high-quality medical devices. In the medical field, CNC machines are used to create components for surgical instruments, prosthetics, implants, and diagnostic equipment. The ability to produce complex geometries with tight tolerances ensures that medical devices meet stringent regulatory standards and function reliably in critical healthcare settings.

The adoption of automotive CNC machines in medical device manufacturing also accelerates the development process. Rapid prototyping capabilities enable quick iterations and adjustments, facilitating faster innovation and time-to-market for new medical technologies. Additionally, the use of advanced materials such as titanium and surgical-grade stainless steel is made feasible by the robust capabilities of CNC machining. This versatility not only enhances the performance and durability of medical devices but also contributes to patient safety and outcomes. As a result, the integration of automotive CNC machining techniques into the medical device industry represents a significant advancement, leveraging high-precision technology to improve healthcare solutions.

Automotive CNC (Computer Numerical Control) machines have revolutionized the machining and manufacturing sectors of the automotive industry. These machines are used to create highly precise and complex parts, ranging from engine components to intricate transmission systems. By utilizing CNC technology, manufacturers can achieve unparalleled accuracy and consistency, reducing human error and ensuring each part meets strict tolerances. CNC machines in automotive applications can handle a variety of materials, including aluminum, steel, and composites, making them versatile tools for producing everything from prototype parts to mass production runs. The automation provided by CNC machining also enhances production efficiency, allowing for faster turnaround times and increased throughput.

In the manufacturing process, automotive CNC machines play a critical role in producing parts that are essential for the functionality and safety of vehicles. The precision offered by CNC machining ensures that components such as brake systems, gearboxes, and suspension parts are manufactured to exact specifications, which is crucial for vehicle performance and reliability. Additionally, CNC machines facilitate the implementation of advanced manufacturing techniques, such as multi-axis machining, which enables the creation of complex geometries that would be difficult or impossible to achieve with traditional machining methods. This capability not only improves the overall design and performance of automotive parts but also supports innovation in the development of new automotive technologies. As the automotive industry continues to evolve, the integration of CNC machines in manufacturing processes remains a key factor in maintaining competitive advantage and ensuring the production of high-quality vehicles.

Sure, here are some frequently asked questions (FAQ) with answers for manufacturing automotive CNC machine quality work from SourcifyChina factory:

What types of CNC machines do you use for automotive manufacturing?

SourcifyChina utilizes a range of CNC machines, including 3-axis, 4-axis, and 5-axis milling machines, as well as CNC lathes and multi-axis turning centers. This diversity allows us to handle complex geometries and high-precision components required in the automotive industry.

How do you ensure the quality of CNC machined automotive parts?

We employ stringent quality control measures, including in-process inspections, final inspections, and the use of high-precision measurement tools such as CMM (Coordinate Measuring Machines). We follow ISO 9001 and IATF 16949 standards to ensure consistency and reliability in our production.

Can you handle custom designs and specifications?

Yes, we specialize in custom manufacturing. Our team works closely with clients to understand their specific requirements and provides tailored solutions. We can handle everything from prototyping to full-scale production runs.

What materials can you work with?

We work with a wide range of materials commonly used in the automotive industry, including aluminum, steel, titanium, and various high-performance alloys. We also have experience with plastics and composites.

What is your typical lead time for production?

Lead times vary depending on the complexity and volume of the order. Generally, prototyping can be completed within 2-4 weeks, while full production runs may take 4-8 weeks. We strive to meet our clients’ deadlines and offer expedited services when necessary.

Do you offer any post-machining services?

Yes, we provide a comprehensive range of post-machining services, including heat treatment, surface finishing (anodizing, plating, painting), and assembly. This ensures that the parts we deliver are ready for immediate use in your manufacturing process.

How do you handle shipping and logistics?

We offer global shipping and work with reliable logistics partners to ensure timely and safe delivery of your products. We handle all customs documentation and provide tracking information to keep you informed throughout the process.

Can you provide references or case studies of past automotive projects?

Absolutely. We have a portfolio of successful projects with various automotive clients. Upon request, we can provide detailed case studies and references to showcase our expertise and the quality of our work.

When considering automotive CNC machine manufacturing from SourcifyChina factory, here are some tips to ensure a successful partnership:

1. Define Specifications Clearly: Outline your requirements in detail, including material types, tolerances, dimensions, and quantities. Clear communication ensures the factory understands your needs.

2. Evaluate Capabilities: Assess SourcifyChina’s manufacturing capabilities. Check their equipment, technology, and expertise in producing automotive parts to ensure they meet your standards.

3. Quality Control: Ensure robust quality control processes are in place. This includes inspecting raw materials, in-process checks, and final product inspections. Ask for certifications like ISO 9001 or IATF 16949.

