Choosing “SourcifyChina” Factory for purchasing cutting machines for fabric from China offers unmatched quality. They use state-of-the-art technology that ensures precision cutting and long-lasting performance, vital for any textile manufacturer.

One of the key benefits of working with SourcifyChina is their rigorous quality control. Every machine undergoes extensive testing to meet international quality standards, so buyers can be confident in their investment.

Moreover, “SourcifyChina” Factory excels in customer service. Buyers receive detailed guidance throughout the purchasing process, from selection to after-sales support, ensuring a seamless transaction.

Financial advantages also abound when opting for “SourcifyChina.” Their competitive pricing and flexible payment options make it easy for businesses of all sizes to secure high-quality machinery without breaking the bank.

Lastly, SourcifyChina’s strategic location in China allows for swift shipping and reduced logistic costs, ensuring timely delivery and reducing downtime for buyers. Their robust supply chain management further guarantees reliability and efficiency.

In conclusion, “SourcifyChina” Factory offers a blend of superior quality, excellent customer service, financial flexibility, and efficient logistics. This combination makes them an ideal choice for buyers seeking cutting machines for fabric from China.

Cutting machines for fabric come in various types, catering to different industrial and hobbyist needs. Key options include manual, semi-automatic, and fully automatic machines, each with unique features and capabilities.

– Manual Fabric Cutters:

– Rotary cutters

– Scissors

– Craft knives

– Pinked cutters

– Semi-Automatic Fabric Cutters:

– Electric rotary cutters

– Foam cutting machines

– Hot knife cutters

– Hand-held electric shear

– Fully Automatic Fabric Cutting Machines:

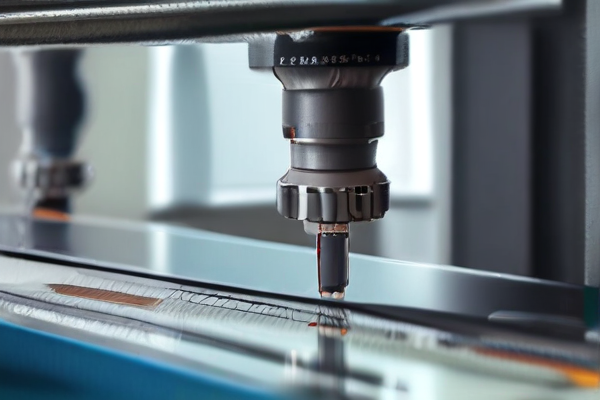

– CNC (Computer Numerically Controlled) machines

– Laser cutting machines

– Ultrasonic cutting machines

– Industrial cutting tables with automated feeds

– Die Cutting Machines:

– Manual die-cutting machines

– Electronic die-cutting machines

– Specialty dies for fabric

Each type of machine offers various pros and cons, such as precision, speed, and ease of use, to meet the specific demands of different fabric cutting tasks.

Cutting machines for fabric are essential tools in the textile industry, ensuring precision, speed, and efficiency in cutting fabric for various applications. They cater to diverse needs, from small-scale fashion designers to large-scale manufacturing units.

– Apparel Manufacturing: Precision cutting for garments, ensuring consistency and reducing fabric waste.

– Home Textiles: Crafting items like curtains, bedspreads, and upholstery with exact measurements.

– Automotive Interiors: Cutting materials for car seats, headliners, and interiors with accuracy.

– Furniture Upholstery: Efficiently cutting fabric for sofas, chairs, and cushions.

– Industrial Textiles: Cutting materials for filters, tents, and technical fabrics.

– Crafting and DIY Projects: Assisting hobbyists in achieving professional-quality cuts for various projects.

– Quilting: Precise cutting of fabric pieces, enhancing quilt-making efficiency.

– Athletic Wear: Exact cutting for stretchable and technical fabrics, essential for sportswear.

– Fashion Design: Supporting designers by producing intricate and accurate patterns.

