Title: Reliable SourcifyChina Factory: Custom Plexiglass Solutions for High-Quality, Durable Products

SourcifyChina Factory stands out due to its commitment to quality and precision. With state-of-the-art equipment and skilled craftsmen, they ensure that each plexiglass product is manufactured to meet exact specifications, making it ideal for customized orders.

Focusing on customer satisfaction, SourcifyChina offers unparalleled support throughout the purchasing process. They provide detailed consultations, ensuring that clients get exactly what they envision in their custom plexiglass projects. Their attentive service builds lasting relationships with customers.

One key advantage of SourcifyChina is its competitive pricing. By leveraging their strong relationships with raw material suppliers and optimizing production processes, they can offer high-quality plexiglass products at prices that suit various budgets without compromising on quality.

In addition, SourcifyChina Factory is highly flexible in production capabilities. Whether it’s a small batch or a large order, they can accommodate varying quantities efficiently, easing the logistical concerns often associated with overseas manufacturing.

Timely delivery is another critical factor where SourcifyChina excels. Through well-coordinated logistics and reliable shipping partners, they ensure that orders are delivered on schedule. This reliability helps businesses maintain their project timelines without unexpected delays.

Ultimately, choosing SourcifyChina Factory for custom plexiglass purchases ensures quality, affordability, and excellent customer service. Their dedication to meeting clients’ unique needs makes them an ideal partner in bringing customized plexiglass visions to life.

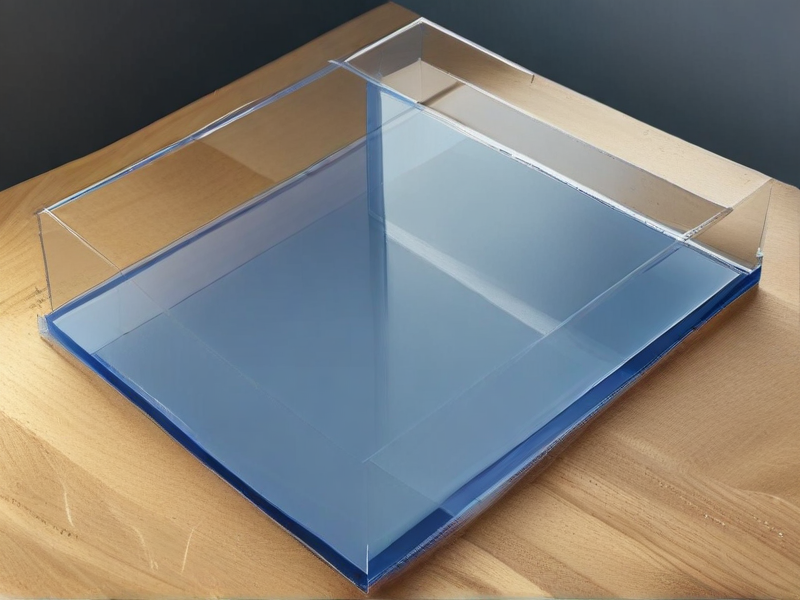

Custom plexiglass offers flexibility in design and functionality, catering to various applications with options for thickness, color, and finishes. Whether for industrial, commercial, or personal use, there’s a suitable type available.

– Thickness Options: Available in multiple thicknesses ranging from 1mm to 25mm, allowing for different strength and durability needs.

– Color Choices: Clear, frosted, tinted, and colored options are available to match aesthetic preferences or functional requirements.

– Finish Types:

– Glossy: Provides a shiny and reflective surface, ideal for modern designs.

– Matte: Offers a non-reflective surface that reduces glare and fingerprints.

– Textured: Enhances grip and adds a unique visual effect.

– Cutting and Shaping:

– Laser Cut: Precision cutting for intricate designs.

– CNC Machined: Allows for detailed and complex shapes.

– Bent and Molded: Custom bending and molding for unique shapes and applications.

– Special Coatings:

– UV Resistant: Protects against UV rays, extending the material’s lifespan.

– Anti-Scratch: Increases durability by making the surface more resistant to scratches.

– Anti-Reflective: Reduces glare and improves visibility.

