Choosing “SourcifyChina” Factory for buying true position GD&T items from China ensures high precision and reliability. The factory adheres to stringent quality standards, ensuring that every product meets international specifications. This dedication to accuracy is vital for industries requiring precise measurements.

Moreover, SourcifyChina has a robust supply chain, which guarantees timely delivery and reduces lead time. Their experienced team can handle large orders efficiently, ensuring that buyers’ schedules are always met. This reliability minimizes downtime and increases productivity.

Additionally, SourcifyChina’s customer support is exceptional. They provide comprehensive assistance—from initial inquiries to post-purchase support. This level of service ensures buyers have a seamless purchasing experience and can rely on continuous support for any future needs.

Finally, the factory’s competitive pricing offers great value for money without compromising quality. By choosing SourcifyChina, buyers gain access to top-tier products that are both affordable and dependable, making it an ideal choice for any serious purchaser.

True position in GD&T (Geometric Dimensioning and Tolerancing) precisely defines the location of a feature. It can be applied to holes, slots, pins, and other features to ensure accurate placement within designated tolerances.

– Feature Control Frame: Lists datum references and tolerance values.

– Composite Tolerance: Applies multiple tolerances to different criteria such as orientation and location.

– Cylindrical Tolerance Zone: Provides a 3D boundary within which the feature must lie.

– Projected Tolerance Zone: Extends the tolerance boundary beyond the feature.

– Concentricity vs. Position: Concentricity is often less practical; true position offers more functional control.

– Bonus Tolerance: Derived from feature size variations, enhancing manufacturing flexibility.

– Datum Shift: Allows secondary datum features to shift within primary datum boundaries.

– Statistical Tolerance: Combines true position with statistical methods for enhanced quality control.

– Zero Tolerance at MMC (Maximum Material Condition): Allows positional tolerance to be zero when the feature is at its maximum material limit.

– Simultaneous Requirement: Applies when multiple features must adhere to the same tolerance zone.

True position GD&T provides a robust method to control and communicate feature placement, enabling high precision in manufacturing processes.

True Position GD&T (Geometric Dimensioning and Tolerancing) is crucial in accurately defining the location of features within manufacturing blueprints. Its application ensures parts are produced within design specifications, improving quality and interchangeability.

– Quality Control: Ensures parts meet design tolerances, reducing the risk of defective products.

– Interchangeability: Standardizes parts, making it easier to replace or repair components.

– Assembly Efficiency: Simplifies the assembly process by ensuring parts fit together correctly.

– Cost Reduction: Minimizes waste and rework by providing clear tolerancing guidelines.

– Enhanced Communication: Improves understanding between design and manufacturing teams.

– Functional Performance: Ensures that parts will function as intended within the assembly.

Overall, True Position GD&T is an essential tool in modern manufacturing that drives precision, efficiency, and quality.

SourcifyChina, a renowned manufacturing platform, excels in procuring materials for precision engineering projects. One core focus is on GD&T (Geometric Dimensioning and Tolerancing) applications, ensuring exacting standards. Their expertise spans a variety of materials.

Metals such as stainless steel, aluminum, and titanium are integral for SourcifyChina’s GD&T projects due to their durability and machined precision. These metals maintain stable dimensions under stress, which is crucial for true position requirements.

Plastics also play a significant role, with high-performance thermoplastics like PEEK and Delrin being chosen for their strength and thermal stability. These materials can be precisely molded to meet tight tolerances specified by GD&T.

Composites, including carbon fiber and fiberglass, are increasingly utilized for their strength-to-weight ratio benefits. Their high stiffness and low thermal expansion make them suitable for parts needing accurate positioning in variable environments.

Ceramics are also utilized, prized for their hardness and resistance to wear and corrosion. They are often used in applications where electrical insulation and high-temperature stability are required, providing reliability under extreme conditions.

SourcifyChina’s commitment to quality materials ensures that components meet stringent GD&T standards, achieving exact tolerances and true position requirements. This precision is critical in industries such as aerospace, automotive, and medical devices where failure is not an option. By leveraging a diverse range of materials, SourcifyChina provides tailored solutions that align with clients’ specific engineering needs, underscoring their reputation in precise manufacturing solutions.

