Boost Your Manufacturing Efficiency with Reliable SourcifyChina Factory Screw Machines

Are you looking for dependable screw machines to elevate your manufacturing process? Discover how SourcifyChina offers top-quality, reliable machines to streamline your production and ensure precision in every screw you create.

Choosing SourcifyChina for purchasing screw machines from China provides exceptional benefits. First, they offer unparalleled experience in sourcing high-quality machinery. Their extensive network of reputable manufacturers ensures you receive durable, reliable equipment to meet your specifications.

Secondly, SourcifyChina boasts competitive pricing without compromising quality. Their established relationships with manufacturers allow them to negotiate favorable terms, resulting in significant cost savings for buyers. This aspect is crucial for businesses looking to maximize their investment.

Additionally, SourcifyChina provides comprehensive support throughout the purchasing process. From initial consultation to final delivery, their dedicated team assists with logistics, customs, and after-sales service. This end-to-end support guarantees a smooth and hassle-free experience for buyers.

Lastly, SourcifyChina emphasizes transparency and integrity. Buyers receive detailed information about the manufacturing process, quality control measures, and shipment tracking. This commitment to honesty builds trust and confidence, ensuring long-term business partnerships. In conclusion, SourcifyChina offers unmatched expertise, competitive pricing, comprehensive support, and unwavering transparency, making them the ideal partner for purchasing screw machines from China.

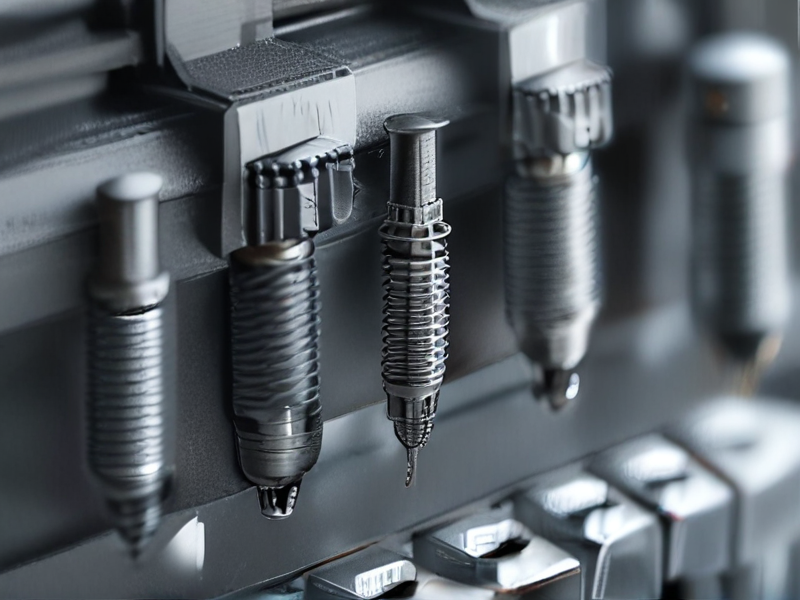

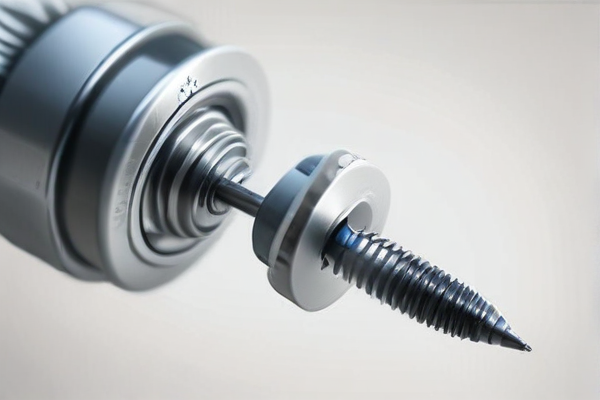

Screw machines are versatile tools designed to produce high-precision threaded components efficiently. Available in various types, including automatic and CNC, each machine offers unique advantages for different manufacturing needs.

– Automatic Screw Machines: Ideal for mass production, these machines operate continuously with minimal human intervention.

– Swiss Screw Machines: Provide high precision for small parts; known for their tight tolerances.

– CNC Screw Machines: Offer versatility and precision with computer control, suitable for complex shapes.

– Hydromat Machines: Combine rotary transfer mechanisms with multiple cutting tools, excellent for high-volume production.

