SourcifyChina Factory offers top-quality rigging and lifting products, ensuring buyers receive reliable and durable equipment. Known for stringent quality control, the factory guarantees that all products meet international standards, providing peace of mind for purchasers.

Cost-efficiency is a significant advantage at SourcifyChina Factory. By sourcing directly, buyers benefit from competitive pricing without compromising product quality, making it a smart financial decision for businesses looking to optimize their budgets.

With extensive industry experience, the SourcifyChina team brings valuable expertise to the table, assisting buyers in selecting the most suitable rigging and lifting solutions for their unique needs, ensuring optimal performance and safety.

SourcifyChina Factory prioritizes customer satisfaction through exceptional service. The dedicated support team is readily available to address queries, offer guidance, and resolve issues, cultivating long-term, trusting relationships with buyers.

Innovative technology and modern manufacturing processes are leveraged at SourcifyChina Factory to produce advanced rigging and lifting equipment, enabling buyers to stay ahead of the competition with cutting-edge solutions.

Timely delivery is a hallmark of SourcifyChina Factory. Understanding the importance of meeting project deadlines, the factory ensures efficient production schedules and swift logistics, contributing to the seamless execution of buyer projects.

In summary, SourcifyChina Factory stands out as the ideal choice for purchasing rigging and lifting equipment from China due to its unwavering commitment to superior quality, cost efficiency, expert guidance, exceptional customer service, technological innovation, and reliable delivery. These factors collectively make SourcifyChina Factory a trusted partner for businesses seeking dependable and advanced lifting solutions.

Rigging and lifting equipment are essential for moving heavy loads safely and efficiently in construction, manufacturing, and logistics. Various tools and techniques are available, each suitable for different applications and weight capacities.

– Slings: Wire rope slings, synthetic web slings, and chain slings.

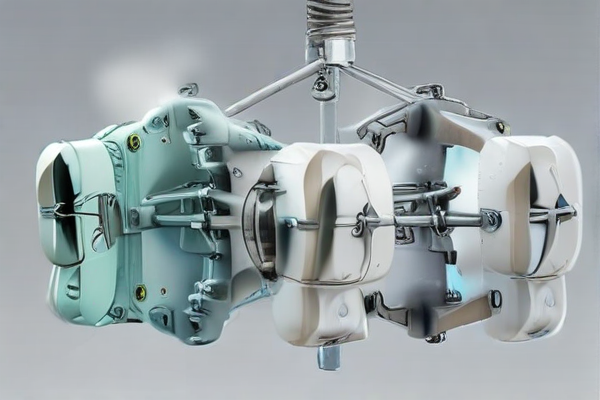

– Hoists: Manual hoists, electric hoists, and pneumatic hoists.

– Cranes: Mobile cranes, tower cranes, and overhead cranes.

– Shackles: Screw pin shackles, bolt-type shackles, and round pin shackles.

– Hooks: Eye hooks, clevis hooks, and swivel hooks.

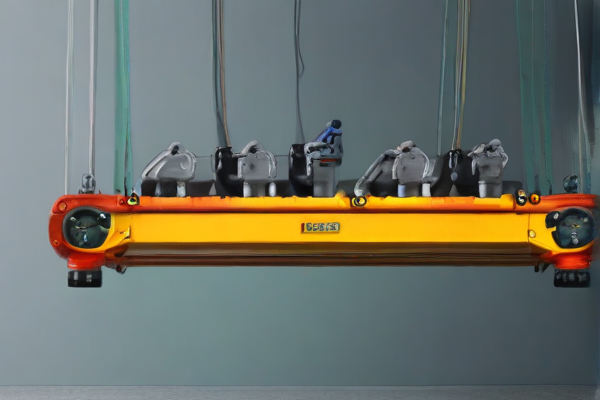

– Lifting Beams and Spreaders: Adjustable lifting beams and spreader bars.

– Winches: Hand winches, electric winches, and hydraulic winches.

– Rigging Hardware: Turnbuckles, thimbles, and eye bolts.

– Load Testing Equipment: Load cells, dynamometers, and tension meters.

– Personal Protective Equipment (PPE): Helmets, gloves, and safety harnesses.