– Printing and Engraving: Options for custom engravings, designs, or logos using laser engraving or screen printing.

– Applications:

– Architectural: Used in windows, skylights, and room dividers.

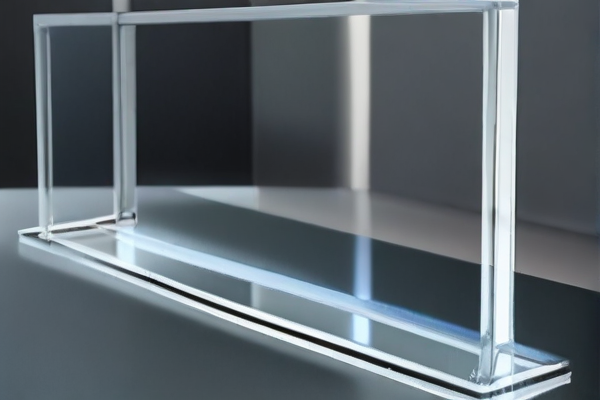

– Signage: Custom signs for businesses, events, and exhibitions.

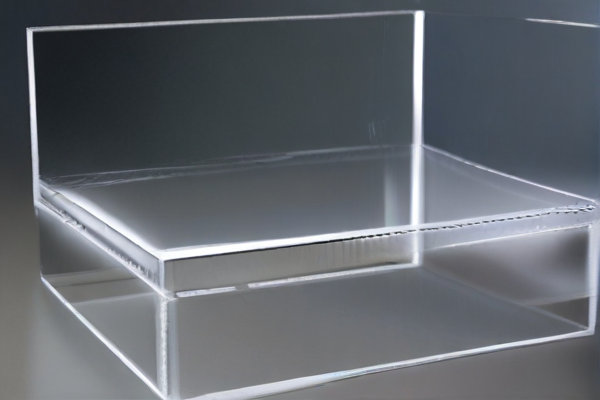

– Displays: Retail displays, exhibition stands, and showcases.

– Protective Barriers: Safety screens and shields for health and safety measures.

With diverse customization options, custom plexiglass caters to unique project needs while ensuring quality and durability.

Custom plexiglass offers versatile solutions for various applications, blending durability with aesthetic appeal. Its adaptability makes it an ideal choice for both residential and commercial needs.

– Retail Displays: Eye-catching product displays and protective barriers.

– Signage: Weather-resistant and customizable for signs.

– Architectural Elements: Skylights, partitions, and wall panels.

– Furniture: Modern, durable tables and shelves.

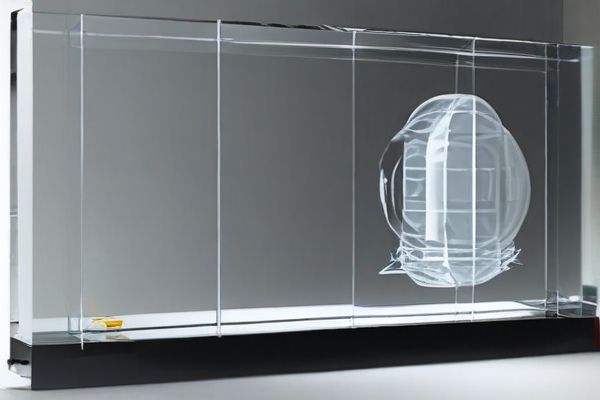

– Aquariums: Clear, sturdy material for tanks.

– Protective Barriers: Sneeze guards and shields.

– Arts and Crafts: Customizable pieces for artistic projects.

– Greenhouses: Strong, transparent panels for optimal plant growth.

– Automotive Applications: Headlight covers and interior features.

– Medical Equipment: Clear, sterilisable barriers and components.

– Exhibition Stands: Portable and aesthetically pleasing display surfaces.

– Windows: Shatter-resistant and energy-efficient window panes.

– Lighting Fixtures: Durable and transparent covers.

– Machine Guards: Safety shields in industrial settings.

– Boat Windshields: Clear, tough windshields and windows for marine vessels.

– Picture Framing: Lightweight, clear alternative to glass.

– Home Decor: Custom shelving, tabletop surfaces, and decorative panels.