– Multi-Spindle Screw Machines: Feature multiple spindles for simultaneous machining, boosting production speed.

– Single-Spindle Screw Machines: Designed for simpler projects, cost-effective for smaller runs.

– Turret Screw Machines: Utilized for operations requiring various sequential processing steps without tool change delays.

Screw machines are versatile devices used for precision manufacturing of small-to-medium sized components. They play an essential role in producing complex parts efficiently and accurately in various industries.

– Automotive: Manufacturing engine components and fasteners.

– Electronics: Producing connectors and small intricate parts.

– Medical Devices: Creating surgical tools and implants.

– Aerospace: Fabricating precision aircraft components.

– Defense: Crafting specialized military hardware.

– Consumer Goods: Making parts for appliances and tools.

– Jewelry: Producing detailed and precise jewelry pieces.

– Hydraulics: Manufacturing fittings and other hydraulic components.

– Telecommunications: Crafting parts for communication devices.

– Watchmaking: Producing finely detailed watch components.

– Industrial Machinery: Manufacturing parts for industrial equipment.

– Plumbing: Creating fittings and connectors for plumbing systems.

– Optics: Producing parts for precision optical instruments.

– Agriculture: Crafting components for farming equipment.

– Marine: Manufacturing parts for boats and marine engines.

– Heavy Equipment: Producing durable machinery parts.

– Robotics: Crafting components for automated systems.

– Energy: Manufacturing components for turbines and generators.

– Office Equipment: Creating parts for printers and copiers.

– Sports Equipment: Producing precise components for sporting goods.

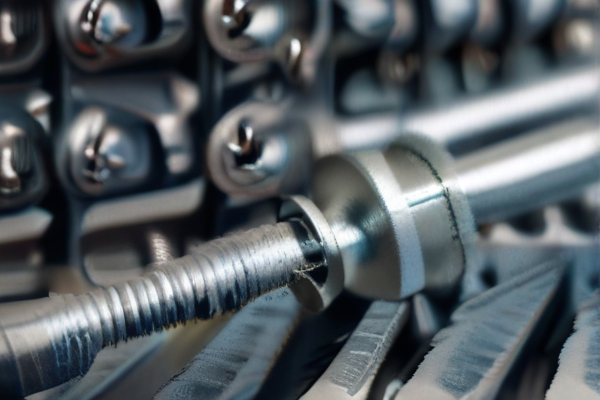

SourcifyChina’s screw machines are manufactured using premium materials to ensure durability and reliability. Stainless steel is predominantly used, given its excellent resistance to corrosion and rust. Precision-crafted components ensure seamless operation and longevity.

In addition to stainless steel, high-strength alloys are utilized in critical parts of the screw machines. These alloys enhance the machines’ capacity to withstand high-pressure applications, contributing to their rugged performance in demanding industrial environments.

The cutting tools incorporated in SourcifyChina’s screw machines often feature tungsten carbide tips. This material is known for retaining sharpness over extended periods, reducing wear and tear, and significantly improving production efficiency.

The base and housing of these screw machines are commonly made from cast iron. Cast iron’s high compressive strength and vibration-damping properties contribute to the machines’ stability and smooth operation. This makes them an ideal choice for high-precision tasks.

SourcifyChina ensures that all materials undergo stringent quality checks to meet international standards. The combination of these superior materials results in robust, efficient screw machines that are reliable for various manufacturing needs.

SourcifyChina employs a rigorous quality control process to ensure the precision and reliability of their screw machines. Each machine undergoes meticulous inspections at every stage of production, from raw material selection to final assembly. This ensures that only the highest-grade components are used, enhancing overall machine durability and performance.

Advanced technologies such as laser measurement systems and automated vision inspection tools are integrated into the manufacturing workflow. These technologies detect even the minutest defects, allowing for corrective actions to be taken immediately. This minimizes errors and ensures product consistency across batches.

Skilled technicians perform routine tests and calibrations on the screw machines. These tests include thermal stability assessments, torque testing, and operational efficiency checks. The technicians are trained to adhere to stringent industry standards, ensuring that each machine meets or exceeds customer expectations.

Post-production, each screw machine is subjected to a series of operational tests to simulate real-world conditions. These tests help verify that the machines can perform reliably under various working environments, ensuring long-term customer satisfaction. Comprehensive documentation and traceability are maintained throughout the process.