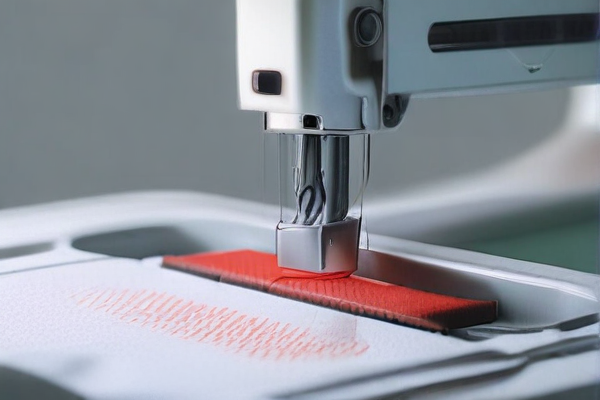

– Embroidery: Preparing fabric pieces for detailed and accurate embroidery work.

– Soft Toys: Cutting fabric for creating plush toys with precision.

– Medical Textiles: Cutting specialized fabrics used in healthcare, such as bandages and hospital uniforms.

– Costume Design: Facilitating the creation of costumes with intricate details.

– Footwear: Cutting materials for shoes, ensuring each piece meets design specifications.

– Patchwork: Precise cutting for creating uniform patches in patchwork designs.

– Decorative Items: Producing items like fabric flowers, ribbons, and other decorations.

– Protective Gear: Cutting materials for masks, gloves, and other protective clothing.

– Technical Apparel: Cutting performance fabrics for outerwear, such as jackets and raincoats.

– Signage and Banners: Cutting fabric for promotional materials like banners and flags.

– Retail Displays: Crafting fabric elements used in store displays and visual merchandising.

These applications highlight the versatility and critical role of fabric cutting machines in various sectors, driving both creativity and efficiency.

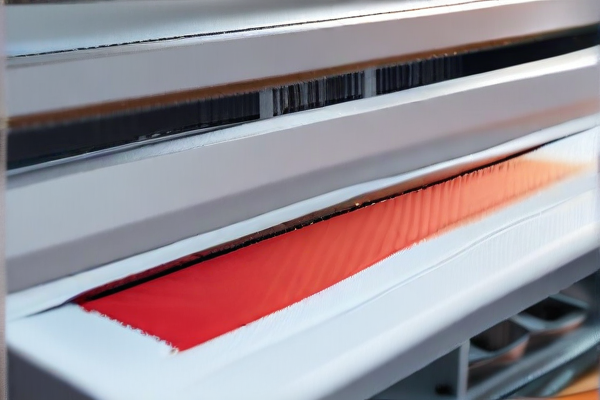

SourcifyChina cutting machines for fabric are crafted to cater to diverse fabric types and thicknesses. Engineered with durability in mind, these machines utilize premium-grade metals to withstand rigorous operational use.

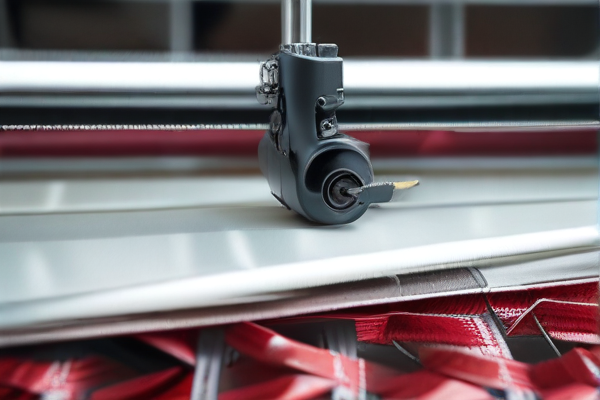

The cutting mechanisms are enhanced by high-precision blades made from robust alloys. These alloys ensure longevity and precision in fabric cutting, reducing the need for constant maintenance.