– Advertising: High-visibility display boards and banners.

– Laboratory Use: Durable, clear enclosures and shields.

– Museum Displays: Protection for exhibits while maintaining visibility.

“SourcifyChina custom plexiglass” offers a versatile and durable material for a variety of applications. Plexiglass, also known as acrylic or PMMA, is a transparent thermoplastic. It’s prized for its excellent optical clarity, making it an ideal substitute for traditional glass.

One of the standout features of custom plexiglass is its weather resistance. It withstands UV radiation without yellowing or degrading, ensuring longevity. This property makes it perfect for outdoor signage, window panes, and protective barriers. Additionally, it boasts superior impact resistance compared to glass, reducing the risk of shattering.

The material is lightweight, which simplifies installation and reduces shipping costs. Despite its light weight, plexiglass offers rigid structural support. This balance between weight and strength makes it suitable for DIY projects, industrial applications, and artistic creations. It can be easily cut, drilled, and fabricated into various shapes and sizes.

Another advantage is its versatility in finishes and colors. SourcifyChina offers customization options, allowing clients to choose from clear, frosted, colored, or mirrored plexiglass. This customization grants designers and architects the flexibility to meet specific aesthetic and functional requirements. Customization also extends to thickness, further enhancing its array of applications.

Furthermore, plexiglass is more cost-effective than glass. Its affordability, coupled with its durable properties, makes it a popular choice for businesses and consumers alike. Whether for point-of-sale displays, aquariums, or building materials, plexiglass from SourcifyChina provides a budget-friendly yet high-quality solution.

In summary, SourcifyChina custom plexiglass combines clarity, durability, and customization. It is ideal for various applications due to its lightweight nature, impact resistance, and weather durability. Its customizable features provide flexibility for both functional and aesthetic purposes. With its cost-effective advantage, SourcifyChina custom plexiglass remains a premium choice for diverse uses.

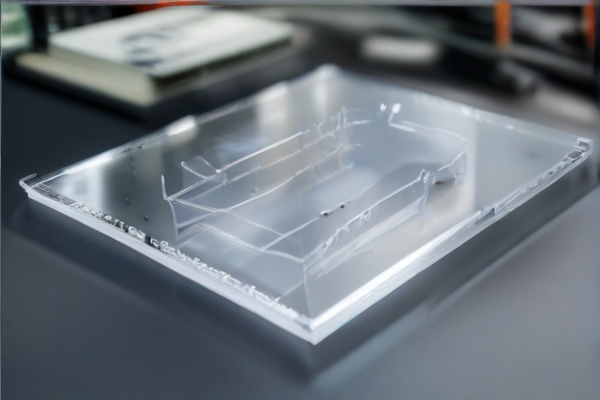

SourcifyChina ensures the highest quality standards in their custom plexiglass manufacturing process by adhering to strict guidelines and precise specifications. This begins with sourcing premium raw materials for optimal durability and clarity.

Each sheet undergoes rigorous inspection for imperfections before entering production. The cutting-edge machinery employed guarantees precise cuts and shapes, maintaining uniformity and consistency across batches.

Quality control experts conduct continuous testing throughout the production cycle. This includes checking dimensions, transparency, and resistance to scratches, ensuring each piece meets the client’s strict standards.

Post-production, the final products undergo a thorough inspection and polishing process. This ensures the plexiglass’ superior finish, free from bubbles or blemishes, ready for seamless integration into various applications.

Finally, robust packaging protocols safeguard against damage during transit. SourcifyChina’s commitment to meticulous quality control and rigorous testing processes guarantees pristine custom plexiglass, delivered on time, every time.

SourcifyChina excels in customizing plexiglass to meet diverse needs. Leveraging advanced technology, the company offers precise cutting, engraving, and shaping services. Their expertise ensures high-quality tailored products.

The company caters to various industries, providing solutions like signage, displays, and protective barriers. Their customized plexiglass products are durable and versatile, making them suitable for both commercial and residential applications.

SourcifyChina ensures consistent quality through rigorous quality control. Each piece undergoes meticulous inspection before delivery, guaranteeing customer satisfaction and dependable performance in every application.

