Title: “Reliable SourcifyChina: Top Factory Piping Manufacturers for Quality and Efficiency”

In the domain of manufacturing, SourcifyChina stands out as a beacon of reliability and excellence. Renowned for connecting businesses with top-tier factory piping manufacturers, they ensure superior quality and remarkable efficiency in every pipe produced.

Choosing SourcifyChina Factory for purchasing piping manufacturers from China offers numerous advantages. Their quality control ensures high standards, minimizing defects and enhancing reliability. This makes them a trustworthy partner for sourcing high-quality components.

In addition to impeccable quality, SourcifyChina provides competitive pricing through efficient production processes. This cost-effectiveness benefits buyers by offering superior products within budget constraints, facilitating better resource allocation.

Timely delivery is another crucial factor. SourcifyChina has streamlined logistics, ensuring that products reach their destination on schedule. This reduces downtime and helps maintain project timelines, which is critical for businesses.

Excellent customer service is a hallmark of SourcifyChina. Their responsive, knowledgeable team assists buyers throughout the purchasing process, from inquiry to after-sales support. This fosters a solid buyer-supplier relationship.

Moreover, SourcifyChina enables customization to meet specific buyer requirements. They offer a range of piping solutions tailored to diverse applications, catering to both standard and specialized needs.

Their experience in the industry equips them with the expertise to handle complex orders, ensuring that even the most intricate specifications are met. This ability to deliver on challenging demands is invaluable for clients.

By choosing SourcifyChina, buyers leverage a partner with a proven track record of excellence. Their commitment to quality, affordability, reliability, customer support, and custom solutions makes them the ideal choice for sourcing piping manufacturers from China.

Piping manufacturers offer a variety of products tailored to different industries and applications. These manufacturers provide materials like steel, plastic, and copper, each with specific properties suited for unique requirements such as durability, cost, and resistance.

– Steel Pipes: Best for high-pressure and high-temperature applications.

– Plastic Pipes: Ideal for water supply, drain, waste, and vent systems.

– Copper Pipes: Known for excellent thermal conductivity, often used in heating systems.

– Aluminum Pipes: Lightweight, corrosion-resistant, used in aerospace and industrial applications.

– Stainless Steel Pipes: High resistance to corrosion, used in food processing and pharmaceutical industries.

– Ductile Iron Pipes: Strong and durable, commonly used in municipal water service.

– Concrete Pipes: Often used in large-scale infrastructure projects like sewer systems.

– Galvanized Steel Pipes: Coated to prevent rust, typically used in outdoor or industrial settings.

– PVC Pipes: Cost-effective and versatile, widely used in residential plumbing.

– PEX Pipes: Flexible and easy to install, popular in residential plumbing.

Options:

– Custom Fabrication: Piping tailored to specific applications or dimensions.

– Coatings and Linings: Various internal and external protections to extend pipe life.

– Fittings and Flanges: Essential for connecting and securing piping systems.

– Pre-insulated Pipes: Provides thermal insulation for energy efficiency.

– Environmental Standards Compliance: Certifications for eco-friendly and energy-efficient products.

Choosing a piping manufacturer involves evaluating these options based on the project’s specific needs and the material properties required for optimal performance and longevity.

Piping manufacturers play a crucial role in various industries by supplying essential components for fluid and gas transportation systems. Their applications span across numerous sectors, ensuring reliable and efficient operations.

– Oil and Gas: Provide durable pipes for transporting crude oil, natural gas, and refined products.

– Chemical Processing: Supply chemical-resistant piping systems for safe and efficient chemical transport.

– Water Treatment: Offer corrosion-resistant pipes for water purification plants and distribution systems.

– Power Generation: Deliver high-temperature and high-pressure pipes for thermal and nuclear power plants.

– Construction: Supply structural and plumbing pipes for residential, commercial, and industrial buildings.

– Pharmaceuticals: Ensure sterile and contamination-free pipes for the pharmaceutical industry.

– Food and Beverage: Provide sanitary piping solutions for processing, packaging, and transportation within the food industry.