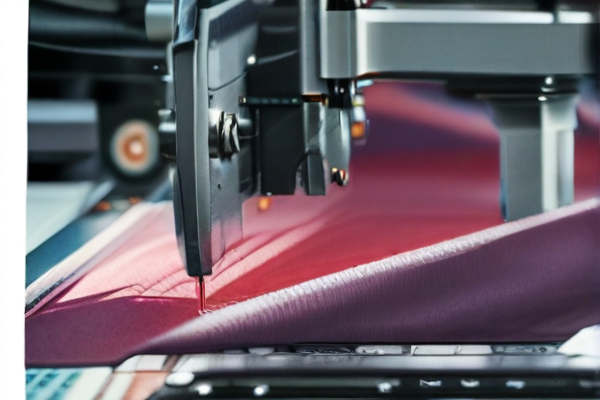

To ensure optimal performance, the machines incorporate advanced control systems. These systems facilitate smooth operation and precise adjustments, enhancing user control even with complex fabric patterns and multiple layers.

Ergonomically designed, the machines prioritize user comfort and safety, featuring easy-to-use interfaces and protective mechanisms. This thoughtful engineering minimizes operator fatigue and maximizes productivity.

Overall, SourcifyChina cutting machines for fabric exemplify a blend of strong construction materials, high-tech precision, and user-centric design. They are well-suited for both small-scale tailoring shops and large-scale industrial textile manufacturing, providing reliable and efficient fabric cutting solutions.

SourcifyChina ensures the highest quality standards in their fabric cutting machines through a meticulous manufacturing process. Each machine undergoes rigorous design evaluation to meet industry needs.

The assembly process sees skilled technicians meticulously putting together each component with precision, ensuring optimal functionality and durability. High-grade materials are sourced to ensure long-lasting performance.

Every machine is subjected to stringent testing, including functionality checks and stress tests, to verify reliability and accuracy. Quality control teams scrutinize each unit for mechanical and software defects.

The finalized cutting machines undergo a final inspection before packaging. This ensures that only the highest quality machines reach the market, guaranteeing customer satisfaction.

SourcifyChina’s cutting machines for fabric exhibit unmatched precision and efficiency. These advanced machines ensure clean, accurate cuts for a variety of textile materials, minimizing waste and optimizing output. Enhanced with digital control systems, they cater to both small-scale and large-scale production needs.

The machines feature robust construction and user-friendly interfaces, making them ideal for various industries, including fashion, automotive, and home textiles. With adjustable cutting speeds and versatile blade options, they accommodate different fabric types and thicknesses seamlessly.

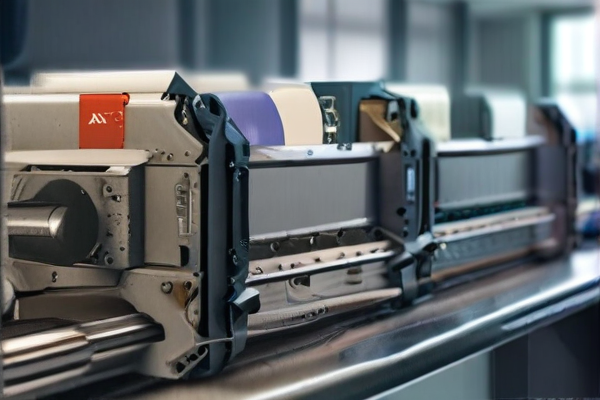

SourcifyChina’s cutting machines integrate seamlessly with CAD/CAM systems, streamlining the design-to-production process. This connectivity facilitates rapid prototyping and accurate pattern replication, significantly reducing time-to-market for new products.

Safety is a critical aspect, and these machines incorporate multiple safety mechanisms to protect operators. Features such as automatic shut-off, emergency stops, and protective enclosures ensure a secure operational environment.

Maintenance is straightforward, thanks to easily accessible components and self-diagnostic capabilities. This reduces downtime and enhances productivity, enabling businesses to maintain continuous operations without frequent interruptions.