In addition to quality, SourcifyChina offers efficient turnaround times. They understand the importance of meeting deadlines and striving for prompt delivery without compromising quality.

Their customization capabilities extend beyond standard shapes and sizes. SourcifyChina can create complex and intricate designs, allowing clients to achieve unique, aesthetically pleasing solutions that perfectly match their specifications.

SourcifyChina’s customer support is another standout feature. They provide dedicated assistance throughout the project’s lifecycle, from initial consultation and design to final production and delivery.

In essence, SourcifyChina custom plexiglass services provide robust solutions for various applications, ensuring quality, efficiency, and customer satisfaction with every project.

Custom plexiglass offers numerous advantages, making it a versatile and cost-effective material for various applications.

– Durability: Plexiglass is shatter-resistant and far more durable than glass, making it ideal for high-traffic areas.

– Lightweight: It is much lighter than traditional glass, making it easier to handle and install.

– UV Resistance: Offers excellent UV resistance, preventing discoloration and degradation over time.

– Transparency: Provides exceptional clarity and light transmission, rivaling that of glass.

– Customization Options: Can be cut, drilled, and shaped to any specification, offering unparalleled flexibility.

– Cost-Effective: Generally more affordable than regular glass while offering superior performance.

– Safety: Less likely to break into sharp pieces, providing a safer option for homes and businesses.

– Insulation: Offers better thermal insulation compared to regular glass, contributing to energy efficiency.

– Low Maintenance: Easy to clean and maintain, with a longer lifespan.

– Versatility: Suitable for a myriad of uses, from windows and partitions to displays and protective shields.

Custom plexiglass, also known as acrylic glass, offers a versatile and durable option for various applications due to its unique features and adaptability.

– Durability: Plexiglass is known for its high resistance to impact and shattering, making it safer and stronger than traditional glass.

– Clarity and Transparency: It provides excellent optical clarity, making it ideal for windows, displays, and signage.

– Lightweight: Plexiglass is significantly lighter than glass, which simplifies installation and reduces structural support requirements.

– UV Resistance: It resists yellowing and degradation over time when exposed to ultraviolet light.

– Customizable Shapes and Sizes: Available in various thicknesses and can be easily cut, shaped, and drilled to meet custom specifications.

– Weather Resistant: It withstands harsh weather conditions, making it suitable for outdoor applications.

– Chemical Resistance: Resilient to many chemicals and solvents, enhancing its suitability for industrial environments.

– Easy Maintenance: Plexiglass surfaces are easy to clean and scratch-resistant, requiring minimal upkeep.

These features make custom plexiglass a preferred material for a wide range of uses, including protective barriers, signage, windows, aquariums, and more.

SourcifyChina specializes in custom plexiglass products, meticulously crafted to meet diverse client needs. With advanced manufacturing techniques, they deliver top-notch quality, offering durability and aesthetic appeal. The company excels in creating personalized items, ranging from display stands to decorative panels.

Their bespoke services ensure that every project is tailored to specific requirements. Whether you need unique signage, intricate laser-cut designs, or protective barriers, SourcifyChina has the expertise to bring your vision to life. They work closely with clients, understanding their specifications to create functional and visually stunning products.

SourcifyChina prides itself on exceptional customer service, ensuring transparency and timely delivery. Each project goes through rigorous quality checks to meet industry standards, providing peace of mind to clients. Their team comprises skilled professionals who are adept at transforming ideas into reality, utilizing the best materials and latest technologies.

The company’s commitment to sustainability is evident in its eco-friendly production processes. By minimizing waste and using recyclable materials, SourcifyChina contributes to a greener future, without compromising on quality or innovation. Their dedication to both client satisfaction and environmental responsibility sets them apart in the market.

In essence, SourcifyChina’s custom plexiglass products are a blend of craftsmanship, innovation, and reliability. They cater to various industries, delivering solutions that perfectly balance form and function. By choosing SourcifyChina, clients benefit from unparalleled expertise, superior quality, and a partnership that prioritizes their unique needs and visions.