SourcifyChina focuses on enabling manufacturing precision through the application of true position GD&T (Geometric Dimensioning and Tolerancing). This method ensures that every component meets stringent positional tolerances, pivotal for high-quality assemblies.

True position GD&T offers an advanced framework for defining and communicating tolerances in manufacturing. It provides a comprehensive, standardized language for engineers and quality control teams to ensure parts fit together perfectly, eliminating ambiguities.

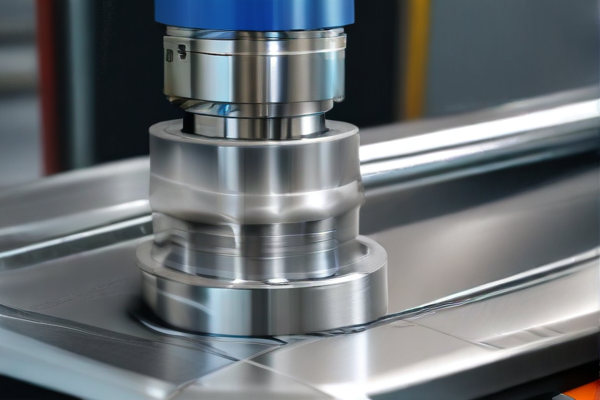

The quality control process at SourcifyChina involves rigorous inspection techniques. Advanced measurement tools such as coordinate measuring machines (CMMs) are employed to verify the true position of each feature against defined tolerances.

Incorporating true position tolerance allows for optimized cost and performance. By specifying allowable positions within a three-dimensional space, SourcifyChina can minimize material wastage and reduce rework, leading to increased productivity.

Each stage of SourcifyChina’s manufacturing process is infused with stringent quality checks. By integrating real-time data analytics and IoT-enabled devices, the deviation of parts from their true position can be instantly identified and corrected.

SourcifyChina’s commitment to quality is evidenced through detailed documentation and traceability. Every component is documented with its inspection results, providing clients assurance of adherence to pre-defined tolerances and specifications.

With a skilled team of engineers and quality inspectors, SourcifyChina ensures each part meets its true position specifications. Training programs are regularly conducted to keep staff updated with the latest GD&T techniques and technological advancements.

Customer satisfaction is paramount, and reviewing client feedback is part of SourcifyChina’s continuous improvement strategy. Through meticulous application of true position GD&T, SourcifyChina delivers parts with exceptional precision, aligning with client requirements and industry standards.

By focusing on true position GD&T, SourcifyChina maintains high production standards while minimizing errors. This dedication to precision and quality makes SourcifyChina a reliable partner in the manufacturing industry.

SourcifyChina specializes in advanced GD&T (Geometric Dimensioning and Tolerancing) capabilities, ensuring precision in manufacturing processes. One key feature is true position analysis, which measures the exact position of features in relation to each other. This guarantees high accuracy and quality control critical for complex assemblies.

Their expertise in true position GD&T helps manufacturers achieve optimal alignment, minimizing errors and reducing manufacturing costs. SourcifyChina’s capabilities are particularly beneficial for industries requiring tight tolerances, such as aerospace and automotive, ensuring each part fits perfectly within the assemblies.

Moreover, the use of advanced metrology equipment allows for real-time data collection and analysis, providing immediate feedback to improve machining processes. This helps in maintaining consistent quality and high production efficiency, ensuring parts meet strict design specifications.

In addition, SourcifyChina offers specialized training and consultation in GD&T standards, helping clients to better understand and implement these practices. This empowers companies to improve their own manufacturing processes and product quality over time.

Collaborating with SourcifyChina ensures that clients benefit from state-of-the-art technology and extensive expertise in true position GD&T, leading to superior product performance and reliability. Their commitment to precision and quality makes them an invaluable partner in achieving manufacturing excellence.

True Position in Geometric Dimensioning and Tolerancing (GD&T) enhances precision and flexibility in manufacturing by defining the exact location of features. This improves assembly quality and functional performance.