Complete customer support and training programs are available, ensuring that clients can fully harness the capabilities of SourcifyChina’s cutting machines. Dedicated after-sales service and technical assistance contribute to maximizing machine performance and longevity. In essence, these cutting machines represent a blend of precision, versatility, and reliability, indispensable for modern fabric cutting demands.

Cutting machines for fabric offer numerous advantages, revolutionizing the textile industry by enhancing precision, efficiency, and productivity.

– Precision: Cutting machines ensure accurate and consistent cuts, minimizing fabric wastage and ensuring high-quality products.

– Efficiency: They speed up the cutting process, significantly reducing labor time and costs.

– Enhanced Productivity: With automated operations, cutting machines can handle large volumes quickly, boosting overall output.

– Consistency: Automated machines ensure uniformity in cuts, crucial for mass production and maintaining quality standards.

– Versatility: Modern fabric cutting machines accommodate various materials, from delicate silks to sturdy denims, increasing their utility.

– Safety: These machines come equipped with safety features to protect operators, reducing accidents and injuries.

– Customization: Advanced cutting machines offer options for intricate patterns and designs, expanding creative possibilities.

– Reduced Labor Costs: By automating the cutting process, businesses can save on labor costs and allocate human resources to other areas.

– Energy Efficiency: Many modern cutting machines are energy-efficient, making them environmentally friendly and cost-effective in the long run.

– Scalability: Cutting machines can easily scale operations to meet varying production demands, from small batches to large-scale manufacturing.

In summary, fabric cutting machines bring substantial benefits by improving accuracy, speed, and safety while reducing costs and increasing productivity. Their versatility and customization capabilities further underscore their value in the textile industry.

Cutting machines for fabric are essential tools in the textile industry, ensuring precision and efficiency in fabric cutting processes. These machines come with a variety of features designed to enhance productivity and quality.

– Precision Cutting: Advanced algorithms and sensors contribute to highly precise cuts, reducing fabric waste and ensuring consistency.

– Automation: Many cutting machines are equipped with automated systems that streamline the cutting process, minimizing the need for manual intervention.

– Versatility: These machines can handle a range of fabrics, from delicate silks to heavy-duty materials like denim or canvas.

– Speed: High cutting speeds improve overall production efficiency, vital for meeting tight deadlines.

– Safety Features: Integrated safety mechanisms, such as automatic shut-off and blade guards, protect operators from potential hazards.

– Digital Integration: Modern machines support various digital formats, allowing designs to be input directly from CAD software, enhancing workflow.

– User-Friendly Interface: Touchscreen displays and intuitive controls make these machines easy to operate, even for less experienced users.

– Energy Efficiency: Newer models are designed to consume less energy, making them more environmentally friendly.

– Customizable Settings: Users can adjust settings to accommodate different types of cuts, fabric thicknesses, and project specifications.

– Low Maintenance: Built with high-quality components, these machines require minimal maintenance, reducing downtime and operational costs.

– Portability: Some cutting machines are designed to be portable, making them ideal for small workshops or on-site projects.

– Noise Reduction: Enhanced engineering minimizes noise levels, creating a more comfortable working environment.

– Software Updates: Regular software updates ensure that the machines remain current with the latest technological advancements.

Investing in a cutting machine for fabric can revolutionize production processes by enhancing precision, speed, and overall efficiency.

SourcifyChina specializes in cutting-edge machines designed for precision fabric cutting, streamlining the textile manufacturing process. These machines ensure high accuracy, minimizing material waste and enhancing productivity.

Custom products from SourcifyChina are tailored to meet specific industry needs. Whether it’s intricate patterns or large-scale production, these cutting machines can be customized to deliver impeccable results.

Projects executed with SourcifyChina’s fabric cutting machines boast superior quality. The advanced technology embedded in these machines ensures that every cut is precise, leading to higher quality finished products.

SourcifyChina also provides excellent customer support. From installation to maintenance, their team is dedicated to ensuring that the machines operate optimally, enhancing the overall efficiency of textile projects.