SourcifyChina Custom Plexiglass stands as a premier provider in the field of high-quality plexiglass products, tailored to meet the diverse needs of its clientele. With a dedication to excellence, the company specializes in delivering customized solutions that cater to a myriad of industries, including retail, construction, and automotive sectors. Utilizing advanced manufacturing techniques and state-of-the-art equipment, SourcifyChina ensures that each product exhibits superior clarity, durability, and precision. By offering an extensive range of customization options such as different sizes, shapes, and finishes, the company enables clients to implement their unique visions with unmatched accuracy. Furthermore, SourcifyChina prides itself on maintaining rigorous quality control standards, guaranteeing that every piece of plexiglass adheres to stringent performance criteria. Beyond the product itself, the company is committed to exceptional customer service, providing comprehensive support throughout the design, production, and delivery stages. This customer-centric approach, combined with competitive pricing and prompt delivery, solidifies SourcifyChina Custom Plexiglass as a trusted partner for innovative and reliable plexiglass solutions.

Custom plexiglass is an invaluable material in the aerospace, defense, and marine industries due to its unique properties of lightweight strength, optical clarity, and resistance to impact and harsh conditions. In aerospace applications, custom-shaped plexiglass can be used for cockpit canopies, instrument panels, and interior windows, where its transparency and durability ensure pilot visibility and safety while reducing the overall weight of the aircraft. This contributes to fuel efficiency, a critical consideration in aviation. Additionally, plexiglass can be engineered to withstand significant temperature fluctuations and pressure changes encountered at high altitudes, maintaining structural integrity and performance.

In defense, custom plexiglass serves as a vital material for protective armor, visors, and transparent shields that offer high-impact resistance against ballistic threats while maintaining visibility for personnel. Its adaptability and customizability allow for the inclusion of advanced coatings and treatments that enhance its capabilities, such as anti-reflective finishes and scratch resistance. In marine environments, plexiglass finds application in submarine periscopes, ship windows, and underwater viewing ports due to its exceptional clarity and resistance to corrosion and UV degradation. Plexiglass also contributes to vessel safety by providing clear, durable surfaces that can withstand the harsh, saline conditions of the sea, ensuring long-term reliability and performance in both military and commercial marine applications.

Custom plexiglass, also known as acrylic glass, boasts significant applications within the automotive industry. Its lightweight nature, compared to traditional glass, contributes to better fuel efficiency and performance, making it a preferred material for windshields, windows, and panoramic sunroofs. Additionally, custom plexiglass provides exceptional optical clarity and resistance to UV rays, ensuring longevity and minimal degradation over time. Advanced manufacturing techniques allow for the creation of shaped and tinted plexiglass components that seamlessly integrate with aerodynamic designs, enhancing the aesthetic appeal of modern vehicles. Beyond mere aesthetics, its impact resistance greatly improves passenger safety, and ease of maintenance makes it an attractive choice for a variety of automotive applications.

In the realm of electronics, custom plexiglass offers distinct advantages for both protective and aesthetic purposes. It is widely used in the creation of display screens, protective covers, and casings for various electronic devices due to its durability and transparency. For instance, monitor and television screens often utilize plexiglass to provide shatter-resistant surfaces that protect sophisticated internal components. The material’s lightweight properties also make it ideal for enclosures and housing of embedded systems, where weight reduction is crucial without compromising strength. Additionally, custom plexiglass can be enhanced with anti-glare or anti-scratch coatings, elevating the user experience while preserving the sleek, modern look of gadgets. Its versatility further extends into the creation of custom LED diffusers and light guides, which are essential for maintaining uniform light distribution in backlit screens and other illuminated electronic displays.

Custom Plexiglass, a versatile and durable material, has found substantial applications across various construction domains. In the building industry, its lightweight yet robust nature makes it an excellent alternative to traditional glass windows, especially in large commercial structures. Custom Plexiglass can be manufactured in different thicknesses and degrees of transparency, allowing architects to implement innovative designs while maintaining energy efficiency and safety standards. Additionally, its high impact resistance means it is less prone to shattering, enhancing the security and longevity of structures. Being easily moldable, it also offers architects and builders the flexibility to create bespoke components, like skylights and partitions, tailored to specific architectural needs.