– HVAC: Equip HVAC systems with pipes for heating, ventilation, and air conditioning applications.

– Automotive: Supply exhaust and fuel piping for automotive manufacturing and maintenance.

– Mining: Offer robust hydraulic and slurry transport pipes for mining operations.

– Marine: Provide specialized pipes for shipbuilding and offshore structures.

– Aerospace: Supply lightweight, high-strength piping for fuel and hydraulic systems in aircraft.

– Irrigation: Deliver pipes designed for efficient water distribution in agricultural applications.

– Firefighting: Ensure reliable fire suppression systems with high-quality piping.

– Infrastructure Development: Supply pipes for urban infrastructure like bridges, tunnels, and sewage systems.

– Renewable Energy: Provide piping for geothermal and solar thermal energy systems.

– Research and Development: Supply custom pipes for experimental setups and new technology testing.

– Industrial Manufacturing: Offer specialized pipes for machinery and equipment in various manufacturing processes.

– Telecommunications: Provide conduits for protecting cables in communication networks.

Overall, piping manufacturers are integral to maintaining the functionality and safety of essential infrastructure and services across a wide array of industries.

SourcifyChina specializes in providing high-quality piping materials, primarily focusing on stainless steel, carbon steel, and alloy steel. These materials are known for their durability, corrosion resistance, and suitability for various industrial applications.

Stainless steel pipes from SourcifyChina are highly resistant to corrosion, making them ideal for industries dealing with chemicals, water, and high-humidity environments. Their smooth finish and robustness enhance their longevity and reduce maintenance costs.

Carbon steel pipes are valued for their strength and adaptability. SourcifyChina ensures that these pipes meet industry standards for mechanical properties, making them suitable for construction, energy, and transportation sectors.

Alloy steel pipes offer a blend of strength, hardness, and resistance to wear, making them suitable for high-pressure and high-temperature environments. SourcifyChina’s alloy steel pipes are heat-treated to maximize their performance and durability.

SourcifyChina’s commitment to quality and customization extends to providing specific grades and specifications tailored to clients’ unique needs. Their rigorous quality assurance processes ensure that all pipes meet international standards.

In addition to material excellence, SourcifyChina offer competitive pricing and efficient logistics, ensuring timely delivery of products. Their customer-centric approach guarantees a seamless experience, from inquiry to installation.

Overall, SourcifyChina’s diverse range of piping materials ensures reliability and efficiency across various industrial applications, backed by robust quality control and responsive customer service. Whether for large-scale projects or specialized needs, SourcifyChina stands out as a trusted supplier.

SourcifyChina pipelining manufacturers prioritize stringent quality control processes to ensure exceptional product standards. Raw materials undergo rigorous selection, ensuring durability and compliance with industry regulations. The sourcing team meticulously examines suppliers, choosing only those meeting high-quality benchmarks.

In the subsequent stages, advanced precision tools are employed to maintain accuracy during production. State-of-the-art machinery ensures consistent dimensions and flawless finishes. Regular maintenance of these tools further guarantees uninterrupted manufacturing excellence.

Post-production inspection is a significant aspect of SourcifyChina’s quality control. Trained inspectors perform detailed checks, targeting possible defects and deviations. Automated systems augment these inspections, ensuring no flaw goes unnoticed.

Apart from inspections, SourcifyChina enforces rigorous testing protocols. Pipes are subjected to pressure tests, corrosion resistance assessments, and endurance evaluations. These tests are fundamental in certifying the pipes’ capability to meet real-world demands and environmental challenges.

Continuous improvement and feedback mechanisms form the backbone of SourcifyChina’s quality control. Feedback from clients and industry audits are reviewed regularly, prompting necessary adjustments in their processes. This dynamic approach ensures that they stay ahead of the curve.

Quality control at SourcifyChina doesn’t just end at production; it extends to packaging and logistics. Secure and robust packaging materials are used to protect products during transit, ensuring they reach customers without any damage. Logistics protocols are optimized to minimize transit time and preserve product integrity.