Investing in SourcifyChina’s fabric cutting machines is a smart choice for any textile business. Their combination of advanced technology, custom options, and stellar support ensures long-term benefits and operational excellence.

SourcifyChina Cutting Machines for Fabric is a leading manufacturer and supplier specializing in high-precision cutting equipment specifically designed for textile industries. Established with a mission to innovate and streamline production processes, the company excels in providing cutting-edge solutions that combine efficiency, reliability, and advanced technology. Their product line includes an array of automatic and semi-automatic fabric cutting machines that cater to diverse requirements, whether for small-scale artisanal workshops or large industrial operations. With a commitment to quality and customer satisfaction, SourcifyChina ensures its machines are engineered to deliver seamless performance, reducing material wastage and optimizing productivity. The company’s strategic location in China enables it to leverage advanced manufacturing capabilities and maintain competitive pricing while adhering to international standards. Additionally, SourcifyChina provides comprehensive after-sales support and training programs, ensuring that clients can maximize the potential of their investments. Known for its innovative approach and unwavering dedication to excellence, SourcifyChina Cutting Machines for Fabric is a trusted partner for businesses looking to enhance their textile production capabilities.

Cutting machines for fabric play a crucial role in the aerospace, defense, and marine industries, where precision and efficiency are key. In aerospace, high-performance textiles are often used for aircraft interiors, such as seats, cabin dividers, and insulation materials. These textiles require precise cutting to meet stringent safety and quality standards. Advanced cutting machines ensure that every piece of fabric adheres to exact specifications, reducing material wastage and ensuring consistency in production. This precision is vital for maintaining the integrity and performance of the aircraft, leading to safer and more reliable air travel.

In the defense and marine sectors, fabric cutting machines are employed to produce various components, including uniforms, tarpaulins, sails, and protective gear. These applications demand durability and exact fit, which can only be achieved through precise cutting. Automated cutting machines equipped with advanced software can handle complex patterns and multiple layers of fabric, enhancing both speed and accuracy. This capability is particularly important for the rapid production of essential items during emergencies or military operations. Moreover, the machine’s efficiency translates to cost savings and quicker turnaround times, allowing for better resource allocation and operational readiness in these highly demanding industries.

Cutting machines for fabric play a vital role in both the automotive and electronics industries, where precision and efficiency are paramount. In the automotive sector, these machines are essential for producing components such as seat covers, airbags, and interior linings. Advanced fabric-cutting technology enables manufacturers to achieve intricate designs and shapes with minimal material wastage, reducing costs and enhancing the quality of the final product. Automated cutting systems often incorporate computerized controls and laser technology to ensure each piece is cut with impeccable accuracy. This high level of precision is critical for maintaining consistency in mass production and adhering to the stringent safety and performance standards required in the automotive industry.

Similarly, in the electronics industry, fabric-cutting machines are indispensable for producing items like protective casings, insulation materials, and various wearable electronic components. As the demand for smaller, more complex electronic devices grows, the need for precision-cut fabric parts increases. Cutting machines equipped with laser or ultrasonic technology can handle delicate and intricate patterns without causing fraying or damage to the material. These machines can cut through a variety of fabrics, including those used for flexible circuits and smart textiles, facilitating advancements in the development of innovative electronic products. The ability to produce exact shapes and sizes quickly and efficiently supports the rapid prototyping and production cycles that are common in the fast-paced electronics market.

Cutting machines for fabric, traditionally pivotal in textiles and apparel industries, have found valuable applications within the construction sector. In construction, these machines are employed to precisely cut non-woven fabrics, geotextiles, and other technical textiles that serve critical roles, such as reinforcement layers, moisture barriers, and filtration systems in infrastructure projects. The precision and efficiency of modern cutting machines allow for the customization of materials to fit specific project requirements, ensuring structural integrity and optimizing performance. These fabrics, often treated with various coatings to enhance their durability against environmental factors, benefit from the cutting machine’s ability to handle complex patterns and intricate shapes, ensuring seamless integration into construction designs.