Proper selection and use of rigging and lifting equipment ensure safety, efficiency, and the preservation of both personnel and materials involved in lifting activities.

Rigging and lifting are essential practices in various industries, enabling the safe and efficient handling of heavy materials and equipment. They are critical in maintaining workplace safety and operational efficiency.

– Construction Industry: Erecting structures, installing heavy machinery, and positioning large materials.

– Marine Operations: Moving cargo on and off ships, installing underwater structures.

– Manufacturing: Handling large components, assembly line management.

– Entertainment: Setting up stages, lighting, and sound equipment.

– Mining: Transporting mined materials, maintaining heavy equipment.

– Oil and Gas: Maneuvering drilling equipment, assembling rigs.

– Aerospace: Handling aircraft parts, assembling spacecraft.

– Utilities: Managing powerline installations, maintaining infrastructure.

– Wind Energy: Installing and maintaining wind turbines.

– Forestry: Moving logs, operating heavy machinery.

– Automotive: Lifting and installing engines and other large components.

– Railroad: Track maintenance, handling heavy rail equipment.

– Public Works: Infrastructure projects, bridge maintenance.

– Event Management: Setting up and dismantling event venues.

– Military: Handling heavy equipment, logistical support.

– Agriculture: Moving large farm equipment, handling harvests.

– Aviation: Handling aircraft maintenance, moving heavy equipment.

– Warehousing: Efficient storage and retrieval of heavy goods.

– Healthcare: Moving large medical equipment, hospital construction.

– Research Labs: Installing and moving heavy lab equipment.

SourcifyChina offers a substantial selection of high-quality rigging and lifting materials. These include chains, slings, hooks, and shackles, all designed to endure heavy loads and harsh conditions. Each product is manufactured under strict quality control standards to ensure reliability and safety.

Their rigging equipment, such as wire ropes and turnbuckles, is crafted from durable steel, making them suitable for industrial, maritime, and construction applications. The company’s stainless steel offerings boast excellent resistance to corrosion, extending their lifespan even in marine environments.

Polyester slings are versatile options provided by SourcifyChina, characterized by their lightweight nature and high tensile strength. These slings are resistant to abrasions and chemicals, making them ideal for various lifting operations.

SourcifyChina also prioritizes innovation by integrating modern technologies into their lifting solutions. This incorporation enhances performance and efficiency, ensuring that customers receive the most advanced tools in the market. Additionally, their products are rigorously tested to meet international safety standards, giving clients peace of mind.

The variety and durability of SourcifyChina’s rigging and lifting materials make them a trusted choice for industries requiring reliable and robust equipment. Whether for heavy-duty lifting or precision rigging, their products deliver consistent performance.

SourcifyChina’s rigging and lifting quality control process is implemented meticulously to ensure safety and reliability. Each step is carefully monitored, beginning with the selection of high-quality raw materials. This selection process involves rigorous testing to confirm that only the best materials are used, ensuring durability and strength.

Once materials are approved, the manufacturing process involves precision engineering and strict adherence to industry regulations. Specialized machinery and skilled technicians work in tandem to create components that meet exact specifications and standards. Each stage is scrutinized to avoid any discrepancies.

Post-production, a series of inspections are conducted. These include stress tests, load-bearing assessments, and visual examinations to identify potential faults or weaknesses. The products undergo non-destructive testing methods to ensure integrity without causing damage.

Finally, products are subjected to random sampling and third-party audits to validate internal quality control measures. These additional checks fortify the reliability of the rigging and lifting equipment. The products are then packaged and labeled with detailed information for traceability.

By maintaining a thorough and diligent quality control process, SourcifyChina guarantees that their rigging and lifting products meet the highest safety standards. This comprehensive approach ensures customer satisfaction and long-term trust in their brand.

SourcifyChina excels in providing top-tier rigging and lifting solutions for diverse industries. Their range of services includes customized equipment for material handling, ensuring safety and efficiency.

Highly skilled in the design and fabrication of lifting gear, SourcifyChina offers robust and durable equipment. Each product undergoes rigorous testing to meet international safety standards.

The company’s commitment to quality extends to its comprehensive training programs. These programs ensure that personnel can operate lifting equipment safely and effectively, minimizing workplace accidents.