Customer feedback is also integral to the quality control loop. SourcifyChina actively solicits and analyzes client input, continually refining their manufacturing processes and quality checks based on this feedback. This commitment to continuous improvement solidifies their reputation for producing high-quality screw machines.

In conclusion, SourcifyChina’s quality control manufacturing process is a blend of stringent inspections, advanced technologies, skilled labor, and customer feedback. This multi-faceted approach ensures that every screw machine not only meets but surpasses industry standards, delivering unparalleled performance and reliability. Their dedication to quality and precision makes them a trusted name in screw machine manufacturing.

SourcifyChina’s screw machines excel in high-precision manufacturing, meeting the increasingly stringent demands of industries such as automotive, aerospace, and electronics. These machines offer consistent and reliable performance, ensuring products meet exact specifications.

The advanced technology incorporated into SourcifyChina’s screw machines enables rapid production cycles without compromising quality. This efficiency reduces the time-to-market for new products, providing businesses with a competitive edge and increased profitability.

Customization is a key feature, allowing businesses to tailor the machines for specific production needs. With various tooling options and adaptable software, SourcifyChina’s screw machines offer unparalleled flexibility in manufacturing processes.

Durability and ease of maintenance further enhance the appeal of SourcifyChina’s offerings. Built from robust materials and designed for easy access to components, these machines boast lower downtime and reduced operational costs.

Finally, SourcifyChina’s commitment to customer support ensures users can maximize machine productivity. From initial setup to ongoing training, SourcifyChina provides comprehensive support, helping businesses fully leverage their advanced screw machining capabilities.

Screw machines offer numerous benefits in the manufacturing industry, significantly enhancing efficiency, precision, and cost-effectiveness. These versatile devices streamline production processes and reduce labor costs.

– High Efficiency: Screw machines automate repetitive tasks, leading to faster production cycles and increased output.

– Precision and Consistency: They produce components with exceptional accuracy, ensuring uniformity and reducing the likelihood of errors.

– Cost-Effective: The automation reduces the need for manual labor, lowering operational costs over time.

– Versatility: Capable of handling various materials and producing diverse parts, they are suitable for multiple industries.

– Reduced Waste: High precision minimizes material waste, making them an environmentally friendly option.

– Ease of Use: Modern screw machines are equipped with advanced controls that simplify operation and reduce the need for extensive training.

– Enhanced Safety: Automation and protective features decrease the risk of workplace accidents.

– Scalability: Ideal for both small-scale and large-scale production, offering flexibility to grow with business demands.

– Durability: Built to endure high-volume production, these machines provide long-term reliability and performance.

Overall, screw machines are an invaluable asset in manufacturing, fostering productivity and quality while maximizing resource efficiency.

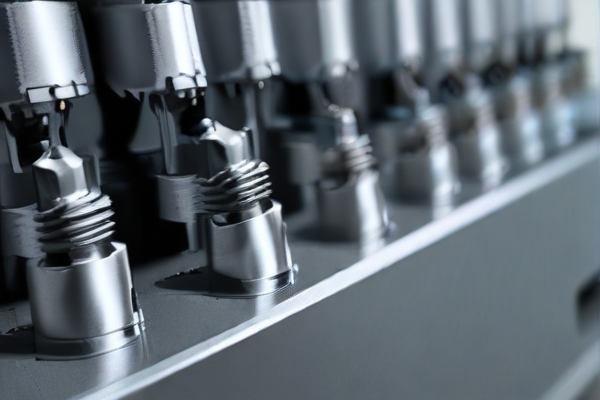

Screw machines are highly specialized tools designed for high-speed, precision machining of screws and threaded components, often used in mass production.

– Automatic Operation: Screw machines can perform unattended machining once set up.

– High Precision: Capable of producing parts with tight tolerances.

– Multi-Spindle Configuration: Some models feature multiple spindles for simultaneous machining.

– Rapid Production: Optimized for high-speed operations, ideal for mass production.

– Versatility: Can machine various materials such as metals and plastics.

– Complex Machining: Capable of performing multiple operations like drilling, tapping, and turning.

– CNC Integration: Modern screw machines often come equipped with computerized numerical control for enhanced automation and precision.

– Advanced Tooling: Equipped with a range of cutting tools for different machining needs.

– Longer Tool Life: Advanced lubrication and cooling systems extend the life of cutting tools.

