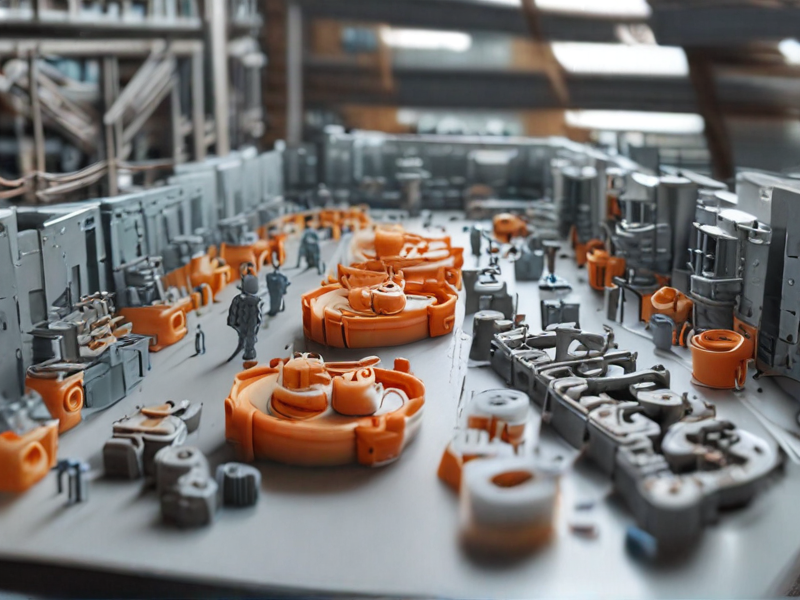

Choosing SourcifyChina for purchasing plastic molds from China guarantees high-quality production. The factory employs advanced technology and skilled craftsmanship, ensuring precision and durability in every mold they produce. This commitment translates into long-lasting and reliable products for end-users.

SourcifyChina offers competitive pricing without compromising quality. Their cost-effective solutions help buyers save on production expenses, making them an ideal choice for businesses aiming to optimize their budget. Transparent pricing practices also ensure there are no hidden costs, fostering trust and satisfaction.

Timely delivery is another advantage with SourcifyChina. The factory prioritizes meeting deadlines and ensures that every order is processed and shipped efficiently. This reliability helps buyers maintain their production schedules and meet market demands effectively, minimizing downtime and delays.

Exceptional customer service is a hallmark of SourcifyChina. The team is dedicated to assisting clients throughout the process, from initial consultations to after-sales support. This personalized approach ensures that buyer needs are thoroughly met, fostering long-term partnerships and repeat business.

In conclusion, SourcifyChina stands out as a premier choice for purchasing plastic molds from China due to its combination of high-quality products, competitive pricing, timely delivery, and excellent customer service. Buyers can confidently rely on the factory for all their plastic molding needs, leading to successful and efficient manufacturing operations.

The cost of plastic molds varies depending on factors like mold complexity, material, production volume, and manufacturing location. Different types of molds, such as injection, blow, and compression molds, offer various cost options.

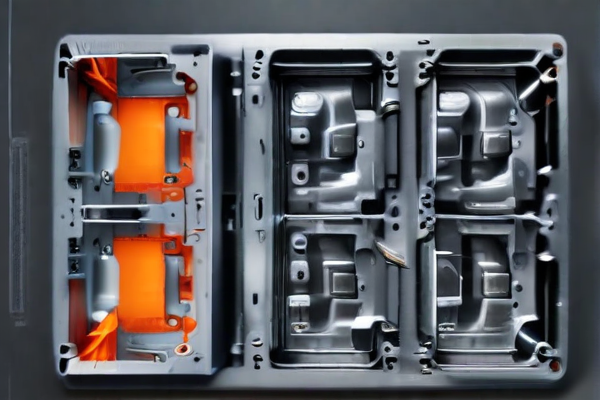

– Injection Molds: Suitable for high-volume production; higher initial cost but lower per-unit cost.