SourcifyChina also offers personalized consultation services. Their experts work closely with clients to develop tailored solutions that meet specific project requirements.

A cornerstone of SourcifyChina’s service is their 24/7 customer support. This includes maintenance services, ensuring minimal downtime and continuous operation for their clients’ businesses.

Rigging and lifting play a crucial role in various industries, enhancing safety, efficiency, and productivity. Properly executed, these practices ensure secure handling of heavy loads.

– Increased Safety: Rigging and lifting minimize the risk of accidents by using proper techniques and equipment.

– Enhanced Productivity: Efficient load handling reduces downtime and accelerates project timelines.

– Cost-Effectiveness: Preventing damages to materials and equipment lowers repair and replacement costs.

– Precision: Facilitates the precise installation of components, essential for projects requiring exact placement.

– Versatility: Applicable in diverse industries such as construction, manufacturing, and shipping.

– Compliance: Meets regulatory standards, ensuring business operations remain lawful.

– Skill Development: Training in rigging and lifting builds workforce competence and confidence.

Features of Rigging and Lifting

Rigging and lifting are vital operations in various industries, ensuring the safe transportation and placement of heavy loads. Key features to consider include safety, efficiency, and equipment durability.

– Safety: Ensuring the safety of both personnel and materials is paramount. This involves proper training and adherence to safety regulations.

– Efficiency: Streamlined processes and well-maintained equipment increase operational efficiency and reduce downtime.

– Equipment Variety: A wide range of tools such as slings, shackles, and lifting beams are available to suit different tasks.

– Durability: Using robust and high-quality materials extends the lifespan of rigging equipment, ensuring reliable performance.

– Load Capacity: It’s crucial to know the load limits of rigging and lifting gear to avoid overloading, which can lead to accidents.

– Inspection and Maintenance: Regular checks and maintenance help in early detection of wear and tear, preventing failures.

– Flexibility: Modular and adaptable equipment designs ensure that rigging solutions can be customized for various applications.

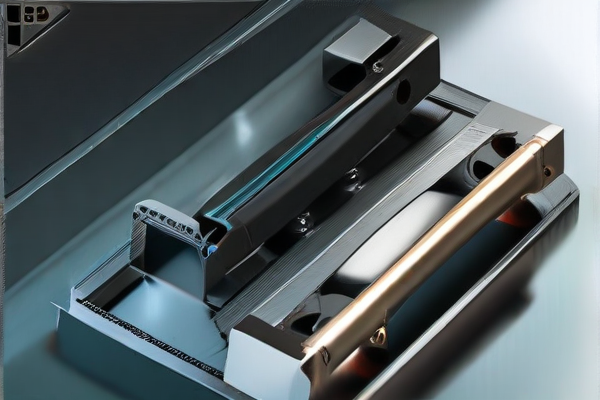

– Control Systems: Advanced control systems like remote-operated cranes offer enhanced precision and safety.

– Compliance: Equipment and processes must comply with industry standards and regulatory requirements for safety and quality.

– Versatility: Capable of handling a wide range of materials and shapes, making the process widely applicable across different sectors.

– Ergonomics: Equipment designed with user comfort in mind reduces the risk of operator fatigue and injury.

In summary, the effectiveness of rigging and lifting operations hinges on a combination of robust equipment, trained personnel, and stringent safety protocols, ensuring safe and efficient load handling.

SourcifyChina specializes in providing high-quality rigging and lifting custom products tailored to meet the specific needs of various industrial sectors. Their extensive range of offerings ensures reliable and safe lifting solutions for any project requirements.

The company excels in fabricating custom lifting equipment such as slings, lifting hooks, and chain hoists, ensuring each product meets rigorous safety standards. Their expert team works closely with clients to design and manufacture products that align perfectly with project demands.

In addition to manufacturing, SourcifyChina focuses on customized project services. They provide end-to-end project management, including initial consultation, product design, and implementation, ensuring seamless project execution.

SourcifyChina’s commitment to quality and safety is evident in their meticulous attention to detail. Each product undergoes comprehensive inspection and testing processes, guaranteeing clients receive dependable and durable lifting solutions.

Furthermore, SourcifyChina’s global supply chain enables them to deliver custom rigging and lifting products on time and within budget. They leverage advanced manufacturing technologies and materials to offer competitive pricing without compromising on quality.