In conclusion, SourcifyChina’s dedication to quality control is a multi-faceted endeavor that encompasses every stage of the manufacturing process. From meticulous raw material selection to advanced testing and continuous feedback incorporation, their unwavering focus ensures the delivery of top-tier piping products globally. This commitment to quality reassures clients of the reliability and longevity of their products.

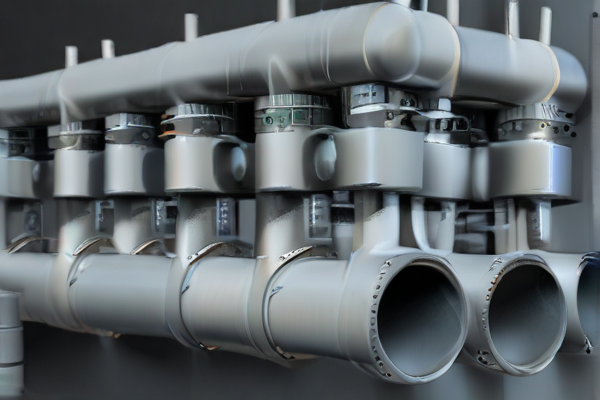

SourcifyChina piping manufacturers excel in producing high-quality pipes that meet global standards. Their capabilities encompass a vast range of materials including stainless steel, carbon steel, and PVC. This ensures that they can cater to diverse industry needs, from residential construction to heavy-duty industrial applications.

Advanced production facilities enable SourcifyChina to deliver precision-engineered products. State-of-the-art machinery and stringent quality control measures ensure that every pipe manufactured is flawless. Innovative techniques like automated welding and computer-aided design (CAD) contribute to the high efficiency and reliability of their products.

Customization is another key aspect of SourcifyChina’s offerings. They provide tailored solutions based on specific client requirements, whether it’s unique dimensions, material grades, or additional features like corrosion resistance. This flexibility makes them a preferred supplier for complex projects that demand precision and bespoke designs.

SourcifyChina also emphasizes sustainability in their manufacturing processes. They implement eco-friendly practices, reducing waste and energy consumption. By prioritizing sustainability, they not only comply with environmental regulations but also fulfill the growing demand for green manufacturing solutions among global clients.

Global logistics capabilities bolster SourcifyChina’s competitive edge. With a robust supply chain network and strategic partnerships, they ensure timely delivery of products across international borders. Their efficient logistics management minimizes delays, helping clients maintain their project schedules without disruptions.

Customer support is integral to SourcifyChina’s operations. They offer exceptional after-sales service, assisting clients with installation, maintenance, and troubleshooting. Comprehensive technical support and extended warranties further reinforce their commitment to customer satisfaction.

Reliability, innovation, and customer-oriented service define SourcifyChina’s approach in the piping industry. Their extensive capabilities not only meet but often exceed client expectations, solidifying their reputation as leaders in the market. Partnering with SourcifyChina translates to investing in superior quality and dependable solutions for all piping needs.

Piping manufacturers play a pivotal role in various industries, offering essential solutions for fluid transport and infrastructure. Their contributions span across many sectors, enhancing efficiencies and ensuring safety.

– Enhanced Durability: High-quality piping systems are designed to withstand extreme conditions, reducing the frequency of repairs and replacements.

– Customization: Manufacturers provide tailored solutions to meet specific industrial requirements, ensuring optimal performance.

– Advanced Technology: Adoption of the latest technologies ensures precision and reliability in piping systems.

– Cost-effectiveness: Bulk manufacturing and economies of scale translate into lower costs for industrial projects.

– Safety: Adhering to stringent industry standards, manufacturers ensure products are safe for use in critical applications.

– Environmental Sustainability: Innovative materials and manufacturing methods reduce environmental impact and improve sustainability.

– Expert Support: Comprehensive technical support and consultation services are often provided, assisting clients through installation and maintenance phases.

– Versatility: With a wide range of materials and designs available, manufacturers cater to diverse applications from residential plumbing to complex industrial networks.

– Increased Efficiency: Greater system efficiency and reliability lead to smoother operations and reduced downtime.

By leveraging these benefits, businesses can significantly enhance their operational capabilities and maintain robust infrastructure, ultimately leading to sustained growth and development.