– Blow Molds: Ideal for hollow parts like bottles; moderate costs, especially for simple designs.

– Compression Molds: Best for lower volume, large parts; generally lower initial cost but higher per-unit cost.

– Transfer Molds: Used for over-molding or insert molding; costs vary based on complexity and materials.

– Rotational Molds: Used for large, hollow items; lower mold costs, but higher per-unit costs due to longer cycle times.

– Thermoforming Molds: Suitable for thin-walled items; lower mold cost but limitations on part complexity.

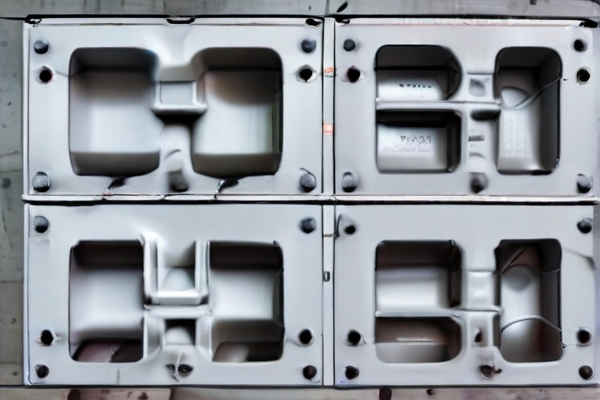

– Multi-Cavity Molds: Higher initial cost but can produce multiple parts simultaneously, reducing per-unit cost.

– Family Molds: Allows different parts to be molded in one cycle; offers cost efficiency for complex assemblies.

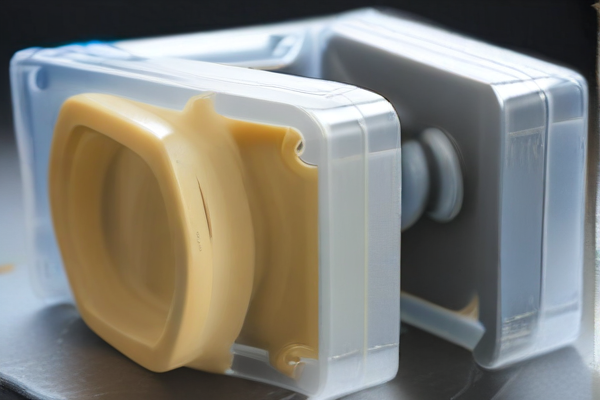

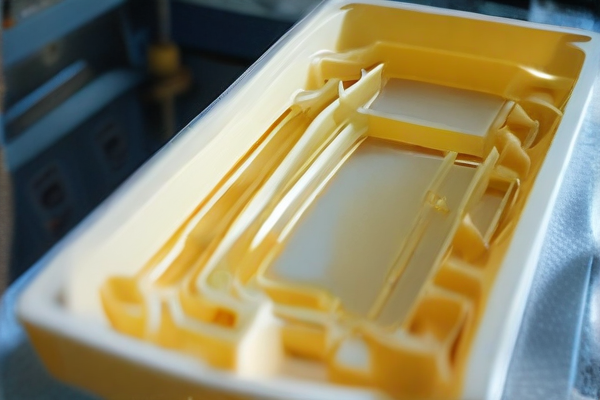

– Prototype Molds: Less durable molds for short runs and testing; lower initial investment.

Factors influencing mold costs:

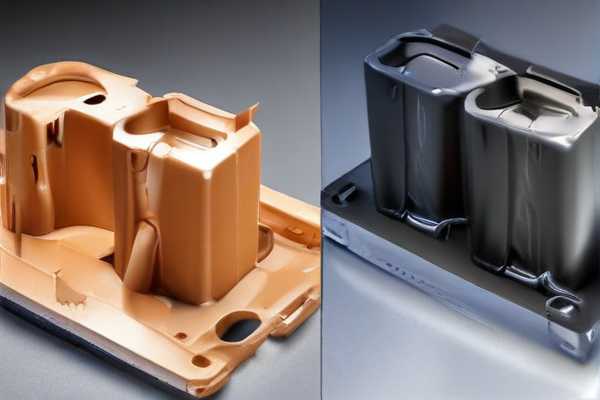

– Material: Steel (higher durability, higher cost) vs. aluminum (less durable, lower cost).