In the realm of energy, cutting machines for fabric are instrumental in the production of materials used in renewable energy technologies. Specific applications include cutting advanced composites and technical fabrics essential for manufacturing wind turbine blades, solar panel covers, and insulation for energy-efficient buildings. These cutting machines ensure that fabrics are prepared with exacting precision, reducing material wastage and enhancing the overall energy efficiency of the production process. Furthermore, as the demand for renewable energy sources grows, the ability to produce high-quality, reliable components quickly and efficiently becomes paramount. The advancement of cutting technology in fabric processing contributes to the overall success and sustainability of energy projects, promoting the use of eco-friendly materials and reducing the environmental footprint of energy production industries.

The industrial equipment industry has seen a robust integration of advanced cutting machines specifically designed for fabric applications. These machines, including laser cutters, die cutters, and automated knife systems, have revolutionized the textile sector by enhancing precision and reducing production time. Laser cutting machines, for instance, employ high-powered lasers to achieve intricate designs, providing unparalleled detail that manual methods cannot attain. Automated knife systems, on the other hand, use sharp blades, often coupled with computerized controls, to deliver precise cuts at a faster rate, minimizing material wastage. The heightened accuracy of these machines not only boosts efficiency but also allows manufacturers to experiment with complex patterns and intricate designs, facilitating innovation and cutting-edge fashion trends.

Such cutting machines are indispensable in various industries beyond fashion, such as automotive, aerospace, and home furnishings. In the automotive sector, fabrics are essential for car interiors, including seats, carpets, and headliners. The precision offered by industrial fabric cutting machines ensures consistent quality and fit, which is crucial for safety and aesthetic purposes. In aerospace, lightweight but durable fabrics are cut for use in aircraft interiors, where accuracy directly impacts both functionality and safety standards. The home furnishings industry also benefits significantly, as these machines enable the mass production of upholstery, draperies, and wall coverings with exact dimensions and designs. The ability to efficiently and accurately cut fabric in diverse applications underscores the transformative role of advanced cutting machines in propelling the industrial equipment industry forward, meeting the stringent demands of quality, speed, and innovation.

Cutting machines for fabric find innovative applications in the medical device industry, significantly enhancing the precision and efficiency of producing medical textiles. These specialized machines are integral in manufacturing a broad array of medical textiles, including surgical gowns, drapes, masks, and wound dressings. The advanced technology embedded in modern cutting machines allows for intricate designs and precise cuts that comply with stringent industry standards. This precision is paramount for ensuring that products are free from defects and meet the necessary sterility and safety requirements. Automated fabric cutting reduces human error, streamlines the production process, and enables mass production with uniform quality, which is critical in medical settings where consistency can impact patient outcomes.

Additionally, cutting machines contribute to the rapid and cost-effective production of customized medical devices. For instance, in the creation of custom orthotic and prosthetic devices, fabric cutting machines can swiftly and accurately cut high-performance textiles tailored to individual patient specifications. This capability supports the growing demand for personalized medical solutions, enhancing patient comfort and treatment effectiveness. Furthermore, advancements in digital cutting technologies, such as laser and CNC cutting, facilitate the incorporation of smart textiles that include embedded sensors and therapeutic functionalities. These innovations highlight the cutting machine’s role in driving the advancement of medical textiles and devices, ultimately contributing to improved healthcare delivery and patient care.

Cutting machines for fabric play a crucial role in both machining and manufacturing applications, acting as pivotal tools in industries ranging from fashion to automotive. In machining, these devices ensure precision and efficiency in the cutting process, transforming raw fabric into specific shapes and sizes required for various products. Modern cutting machines are equipped with advanced technologies, such as computer numerical control (CNC) systems and laser cutting capabilities, which enable highly accurate and repetitive cuts. This precision is vital in high-volume production environments where consistency is key to maintaining quality standards. The integration of automated systems reduces human error, expedites production times, and allows for intricate designs that would be difficult to achieve manually.