Piping manufacturers offer a range of features that ensure high-quality and efficient pipeline systems suitable for various industries. These features include:

– Quality Materials: Use of durable materials like stainless steel, carbon steel, and PVC to ensure longevity and reliability.

– Customization: Ability to create bespoke piping solutions tailored to specific project needs and specifications.

– Advanced Technology: Integration of state-of-the-art machinery and processes, such as CNC machining and automated welding, for precision and efficiency.

– Certifications: Compliance with international standards and certifications like ISO, ANSI, and ASME to ensure superior quality and safety.

– Expertise and Experience: Professional teams with extensive knowledge and experience to provide guidance, support, and innovative solutions.

– Testing and Inspection: Rigorous testing and quality control measures, including hydrostatic, radiographic, and ultrasonic tests, to guarantee product integrity.

– Sustainability: Implementation of eco-friendly practices and materials to minimize environmental impact.

– Supply Chain Management: Robust supply chain systems to ensure timely delivery and availability of products globally.

– After-Sales Support: Comprehensive after-sales services, including maintenance, repair, and technical support, to ensure long-term client satisfaction.

– Cost Efficiency: Competitive pricing models and cost-effective solutions without compromising on quality.

– Design and Engineering Services: In-house design and engineering teams to provide detailed planning and layout services for complex piping systems.

These features collectively contribute to the reliability, efficiency, and effectiveness of piping systems across various applications, from industrial to residential projects.

SourcifyChina is a renowned name in the piping industry, specializing in manufacturing high-quality custom products. With a robust production facility and an experienced team, they offer a wide range of piping solutions tailored to the specific needs of various industries, including oil and gas, water treatment, and chemical processing.

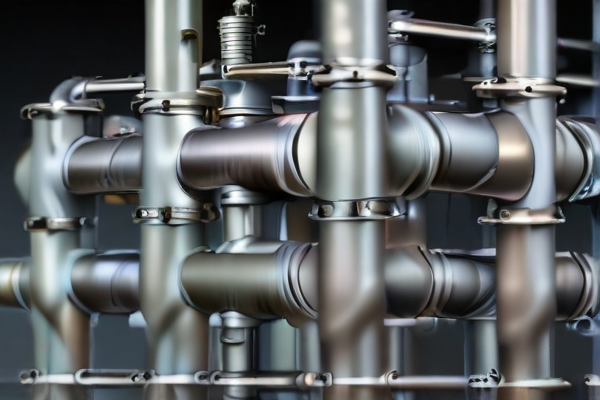

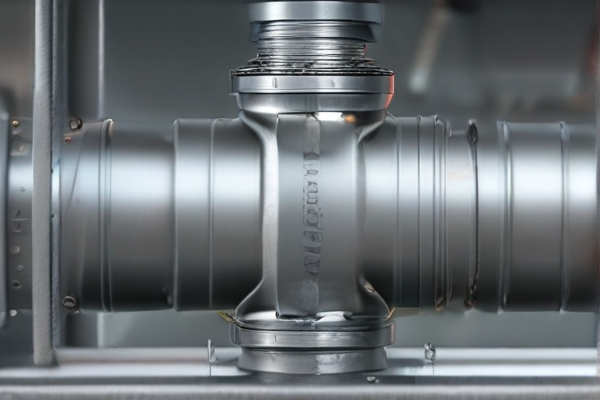

Their custom product line includes unique pipeline fittings, valves, and flanges, built to meet specific project requirements. These customized piping products are crafted using advanced techniques and high-grade materials, ensuring durability, precision, and reliability for optimal performance in demanding environments.

SourcifyChina excels not only in manufacturing but also in managing complex projects. They offer end-to-end solutions, from initial design and consultation to final installation and after-sales support. Their project management team ensures that all projects are executed seamlessly, adhering to international standards and customer specifications.

What sets SourcifyChina apart is their commitment to quality and customer satisfaction. They employ stringent quality control measures and adopt cutting-edge technologies to deliver superior products. Their dedication is reflected in their long-term partnerships and repeat business from satisfied clients around the globe. By choosing SourcifyChina, you’re opting for unparalleled expertise and excellence in custom piping solutions.