– Complexity: Intricate designs increase machining time and costs.

– Size: Larger molds require more material and machining.

– Precision Requirements: Tighter tolerances increase costs.

– Production Volume: Higher volumes justify higher initial costs by reducing per-part costs.

– Manufacturing Location: Costs vary globally, with lower prices often found in countries like China.

Considering these factors can help in selecting the most cost-effective plastic mold for your production needs.

Plastic mold cost is a crucial factor in manufacturing various custom plastic parts. It directly impacts the budget and feasibility of producing items like automotive components, medical devices, and consumer electronics.

– Automotive Industry: Molds for plastic parts used in cars, like dashboards and bumpers.

– Medical Devices: Sustainable cost for producing medical equipment.

– Consumer Electronics: Cost-efficient cases and parts for gadgets.

– Packaging: Economical production of packaging for food and beverages.

– Household Goods: Low-cost molds for everyday household items.

– Toys: Affordable production for various plastic toys.

– Industrial Components: Less expensive molds for industrial use products.

– Construction Materials: Cost-effective molds for plastic-based construction materials.

– Cosmetics: Production of packaging for beauty products at lower costs.

– Original Equipment Manufacturer (OEM) Parts: Expenditure control for OEM plastic parts.

– Prototypes: Budget-friendly prototype development.

SourcifyChina is renowned for providing high-quality plastic mold solutions at competitive costs. Utilizing advanced materials like high-grade steel and aluminum, the company’s molds ensure durability and precision in manufacturing.

The diverse materials accommodate various industry needs, including consumer electronics, automotive parts, and medical devices. Each material is carefully selected to match the specific requirements of a project, ensuring optimal performance.

Precision engineering and stringent quality controls are hallmarks of SourcifyChina’s mold production process. By leveraging state-of-the-art technology, the company minimizes manufacturing errors, contributing to cost efficiency and product reliability.

Cost-effectiveness doesn’t compromise quality. SourcifyChina’s commitment to affordable pricing includes transparent cost evaluations and meticulous project management. This approach fosters long-term partnerships aimed at mutual growth and success in global markets.

SourcifyChina addresses the plastic mold cost by streamlining procurement processes, leveraging competitive pricing, and opting for high-volume production. By minimizing overhead and operational expenses, they offer cost-effective mold solutions without compromising on quality.

Quality control in SourcifyChina’s manufacturing process is rigorous. They implement stringent testing and inspection protocols at each stage, from raw material selection to mold assembly. This ensures that every product meets or exceeds international standards.

Advanced technology plays a crucial role in SourcifyChina’s quality assurance. Utilizing state-of-the-art machinery and automated systems, they maintain precision and consistency in mold production, reducing human error and enhancing efficiency.

Customer feedback is integral to their quality control strategy. SourcifyChina actively seeks and analyzes client input to improve reliability and performance. Regular audits and continuous improvement plans are in place to align with customer expectations and industry advancements.

In summary, SourcifyChina delivers cost-effective plastic molds through efficient procurement, advanced technology, and stringent quality control measures. Their dedication to excellence and customer satisfaction sets them apart in the competitive manufacturing landscape.

SourcifyChina specializes in offering cost-effective plastic mold solutions. They leverage advanced technology to maintain low production costs, making them a leader in the industry. Their competitive pricing ensures businesses achieve high-quality results without significant financial strains.

Their extensive network of manufacturers allows for efficient sourcing of materials, further cutting manufacturing expenses. This network ensures reliability and timely delivery of mold components, enhancing overall productivity.

