Choosing SourcifyChina Factory for purchasing pipe manufacturers from China ensures reliability and quality. With extensive industry experience, they have established a robust network of vetted manufacturers, guaranteeing top-tier products and competitive pricing.

Their professional team manages the entire procurement process, from sourcing and negotiation to quality control and logistics, simplifying complex supply chain challenges. SourcifyChina places a strong emphasis on transparency and communication, keeping buyers informed at every stage and fostering trustful, long-term business relationships.

Additionally, SourcifyChina offers tailored solutions to meet diverse buyer specifications, ensuring that the provided products align perfectly with client needs and standards. Their stringent quality assurance protocols minimize risks and deliver superior products consistently.

In conclusion, SourcifyChina stands out as an ideal partner for sourcing pipes from China due to their comprehensive services, industry expertise, and commitment to quality and customer satisfaction. Whether you’re large-scale or small-scale, they deliver efficient and effective solutions, streamlining the procurement process for a seamless experience.

Pipe manufacturers offer a diverse range of pipes designed for various applications, including industrial, residential, and commercial uses. They produce pipes using materials like steel, PVC, HDPE, and copper to cater to different requirements.

– Steel Pipes: Durable, typically used in construction and industrial applications.

– PVC Pipes: Lightweight, corrosion-resistant, ideal for plumbing and drainage systems.

– HDPE Pipes: Flexible and durable, suitable for irrigation and gas distribution.

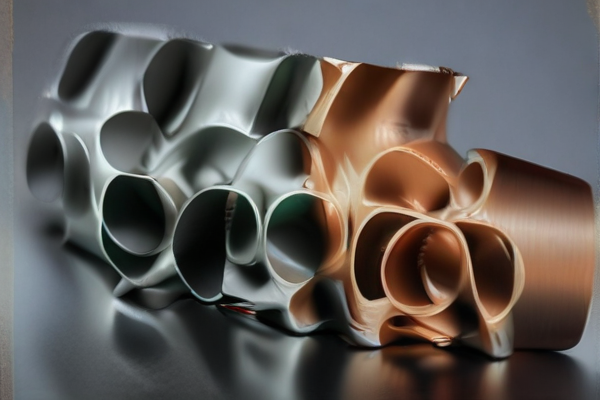

– Copper Pipes: High thermal conductivity, often used in heating and cooling systems.

– Ductile Iron Pipes: Strong and resilient, commonly used in water and sewage systems.

– CPVC Pipes: Chlorinated for higher temperature resistance, used for hot water pipes.

– Stainless Steel Pipes: Corrosion-resistant, utilized in chemical industry and food processing.

– Concrete Pipes: Heavy-duty, used in large-scale drainage and sewerage infrastructure.

Each type offers specific advantages tailored to different environmental and usage conditions. Given the wide array of choices, selecting the right pipe material and type is crucial for optimizing performance and longevity in any given project.

Pipe manufacturers play a crucial role in various industries, providing essential materials for construction, infrastructure, and utilities. Their products are indispensable for numerous applications, ensuring efficient fluid and gas transportation.

– Construction: Pipes are used in residential, commercial, and industrial buildings for plumbing, HVAC systems, and drainage.

– Oil and Gas: Pipelines transport crude oil, natural gas, and petroleum products across vast distances.

– Water Supply and Treatment: Pipes are integral for potable water distribution and wastewater management systems.

– Agriculture: Irrigation systems rely heavily on pipes for water distribution to crops.

– Chemical Processing: Specialized pipes handle the transfer of reactive or hazardous chemicals safely.

– Power Generation: Steam and cooling water pipes are essential in thermal power plants.

– Telecommunication: Conduits protect cables and fiber optics, facilitating secure data transmission.

– Food and Beverage: Sanitary pipes are crucial for the hygienic transfer of liquids and gases in production processes.

– Fire Protection: Sprinkler systems rely on durable pipes to ensure safety in case of fires.

– Marine Industry: Pipes are used in shipbuilding for operational systems like ballast, fuel, and water.

– Automotive Industry: Fuel, brake, and hydraulic fluid lines in vehicles depend on high-quality pipes.