Clients from diverse industries, including construction, maritime, and heavy machinery, trust SourcifyChina for their customized rigging and lifting needs. The company’s reputation for excellence and client-centric approach drives their success in delivering tailor-made solutions that enhance operational efficiency.

Overall, SourcifyChina stands as a premier partner for all rigging and lifting requirements, combining technical expertise with customized services to support complex projects. Through their dedication to innovation and quality, they continue to set industry benchmarks, ensuring client satisfaction and operational safety in every endeavor.

SourcifyChina Rigging and Lifting is a reputable company dedicated to delivering high-quality rigging and lifting solutions tailored for a diverse range of industries. Specializing in providing both standard and custom rigging equipment, the company is known for its meticulous attention to safety standards and robust product reliability. SourcifyChina integrates advanced manufacturing techniques with rigorous quality control processes to produce equipment that can withstand the most challenging environments. Their extensive product lineup includes wire ropes, lifting slings, chain hoists, and load binders, each designed to meet the exacting demands of their clients. Beyond just supplying hardware, the company prides itself on exceptional customer service, offering comprehensive consultation services to ensure each client selects the right tools for their unique lifting and rigging needs. With a commitment to innovation and continuous improvement, SourcifyChina Rigging and Lifting has established itself as a trusted partner for industries including construction, logistics, marine, and engineering, making lifting operations safer and more efficient worldwide.

In the Aerospace industry, rigging and lifting technologies play a crucial role in the efficient assembly, maintenance, and transportation of aircraft components. Precision and safety are of paramount importance when dealing with large, often delicate parts such as fuselages, wings, and engines. Advanced lifting systems such as gantry cranes, hydraulic lifts, and specialized rigging hardware enable technicians to maneuver these components accurately within production facilities and during maintenance procedures. Composite materials, increasingly used in modern aircraft, demand specialized rigging approaches to prevent damage. These equipment and techniques ensure not only the integrity of high-value components but also the safety of personnel, ultimately contributing to streamlined operations and reduced downtime.

In the Defense sector, rigging and lifting solutions are indispensable for the handling of heavy and complex equipment such as tanks, missiles, and support vehicles. These operations are often conducted under challenging and time-sensitive conditions, emphasizing the need for reliable and robust lifting systems. Mobile cranes, hoists, and tailored rigging assemblies are commonly used to deploy and retrieve equipment during military operations. Furthermore, the advent of advanced rigging technologies has enabled more efficient logistics and transportation of defense apparatus across various terrains and environments. Similarly, in Marine applications, the deployment and recovery of maritime assets such as ships, submarines, and offshore structures depend heavily on sophisticated rigging and lifting equipment. This includes shipyard cranes, winches, and dynamic positioning systems, which facilitate the precise handling of massive structures, ensuring operational efficacy and safety in often volatile marine conditions. Thus, in Aerospace, Defense, and Marine fields, rigging and lifting are fundamental to operational success and technological advancement.

The automotive industry relies heavily on rigging and lifting techniques to streamline the manufacturing and maintenance processes. During assembly, large and heavy components such as engines, transmissions, and car bodies must be precisely positioned and secured. Rigging, which involves the use of ropes, cables, and lifting gear, plays a crucial role in ensuring these components are moved safely and accurately. Advanced lifting equipment like hydraulic lifts, cranes, and automated guided vehicles (AGVs) facilitate the efficient transportation and installation of parts. This precision is vital for maintaining the integrity and performance of vehicles. Furthermore, rigging and lifting systems contribute significantly to the automotive supply chain, enabling the swift handling of heavy raw materials and aiding in the efficient movement of goods through various production stages.

In the electronics sector, rigging and lifting applications are equally essential, particularly in the fabrication and installation of large-scale equipment such as semiconductor manufacturing machinery, server racks, and data center hardware. Given the delicate nature of electronic components and the stringent cleanroom standards required in semiconductor fabrication facilities, rigging tasks demand an exceptional degree of precision and care. Specialized lifting equipment like cleanroom-compatible cranes and fine-motion control hoists are employed to move sensitive devices without causing damage or contamination. Additionally, rigging solutions are deployed to handle substantial yet delicate electronic assemblies in environments like data centers, where server racks and other IT infrastructure components must be securely installed and maintained. Ensuring the safe and efficient relocation of these critical assets is essential to minimizing downtime and maintaining operational continuity.