SourcifyChina is a leading player in the piping manufacturing industry, dedicated to bridging the gap between high-quality production and cost-effective solutions. Established with a mission to serve global markets, the company specializes in the development, fabrication, and supply of a comprehensive range of piping products, including but not limited to seamless pipes, welded pipes, flanges, and fittings. SourcifyChina stands out due to its adherence to international standards and strict quality control measures, ensuring that every product meets the stringent demands of sectors such as oil and gas, petrochemical, power plants, and construction. Leveraging advanced technology, innovative methodologies, and a team of skilled professionals, the company excels in delivering customized solutions tailored to meet the unique needs of each client. Moreover, SourcifyChina’s commitment to sustainability and ethical business practices has earned it a reputation for reliability and integrity in the competitive landscape of global manufacturing. With a robust supply chain, timely deliveries, and exceptional customer service, SourcifyChina continues to enhance its footprint across various international markets, establishing itself as a trusted partner for businesses in need of high-quality piping solutions.

Piping manufacturers play a crucial role in the Aerospace, Defense, and Marine industries by providing specialized solutions tailored to the unique demands of each sector. In the aerospace industry, the need for lightweight, high-strength piping systems is paramount. These systems must withstand extreme conditions, including high pressures, temperatures, and vibrations encountered during flight. Manufacturers often use advanced materials such as titanium and nickel alloys to meet these rigorous standards. Additionally, precision engineering ensures that the piping does not compromise the performance or safety of critical aircraft systems, including fuel lines, hydraulic systems, and environmental control systems.

In the defense sector, piping systems are integral to various applications, ranging from military vehicles to naval vessels. Here, the emphasis is on durability and reliability under adverse conditions. Piping manufacturers produce components that can resist corrosion, impact, and wear while delivering optimal performance in combat scenarios. For example, the hydraulic and fuel systems of tanks and armored vehicles require robust piping solutions to function effectively in the field. Similarly, in marine applications, piping systems are essential for the operation of both surface vessels and submarines. Marine-grade materials such as duplex stainless steel and copper-nickel alloys are commonly used to combat the corrosive nature of seawater, ensuring long-lasting and reliable performance. By integrating advanced material science with precise manufacturing processes, piping manufacturers contribute significantly to the efficiency, safety, and longevity of systems critical to these industries.

Piping manufacturers play a crucial role in the automotive industry, where precision, durability, and reliability are paramount. Automotive systems, which include fuel lines, brake lines, and cooling systems, demand high-quality piping solutions to ensure optimal performance and safety. Manufacturers produce specialized pipes that can withstand extreme temperatures, pressures, and corrosive substances, which are commonly encountered in vehicle operations. Advanced materials such as stainless steel, aluminum, and high-strength polymers are frequently employed due to their superior properties. Furthermore, innovative manufacturing processes like hydroforming and CNC machining enable the creation of intricate pipe shapes and configurations that enhance the efficiency and longevity of automotive components.

In the realm of electronics, piping manufacturers are integral to the development and maintenance of sophisticated cooling systems essential for high-performance devices. Modern electronics, including servers, data centers, and high-end computing equipment, generate substantial heat during operation. Efficient thermal management systems rely on precision-engineered piping that facilitates effective heat dissipation and fluid circulation. Materials such as copper and specialized plastics are often used due to their high thermal conductivity and resistance to thermal expansion. Piping manufacturers also contribute to the design of custom liquid cooling loops and heat exchanger systems, ensuring that electronic components maintain optimal temperatures for peak performance and longevity. By providing tailored solutions, these manufacturers help advance the electronics industry’s capabilities while supporting the growing demand for more powerful and efficient technology.