SourcifyChina’s skilled engineering team designs and customizes molds to meet specific client requirements. They prioritize precision and detail, ensuring top-grade craftsmanship. Their expertise guarantees molds are both durable and highly functional, reducing long-term costs.

Client satisfaction remains paramount for SourcifyChina. They offer comprehensive support, from initial consultation to final product delivery. Continuous communication during the process ensures that projects stay on track, resulting in timely and satisfactory outcomes.

Additionally, SourcifyChina integrates rigorous quality assurance protocols. Every mold undergoes meticulous inspection to comply with international standards. This attention to detail minimizes defects, ensuring robust and reliable mold performance.

Besides cost efficiency, their commitment to sustainability sets them apart. SourcifyChina utilizes eco-friendly materials and processes wherever feasible. This focus on sustainability helps clients reduce their environmental impact while maintaining high-quality standards.

Conclusively, SourcifyChina excels in providing affordable plastic mold solutions without compromising on quality or sustainability. Their comprehensive approach—from design to delivery—ensures that clients receive exceptional value. Businesses can confidently rely on their expertise to meet and exceed their production goals efficiently.

Plastic mold cost offers several benefits, contributing to its widespread use in various industries. Below are some key advantages:

– Cost Efficiency: Plastic molds are cost-effective for mass production, reducing per-unit costs.

– High Precision: Modern molding techniques ensure consistent, precise dimensions.

– Durability: Plastic molds can be reused for thousands of cycles, offering long-term savings.

– Design Flexibility: Complex designs and intricate details are easily achievable.

– Speed: Faster production times compared to other manufacturing methods.

– Versatility: Suitable for a wide range of industries including automotive, medical, and consumer goods.

– Material Efficiency: Minimal waste, optimizing material use.

– Reduced Labor Costs: Automation in molding processes lowers the need for manual labor.

– Environmental Benefits: Recyclable materials can be used, reducing environmental impact.

– Quality Control: High-quality output with fewer defects and consistent performance.

– Scalability: Easy to scale up production based on demand without significant cost increases.

These benefits collectively make plastic molding an attractive option for manufacturers looking to produce high-quality, cost-effective products at scale.

Calculating the cost of plastic molds entails multiple components that influence overall expenses, making it essential to understand these factors for accurate budgeting.

– Material Type: The choice of materials like steel or aluminum impacts the cost, depending on durability and suitability.

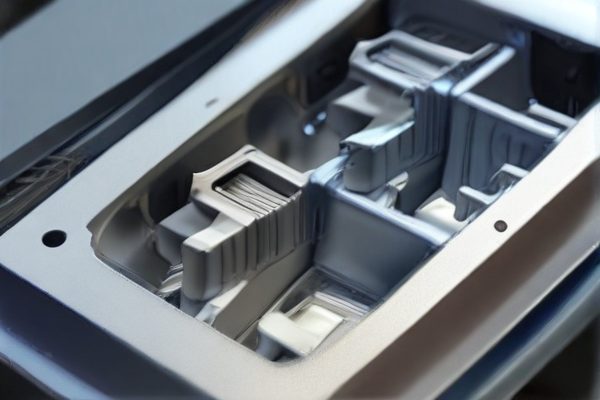

– Mold Design Complexity: Intricate designs and tolerances require more detailed work, driving up costs.

– Size and Cavity Count: Larger molds or those with multiple cavities generally increase the price.

– Production Volume: Higher production volumes can justify the cost of more expensive molds due to cost-per-unit savings.

– Tooling Precision: Precision tools and machining add to the cost but ensure higher quality and lesser wastage.

– Cycle Time Requirements: Faster cycle times typically need higher quality molds, influencing the total cost.

– Lead Time: Shorter lead times often incur rush fees and increase the final expenditure.

– Post-Processing Needs: Finishing processes like polishing or additional treatments will add to the price.

– Geographical Location: Manufacturing costs can vary significantly based on the region due to labor and resource costs.

– Supplier Expertise: Experienced suppliers often charge more but can deliver higher quality and reliability.