Rigging and lifting are essential operations in the construction industry, providing the means to safely and efficiently move heavy materials and equipment. These practices involve the use of specialized machinery such as cranes, hoists, and derricks alongside accessory tools like slings, shackles, and chains. The proper execution of rigging and lifting ensures that large beams, concrete sections, and prefabricated structures can be positioned with precision during building processes. Utilizing experienced riggers and adopting stringent safety protocols diminishes the risk of accidents, ensuring both worker safety and structural integrity. Moreover, advancements in lifting technology, including the integration of remote control systems and enhanced load indicators, have significantly improved the efficacy and safety of these operations, contributing to the progress and complexity of modern construction projects.

In the energy sector, rigging and lifting play a pivotal role in the installation, maintenance, and decommissioning of infrastructure such as wind turbines, solar panels, and oil rigs. The transportation and positioning of heavy components, such as nacelles, rotor blades, and subsea equipment, require meticulous planning and execution. For renewable energy installations like wind farms, these processes are critical to achieving precise alignment and optimal functionality of energy-generating units. Similarly, in the oil and gas industry, heavy lifting operations are crucial for the installation of pipelines and refinery components. The adoption of advanced rigging techniques and lifting equipment ensures not only operational efficiency but also compliance with stringent environmental and safety regulations. The ability to maneuver and position extremely heavy and unwieldy components with precision supports the expansion and sustainability of energy infrastructures globally.

The industrial equipment industry consistently relies on rigging and lifting techniques to ensure the safe and efficient transport, installation, and maintenance of heavy machinery. Rigging involves the use of specialized equipment, such as ropes, chains, and slings, to secure loads for movement. This essential practice ensures that massive components—ranging from turbines and transformers to complex assembly line machinery—are precisely positioned without causing damage or posing safety hazards. Lifting complements rigging by utilizing hoists, cranes, and other mechanical devices to elevate and move these hefty loads. Proper training and adherence to safety protocols are critical, as any misstep can result in significant operational setbacks and potential injury.

In the application of these techniques, the industrial equipment sector employs advanced equipment and skilled professionals to address increasingly sophisticated demands. For instance, custom-engineered cranes and automated rigging systems are now prevalent in factories and construction sites, delivering precision and reducing human error. Additionally, the integration of IoT (Internet of Things) technology allows for real-time monitoring of load weights, stress on rigging components, and equipment positioning, further enhancing safety and efficiency. This technological advancement is particularly crucial for industries such as oil and gas, manufacturing, and construction, where the margin for error is minimal. Through continuous improvement in rigging and lifting methodologies, the industrial equipment industry not only boosts productivity but also ensures the well-being of its workforce and the longevity of its machinery.

Medical devices, particularly those that are large, sophisticated, and precision-engineered, often require meticulous handling during transportation, installation, and maintenance to ensure their functionality and safety. “Rigging and lifting” are crucial processes in this context, involving the use of specialized equipment and techniques to move these devices securely and accurately. For instance, Magnetic Resonance Imaging (MRI) machines, patient monitors, and surgical robots are not only hefty but also incredibly delicate, necessitating the use of cranes, hoists, and other rigging apparatuses capable of gently yet steadily maneuvering them into place. This precision is paramount to avoid any potential damage that could compromise the device’s effectiveness or safety, impacting patient care and operational efficiency within healthcare facilities.

In addition to ensuring physical safety, rigging and lifting operations for medical devices must adhere to stringent regulatory and safety standards to mitigate risks. Technicians and engineers involved must be highly trained in both the operation of lifting equipment and the specifics of the medical devices being handled. These professionals often rely on detailed planning, including load calculations, ground condition assessments, and customized rigging solutions tailored to the unique dimensions and sensitivities of the equipment. This holistic approach ensures that the devices are not only moved safely but are also precisely positioned for optimal function. Ultimately, effective rigging and lifting practices are fundamental in the lifecycle of medical devices, from initial deployment to periodic maintenance and eventual replacement, safeguarding the investment in technology and, more importantly, patient health outcomes.