Piping manufacturers play an instrumental role in the construction industry by providing essential materials that serve as the backbone for water distribution, gas supply, and sewage systems within residential, commercial, and industrial buildings. Utilizing a wide range of materials such as steel, copper, PVC, and PEX, these manufacturers ensure that their pipes meet the stringent standards required for durability, safety, and efficiency. The integration of advanced technologies and quality control measures allows for the production of piping systems that can withstand high pressure, extreme temperatures, and other environmental stresses. This reliability is crucial for the construction sector as it directly impacts the longevity and integrity of infrastructure projects, from high-rise buildings to sprawling housing developments.

In the energy sector, piping manufacturers provide critical infrastructure for the transportation of oil, gas, and other energy resources. Pipelines spanning hundreds or even thousands of miles facilitate the efficient and secure movement of these fuels from extraction sites to refineries and ultimately to consumers. The manufacture of high-grade, corrosion-resistant pipes is vital for these systems to prevent leaks, ruptures, and environmental contamination. Advanced materials such as stainless steel and specialized coatings are often employed to ensure longevity and integrity under harsh conditions. Additionally, piping manufacturers are increasingly focusing on innovations that support renewable energy systems, including geothermal and solar thermal applications, by supplying the necessary piping solutions that help in harnessing and distributing these green energy sources.

Together, these aspects underline the indispensable role of piping manufacturers in sustaining and advancing both the construction and energy sectors. Their expertise and technological advancements are crucial for shaping a resilient, efficient, and sustainable future infrastructure.

The industrial equipment industry heavily relies on piping manufacturers to supply the critical infrastructure necessary for a wide range of applications, from chemical processing plants to power generation facilities. Piping systems are essential for the safe and efficient transport of fluids, gases, and sometimes solids within these complex industrial operations. High-quality piping reduces the likelihood of leaks or breakdowns, ensuring operational efficiency and safety. Advanced materials and manufacturing techniques have enabled the production of pipes that can withstand extreme temperatures, high pressures, and corrosive substances, making them indispensable in sectors such as oil and gas, petrochemicals, and pharmaceuticals.

Beyond their fundamental role in fluid transport, piping systems also facilitate processes such as heating, cooling, and steam generation, which are vital to various industrial applications. Piping manufacturers are increasingly integrating smart technologies into their products, providing real-time monitoring and data analytics capabilities. This integration helps in predictive maintenance, minimizing downtimes, and extending the lifespan of piping assets. The development of eco-friendly and energy-efficient pipes is also gaining momentum, driven by the global push towards sustainability. As industries continue to evolve and scale up their operations, the demand for innovative and robust piping solutions is expected to grow, further solidifying the role of piping manufacturers in the industrial equipment landscape.

Piping manufacturers play a crucial role in the medical devices industry, offering specialized components that ensure the seamless delivery of essential fluids and gases. Medical devices such as ventilators, dialysis machines, and anesthetic delivery systems rely heavily on high-quality, reliable piping to function effectively. These manufacturers produce pipes that meet stringent regulatory standards, ensuring they are biocompatible, non-reactive, and can withstand sterilization processes. The precision and reliability offered by piping manufacturers are vital in maintaining the operational efficacy of these life-saving devices, preventing any contamination or leakage that could place patients at risk.

Moreover, the advancements in materials science have enabled piping manufacturers to innovate and provide customized solutions tailored to specific medical applications. Lightweight, flexible, and durable materials such as advanced polymers or stainless steel are commonly used, providing both the strength needed to endure high-pressure scenarios and the flexibility required for intricate medical equipment designs. The ability to produce piping that adheres to exact specifications allows for the optimization of device performance and patient care outcomes. As medical technology continues to evolve, the collaboration between piping manufacturers and medical device engineers will remain pivotal in driving forward innovations that enhance healthcare delivery and patient safety.

Machining and manufacturing play a crucial role in the production processes of piping manufacturers, driving advancements in precision and efficiency. CNC (Computer Numerical Control) machining, a prevalent technology in this sector, enables the creation of intricate parts with high accuracy, essential for meeting the stringent tolerances required in piping systems. This method involves automated machine tools that execute programmed instructions to cut, shape, and finish materials, ensuring consistency across large production runs. The meticulous nature of CNC machining is particularly beneficial for creating flanges, fittings, and complex pipe sections, ensuring that each piece meets exact specifications for effective assembly and operation in various applications, such as plumbing, gas distribution, and industrial process systems.