– Enhanced Accuracy: True Position calculations provide a precise, 3D location of features, reducing ambiguity.

– Improved Tolerance Zone: Using a cylindrical tolerance zone allows for better control and inspection of parts.

– Cost Efficiency: Reduces waste and rework by ensuring parts fit properly the first time.

– Simplified Inspection: Easier to verify with Coordinate Measuring Machines (CMM) and other technologies.

– Flexibility in Manufacturing: Offers more leeway in production, accommodating minor variations without compromising functionality.

– Optimized Functionality: Ensures parts fit and function as intended, enhancing the overall product reliability.

– Standardization: Adheres to ASME Y14.5 standards, promoting consistency in communication and manufacturing across industries.

– Streamlined Design Process: Simplifies complex designs by allowing for more versatile and accommodating specifications, reducing design iterations.

These benefits underscore True Position as a critical aspect of efficient and reliable manufacturing.

True Position in Geometric Dimensioning and Tolerancing (GD&T) is a vital concept that defines how far away a feature can deviate from its perfect location. This allows for a more precise and functional part design.

Key Features of True Position GD&T:

– Datum Reference Frame: Defines the part’s orientation, using specified planes as a reference.

– Tolerance Zone: Typically a cylindrical or spherical zone around the true position.

– Functional Role: Ensures that features fit and operate correctly in assembly.

– Measurement Versatility: Enables the use of various measurement tools and techniques.

– Composite Tolerance: Allows for refined control within primary and secondary features.

– Simultaneous Requirement: Allows related features to maintain positional relationships.

– Bonus Tolerance: Utilizes material boundaries to provide additional tolerance based on size.

– Flexible Design: Facilitates interchangeable part designs with lenient manufacturing processes.

– Cost Efficiency: Reduces manufacturing costs by allowing acceptable deviation limits.

– Improved Product Quality: Ensures consistent quality and reliability across different batches.

These elements together help enhance the functional integrity and manufacturability of components while ensuring compliance with industry standards.

SourcifyChina specializes in providing custom products and projects with a focus on true position Geometric Dimensioning and Tolerancing (GD&T). True position GD&T allows for precise measurements critical in high-tolerance manufacturing, ensuring components fit together seamlessly.

With advanced technologies, SourcifyChina ensures the true position of parts aligns to specified tolerances, reducing assembly issues and product rework. Their expertise in GD&T principles allows them to cater to various industries including aerospace, automotive, and medical, delivering products that meet stringent quality standards.

Moreover, their team is equipped to handle complex engineering challenges, utilizing state-of-the-art machinery and inspection tools. Clients benefit from reduced lead times and cost-effective solutions. SourcifyChina prides itself on maintaining high levels of accuracy and repeatability, crucial for intricate assemblies.

In essence, SourcifyChina’s strength lies in its ability to provide custom solutions tailored to project-specific requirements, all while maintaining precision through true position GD&T. This commitment to quality and efficiency makes them a valuable partner in the global manufacturing sector. Their services ensure that each project is completed to perfection, ensuring client satisfaction and trust.

SourcifyChina, a prominent firm specializing in true position geometric dimensioning and tolerancing (GD&T), stands at the forefront of precision engineering and quality assurance in China. Leveraging cutting-edge technology and a deep understanding of GD&T principles, they provide unparalleled solutions in the manufacturing sector, ensuring that every component meets the most stringent industry standards. With a focus on true position, SourcifyChina ensures that the critical tolerances of parts align perfectly concerning their designated coordinate systems, thereby optimizing functionality and interchangeability. Their expertise spans across various industries including automotive, aerospace, and consumer electronics, where precision and reliability are paramount. By offering comprehensive consulting, training, and implementation services, SourcifyChina not only enhances the precision of manufacturing processes but also upskills the workforce, thereby fostering a culture of excellence and innovation. Their commitment to quality and precision makes them a trusted partner for companies aiming to achieve superior product performance and regulatory compliance.