In the intricate world of machining and manufacturing, “rigging and lifting” play a pivotal role in ensuring the efficient and safe handling of heavy machinery and materials. Rigorous precision is necessary when positioning and assembling large components such as metal workpieces, dies, and molds. Advanced rigging techniques, which include the use of slings, shackles, and hoists, are essential for maneuvering these heavy parts into place without causing damage or misalignment. Proper rigging ensures that machinery is installed and maintained correctly, minimizing downtime and preserving the integrity of both the equipment and the work environment. Consequently, skilled riggers and operators are indispensable in this sector, as they possess the expertise to implement these complex procedures safely and effectively.

In addition to installation, rigging and lifting are crucial during the transportation phase within the manufacturing process. Efficient materials handling incorporates the strategic use of cranes, forklifts, and automated guided vehicles (AGVs) to move substantial loads of raw materials or finished goods through various stages of production. This careful orchestration not only aids in maintaining a continuous workflow but also reduces the risk of accidents and injuries associated with manual handling of heavy items. Furthermore, the integration of advanced technologies such as sensors and IoT in lifting equipment enhances precision and safety, providing real-time data to monitor load conditions. Thus, the role of rigging and lifting transcends mere logistics, underpinning the operational efficiency and safety that are critical to the success of machining and manufacturing industries.

FAQs for Manufacturing Rigging and Lifting Quality Work from SourcifyChina Factory

1. What certifications does SourcifyChina factory hold for quality assurance?

SourcifyChina factory is ISO 9001 certified, ensuring that our manufacturing processes meet the highest quality standards. We also comply with other industry-specific certifications like ASME and OSHA for rigging and lifting equipment.

2. How can I ensure the durability of the rigging and lifting equipment?

Our products undergo rigorous testing, including load tests, fatigue tests, and material strength assessments. Each batch is inspected to meet high durability standards, ensuring extended service life.

3. What materials are used in your rigging and lifting equipment?

We use high-grade steel, alloys, and synthetic materials designed to offer robustness and reliability. Materials are selected based on the specific requirements of the equipment to ensure performance in demanding environments.

4. Can SourcifyChina factory customize rigging and lifting solutions?

Absolutely! We offer customized solutions tailored to your specific needs. Our experienced engineers work closely with clients to design and manufacture equipment that meets unique operational requirements.

5. What is the average lead time for orders?

Lead times vary depending on the complexity and quantity of the order. Typically, standard equipment orders are fulfilled within 4-6 weeks, while custom projects may require 8-12 weeks.

6. How do you ensure product safety and compliance?

Safety is our top priority. Our products adhere to international safety standards and undergo multiple inspections and tests during the production process. Detailed documentation, including safety manuals and compliance certificates, is provided with each order.

7. What after-sales services do you offer?

We offer comprehensive after-sales support, including installation assistance, maintenance services, and training programs. Our customer service team is available to provide technical support and address any issues promptly.

8. How can I place an order or request a quote?

You can easily place an order or request a quote through our website, via email, or by contacting our sales team directly. Provide us with your specifications, and we will get back to you with a tailored solution.

9. Are there any bulk order discounts?

Yes, we offer competitive pricing and discounts for bulk orders. Contact our sales team to discuss your requirements and benefit from our attractive pricing structure.

When working with the SourcifyChina factory for rigging and lifting manufacturing, here are a few essential tips to ensure a smooth and efficient process:

1. Clearly Define Requirements: Specify your exact needs, including dimensions, load capacities, materials, and safety standards. Precise communication helps avoid misunderstandings and ensures the final product meets your expectations.

2. Quality Check: Perform thorough inspections and require certifications like ISO or CE to ensure quality and safety standards. Request sample products to assess craftsmanship and durability before bulk production.

3. Cost Estimation: Get a detailed breakdown of costs, including materials, labor, shipping, and any additional services. This helps avoid unexpected expenses and allows for better budgeting.

4. Lead Time and Delivery: Establish a clear timeline from production to delivery. Factor in potential delays and communicate regularly with the factory to stay updated on progress.

5. Supplier Relationship: Build a strong rapport with your factory contact. Cultivating a good working relationship can facilitate smoother negotiations, faster problem resolution, and priority treatment in urgent situations.