– Compact Design: Space-efficient, making them suitable for various industrial environments.

– Ease of Maintenance: Designed for quick servicing and minimal downtime.

– Consistent Output: Ensures uniformity in large batches of components.

– Noise Reduction: Modern machines are engineered to operate with reduced noise levels.

– Energy Efficient: Built with energy-saving technologies to lower operational costs.

– Safety Features: Integrated safety mechanisms to protect operators and equipment.

– Customization Options: Can be tailored to specific production requirements.

SourcifyChina specializes in the manufacture of screw machines, renowned for their unparalleled precision and reliability. These machines are engineered to fulfill diverse industrial requirements, enabling efficient production lines.

The company’s commitment to customization allows clients to design products tailored to their specific needs. SourcifyChina offers end-to-end services, from initial concept design to final delivery, ensuring customer satisfaction at each step.

Their screw machines are employed across various sectors, including automotive, electronics, and consumer goods, proving their versatility and applicability. Each machine boasts cutting-edge technology, ensuring durability and superior performance.

Additionally, SourcifyChina provides comprehensive project management services. They assist clients in planning and executing complex projects, ensuring timelines and budgets are strictly adhered to. Their team of experts collaborates with clients to ensure the seamless integration of screw machines into existing production lines, enhancing overall efficiency. In summary, SourcifyChina’s dedication to quality, customization, and complete project management makes them a preferred choice for industrial screw machines and related solutions.

SourcifyChina Screw Machines is a distinguished company specializing in the production and supply of high-precision screw machines and related components. With a commitment to quality and innovation, the company has carved a niche in both domestic and international markets. Known for integrating advanced technology and efficient manufacturing processes, SourcifyChina Screw Machines offers a diverse range of products that cater to various industries, including automotive, electronics, and medical equipment. The company’s state-of-the-art facilities are equipped with the latest CNC technology, ensuring consistency, durability, and precision in every product. Moreover, their robust quality control system adheres to international standards, reinforcing their reputation for reliability and excellence. By fostering a customer-centric approach and providing bespoke solutions, SourcifyChina Screw Machines has built long-term relationships with clients worldwide, driving growth and continuous improvement in the field of screw machine manufacturing.

Screw machines play an essential role in the aerospace, defense, and marine industries, serving as the backbone for the production of highly precise and complex components. In aerospace, the demand for lightweight yet durable parts necessitates the use of materials like titanium and aluminum alloys, which screw machines can handle efficiently. These machines are capable of producing intricate parts such as aircraft fasteners, landing gear components, and turbine blades with high precision and tight tolerances, ensuring reliability and performance in critical flight conditions. Given the stringent quality requirements and the need for impeccable consistency in aerospace manufacturing, screw machines offer the repetitive accuracy essential for producing vast quantities of identical parts without compromising quality.

In the defense sector, the versatility and precision of screw machines are leveraged to manufacture a wide range of military hardware components, including firearms parts, ammunition casings, and electronic connectors used in advanced communication systems. The ability to work with tough materials like stainless steels and exotic metals makes screw machines indispensable for producing robust and reliable components that can withstand harsh operating environments and rigorous safety standards. Similarly, in the marine industry, screw machines are utilized to produce high-precision parts for navigation systems, engine components, and underwater exploration equipment. These machines help in manufacturing corrosion-resistant components necessary for prolonged exposure to saltwater and other marine conditions. Overall, screw machines provide the precision, efficiency, and adaptability required to meet the demanding specifications and high production standards of aerospace, defense, and marine applications.