Geometric Dimensioning and Tolerancing (GD&T) is essential in industries where precision and reliability are paramount, such as aerospace, defense, and marine. True Position, a critical GD&T concept, specifies the exact coordinate location where a feature, such as a hole or slot, is intended to exist in relation to other features on the part. In aerospace applications, True Position ensures critical components in aircraft structures and systems are precisely aligned to meet stringent safety and performance standards. For instance, the alignment of fastener holes in a fuselage panel must precisely match those of adjoining sections to ensure structural integrity and aerodynamic efficiency. This accuracy guarantees that parts can be assembled without undue stress, contributing to the overall longevity and reliability of the aircraft.

In defense and marine industries, True Position GD&T plays a similarly vital role in maintaining the fit and function of complex systems. Defense equipment, such as missile systems and armored vehicles, requires components to be meticulously aligned to function correctly under extreme conditions. A misaligned component could jeopardize the mission and safety of personnel. Similarly, in marine applications, from submarine hull construction to navigation equipment alignment, True Position ensures parts fit together with precision to withstand harsh marine environments and operational stresses. The use of True Position within these sectors helps in minimizing wear and tear, reducing maintenance costs, and enhancing the overall operational efficiency and reliability of essential systems. By adhering to stringent positional tolerances, these industries achieve a high level of precision necessary for advanced technological applications.

In the automotive industry, true position GD&T (Geometric Dimensioning and Tolerancing) plays a crucial role in ensuring precision and reliability. It is employed extensively in the manufacturing and assembly of components such as engine parts, transmission systems, and chassis components. True position helps in defining the exact location of features like holes, bosses, and slots relative to their respective datum points, ensuring that each part fits together seamlessly. This precision is paramount in reducing assembly errors, improving vehicle performance, and enhancing safety. For instance, in an engine block, the precise location of cylinder bores is critical to the engine’s efficiency and longevity. By using true position GD&T, manufacturers can achieve tighter tolerances and consistent quality, which is pivotal in meeting the rigorous standards of the automotive industry.

In the electronics sector, true position GD&T is equally essential, particularly in the fabrication of Printed Circuit Boards (PCBs) and semiconductor components. Accurate positioning of electronic elements like microchips, resistors, and connectors is vital to ensure optimal functionality and signal integrity. True position tolerances help to control the positional accuracy of drilled holes, pads, and other mounting features, which is crucial for the reliable performance of high-density PCBs. This precision aids in minimizing issues such as misalignment or electrical shorts, thereby enhancing the overall durability and performance of electronic devices. Additionally, in the assembly of consumer electronics like smartphones and computers, true position GD&T ensures that connectors and interfaces align perfectly, facilitating efficient assembly processes and reducing the likelihood of product malfunctions. Through meticulous control of part geometries and placements, true position GD&T helps maintain high standards of quality and functionality in the fast-evolving electronics industry.

In the construction industry, precise alignment and positioning of components are paramount in ensuring the structural integrity and aesthetic appeal of buildings and infrastructure. True Position GD&T (Geometric Dimensioning and Tolerancing) finds substantial application here as it provides a comprehensive framework for defining the permissible variability in the location of features such as columns, anchor bolts, and beams. By employing True Position, construction engineers can communicate exact tolerances for the placement of critical elements, ensuring that even with permissible manufacturing deviations, the overall structure remains aligned and meets stringent safety standards. This level of precision helps avoid costly rework and enhances the efficiency of assembly processes, fostering seamless integration of prefabricated components.

In the energy sector, True Position GD&T is equally critical, especially in the manufacturing and assembly of components for power generation and distribution systems. For example, in the production of wind turbines, True Position is used to ensure the precise alignment of rotor blades and hubs, which is vital for optimizing performance and minimizing mechanical stress. Similarly, in nuclear power plants, the exact positioning of reactor core components can significantly impact the system’s safety and efficiency. Even in the oil and gas industry, ensuring the accurate placement of drilling equipment and pipelines reduces the risk of leaks and failures. By defining allowable position variations within tight tolerances, True Position GD&T supports the development of robust and reliable energy solutions that meet regulatory standards and operational demands.