– Geothermal Systems: Pipes facilitate the transfer of thermal energy in heating and cooling applications.

– Renewable Energy: Piping systems are essential in solar, wind, and bioenergy installations.

– Pharmaceuticals: These industries require high-purity piping for processing and manufacturing.

– Mining: Pipes transport slurry, tailings, and process water in mining operations.

Overall, pipe manufacturers serve a diverse range of applications, providing the backbone for essential infrastructure and industry operations.

SourcifyChina is committed to delivering high-quality piping solutions, meticulously crafted from premium materials. Leading pipe manufacturers in China use a variety of materials tailored to specific applications, ensuring durability and performance. Predominantly, stainless steel is a popular choice because of its superior resistance to corrosion and ability to withstand high pressures and temperatures.

Furthermore, PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride) are frequently utilized for their lightweight and cost-effectiveness in non-corrosive and low-pressure environments. These materials are extensively used in residential plumbing, irrigation systems, and in the chemical industry due to their affordable and flexible properties.

Copper pipes, another material commonly used by SourcifyChina’s manufacturers, offer excellent thermal conductivity and corrosion resistance. These are especially favored in hot water supply systems and HVAC (Heating, Ventilation, and Air Conditioning) applications, ensuring reliable and efficient performance over time.

Lastly, carbon steel pipes are chosen for their robust strength and ability to handle high-pressure applications. These pipes are crucial in the oil and gas industry, water supply systems, and industrial processes. The variety of materials employed by SourcifyChina’s manufacturers guarantees customized solutions that meet diverse industry needs, combining reliability, efficiency, and cost-effectiveness.

SourcifyChina pipe manufacturers adhere to stringent quality control processes from raw material selection to final product inspection. They ensure all materials meet industry standards to guarantee durability and performance.

During production, advanced machinery and technology are employed to maintain precise measurements and consistent quality. Skilled technicians oversee each step, minimizing errors and ensuring the highest production standards.

Regular inspections and tests, including pressure tests and chemical analysis, are conducted to verify product integrity and compliance with specifications. These rigorous tests help in identifying and rectifying defects promptly.

The final quality control stage involves thorough inspections and certifications from third-party organizations. These certifications validate that the pipes meet both national and international standards, ensuring reliability and safety.

In conclusion, SourcifyChina’s meticulous quality control in their pipe manufacturing process ensures that every product meets rigorous standards. This commitment to quality ensures long-lasting, dependable pipes suitable for various applications.

SourcifyChina pipe manufacturers specialize in a wide range of piping solutions, catering to diverse industries including construction, plumbing, and oil and gas. Their versatile product line includes steel, PVC, copper, and HDPE pipes, meeting various industry standards and specifications.

Advanced manufacturing facilities and cutting-edge technology enable these manufacturers to produce high-quality and durable pipes. Their production processes adhere strictly to international certifications, ensuring that the products are reliable and suitable for both domestic and global markets.

Expert teams of engineers and technicians at SourcifyChina ensure that each pipe is crafted with precision. Continuous research and development efforts foster innovation, further enhancing product performance and durability, so they can withstand demanding environments and applications.

In addition to producing top-notch pipes, SourcifyChina manufacturers offer customized solutions to meet specific client requirements. Flexible production lines allow them to handle large orders with ease, while also accommodating smaller, more specialized needs with the same level of commitment and quality control.

Dedicated customer support is a hallmark of SourcifyChina pipe manufacturers. They provide pre-sale consulting and post-sale technical assistance to ensure that clients receive the best possible service. This approach builds long-term relationships and ensures client satisfaction on every project.

Ultimately, SourcifyChina pipe manufacturers excel through a combination of state-of-the-art technology, stringent quality management, and exceptional customer service. Their comprehensive capabilities make them a preferred choice for businesses seeking reliable piping solutions on a global scale.

Pipe manufacturers play a crucial role in various industries by providing essential components for infrastructure, construction, and fluid transport systems.

Key Benefits:

– Quality Assurance: Pipe manufacturers adhere to stringent quality control standards, ensuring durable and reliable products.