In the realm of energy applications, custom Plexiglass plays a pivotal role in enhancing the efficiency and efficacy of solar panels and other renewable energy systems. Due to its excellent light transmission properties, Plexiglass is utilized to cover and protect photovoltaic cells, ensuring maximum light penetration while shielding the cells from environmental damage such as rain, dust, and debris. Its UV resistance further extends the lifespan of solar panels, making energy systems more sustainable and cost-effective over time. Moreover, custom Plexiglass can be fabricated into unique shapes and sizes to fit specialized energy equipment, contributing to the optimization of devices like solar water heaters and concentrated solar power systems. Its adaptability and durability are thus crucial in advancing both traditional and renewable energy infrastructure.

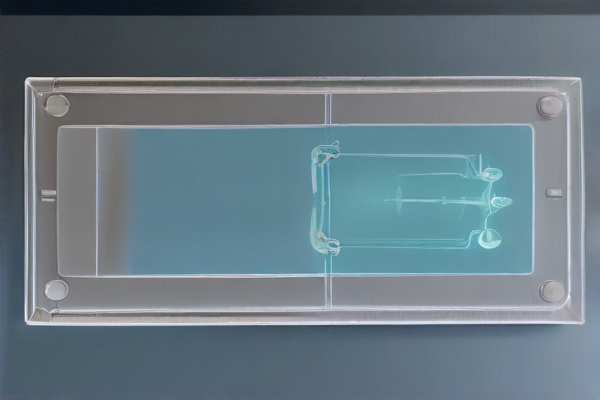

The industrial equipment industry significantly benefits from the integration of custom plexiglass due to its versatile and durable nature. Custom plexiglass, or acrylic glass, is valued for its exceptional clarity, impact resistance, and lightweight properties compared to traditional glass. In machinery manufacturing, plexiglass is extensively used for creating protective barriers, sight windows, and machine guards. These components are essential for worker safety, providing a clear view of the operating machinery while effectively shielding from debris or moving parts. The ability to custom fabricate plexiglass to exact specifications ensures that it seamlessly fits into various forms of industrial equipment, enhancing both operational efficiency and workplace safety standards.

Moreover, custom plexiglass finds application in industrial control panels and display cases, offering robust protection for sensitive instruments and electronic controls without compromising visibility. The adaptability of plexiglass enables it to be cut, drilled, and shaped into complex forms, accommodating unique industrial designs and requirements. Its high resistance to environmental factors such as UV radiation and chemicals makes it suitable for both indoor and outdoor use, ensuring long-lasting performance. The ease of maintenance and cleaning also adds to its appeal, reducing downtime and operational disruptions. Consequently, custom plexiglass serves as an indispensable material in the industrial equipment sector, combining practicality with enhanced safety features to support a wide range of applications.

Medical devices frequently employ custom plexiglass due to its myriad benefits, including clarity, durability, and resistance to chemicals. Medical professionals rely on precise visual inspections, and the high optical clarity of custom plexiglass ensures unobstructed views, which are critical for diagnostic equipment such as MRI machines and x-ray display screens. Its durable nature makes it resistant to scratches and breakages, essential for maintaining the longevity and reliability of medical devices. Additionally, custom plexiglass can be shaped and sized to specific requirements, accommodating the ergonomic and functional designs of various medical instruments. Its chemical resistance further ensures that the material remains unaffected by disinfectants and sterilization processes, which is vital for maintaining hygiene in medical environments.

Beyond diagnostics, custom plexiglass finds extensive applications in surgical settings and patient care. In operating rooms, equipment enclosures and protective barriers constructed from custom plexiglass help to maintain sterile fields while allowing clear visibility for surgeons and support staff. Custom plexiglass is also utilized in the production of incubators and other life-support systems, where the need for a controlled environment and consistent monitoring is paramount. The ability to produce custom shapes and sizes means that these devices can be tailored precisely to the patient’s needs, enhancing both comfort and safety. Consequently, the versatility and robust performance of custom plexiglass make it an invaluable material in the advancement and functionality of contemporary medical devices.