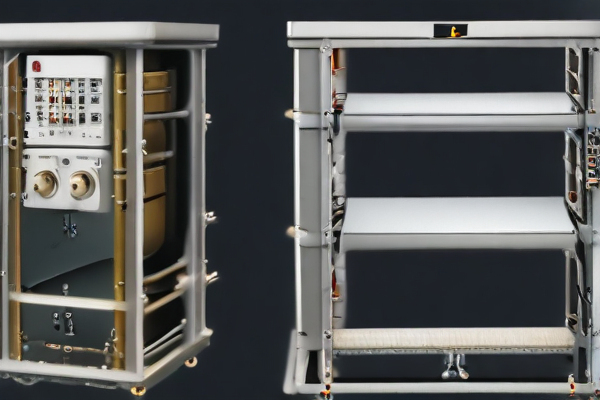

The industrial equipment industry relies heavily on the precision and accuracy of components to ensure the seamless operation of machinery and systems. The application of True Position Geometric Dimensioning and Tolerancing (GD&T) in this industry plays a crucial role in maintaining high standards of quality and performance. True Position GD&T is a method of specifying the allowable deviation of feature locations relative to a specified datum. It is instrumental in achieving the precise alignment and fit of components which is pivotal in complex assemblies such as automated robotic systems, manufacturing equipment, and heavy machinery. By implementing True Position, manufacturers can minimize discrepancies that may arise from variations in component dimensions, thus reducing the risk of machine failure, increasing reliability, and maximizing productivity.

Furthermore, True Position GD&T facilitates better communication and understanding among engineers, machinists, and quality control personnel. By providing a clear and unambiguous description of feature locations, it eliminates the potential for misinterpretation and manufacturing errors. This precision is critical in the industrial equipment sector, where even minute deviations can lead to significant functional discrepancies. For instance, in the production of hydraulic pumps, motors, and precision gears, ensuring exact alignment and positioning can prevent issues like leakage, misalignment, and inefficient operation. Moreover, by enabling more efficient use of materials and reducing the need for extensive rework or adjustments, True Position GD&T ultimately contributes to cost savings and shorter lead times. This standardized approach not only enhances product quality but also streamlines processes, positioning companies to better compete in the global market.

True position Geometric Dimensioning and Tolerancing (GD&T) plays a critical role in the manufacturing and quality control of medical devices. Medical devices are often subject to stringent regulatory standards, given the direct impact they have on patient health and safety. True position GD&T ensures that the components of these devices, such as surgical instruments, implants, and diagnostic machines, are manufactured to precise specifications. By defining the exact coordinate location where features should exist, true position helps maintain tight tolerances that are essential for the reliable performance of medical devices. For instance, the alignment and fitment of an orthopedic implant’s components must be meticulously controlled to ensure proper function and long-term stability within the human body. Any deviation can not only compromise the device’s efficacy but also pose significant health risks.

Moreover, the application of true position in GD&T enables effective communication between design engineers, manufacturers, and quality inspectors. It reduces ambiguities and allows for a uniform interpretation of specifications, minimizing the risk of errors that can result from miscommunication. This is especially crucial in the medical device industry, where even minor discrepancies can lead to costly recalls and adverse patient outcomes. By utilizing true position, manufacturers can conduct precise inspections and quality checks, employing advanced metrology equipment to verify that every component meets the necessary criteria. As a result, true position GD&T contributes to the production of highly reliable medical devices, enhancing patient safety and supporting the overall quality assurance framework within this heavily regulated industry.

True Position is a geometric dimensioning and tolerancing (GD&T) feature that is crucial in the fields of machining and manufacturing for ensuring the precise location of holes, slots, and other features on a part. By defining the exact nominal location within a tolerance zone, true position eliminates ambiguity, allowing for more precise and efficient production. In machining processes, utilizing true position GD&T helps machinists and engineers in inspecting and aligning components with high accuracy. This minimizes errors and ensures parts fit together as intended, thereby improving the overall quality and functionality of the final product. The use of true position also aids in reducing material wastage as it allows for parts to be produced within tight tolerances, minimizing the need for rework or rejection.