– Customization: They offer custom solutions tailored to specific project requirements, meeting unique needs.

– Efficiency: Advanced manufacturing techniques enhance production efficiency and reduce lead times.

– Compliance: Manufacturers ensure pipes meet regulatory and safety standards, minimizing risks.

– Innovation: Continuous research and development lead to innovative products with enhanced performance.

– Cost-effectiveness: Competitive pricing and bulk production lower overall costs.

– Sustainability: Many manufacturers are adopting eco-friendly materials and processes to reduce environmental impact.

– Support and Services: Comprehensive customer support, including technical assistance and after-sales service.

– Global Reach: Established manufacturers often have a wide distribution network, ensuring product availability worldwide.

Pipe manufacturers offer a range of specialized features to meet the needs of diverse industries. They provide tailored solutions, high-quality materials, and ensure strict compliance with industry standards.

– Material Variety: Available in various materials like steel, PVC, and copper.

– Customization: Capable of producing pipes to precise specifications, including diameter, length, and material composition.

– Quality Assurance: Stringent quality checks, including pressure testing and corrosion resistance.

– Advanced Technology: Utilization of modern machinery and techniques for efficient production.

– Industry Standards Compliance: Adherence to international benchmarks, such as ISO, ASTM, and ANSI.

– Inventory Management: Strong supply chain management to ensure timely availability of products.

– Sustainability: Commitment to environmentally friendly practices and materials.

– Customer Support: Comprehensive technical assistance and after-sales service.

– Logistics: Robust distribution network for timely delivery.

– Cost-Effectiveness: Competitive pricing without compromising on quality.

These features collectively make pipe manufacturers reliable partners in numerous industrial applications, from plumbing and construction to oil and gas extraction.

SourcifyChina is renowned for connecting clients with reliable and efficient pipe manufacturers in China. Offering an extensive range of custom products, they ensure each item meets industry standards and specific customer requirements.

Their custom products include various types of pipes such as stainless steel, PVC, and galvanized options. Each product is crafted to ensure durability and high performance in numerous applications, from residential plumbing to large-scale industrial projects.

SourcifyChina’s commitment to collaboration ensures that every custom design and request is met with precision. Their expertise in project management allows clients to enjoy seamless execution, from initial consultation to final delivery.

By leveraging advanced manufacturing techniques and rigorous quality control, SourcifyChina ensures that their custom pipes not only meet but exceed clients’ expectations. They prioritize innovation and efficiency to stay ahead in the competitive market.

In conclusion, SourcifyChina excels in providing top-tier custom pipe solutions tailored to diverse project needs. With a focus on quality, innovation, and client satisfaction, they continue to be a trusted partner for businesses worldwide.

SourcifyChina Pipe Manufacturers is a leading industrial entity based in China, specializing in the production and supply of high-quality piping solutions. Renowned for their extensive range of products, SourcifyChina offers a diverse selection of pipes, including PVC, steel, and HDPE pipes, catering to various sectors such as construction, water supply, and oil & gas industries. The company prides itself on employing state-of-the-art manufacturing processes and stringent quality control measures to ensure that each pipe meets international standards. By leveraging advanced technology and a team of skilled professionals, SourcifyChina ensures durability, consistency, and performance in their piping solutions. Their robust supply chain and logistics network enable them to efficiently deliver products worldwide, maintaining timely delivery schedules. Committed to sustainability, SourcifyChina incorporates eco-friendly practices and materials in their production processes, striving to reduce environmental impact. With a customer-centric approach, they offer personalized solutions and exceptional after-sales support, building long-term relationships with clients. SourcifyChina Pipe Manufacturers stands as a trusted partner for infrastructure projects globally, underpinned by their dedication to quality, innovation, and customer satisfaction.

Pipe manufacturers play a pivotal role in the aerospace industry, where precision and reliability are paramount. Aerospace applications often require pipes that can withstand extreme temperatures, pressure variations, and chemical exposure. These pipes are integral to systems such as fuel lines, hydraulic systems, and cooling networks. Advanced materials like titanium, Inconel, and specialized stainless steels are commonly employed to meet stringent aerospace standards. The pipes must also be lightweight to contribute to fuel efficiency while maintaining structural integrity. Manufacturers achieve this balance through cutting-edge fabrication techniques, ensuring that every pipe meets rigorous specifications for safety and performance.