In the broader scope of manufacturing, piping manufacturers leverage a combination of traditional methods and advanced technologies to meet diverse market needs. Processes such as extrusion, welding, and bending are fundamental, while innovations in additive manufacturing (3D printing) and laser cutting are increasingly integrated into production lines. These manufacturing techniques not only enhance the physical properties and performance of pipes but also streamline production, reduce waste, and lower costs. Manufacturing strategies focused on incorporating durable materials like stainless steel, copper, and advanced polymers improve pipe longevity and reliability, critical for sectors like oil and gas, water treatment, and chemical processing. The synergy between advanced machining and robust manufacturing practices ensures that piping manufacturers can deliver high-quality, dependable products that adhere to both regulatory standards and client requirements.

FAQ for Piping Manufacturers Quality Work from SourcifyChina Factory

Q1: What types of piping do you manufacture at SourcifyChina Factory?

A1: At SourcifyChina Factory, we specialize in manufacturing a wide range of piping solutions including stainless steel, carbon steel, and alloy pipes. We cater to various industries such as oil and gas, petrochemical, water treatment, and construction.

Q2: How do you ensure the quality of your piping products?

A2: We maintain stringent quality control processes that comply with international standards. This includes raw material inspection, in-process testing, and final product inspection. Our facility is also ISO-certified, which ensures continuous improvement in all our manufacturing processes.

Q3: Can you provide customized piping solutions?

A3: Yes, we provide customized piping solutions tailored to meet specific customer requirements. Our experienced engineering team works closely with clients to develop bespoke designs and specifications.

Q4: What are your lead times for orders?

A4: Lead times can vary depending on the size and complexity of the order. Generally, standard orders are fulfilled within 4-6 weeks, while customized and larger orders may take longer. We always strive to meet our clients’ deadlines and deliver as promptly as possible.

Q5: Do you offer any certifications or documentation with your pipes?

A5: We provide comprehensive documentation with all our piping products, including material test reports, quality certificates, and compliance certificates according to industry standards such as ASME, ASTM, and DIN.

Q6: How can I place an order or request a quote?

A6: You can place an order or request a quote by contacting our sales team through our website, email, or phone. Our team is responsive and ready to assist you with all your piping requirements.

Q7: What after-sales services do you provide?

A7: SourcifyChina Factory offers extensive after-sales support including installation assistance, maintenance guidance, and a customer service hotline to address any issues or concerns promptly.

Q8: Where are your products shipped from, and what shipping methods do you offer?

A8: Our products are shipped from our factory in China. We offer various shipping methods including sea, air, and express courier services, depending on the urgency and size of the order.

When engaging with piping manufacturers from SourcifyChina, it’s essential to ensure quality, compliance, and efficiency. Here are some helpful tips:

1. Supplier Verification:

– Background Check: Verify the manufacturer’s credentials, certifications (ISO, CE), and industry experience.

– References: Ask for references and check reviews from past clients to ascertain reliability.

2. Quality Assurance:

– Material Standards: Ensure the manufacturer adheres to international material standards like ASTM, ASME, or DIN.

– Inspection: Implement rigorous inspection regimes, including third-party inspections.

3. Communication:

– Clear Specifications: Provide detailed specifications and drawings. Confirm that they understand these requirements.

– Regular Updates: Maintain open communication channels to receive regular progress updates.

4. Cost & Payment Terms:

– Transparent Pricing: Acquire a detailed cost breakdown to avoid hidden charges.

– Payment Schemes: Negotiate favorable terms. Typically, an initial deposit followed by payments upon milestones or completion.

5. Logistics & Lead Time:

– Timelines: Establish realistic lead times and ensure they commit to deadlines.

– Shipping: Understand shipping logistics, including handling, customs, and insurance.

6. Trial Orders:

– Small Batch Runs: Start with small trial orders to test the waters before scaling up production.

7. Ethical Practices:

– Sustainable Methods: Ensure the factory follows sustainable and ethical practices to avoid reputational risks.