In manufacturing applications, true position GD&T enhances interoperability and interchangeability of components, which is essential for mass production and assembly line operations. For instance, in the automotive and aerospace industries, where components must meet stringent safety and performance standards, true position ensures that parts from different suppliers can fit together seamlessly. This is achieved through precise control over location tolerances, which aids in maintaining the geometric integrity of parts throughout the production process. Moreover, the use of true position in quality control helps in the early detection of deviations, enabling timely corrective actions. This not only boosts the efficiency of the production process but also leads to substantial cost savings by reducing downtime and improving product reliability.

Sure, here is a list of Frequently Asked Questions (FAQ) regarding manufacturing “true position GD&T quality work from SourcifyChina factory”.

1. What is True Position in GD&T?

True Position in Geometric Dimensioning and Tolerancing (GD&T) refers to the exact coordinate or location of a feature in relation to its datum reference frame. It’s the most accurate way to gauge whether a feature is in the correct place.

2. Why is True Position important in manufacturing?

True Position ensures the precise location of features, which is crucial for assembly and proper function of the part. It reduces errors, enhances quality, and improves interoperability between components.

3. What is SourcifyChina factory’s capability in True Position GD&T work?

SourcifyChina factory is equipped with advanced machinery and a skilled workforce to deliver precise True Position GD&T quality work. Our capabilities include CNC machining, laser cutting, and advanced metrology tools like CMM for accurate measurements.

4. How does SourcifyChina ensure quality in True Position tolerances?

We follow a stringent quality control process that includes initial design reviews, in-process inspections, and final verification using state-of-the-art measurement equipment. We also adhere to international standards and customer-specific requirements.

5. Can you handle custom True Position GD&T projects?

Yes, SourcifyChina specializes in custom manufacturing solutions. We can handle projects with specific True Position requirements tailored to your design needs. Our engineering team collaborates closely with clients to meet unique specifications.

6. What industries benefit from SourcifyChina’s True Position GD&T work?

Industries such as automotive, aerospace, medical devices, electronics, and consumer products benefit from our True Position GD&T services. Our expertise helps ensure high precision and reliability in critical applications.

7. Is SourcifyChina able to provide documentation for GD&T work?

Absolutely. We provide comprehensive documentation, including inspection reports, measurement data, and compliance certificates to validate the quality and accuracy of our GD&T work.

8. How do I get a quote for True Position GD&T work from SourcifyChina?

You can contact our sales team via email or through our website. Provide detailed drawings and specifications, and we will deliver a tailored quote based on your requirements.

This information provides a concise understanding of SourcifyChina’s capabilities and processes in delivering high-quality True Position GD&T work.

Certainly! Here are some tips for dealing with true position Geometric Dimensioning and Tolerancing (GD&T) when working with SourcifyChina factory:

1. Clear Communication: Ensure detailed and clear engineering drawings. Include all necessary GD&T symbols, dimensioning data, and references. Miscommunication can lead to production errors.

2. Tolerance Specification: Define tolerance zones precisely. The true position should clearly reference datums and tolerances, which helps ensure all manufactured parts are within acceptable limits.

3. Datum Selection: Carefully select and specify the datum features. Proper datum selection is critical for accurate positioning and measurement consistency.

4. Material Condition Modifiers: Utilize material condition modifiers (MMC, LMC) when applicable. This can provide additional tolerance and help in cost-effective manufacturing processes.

5. Inspection Methods: Discuss and agree upon reliable inspection methods with SourcifyChina. Coordinate measuring machines (CMM) or other precision measurement tools should be employed.

6. Prototyping: Start with prototypes to verify if the factory fully understands and can meet the GD&T requirements, especially for true position tolerances. This step can save costs and time.

7. Feedback Loop: Maintain an open feedback loop. Regular communication with the factory’s quality assurance team can help identify issues early and implement corrective action swiftly.

8. Quality Documentation: Request detailed quality documentation and inspection reports to validate compliance with the specified true position tolerances.