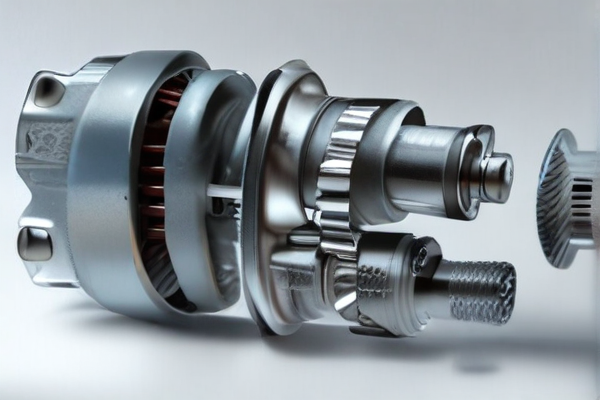

Screw machines, often known as automatic lathes, are essential in the automotive industry due to their precision and efficiency in producing high-quality, complex components. These versatile machines play a pivotal role in fabricating a variety of parts such as screws, bolts, nuts, and spacers, which are critical for the assembly and functionality of vehicles. With the automotive industry’s demand for tight tolerances and mass production, screw machines ensure that components like engine parts, transmission systems, and suspension systems meet stringent specifications. Furthermore, advancements in CNC (Computer Numerical Control) technology have enabled screw machines to perform intricate machining tasks with minimal human intervention, thereby improving production speeds and reducing costs. This seamless integration of screw machines into the automotive manufacturing process underscores their value in enhancing durability, safety, and overall vehicle performance.

In the electronics industry, screw machines are indispensable for manufacturing small, intricate components that are integral to a wide range of electronic devices. These machines excel in producing precision connectors, fasteners, and other minute parts that maintain the integrity and reliability of electronic circuits and devices. For instance, in the manufacturing of smartphones, computers, and other consumer electronics, the precision offered by screw machines ensures that each component fits perfectly within the compact assemblies. Additionally, with the rise of miniaturization and the growing complexity of electronic products, screw machines equipped with multi-axis capabilities and micro-machining techniques are critical. These features allow manufacturers to achieve high precision and repeatability, ensuring that even the tiniest components adhere to exacting standards. Consequently, screw machines not only facilitate the production of high-performance electronics but also drive innovation by supporting the development of ever-smaller and more sophisticated devices.

Screw machines, particularly in the construction industry, play a pivotal role in enabling efficient and precise machining of components. These automatic lathes utilize a rotating screw mechanism to lessen the need for manual labor, significantly enhancing productivity and accuracy. They are indispensable in fabricating parts such as fasteners, bolts, and custom fittings essential for modern construction projects. The ability to produce intricate designs with tight tolerances ensures that components seamlessly integrate into complex architectural frameworks, contributing to the structural integrity and reliability of buildings and infrastructures.

In the energy sector, screw machines are instrumental in the manufacture and maintenance of critical components for various energy systems, including renewable energy technologies. For instance, precision-machined parts are essential for turbines used in wind and hydroelectric power generation. Furthermore, screw machines aid in the production of components for oil and gas exploration equipment, where the exacting standards required to withstand harsh operational environments are paramount. The high-precision capabilities of screw machines not only enhance the operational efficiency of energy systems but also improve the overall reliability and longevity of equipment, thereby supporting sustainable and continuous energy production.

Screw machines, also known as automatic lathes, play a paramount role in the industrial equipment industry due to their ability to produce high-precision, high-volume turned parts efficiently. These machines are highly versatile and can handle a wide range of materials, including metals, plastics, and composites, making them integral in manufacturing components for sectors such as automotive, aerospace, electronics, and medical devices. The precision achieved by screw machines is attributed to their ability to perform multiple cutting operations simultaneously and continuously, thereby reducing production time and costs while maintaining quality and consistency. Their automated, computer-controlled nature allows for intricate designs and tight tolerances, which are crucial for critical applications, such as engine components, medical implants, and electronic connectors.

In addition to precision and versatility, screw machines contribute significantly to advancing manufacturing technology through the incorporation of CNC (Computer Numerical Control) systems. This integration has transformed traditional machining processes, enabling the production of complex geometries that were previously labor-intensive or impossible to achieve. The CNC functionality allows for quick reprogramming and machine setup, facilitating rapid production changes and just-in-time manufacturing practices, which are essential for meeting dynamic market demands. This adaptability enhances productivity and reduces downtime, which is vital for companies striving to maintain a competitive edge in the fast-paced industrial environment. Overall, screw machines epitomize the blend of advanced automation and machining precision, driving innovation and efficiency in the industrial equipment industry.

Screw machines play a pivotal role in the manufacturing of precision medical devices, ensuring accuracy, efficiency, and reliability. These automated lathes, capable of producing intricate and tight-tolerance components, are essential for creating critical parts used in medical applications such as orthopedic implants, dental appliances, and surgical instruments. A key advantage of screw machines is their ability to consistently produce small, complex parts with high precision, which is crucial for devices that must meet stringent regulatory standards and perform reliably in medical environments. For instance, screws for bone fixation and components for insulin pumps are commonly produced using screw machines due to their need for precise dimensions and high-quality finishes.