8. Legal Protection:

– Contracts: Use well-drafted contracts that cover all contingencies, including quality control, delivery schedules, payment terms, and penalties for non-compliance.

– IP Protection: Protect intellectual property rights by incorporating confidentiality agreements.

By following these tips, you can strengthen your partnership with piping manufacturers at SourcifyChina, ensuring a productive and high-quality manufacturing process.

Sure, here are some Frequently Asked Questions (FAQs) along with answers for sourcing piping manufacturers from SourcifyChina Factory:

1. What types of piping do SourcifyChina factories manufacture?

SourcifyChina factories produce a wide range of piping, including but not limited to stainless steel pipes, carbon steel pipes, PVC pipes, and HDPE pipes. They cater to various industries like oil and gas, water treatment, construction, and plumbing.

2. How can I verify the quality of the pipes from the manufacturers?

SourcifyChina provides detailed quality certificates and compliance documents from certified quality control agencies. You can also request samples, visit the factories, or hire third-party inspection services to ensure the quality standards meet your requirements.

3. What is the typical lead time for pipe orders?

Lead times can vary depending on the complexity and quantity of the order. Generally, it ranges from 3 to 8 weeks. Always check with the specific manufacturer for more accurate delivery timelines.

4. Do SourcifyChina factories offer customization options for piping products?

Yes, many factories offer customization services, including specific dimensions, coatings, and material grades to meet your project requirements. Detailed customization requests can be discussed directly with the manufacturer.

5. What are the payment terms and methods available?

Common payment terms are 30% advance payment with 70% payable upon delivery or after a quality inspection. Accepted payment methods often include T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal, depending on the manufacturer’s policies.

6. Is shipping and logistics support available?

Yes, SourcifyChina provides comprehensive shipping and logistics support, including handling customs clearance and documentation. They work with reputed shipping companies to ensure timely and safe delivery of your piping products.

7. How can I initiate a sourcing request with SourcifyChina?

You can initiate a sourcing request by visiting SourcifyChina’s official website, filling out a form with your requirements, or contacting their support team directly via phone or email. Detailed inquiries help in getting more accurate quotes and lead times.

These FAQs should help you navigate the process of sourcing piping manufacturers through SourcifyChina efficiently.

Sourcing piping manufacturers through platforms like Sourcify in China can be efficient and effective if done correctly. Here are some tips to help streamline the process:

1. Detailed Requirements: Clearly outline your product specifications, including materials, dimensions, quantities, and quality standards. Detailed requirements help manufacturers understand your needs and provide accurate quotes.

2. Use Sourcify’s Tools: Sourcify offers tools to manage sourcing projects, compare quotes, and communicate with manufacturers. Utilize these features to keep track of your sourcing process and maintain organized records.

3. Research Manufacturers: Review profiles, ratings, and previous projects of manufacturers listed on Sourcify. Look for factories with experience in piping production and a good track record of quality and reliability.

4. Request Samples: Before placing a large order, request samples to evaluate the quality of the products. This step can save you time and money by ensuring the manufacturer meets your standards.

5. Quality Assurance: Ensure that manufacturers adhere to international quality standards such as ISO or ANSI. Quality certifications are a good indicator of a reliable manufacturer.

6. Communication: Maintain clear and open communication with potential manufacturers. Address any concerns or questions promptly and ensure they understand your requirements fully.

7. Negotiate Terms: Negotiate terms and conditions, including pricing, payment terms, lead times, and shipping. Clear agreements help prevent misunderstandings and delays.

8. Visit Factories: If possible, visit the factories to verify their capabilities and capacity. Factory visits give you a firsthand look at their operations and build stronger business relationships.

9. Due Diligence: Conduct thorough due diligence, including checking references and verifying business licenses. This step helps identify reputable manufacturers.

10. Leverage Sourcify Support: If you encounter challenges, use Sourcify’s support team for assistance. They can provide insights and help resolve issues with manufacturers.

By following these tips, you can efficiently source high-quality piping manufacturers in China using Sourcify, ensuring a smooth and successful procurement process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.