In the manufacturing sector, cutting machines for fabric are indispensable for scaling up production while reducing costs. For instance, in the garment industry, automated fabric cutting machines streamline the initial stages of production by swiftly executing complex patterns and maximizing material utilization, thereby minimizing waste. These machines are equally important in the production of non-apparel products such as upholstery, sporting goods, and industrial textiles. Enhanced cutting technologies like waterjet and plasma cutting also cater to specialized applications that demand high precision without compromising the structural integrity of the fabric. By facilitating faster turnaround times and accommodating diverse materials, cutting machines are integral to modern manufacturing processes, driving efficiency and innovation across various industries.

Sure! Below is a list of frequently asked questions (FAQ) and answers for manufacturing cutting machines for fabric quality work from SourcifyChina factory:

Q: What types of fabric cutting machines do you manufacture?

A: SourcifyChina offers a wide range of fabric cutting machines, including manual cutting machines, automated cutting machines, laser cutting machines, and rotary fabric cutters.

Q: Are your cutting machines suitable for all types of fabric?

A: Yes, our cutting machines are designed to handle a diverse range of fabrics including cotton, silk, polyester, nylon, and blended textiles. Specific models might cater to particular fabric types more effectively.

Q: What is the lead time for manufacturing and delivery?

A: The lead time typically ranges between 4 to 8 weeks, depending on the machine model and order volume. Custom orders may require additional time.

Q: Can you customize cutting machines according to our specifications?

A: Yes, we offer customization options to meet your specific needs. Our engineering team works closely with clients to design machines tailored to their requirements.

Q: What are the warranty terms for your cutting machines?

A: We provide a standard one-year warranty for all our fabric cutting machines, covering parts and labor. Extended warranty options are also available upon request.

Q: Do you offer installation and training services?

A: Yes, we provide on-site installation and training services to ensure your team can operate the machines efficiently. Online support and user manuals are also available.

Q: How do you ensure the quality of your cutting machines?

A: Our machines undergo rigorous quality control processes, including real-time operational testing, material assessments, and performance evaluations to ensure they meet industry standards.

Q: What payment methods do you accept?

A: We accept various payment methods including wire transfers, letters of credit, and other secure payment options as agreed upon during the negotiation process.

Q: Can we visit your factory for a tour?

A: Absolutely! We welcome factory visits and are happy to arrange a tour to demonstrate our manufacturing processes and quality assurance protocols.

Q: How do I place an order with SourcifyChina?

A: You can place an order by contacting our sales team directly via email or phone. Our team will guide you through the order process and provide all necessary documentation.

For more detailed information, please contact SourcifyChina’s customer support or visit our official website.

When considering cutting machines for fabric manufacturing from SourcifyChina factory, it’s crucial to focus on several aspects for an optimal selection. Here are some concise tips:

1. Understand Your Needs: Identify the specific type of fabrics and the production volume your operations demand. SourcifyChina offers various machines tailored for different fabrics like cotton, polyester, or denim.

2. Machine Types: Familiarize yourself with the types of cutting machines available. Laser cutters provide high precision, while knife and rotary cutters are suitable for bulk operations. Automatic fabric cutters increase efficiency and reduce manual labor.

3. Customization Options: Check if SourcifyChina offers customizable solutions to match your exact requirements, such as custom blade types or automation levels.

4. Quality and Durability: Evaluate the build quality and durability of the machines. High-quality machines reduce maintenance costs and downtime.

5. Technological Integration: Look for machines with advanced technological features like CAD compatibility, automated pattern recognition, and integrated software solutions for seamless operation.

6. Energy Efficiency: Opt for energy-efficient models to lower operational costs and adhere to sustainable manufacturing practices.

7. Cost and ROI: Balance the initial investment against the long-term return on investment. Sometimes, a higher upfront cost can be justified by increased efficiency and lower running costs.

8. After-Sales Support: Ensure SourcifyChina provides robust after-sales support, including training, maintenance services, and readily available spare parts.