Furthermore, screw machines enhance the scalability and cost-effectiveness of medical device production. These machines can operate continuously under computer numerical control (CNC), minimizing human error and significantly reducing production time. This capability is particularly beneficial for high-volume production runs required in the medical industry. The integration of advanced materials and complex geometries, which are often necessitated by the demanding requirements of medical devices, is made feasible through the customization options available with screw machines. As a result, medical device manufacturers can develop innovative solutions that improve patient outcomes while maintaining cost efficiency, reinforcing the importance of screw machines in the advancement of medical technology.

Screw machines are pivotal in machining and manufacturing, offering unparalleled precision and efficiency in producing small to medium-sized cylindrical components, such as screws, bolts, and other intricate parts. These automated, multi-spindle machines are engineered to perform a variety of operations—including turning, drilling, threading, and knurling—often in a single set-up. This multi-functionality drastically reduces the need for multiple machines and manual labor. Screw machines capitalize on a continuous-feed system that utilizes bar stock, incrementally feeding material through the machine to maximize production speed and minimize waste. With advances in CNC technology, modern screw machines now offer enhanced control and programmability, allowing for the rapid production of complex parts while maintaining exceptional accuracy and consistency.

In the realm of manufacturing, screw machines are indispensable primarily in industries requiring high-volume production runs, such as aerospace, automotive, medical devices, and electronics. These machines excel in producing components that demand tight tolerances and repetitive precision, such as fasteners, fittings, and bushings. Their ability to operate continuously and autonomously makes them highly cost-effective, as they significantly lower manual intervention and downtime. Additionally, the versatility of screw machines allows for rapid changeovers and adaptability to different material types, ranging from high-strength steels to more delicate metals and plastics. This adaptability broadens their application scope, catering to the diverse needs of modern manufacturing environments where speed, precision, and versatility are critically valued.

Sure, here’s a concise list of frequently asked questions (FAQ) with answers for manufacturing “screw machines quality work from SourcifyChina factory”:

Q1: What materials do you use for manufacturing screw machines?

A1: SourcifyChina factory utilizes high-grade stainless steel, carbon steel, aluminum, and brass to ensure durability and precision in our screw machines.

Q2: What quality control measures are in place?

A2: We adhere to ISO standards, conduct regular inspections, and use advanced testing equipment to ensure each screw machine meets stringent quality criteria.

Q3: Can you customize screw machines according to my specifications?

A3: Yes, we offer tailored solutions to meet specific requirements. Our engineering team can work with you to design and manufacture custom screw machines.

Q4: How long is the turnaround time for an order?

A4: The typical lead time is 4-6 weeks, depending on the complexity and quantity of the order.

Q5: What is your minimum order quantity (MOQ)?

A5: Our MOQ is typically 500 units, but we can accommodate smaller orders on a case-by-case basis.

Q6: What are your payment terms?

A6: We offer flexible payment terms, including T/T, L/C, and others upon agreement.

Q7: Do you provide samples for testing?

A7: Yes, we provide samples so you can evaluate our product quality before placing a bulk order.

Q8: How do you handle shipping and logistics?

A8: We manage the entire logistics process, including international shipping. We partner with reliable carriers to ensure timely delivery.

Q9: What after-sales support do you offer?

A9: We provide comprehensive after-sales support, including technical assistance, maintenance tips, and a robust warranty policy.

Q10: How can I place an order?

A10: You can contact us via our website, email, or phone. Our customer service team will guide you through the ordering process.

These FAQs should give you a clear understanding of the manufacturing quality and services offered by SourcifyChina factory for screw machines.

When sourcing screw machines from SourcifyChina factory, it’s vital to consider several key factors to ensure a smooth and successful partnership.

1. Quality Assurance: Verify the factory’s certifications such as ISO 9001 to ensure quality management systems are in place. Request samples to assess the machining precision and material quality firsthand.

2. Manufacturing Capabilities: Confirm that the factory specializes in producing screw machines and can handle the specific technical requirements you need. Review their machinery and technology to ensure they are up-to-date with industry standards.

3. Experience and Reputation: Look into the factory’s history and client reviews. Factories with extensive experience in screw machine manufacturing are often more reliable and efficient.

4. Cost and Production Efficiency: Compare quotes from multiple sources to ensure competitive pricing. Evaluate not just the unit cost but also the lead times and production capacity to meet your demands without delay.