– Maintenance and Lifespan: High-quality molds with longer lifespans and low maintenance can be more cost-effective in the long run.

Understanding these variables provides a comprehensive view of what influences plastic mold costs, aiding in more precise cost management and planning.

SourcifyChina offers competitive plastic mold costs, ideal for businesses seeking custom products. Their expertise ensures high-quality molds at affordable prices, meeting diverse client needs. With advanced technology, SourcifyChina provides precision and durability in every mold created.

Custom products from SourcifyChina range from small components to large, complex items. They cater to various industries, delivering tailored solutions that enhance efficiency. Their team of skilled engineers collaborates closely with clients, ensuring each project aligns with specific requirements and deadlines.

Project management at SourcifyChina is seamless, thanks to their structured approach and robust processes. They prioritize clear communication, timely deliveries, and stringent quality control. This commitment to excellence fosters long-term relationships with clients.

For any business requiring reliable plastic molding solutions, SourcifyChina is a trusted partner. Their innovative techniques, coupled with industry knowledge, guarantee satisfaction. Their comprehensive services encompass design, production, and post-production support, making them a one-stop solution for all plastic molding needs.

SourcifyChina, a prominent player in the manufacturing industry, specializes in delivering high-quality plastic mold solutions at competitive costs. Located strategically at the heart of China’s industrial belt, the company leverages the region’s robust supply chain and skilled workforce to offer cost-efficient mold-making services to clients across the globe. SourcifyChina is known for its exceptional ability to balance affordability with precision engineering, catering to a wide array of industries including automotive, consumer electronics, and medical devices. By employing state-of-the-art technology and adhering to stringent quality standards, the company ensures that every mold produced meets exact specifications and exceeds customer expectations. Their transparent pricing model and commitment to timely delivery further solidify their reputation, making them a trusted partner for businesses looking to optimize production costs without compromising on quality.

The aerospace, defense, and marine sectors have progressively integrated advanced plastic mold technologies to meet stringent requirements for durability, precision, and weight reduction. In aerospace applications, plastic molding is essential in manufacturing lightweight yet robust components such as interior panels, housings for electronic devices, and even structural elements. The cost of plastic molds in this sector is justified by the significant weight savings, which translates into improved fuel efficiency and lower operational costs. Additionally, high-precision plastic molds ensure the production of components that meet the rigorous safety and performance standards required in aviation, ultimately contributing to enhanced aircraft reliability and performance.

In the defense sector, plastic molds are utilized to produce a myriad of critical components, ranging from protective gear to advanced weaponry casings. The initial investment in creating high-quality molds is offset by the ability to mass-produce parts that are both resilient and lightweight, critical for the mobility and protection of military personnel and equipment. Similarly, in marine applications, plastic molding plays a significant role in crafting parts that can withstand harsh saltwater environments while reducing overall vessel weight. Mold costs in marine applications are balanced by the benefits of corrosion resistance and reduced maintenance expenses, which are vital for the long-term sustainability of marine vessels. Thus, across aerospace, defense, and marine industries, the careful investment in plastic mold costs facilitates the production of high-performance, lightweight components that adhere to strict regulatory and operational standards.

In the automotive industry, the application of plastic molds plays a critical role in the manufacturing of a diverse range of components, from interior parts like dashboards and air vents to exterior elements such as bumpers and grilles. The cost of plastic molds can significantly impact the production budget, particularly for parts requiring high precision and durability. Given the high-volume production characteristic of the automotive sector, initial investments in high-quality molds can be justified as they offer long-term cost efficiency due to their longevity and repeat accuracy. This investment also facilitates the creation of lightweight, high-strength parts that contribute to improved fuel efficiency, compliance with regulatory standards, and enhanced overall vehicle performance.