In the defense and marine sectors, pipe manufacturers provide essential components that ensure the operational effectiveness and safety of naval vessels, submarines, and military vehicles. Defense applications demand pipes that can handle high-pressure scenarios, resist corrosion from seawater, and endure physical impacts. In submarines, for example, pipes must perform reliably under immense underwater pressure and in varying thermal conditions. Similarly, military ground vehicles and aircraft systems utilize robust piping to transport fuel, lubricants, and hydraulic fluids, ensuring the proper functioning of critical systems. In marine settings, pipes made from corrosion-resistant alloys like duplex stainless steel are crucial, as they help prevent leaks and system failures that could compromise the mission or the vessel’s safety. Therefore, the expertise and technology that pipe manufacturers bring to these industries are indispensable for maintaining the integrity and effectiveness of aerospace, defense, and marine operations.

Pipe manufacturers play a crucial role in the automotive industry by providing essential components that contribute to the durability and efficiency of vehicles. Pipes are used for a myriad of applications in vehicles, such as exhaust systems, cooling systems, and fuel lines. The materials chosen, be they stainless steel, aluminum, or high-strength plastics, must withstand extreme temperatures and corrosive environments to ensure the longevity and performance of the vehicle. For instance, exhaust pipes must manage high-temperature gases and resist corrosion, while fuel lines must be capable of withstanding both internal pressure and potential chemical erosion. These requirements necessitate precise engineering and high-quality manufacturing standards, making reliable pipe manufacturers indispensable to automotive OEMs (original equipment manufacturers) and suppliers.

In the electronics sector, pipe manufacturers provide vital components that aid in the protection and management of intricate wiring and hardware systems. Various types of piping solutions, including conduits, trunking, and protective sleeves, ensure the secure and organized distribution of electrical cables and fiber optics. These pipes must offer flexibility, electrical insulation, and resistance to environmental factors such as moisture, heat, and even electromagnetic interference. In complex environments like data centers or industrial settings, the reliability of these protective enclosures enhances system integrity and reduces the risk of operational failures. High-quality, precisely manufactured pipes streamline installation processes, boost safety, and improve the overall efficiency of electronic systems, underlining the importance of pipe manufacturers in the ever-evolving electronics landscape.

Pipe manufacturers play a critical role in the construction industry by providing high-quality piping solutions that ensure the durability and reliability of various structures. In construction, pipes are essential for both residential and commercial buildings, serving as conduits for water supply, drainage systems, and even natural gas. The accuracy and quality of these pipes directly impact the safety and efficiency of these systems. Advanced manufacturing techniques, such as seamless and welded processes, as well as the use of materials like PVC, copper, and steel, allow pipe manufacturers to meet rigorous industry standards. With the increasing demand for sustainable construction practices, manufacturers are also innovating to produce eco-friendly piping solutions that reduce environmental impact while maintaining structural integrity.

In the realm of energy, pipe manufacturers are indispensable, particularly in the oil and gas sectors, where the reliability of transport pipelines is crucial. These pipes are designed to withstand extreme pressures, temperatures, and corrosive environments, ensuring the safe and efficient transportation of crude oil, natural gas, and other energy resources. Moreover, the renewable energy sector also relies on specialized pipes for geothermal heat pumps, bioenergy installations, and even in cooling systems for solar power plants. Advanced materials and manufacturing technologies enable the production of highly durable pipes that meet the stringent performance and safety standards required in these high-stakes applications. As energy demands continue to grow globally, pipe manufacturers are innovating with new materials and technologies to enhance the efficiency and resilience of energy infrastructure.

The industrial equipment sector significantly benefits from the application of pipe manufacturers, as these pipes are integral to diverse processes that underpin various industries, including oil and gas, water treatment, and chemical production. High-quality pipes are essential for the safe, efficient, and reliable transport of fluids and gases under varying pressures and temperatures. Pipe manufacturers supply a broad array of materials such as steel, copper, PVC, and polyethylene, each tailored to meet specific environmental and operational demands. The advanced engineering techniques and stringent quality controls employed by pipe manufacturers ensure that these pipes withstand harsh industrial conditions, reducing the incidence of leaks, bursts, and other failures that could lead to costly downtime and environmental hazards.