5. Customization and Flexibility: Determine if the factory can accommodate custom designs and modifications. A flexible manufacturer can adapt to your specific needs, providing a more tailored service.

6. Communication: Establish clear and consistent communication channels. Effective communication helps in avoiding misunderstandings and facilitates smoother transactions.

7. Logistics and Delivery: Discuss logistics in detail. Ensure they have reliable shipping partners and can manage exports efficiently, minimizing delays.

8. After-Sales Support: Assess the factory’s after-sales support. A manufacturer who offers good after-sales service stands out, providing technical support, maintenance, and repair assistance.

Carefully evaluating these factors will aid in selecting a reliable partner in SourcifyChina factory for your screw machines manufacturing needs.

Sure, here’s a succinct FAQ for sourcing screw machines from SourcifyChina factory:

Q: What types of screw machines can I source from SourcifyChina factory?

A: SourcifyChina offers a wide range of screw machines, including single-spindle, multi-spindle, CNC, and Swiss-type screw machines. Each type is designed to meet different manufacturing needs.

Q: How do I request a quote for screw machines?

A: Visit the SourcifyChina website, navigate to the “Request a Quote” section, fill out the form with your specific requirements, and submit it. You will receive a detailed quote in 1-2 business days.

Q: What is the lead time for ordering screw machines from SourcifyChina?

A: The lead time typically ranges from 4 to 8 weeks, depending on the machine specifications and customization requirements. It’s best to confirm with the sales team for an accurate timeline.

Q: Does SourcifyChina provide customization options for screw machines?

A: Yes, SourcifyChina offers customization options to tailor the machines according to your specific production needs. You can discuss your requirements with their engineering team.

Q: Are there any warranties provided for the screw machines?

A: All screw machines from SourcifyChina come with a one-year warranty covering parts and labor. Extended warranties and maintenance packages are also available.

Q: How can I ensure the quality of the screw machines sourced?

A: SourcifyChina follows strict quality control measures and international standards. They provide inspection reports and can arrange third-party inspections upon request.

Q: What payment methods are accepted?

A: SourcifyChina accepts various payment methods including T/T (bank transfer), L/C (letter of credit), and PayPal. Ensure to discuss with the sales team to choose the most convenient option.

Q: Does SourcifyChina offer after-sales support?

A: Yes, SourcifyChina provides comprehensive after-sales support including installation guidance, troubleshooting, maintenance services, and spare parts supply.

Q: Can I visit the factory before placing an order?

A: Absolutely, factory visits can be arranged. Contact the customer service team to schedule a visit and they will facilitate your trip.

Q: What shipping options are available?

A: SourcifyChina offers multiple shipping options including sea freight, air freight, and express courier services. Shipping terms are typically negotiable based on your requirements.

When sourcing screw machines from SourcifyChina factory, it’s essential to consider various factors to ensure a successful transaction:

1. Research and Verification: Start by researching SourcifyChina and verifying the factory’s credentials. Check certifications, customer reviews, and business licenses to confirm legitimacy.

2. Clear Specifications: Clearly define your requirements. Provide detailed specifications for the screw machines, including dimensions, materials, tolerances, and any special features.

3. Quality Assurance: Inquire about the factory’s quality control processes. Ask for samples or detailed photos of similar products. Ensure they follow international standards relevant to your industry.

4. Communication: Maintain clear and consistent communication. Use clear, concise language and confirm understanding through emails or video calls. Miscommunications can lead to costly mistakes.

5. Negotiate Terms: Negotiate payment terms, lead times, and delivery schedules. Clarify responsibilities for shipping, customs, and import duties.

6. Visit the Factory: If possible, visit the factory to assess its capabilities and operations. This firsthand observation can provide insights that are not available through virtual communication.

7. Third-Party Inspections: Consider hiring a third-party inspection service to evaluate the products before shipment. This can prevent discrepancies and ensure you receive what was agreed upon.

8. Sample Orders: Place a small initial order to test the quality and service. This can reveal potential issues without significant financial risk.

9. Contracts and Agreements: Draft detailed contracts outlining all terms, conditions, warranties, and penalties for non-compliance. Ensure both parties sign and keep copies for reference.

10. Shipping and Logistics: Plan logistics in advance. Ensure the factory has reliable shipping partners and understand the estimated transit times and costs.

By following these steps, you can effectively source screw machines from SourcifyChina with greater confidence and reduce potential risks.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.