In electronics, plastic molds are equally essential, enabling the production of intricate components such as housings, connectors, and switches. The cost of these molds can vary based on factors such as complexity, material choice, and production volume. High-precision molds are indispensable in electronics production as they ensure the consistency and reliability of small, detailed parts, which are crucial for the functionality of consumer electronics, medical devices, and industrial equipment. Investing in high-quality plastic molds can lead to reduced manufacturing defects, lower product failure rates, and higher consumer satisfaction. Although the initial cost may be substantial, the efficiency gains and quality improvements achieved through precision molding are invaluable, fostering innovation and competitiveness in the fast-paced electronics market.

The construction industry has increasingly embraced the use of plastic molds due to their cost-effective and versatile nature. These molds are employed in creating various components such as interlocking tiles, concrete blocks, and intricate architectural details. One significant benefit of using plastic molds in construction is their affordability compared to traditional metal molds. The reduced plastic mold cost comes primarily from the lower material expenses and faster production times, which translate into diminished labor costs. Additionally, plastic molds are lightweight yet durable, making them easy to handle and capable of withstanding multiple uses. This efficiency not only reduces the overall project budget but also accelerates construction timelines, providing a clear advantage in large-scale construction projects.

In the energy sector, plastic molds play a crucial role in the manufacturing of various components necessary for renewable energy systems and traditional power infrastructure. For instance, plastic molds are used to create parts for wind turbine blades, solar panel casings, and insulation components for electrical cables. The reduced cost of plastic molds aids in lowering the manufacturing expenses of these energy devices, consequently making renewable energy solutions more financially accessible. Furthermore, plastic molds facilitate the production of complex geometries that are often necessary for optimizing the performance and efficiency of energy systems. By leveraging the cost benefits of plastic molds, the energy sector can accelerate the development and deployment of more affordable and efficient energy solutions, thereby contributing to the broader goal of sustainable and cost-effective energy production.

The industrial equipment industry relies heavily on precision and durability, making the application of plastic molding a significant aspect of production. Plastic mold cost refers to the expenses involved in creating molds used to manufacture plastic components, which are essential for various industrial equipment. The initial investment in high-quality molds can be substantial, but it is justified by the benefits of producing large volumes of consistent and durable parts. For instance, custom-made plastic molds can be used to produce gears, housing units, and other intricate components with tight tolerances, essential for the smooth functioning of machinery. Advanced molding techniques such as injection molding allow for the production of complex shapes with minimal material wastage, contributing to both cost efficiency and environmental sustainability.

Moreover, plastic mold cost also encompasses the maintenance and replacement expenses over the mold’s lifecycle. High-performance molds are designed to endure extensive use, thereby reducing downtime and ensuring uninterrupted production. However, the selection of appropriate materials and precise manufacturing techniques can significantly affect the mold’s longevity and efficiency. Modern technologies such as Computer-Aided Design (CAD) and 3D printing further optimize the mold creation process, allowing for rapid prototyping and reductions in lead times. By carefully managing plastic mold costs, industrial equipment manufacturers can achieve higher productivity, improved product quality, and significant long-term savings, which are crucial in a competitive market. The strategic investment in plastic molds thus underpins the operational success and innovation within the industrial equipment sector.

The application of plastic mold cost in the realm of medical devices is critical for understanding the economics of producing high-quality, reliable, and safe healthcare products. Plastic injection molding is widely utilized in the production of various medical devices such as syringes, surgical instruments, diagnostic equipment housings, and drug delivery systems. The cost of plastic molds, which includes design, material, and manufacturing expenses, plays a significant role in the overall production budget. Investing in high-quality molds ensures precision and consistency, which are crucial for meeting stringent regulatory standards and reducing the risk of defects that could compromise patient safety. Moreover, economies of scale can be achieved through plastic molding by producing large quantities of components at a relatively low incremental cost per unit, making it an advantageous choice for mass production.