Moreover, innovation in pipe manufacturing plays a crucial role in the sustainable development of industries. Manufacturers are increasingly focusing on producing pipes that are not only durable but also environmentally friendly. For instance, advances in composite materials and the implementation of corrosion-resistant coatings significantly extend the lifespan of pipes, thereby reducing waste and lowering the frequency of replacements. The integration of smart technologies, such as sensors for real-time monitoring of pipeline integrity, further enhances safety and operational efficiency. These smart systems can preemptively identify and address potential issues, thus optimizing maintenance schedules and minimizing disruptions. Consequently, the contribution of advanced pipe manufacturing to the industrial equipment sector is undeniable, fostering a cycle of constant improvement and sustainability.

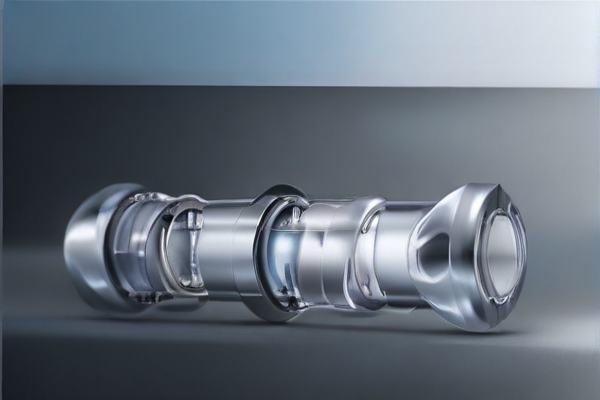

Medical devices represent a critical and innovative application of pipe manufacturing technologies, merging precision engineering with stringent health and safety standards. The manufacturing of pipes and tubing for medical applications requires materials and processes that ensure biocompatibility, durability, and resistance to corrosion and contamination. Stainless steel, certain plastics like PEX (cross-linked polyethylene), and specialized polymers are often employed in the production of medical-grade pipes and tubing, catering to a range of devices from simple IV lines to complex dialysis machines. Manufacturers must follow rigorous standards such as ISO 13485, which dictates the quality management systems for medical devices. These standards ensure that the pipes and tubing produced are free from defects and impurities, providing reliable performance in critical situations.

Moreover, the precision demanded in medical device applications extends to the intricacy of design and the exactitude of dimensions. For instance, microbore tubing used in catheters and intricate surgical instruments must be produced to extremely tight tolerances to ensure appropriate flow rates and mechanical integrity. Advanced manufacturing techniques like extrusion, laser cutting, and automated assembly processes are frequently utilized. Additionally, the surface finish of medical pipes is of paramount importance; thus, manufacturers often employ electro-polishing and passivation to achieve ultrasmooth, clean, and biocompatible surfaces. The adaptability and innovation in pipe manufacturing enable medical devices to operate efficiently, meeting the dynamic needs of modern healthcare and contributing to enhanced patient outcomes. As healthcare technologies evolve, pipe manufacturers will continue to play an indispensable role in the development of advanced medical devices.

Machining and manufacturing play pivotal roles in the pipe manufacturing industry, facilitating the production of high-quality, durable pipes used across various sectors such as plumbing, oil and gas, and construction. In the machining process, raw materials like steel, copper, or PVC are precisely cut, shaped, and finished to meet specific dimensions and performance requirements. This involves a series of carefully controlled operations including cutting, drilling, threading, and milling. Computer Numerical Control (CNC) machines are widely employed in this context to ensure high precision and repeatability, which are critical for maintaining the integrity and consistency of the pipes. The use of automated machining tools also enhances productivity and reduces material wastage, thereby optimizing overall manufacturing efficiency.