6. Compliance and Safety: Ensure the factory adheres to all relevant safety regulations and standards. Verify that products are tested for load-bearing capacity and stability.

7. Contract Detailing: Draft a detailed contract outlining terms of service, quality standards, delivery schedules, payment terms, and dispute resolution mechanisms. This provides legal protection and sets clear expectations.

8. Continuous Improvement: After initial orders, review performance and gather feedback. Use this information to make adjustments and improve future production runs.

By following these tips, you can optimize your rigging and lifting manufacturing process with SourcifyChina, ensuring high-quality products and reliable service.

Frequently Asked Questions (FAQ) for Sourcing Rigging and Lifting Equipment from SourcifyChina Factory

Q1: What types of rigging and lifting equipment do you provide?

A1: SourcifyChina offers a wide range of rigging and lifting equipment, including shackles, hooks, slings, chains, hoists, pulleys, and load binders. Our products are designed to meet international safety standards.

Q2: Can you customize the products according to our specifications?

A2: Yes, we offer customization services to meet your specific requirements. You can provide detailed specifications, including dimensions, materials, and load capacities, and we will manufacture accordingly.

Q3: What are the minimum order quantities (MOQs) for your products?

A3: The MOQ varies depending on the product type. Generally, our MOQs are designed to be flexible to accommodate different business needs. For precise information, please contact our sales team.

Q4: How do you ensure the quality of your rigging and lifting equipment?

A4: Quality assurance is paramount at SourcifyChina. We adhere to strict quality control procedures, from raw material procurement to final product inspection. Our equipment undergoes rigorous testing to ensure safety and reliability.

Q5: What is your lead time for large orders?

A5: Lead times depend on the size and complexity of the order. However, for standard products, the typical lead time is about 4-6 weeks. For customized orders, additional time may be required. Please consult our team for specific timelines.

Q6: Do you provide samples before placing a bulk order?

A6: Yes, we provide samples so you can evaluate the quality before committing to a bulk order. Sample costs can often be credited against your first bulk order.

Q7: What are your payment terms?

A7: Our payment terms are flexible and typically include options such as T/T (Telegraphic Transfer), L/C (Letter of Credit), and other secure payment methods. Specific terms can be discussed to best suit your needs.

Q8: How do you handle shipping and logistics?

A8: SourcifyChina partners with reputable logistics companies to ensure safe and timely delivery of your orders. We handle all aspects of shipping, including export documentation, customs clearance, and transportation.

Q9: Do you offer after-sales support?

Sourcing “rigging and lifting” equipment from SourcifyChina factory can offer quality advantages and cost savings. Here are some tips to ensure a smooth and efficient process:

1. Research and Verify: Conduct thorough research about the factory, including reading reviews, verifying credentials, and checking for relevant certifications to ensure they meet industry standards.

2. Clear Requirements: Clearly outline your specifications and requirements, including material quality, load capacity, dimensions, and any specific regulations the equipment must adhere to.

3. Samples and Prototypes: Request samples or prototypes to evaluate the quality firsthand. This can prevent any surprises when the bulk order arrives.

4. Quality Assurance: Ensure the factory has robust quality control processes. Ask for details about their quality assurance steps and inspection reports for the products.

5. Negotiation and Pricing: Negotiate pricing, but be wary of prices that are significantly lower than the market rate as this can indicate compromised quality. Discuss payment terms and conditions in advance.

6. Visit the Factory: If possible, visit SourcifyChina’s factory to inspect their facilities, meet the team, and understand their production capabilities.

7. Logistics and Shipping: Discuss logistics early on, including shipping methods, delivery timelines, and any potential customs issues. Having a reliable logistics plan is essential.

8. Contracts and Agreements: Draft a clear contract that outlines all terms, including product specifications, delivery schedules, payment terms, and warranty or after-sales service.

9. Communication: Maintain regular communication to stay updated on the production process and address any issues promptly. Use clear channels for communication and consider employing someone who speaks the local language if necessary.

10. Building Relationships: Developing a good relationship with the supplier can lead to better service, potential discounts, and reliability in the long term.

By following these steps, you can ensure a seamless sourcing process for rigging and lifting equipment from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.