Custom plexiglass, also known as acrylic glass, is a versatile material extensively used in machining and manufacturing applications due to its remarkable clarity, durability, and ease of fabrication. In machining, custom plexiglass offers superior dimensional stability, allowing for precise cuts and intricate designs. Techniques such as laser cutting, CNC milling, and engraving can be utilized to achieve complex shapes and detailed patterns, making it an ideal choice for everything from prototypes to finished retail products. Additionally, its lightweight nature simplifies handling and reduces the wear on machinery, further enhancing efficiency in production processes. Custom plexiglass is often preferred in industries like aerospace, automotive, and electronics, where both high performance and aesthetic quality are paramount.

The manufacturing applications of custom plexiglass extend far beyond mere component fabrication. Its exceptional optical properties and weather resistance make it an excellent material for applications such as protective barriers, display cases, signage, and even architectural elements. Companies leverage custom plexiglass to produce large, UV-resistant panels for outdoor signage, ensuring longevity and minimal maintenance. Furthermore, its inherent strength and shatter resistance render it a safer alternative to glass in safety enclosures and personal protective equipment, particularly in environments where transparency and impact resistance are crucial. The adaptability of plexiglass to various finishing techniques, including polishing and coating, allows manufacturers to meet specific aesthetic and functional requirements, enhancing the final product’s overall appeal. Thus, custom plexiglass stands out as a pivotal material in both the machinist’s workshop and the broader manufacturing industry.

Sure, here are some Frequently Asked Questions (FAQ) for manufacturing custom plexiglass quality work from SourcifyChina factory:

Q1: What materials do you use for custom plexiglass projects?

A1: At SourcifyChina, we use high-quality acrylic (plexiglass) materials imported from reputable suppliers. Our plexiglass is durable, weather-resistant, and exhibits excellent optical clarity.

Q2: Can you handle complex designs and custom specifications?

A2: Yes, we specialize in custom plexiglass projects, whether they are simple or highly intricate. Our advanced machinery and skilled team can accommodate a wide range of custom designs and specifications.

Q3: What is the minimum order quantity (MOQ) for custom plexiglass work?

A3: The MOQ typically depends on the complexity and size of your project. However, we are flexible and willing to work with smaller batch sizes to meet your needs.

Q4: How long does it take to complete a custom plexiglass order?

A4: The turnaround time varies based on the complexity and volume of the order. Generally, it takes between 2 to 4 weeks for standard projects. We will provide a more precise timeline once we have details of your specifications.

Q5: Can I get a sample before placing a bulk order?

A5: Yes, we offer prototype and sample services to ensure you are satisfied with the quality and design before proceeding with a full production run.

Q6: What kind of customization options are available?

A6: We offer various customization options including different thicknesses, colors, shapes, finishes, and engravings. We can also provide UV printing and laser cutting services for more intricate designs.

Q7: How do you ensure the quality of the custom plexiglass work?

A7: Quality is our top priority. We follow strict quality control processes, including material inspection, production monitoring, and final quality checks to ensure all products meet your specifications.

Q8: Do you offer international shipping?

A8: Yes, SourcifyChina offers international shipping. We partner with reliable logistics providers to ensure safe and timely delivery of your orders worldwide.

Q9: How do I place an order or request a quote?

A9: You can place an order or request a quote by contacting us via our website or email. Please provide detailed information about your project requirements and we will respond with a tailored quote.

When considering custom plexiglass manufacturing from SourcifyChina factory, here are a few crucial tips to ensure a successful project:

1. Clear Requirements: Define your specifications clearly, including dimensions, thickness, color, and any special treatments like UV resistance or anti-scratch coating.

2. Quality Standards: Confirm that the factory meets international quality standards, such as ISO certifications. This guarantees you receive high-quality materials and workmanship.

3. Prototyping: Request a prototype before full-scale production. This allows you to inspect the quality and make any necessary adjustments to the design.

4. Bulk Order Discounts: Inquire about bulk order discounts, as placing larger orders can significantly reduce your per-unit cost.

5. Communication: Maintain open and consistent communication with the factory. Regular updates help to address any issues promptly and keep the project on track.