The manufacturing aspect of pipe production encompasses several key stages beginning with the selection of raw materials and extending through forming, welding (for metal pipes), and quality control. Advanced manufacturing techniques such as extrusion for plastic pipes and spiral welding for steel pipes ensure robust construction and high resistance to pressure and environmental stresses. Quality control processes, including non-destructive testing methods like ultrasonic testing and X-ray inspection, are integral to verifying the structural soundness and compliance with industry standards. Additionally, the integration of advanced technologies like IoT (Internet of Things) and Industry 4.0 solutions in manufacturing setups has significantly enhanced real-time monitoring and maintenance, helping pipe manufacturers to proactively address potential issues and ensure consistent production quality. These concerted efforts in machining and manufacturing are crucial for delivering reliable and efficient piping solutions essential for modern infrastructure.

Sure, here are some frequently asked questions (FAQ) with answers regarding the manufacturing quality and processes from SourcifyChina Factory, specialized in pipe manufacturing:

Q1: What materials are used for pipe manufacturing at SourcifyChina Factory?

A1: SourcifyChina Factory uses a variety of materials including stainless steel, carbon steel, PVC, and HDPE, depending on the specific requirements and applications of the pipes.

Q2: How does SourcifyChina ensure the quality of their pipes?

A2: Quality is ensured through rigorous quality control processes including material inspection, dimensional checks, pressure testing, and adhering to international standards such as ISO, ASTM, and DIN.

Q3: Can SourcifyChina provide custom pipe sizes?

A3: Yes, SourcifyChina offers custom pipe dimensions and specifications to meet client-specific needs, ensuring tailored solutions for any project.

Q4: What production technologies are employed at SourcifyChina Factory?

A4: The factory utilizes advanced technologies such as automated welding, CNC machining, and laser cutting to produce high-precision and durable pipes.

Q5: What is the typical lead time for an order?

A5: Lead time can vary depending on the order size and complexity, but typically ranges from 4 to 6 weeks. Rush orders can also be accommodated based on availability.

Q6: How does SourcifyChina handle international shipping and logistics?

A6: SourcifyChina has an experienced logistics team that manages international shipping, ensuring safe and timely delivery to any global destination.

Q7: Are the pipes manufactured by SourcifyChina environmentally friendly?

A7: Yes, SourcifyChina follows environmentally sustainable practices, including efficient waste management and the use of recyclable materials wherever possible.

Q8: What industries does SourcifyChina serve?

A8: SourcifyChina caters to a wide range of industries including oil and gas, construction, water treatment, and plumbing, providing high-quality pipe solutions for various applications.

Q9: Does SourcifyChina offer after-sales support?

A9: Absolutely. SourcifyChina provides comprehensive after-sales support including technical assistance, product replacement, and maintenance services.

Q10: How can I request a quote from SourcifyChina?

A10: You can request a quote by visiting the SourcifyChina website and filling out the contact form with your project details, or by directly contacting their sales team via email or phone.

Selecting the right pipe manufacturer from SourcifyChina factory requires careful consideration to ensure quality, reliability, and cost-effectiveness. Here are some tips to help streamline your decision-making process:

1. Evaluate Experience: Look for manufacturers with extensive experience in the pipe industry. Experienced manufacturers are more likely to produce high-quality products and offer reliable customer service.

2. Quality Certifications: Verify if the factory has relevant certifications such as ISO 9001 for quality management systems. Certifications indicate adherence to international quality standards.

3. Material Selection: Ensure the manufacturer uses high-grade materials suitable for your specific application, whether it be PVC, stainless steel, or other materials. Poor material quality can lead to product failure.

4. Production Capacity: Assess the factory’s production capacity to meet your demand without compromising on lead times. This is crucial for maintaining supply chain consistency.

5. Customization Options: Determine if the manufacturer can provide custom pipe sizes, lengths, and other specifications to fit your project’s needs.

6. Quality Control: Inquire about their quality control processes. Reliable manufacturers have stringent QC procedures, including material testing, dimensional checks, and performance evaluations.

7. Technical Support: Good manufacturers offer pre- and post-sales technical support to help you with product specifications, installation guidelines, and troubleshooting.

8. Sample Orders: Request samples before placing a bulk order. This allows you to assess the product quality firsthand.

9. Reviews and References: Check for customer reviews and ask for references. Feedback from other clients can provide insights into the manufacturer’s reliability and product quality.