9. Training and Expertise: Ensure that the factory’s workforce is trained in GD&T principles. Understanding true position requirements is crucial for consistent quality.

10. Standardization: Adhere to international standards such as ISO or ASME Y14.5. Standardization helps ensure both parties have a mutual understanding of GD&T requirements.

By following these tips, you can improve the accuracy and efficiency of manufacturing parts with precise true position requirements at SourcifyChina factory.

Sure, here are some frequently asked questions (FAQ) with corresponding answers regarding sourcing “true position GD&T” from SourcifyChina factory:

Q1: What is true position in GD&T?

A1: True position is a geometric dimensioning and tolerancing (GD&T) term that defines the exact coordinate, or location, of a feature or part. It is used to specify the allowable deviation for the feature’s location from its ideal position.

Q2: How does SourcifyChina ensure the accuracy of true position GD&T?

A2: SourcifyChina utilizes advanced measurement tools and software, such as Coordinate Measuring Machines (CMMs) and CAD models, to ensure precision. Our quality control team conducts thorough inspections to verify that all parts meet the specified true position tolerances.

Q3: Can SourcifyChina handle complex true position GD&T requirements?

A3: Yes, SourcifyChina has experience in handling a wide range of GD&T requirements, including complex true position tolerances. Our skilled engineers and technicians are proficient in interpreting and producing according to detailed engineering drawings.

Q4: What materials can SourcifyChina work with to achieve true position tolerances?

A4: SourcifyChina can work with a variety of materials like metals, plastics, and composites. Our advanced machining and manufacturing processes ensure that true position tolerances are maintained regardless of the material.

Q5: What industries does SourcifyChina serve with true position GD&T capabilities?

A5: SourcifyChina serves several industries including automotive, aerospace, medical devices, and consumer electronics. Our comprehensive understanding of GD&T standards allows us to cater to diverse sector requirements.

Q6: How does SourcifyChina handle quality assurance for true position GD&T?

A6: Quality assurance at SourcifyChina involves multiple inspection stages. We integrate GD&T checks into our production processes and use high-precision instruments to verify compliance, ensuring that each part meets the required tolerances.

Q7: What information should I provide for a true position GD&T sourcing inquiry?

A7: For a comprehensive sourcing inquiry, provide detailed engineering drawings, material specifications, and any additional tolerance requirements. Clear communication helps us deliver parts that meet your exact needs.

Q8: What is the typical lead time for parts requiring true position GD&T from SourcifyChina?

Sourcing true position GD&T (Geometric Dimensioning and Tolerancing) services from SourcifyChina factory can be streamlined by following these tips:

1. Define Requirements: Clearly specify your true position GD&T needs, including tolerance zones and datum references in technical drawings and documentation.

2. Supplier Vetting: Evaluate SourcifyChina by reviewing their portfolio, customer reviews, and case studies. Ensure they have experience with GD&T standards relevant to your industry.

3. Technical Expertise: Confirm that SourcifyChina’s team includes experienced engineers proficient in interpreting and applying GD&T principles.

4. Quality Control: Ask about their quality assurance processes and the equipment used for measuring true position, such as CMM (Coordinate Measuring Machines).

5. Certification: Verify that SourcifyChina holds relevant certifications (ISO 9001, AS9100, etc.), indicating adherence to global quality standards.

6. Sample Production: Request prototypes or samples to assess their capability to meet GD&T specifications accurately.

7. Communication: Establish clear channels of communication to discuss project details and ensure any technical questions can be resolved promptly.

8. Visit the Factory: If feasible, visit SourcifyChina’s facility to witness their production and quality control processes firsthand.

9. Contracts and Agreements: Have detailed contracts specifying GD&T requirements, delivery timelines, and quality standards to protect against non-conformance.

10. Continuous Monitoring: Implement a system for ongoing quality checks during the production phase to ensure compliance with the specified GD&T requirements.

By following these steps, you can effectively source true position GD&T services from SourcifyChina and ensure that the manufactured components meet your precise engineering specifications.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.