9. Customer Reviews and Testimonials: Research customer feedback and testimonials to gauge the reliability and performance of the machines.

10. Compliance and Warranty: Verify that the machines meet necessary compliance standards and come with a comprehensive warranty for added security.

Careful consideration of these factors will help you select the best cutting machine tailored to your fabric manufacturing needs from SourcifyChina.

Here are some FAQs with answers for sourcing cutting machines for fabric from SourcifyChina factory:

Q1: What types of cutting machines for fabric do you offer?

A1: SourcifyChina factory offers various types of cutting machines including electric fabric cutters, laser cutting machines, manual fabric cutters, and automated CNC fabric cutters. Each type is designed to suit different production needs and fabric types.

Q2: How do I place an order?

A2: Placing an order is simple. Visit our website, browse the product catalog, select the cutting machine you need, and fill out the order form. Alternatively, you can contact our sales team directly through email or phone for assistance.

Q3: What is the lead time for delivery?

A3: The lead time for delivery typically ranges from 2-4 weeks depending on the model and quantity ordered. Customized machines may require additional time. We ensure timely updates on your order status.

Q4: Do you provide warranties for your cutting machines?

A4: Yes, we offer a 1-year warranty for all our cutting machines. This covers manufacturing defects and parts replacement. Extended warranty options are also available.

Q5: Can I request a demo before purchasing a cutting machine?

A5: Absolutely! We offer virtual demos via video calls for our cutting machines. For bulk orders, we can arrange an on-site demonstration at our factory or a client’s facility.

Q6: What are the payment options available?

A6: We accept multiple payment methods including T/T (bank transfer), L/C (Letter of Credit), and PayPal. Detailed payment terms will be provided at the time of order placement.

Q7: Do you provide after-sales support?

A7: Yes, SourcifyChina factory provides comprehensive after-sales support including remote troubleshooting, spare parts supply, and regular maintenance services.

Q8: Can I customize the cutting machine according to my needs?

A8: Yes, our engineering team can customize machines to meet specific requirements such as cutting speed, precision, and automation levels. Share your needs, and we will provide a tailored solution.

These FAQs should help streamline the process of sourcing cutting machines for fabric from SourcifyChina factory.

Sourcing cutting machines for fabric from a reliable supplier like SourcifyChina can be an effective way to ensure quality and cost-efficiency. Here are some tips to streamline the process:

1. Research Thoroughly: Begin by understanding the different types of fabric cutting machines. Knowing whether you need manual, semi-automatic, or fully automatic machines helps narrow down your search.

2. Use Online Platforms: Utilize platforms like Alibaba, Made-in-China, and Global Sources to search for SourcifyChina’s profile. These platforms offer reviews, ratings, and detailed information about suppliers.

3. Direct Contact: Reach out directly through email or contact forms on SourcifyChina’s official website. This allows you to ask specific questions and understand their capabilities better.

4. Check Certifications: Verify that the cutting machines adhere to international standards. Look for ISO certifications and other quality marks that ensure high manufacturing standards.

5. Request Samples: Ask for samples or demo videos of the cutting machines. This can give you a better understanding of the machine’s efficiency, precision, and usability.

6. Ask for References: Contact other businesses that have sourced similar machines from SourcifyChina. Their feedback can provide in-depth insights and help you gauge reliability.

7. Compare Costs: Get quotations from multiple suppliers to ensure competitive pricing. Consider including shipping, taxes, and potential tariffs in the total cost evaluation.

8. Negotiate: Don’t hesitate to negotiate terms, prices, and payment conditions to get the best deal and favorable terms of purchase.

9. Evaluate Support: Ensure the supplier offers after-sales services such as installation, maintenance, and technical support.

10. Visit the Factory: If feasible, plan a visit to SourcifyChina’s factory to inspect the facilities, meet the team, and verify the production standards firsthand.

Following these tips will help ensure a smooth and successful sourcing experience.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.