10. Cost and Payment Terms: Balance cost with quality; the cheapest option is not always the best. Also, clarify payment terms and ensure they are reasonable and protect your interests.

These tips can help you navigate the process of selecting a reliable pipe manufacturer from SourcifyChina, ensuring you receive quality products that meet your project requirements.

Sure, here are some frequently asked questions (FAQs) with answers for sourcing pipe manufacturers from SourcifyChina Factory:

Q: What types of pipes can I source from SourcifyChina Factory?

A: SourcifyChina Factory specializes in a wide range of pipes including, but not limited to, stainless steel pipes, carbon steel pipes, PVC pipes, and HDPE pipes. Please provide your specific requirements for a more detailed list.

Q: How can I verify the quality of the pipes from SourcifyChina Factory?

A: SourcifyChina Factory adheres to international quality standards. You can request certifications such as ISO, ASTM, or any other relevant standards. You can also request sample products for evaluation.

Q: What is the minimum order quantity (MOQ) for pipes from SourcifyChina Factory?

A: The MOQ varies depending on the type of pipe and your specific requirements. Typically, MOQs start from 1 ton, but it’s best to contact their sales team for precise information.

Q: How long does it take to manufacture and deliver pipes?

A: Lead times can vary depending on the order size and complexity. Generally, manufacturing takes 2-4 weeks, and shipping times depend on your location. Express shipping options are also available for urgent orders.

Q: Can I customize the pipes according to my specifications?

A: Yes, SourcifyChina Factory offers customization options. You can specify dimensions, materials, coatings, and other technical details to meet your project’s requirements.

Q: What payment methods are accepted by SourcifyChina Factory?

A: They accept various payment methods including wire transfer (T/T), letter of credit (L/C), and sometimes PayPal for smaller orders. It’s best to confirm with their sales team.

Q: Do they offer after-sales support and warranties?

A: Yes, SourcifyChina Factory provides after-sales support and typically offers a warranty period depending on the product type. For specific warranty details, please contact customer service.

Q: How can I start the sourcing process with SourcifyChina Factory?

A: You can initiate the process by contacting their sales team through their official website or via email. Provide essential details about your requirements to get an accurate quote and timeline.

Q: Is there a way to visit the factory for an inspection?

A: Yes, pre-arranged visits for factory inspections are welcome. You can schedule an appointment by contacting their customer support team in advance.

Sourcing pipe manufacturers from SourcifyChina factory can be streamlined with these tips:

1. Define Requirements: Clearly outline the specifications and standards for the pipes you need, including material type, dimensions, and any regulatory compliance requirements.

2. Leverage Sourcify’s Platform: Sourcify provides a vetted network of manufacturers. Use their platform to search for pipe manufacturers specifically. Filter results based on your criteria such as product type, production capacity, and certifications.

3. Supplier Verification: Conduct a thorough background check on potential suppliers. Review their certifications, previous client feedback, and quality control mechanisms. Sourcify can assist in this vetting process.

4. Sample Requests: Request product samples to evaluate the quality firsthand. This is crucial to ensure the manufacturer can meet your quality standards consistently.

5. Clear Communication: Establish clear and open communication channels with potential suppliers. Use detailed documentation and, if necessary, translate materials to avoid misunderstandings.

6. Negotiate Terms: Discuss and finalize terms regarding pricing, lead times, minimum order quantities, and payment conditions. Ensure that these details are agreed upon and documented.

7. Site Visits: If feasible, arrange for site visits to the factories. This will give you a better insight into their production capabilities and working conditions.

8. Contractual Agreements: Ensure all agreements are put into legally binding contracts to protect both parties. Include clauses about quality control, inspection rights, and dispute resolution.

9. Continuous Monitoring: Once you start working with a supplier, keep track of the production processes and quality through regular updates and inspections. Maintaining a collaborative relationship is key to long-term success.

By following these steps, you can effectively source reliable pipe manufacturers from SourcifyChina, leveraging the platform’s resources and ensuring high-quality procurement.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.