6. Lead Times: Understand the production lead times and factor in shipping duration, especially if you have tight deadlines.

7. Custom Designs: Take advantage of SourcifyChina’s ability to handle complex custom designs. Provide detailed CAD drawings or physical samples if possible.

8. Quality Control: Work with SourcifyChina to establish a quality control process. This can include pre-shipment inspections to ensure that the final product meets your standards.

9. Sustainable Practices: If sustainability is a concern, ask about eco-friendly materials and processes.

10. Payment Terms: Review payment terms and options. Ensure that they are favorable and protect your interests, especially for high-value orders.

By following these tips, you can leverage SourcifyChina’s expertise to efficiently produce high-quality custom plexiglass products tailored to your specific needs.

Q: What types of custom plexiglass products can SourcifyChina factory produce?

A: SourcifyChina factory specializes in producing a wide range of custom plexiglass products, including sheets, panels, display stands, signage, enclosures, and furniture. They can also accommodate various shapes, sizes, and colors based on your specifications.

Q: What is the minimum order quantity (MOQ) for custom plexiglass products?

A: The MOQ for custom plexiglass products at SourcifyChina factory may vary depending on the complexity and size of the order. Typically, the MOQ ranges from 100 to 500 pieces. It’s best to contact the factory directly for specific requirements.

Q: How long does it take to produce and deliver custom plexiglass orders?

A: Production and delivery times depend on the size and complexity of the order. Generally, production can take 2-4 weeks, and shipping can take an additional 1-3 weeks. For an accurate timeline, please discuss your project details with SourcifyChina factory.

Q: Can SourcifyChina factory provide samples before full production?

A: Yes, SourcifyChina factory can provide samples based on your design specifications. Sample production usually takes 1-2 weeks, and there may be additional costs for materials and shipping. Samples help ensure that the final product meets your expectations.

Q: What materials and thicknesses are available for custom plexiglass products?

A: SourcifyChina factory offers a variety of materials, including standard, UV-resistant, and impact-resistant plexiglass. Thicknesses can range from 1mm to 30mm or more, depending on your requirements. Customization options can be discussed directly with the factory.

Q: Are there any customization options for colors and finishes?

A: Yes, SourcifyChina factory can produce custom plexiglass products in a wide array of colors and finishes, including clear, frosted, tinted, mirrored, and more. Provide your color preferences and finish requirements when placing your order.

Q: How do I submit my design specifications to SourcifyChina factory?

A: You can submit your design specifications to SourcifyChina factory via email or their online submission form. Include detailed drawings, dimensions, and any other relevant information to ensure accurate production.

Q: What payment methods does SourcifyChina factory accept?

Sourcing custom plexiglass from the SourcifyChina factory can be streamlined by following these tips:

1. Research and Verification:

– Begin by researching SourcifyChina, ensuring they have positive reviews and a solid reputation.

– Verify their certifications and compliance with international quality standards.

2. Specify Requirements:

– Clearly detail your plexiglass specifications, including dimensions, thickness, color, and any custom features or designs.

– Provide drawings or samples if possible to avoid miscommunication.

3. Request Quotes:

– Request detailed quotes, including production costs, shipping, duties, and any additional fees.

– Compare quotes from multiple suppliers if possible to ensure competitive pricing.

4. Sample Order:

– Order a sample to evaluate the quality of the plexiglass before committing to a larger purchase.

– Assess the material for strength, clarity, and adherence to your specifications.

5. Negotiate Terms:

– Negotiate payment terms, production timelines, and minimum order quantities.

– Establish clear terms on quality control and returns for defective items.

6. Communication:

– Maintain open and frequent communication with the factory to monitor progress and address any issues promptly.

– Use clear, concise language to avoid misunderstandings.

7. Quality Control:

– Implement strict quality control measures, either by yourself or hire a third-party inspection service.

– Ensure adherence to specifications before shipment.

8. Logistics:

– Plan for logistics by choosing a reliable shipping method and understanding customs processes.

– Factor in shipping times to avoid delays in your project timeline.

By following these steps, you can efficiently source high-quality custom plexiglass from SourcifyChina, ensuring your project meets its requirements and deadlines.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.