4. Prototyping and Testing: Request prototypes before full-scale production. This helps identify any design flaws or production issues early. Test the prototypes under real-world conditions.

5. Lead Times and Flexibility: Confirm lead times for production and delivery. Discuss flexibility for urgent orders or changes in demand to avoid delays in your supply chain.

6. Cost Management: Understand the pricing structure. Consider factors like setup costs, unit costs, and potential hidden fees. Negotiate for the best terms while ensuring quality is not compromised.

7. Communication: Maintain regular communication with the factory. Use project management tools or set up periodic meetings to track progress and address issues promptly.

8. Compliance and Standards: Verify that the factory complies with industry standards and regulations. This ensures that the parts manufactured are safe and meet legal requirements.

9. Supplier Reliability: Check SourcifyChina’s track record for reliability and on-time delivery. Look for customer reviews or ask for references to gauge their reputation.

10. After-Sales Support: Ensure there is a robust after-sales support system. This includes warranties, replacement policies, and technical support to address any issues that arise post-delivery.

By following these tips, you can effectively collaborate with SourcifyChina to produce high-quality automotive CNC parts.

FAQ for Sourcing Automotive CNC Machines from SourcifyChina Factory

Q1: What types of automotive CNC machines does SourcifyChina offer?

A1: SourcifyChina provides a range of CNC machines suitable for the automotive industry, including milling machines, lathes, routers, and multi-axis machines. They offer both standard and custom solutions tailored to your specific needs.

Q2: How can I get a quote for a CNC machine?

A2: To obtain a quote, you can contact SourcifyChina through their website, email, or phone. Provide detailed specifications and requirements for the CNC machine to receive an accurate quote.

Q3: What is the typical lead time for delivery?

A3: The lead time varies depending on the machine’s complexity and customization. Generally, it ranges from 4 to 12 weeks. For precise lead times, contact SourcifyChina with your specific requirements.

Q4: Are there any minimum order quantities (MOQ)?

A4: SourcifyChina does not typically have a minimum order quantity for CNC machines. They cater to both small and large orders, ensuring flexibility for their customers.

Q5: Do they provide after-sales support and service?

A5: Yes, SourcifyChina offers comprehensive after-sales support, including installation, training, maintenance, and technical assistance to ensure smooth operation of the CNC machines.

Q6: Can I visit the factory for an inspection?

A6: Absolutely. SourcifyChina welcomes factory visits for quality inspections and to better understand your requirements. Contact them to schedule a visit.

Q7: What payment methods are accepted?

A7: SourcifyChina accepts various payment methods, including wire transfer, letter of credit (L/C), and other secure payment options. Confirm the details during the quotation process.

Q8: Are the machines compliant with international standards?

A8: Yes, all CNC machines from SourcifyChina comply with international standards and certifications, ensuring quality and safety in their operation.

Q9: Can SourcifyChina handle custom designs?

A9: Yes, SourcifyChina specializes in custom CNC machine designs to meet specific customer requirements. Provide your detailed specifications for a tailored solution.

Q10: How do I ensure the quality of the CNC machine?

A10: SourcifyChina employs rigorous quality control processes, including pre-shipment inspections and testing. They also provide warranties to guarantee machine performance and reliability.

When sourcing an automotive CNC machine from SourcifyChina factory, consider the following tips to ensure a successful purchase:

1. Define Your Requirements: Clearly outline the specifications you need for the CNC machine. This includes dimensions, material compatibility, precision levels, and any additional features.

2. Research the Supplier: Verify the credibility of SourcifyChina factory. Look for reviews, certifications, and past customer experiences. Check if they have ISO certifications or other industry-specific standards.

3. Request Quotes and Compare: Contact SourcifyChina for a detailed quote. Compare their prices, terms, and conditions with other suppliers to ensure competitive pricing and favorable terms.

4. Evaluate Quality Control: Ask about their quality control processes. Inquire about inspection reports, testing procedures, and whether they offer samples or trial runs.

5. Check Lead Times: Confirm the lead time for production and delivery. Ensure it aligns with your project timeline to avoid delays.

6. Understand Payment Terms: Clarify payment terms and conditions. It’s crucial to understand the initial deposit, balance payment, and acceptable payment methods.

7. Shipping and Logistics: Discuss shipping options and costs. Ensure they can handle the logistics efficiently and provide tracking information.

8. After-Sales Support: Inquire about after-sales service, including warranty, maintenance support, and availability of spare parts.

9. Legal Considerations: Review the contract thoroughly. Ensure it includes all agreed terms, conditions, and warranties. Consider consulting a legal expert if needed.

10. Communication: Maintain clear and consistent communication with the supplier throughout the process. Promptly address any concerns or issues that arise.

By following these tips, you can effectively source an automotive CNC machine from SourcifyChina factory, ensuring quality, reliability, and cost-efficiency.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.