Additionally, the initial cost of plastic molds is often balanced by the long-term benefits they offer, particularly in the medical device industry, where the demand for durable, sterile, and versatile components is high. Modern engineering advancements have enabled the creation of complex and intricate mold designs, allowing manufacturers to produce parts with high accuracy and minimal waste. Despite the upfront investment, the efficiency and speed of plastic injection molding contribute to quicker turnaround times and lower labor costs, thus optimizing the overall production process. Cost considerations also encompass maintenance and longevity of the mold; durable materials and precise manufacturing techniques reduce the likelihood of wear and tear, thereby extending the mold’s lifespan. In summary, while the initial investment in plastic molds for medical devices may be substantial, the cost-efficiency, reliability, and production advantages they offer make them a pivotal component in the medical manufacturing landscape.

The concept of “plastic mold cost” is essential in the machining and manufacturing industries, particularly in the production of plastic components through injection molding. The initial phase of creating a plastic mold involves significant investment, encompassing design, material selection, and precision machining to ensure the mold meets stringent specifications. High precision machining tools and Computer Numerical Control (CNC) machines are often employed to create intricate designs with tight tolerances, which are crucial for producing consistent and high-quality plastic parts. The cost is influenced by various factors, such as the complexity of the mold design, the type of plastic material to be used, and the expected production volume. This upfront expense, although substantial, is critical for manufacturers as it directly impacts the quality and efficiency of the production process.

In the broader context of manufacturing, the cost of plastic molds extends beyond just the initial creation phase. It also includes ongoing maintenance and potential modifications required as production demands evolve. Effective mold design and maintenance can significantly reduce cycle times and material waste, translating to long-term cost savings. Additionally, advancements in additive manufacturing and rapid prototyping have begun to influence traditional mold-making processes, offering manufacturers new ways to reduce costs and increase flexibility. For instance, 3D printing can be used to produce prototype molds quickly, allowing for faster iterative testing and refinement before committing to the final mold design. This adaptability can provide a competitive edge in industries such as automotive, consumer goods, and medical devices, where the ability to respond swiftly to market changes is invaluable. Ultimately, managing plastic mold costs effectively is pivotal for manufacturers aiming to balance quality, efficiency, and profitability.

Sure, here are some frequently asked questions (FAQ) about manufacturing plastic molds and general queries specific to working with SourcifyChina factory:

1. What factors influence the cost of plastic mold manufacturing at SourcifyChina?

The cost of plastic mold manufacturing at SourcifyChina is influenced by several factors, including the complexity of the mold design, the type of plastic material used, the size of the mold, the number of cavities, the precision required, and any additional features such as texture. Bulk orders can often reduce the per-unit cost.

2. How does SourcifyChina ensure the quality of plastic molds?

SourcifyChina ensures quality through strict adherence to international manufacturing standards, utilizing advanced machinery, thorough material inspections, and detailed quality control processes. Our team of skilled engineers and technicians conduct regular audits and testing to maintain high standards.

3. What is the typical lead time for plastic mold manufacturing?

The typical lead time for plastic mold manufacturing varies based on the complexity and requirements of the project. However, on average, it ranges from 4 to 8 weeks. For precise timelines, detailed project specifications need to be reviewed.

4. Can SourcifyChina accommodate custom plastic mold designs?

Absolutely! SourcifyChina specializes in custom plastic mold designs. Clients can provide their own designs, or our experienced design team can collaborate with you to create a tailored solution that meets your specific needs.

5. What type of plastic materials can SourcifyChina work with?

SourcifyChina can work with a wide range of plastic materials including ABS, PC, PVC, POM, PP, PE, PS, PA, and more. Our team can recommend the best material based on the application and required properties of the final product.

6. How does SourcifyChina handle shipping and logistics?

SourcifyChina offers comprehensive shipping and logistics solutions. We coordinate with reliable shipping partners to ensure timely and safe delivery of products, whether it’s for domestic or international destinations. Clients can choose from various shipping methods based on urgency and cost considerations.

7. Does SourcifyChina provide post-production support?

Yes, SourcifyChina offers post-production support, including product testing, assembly, packaging, and ongoing maintenance of molds. Our after-sales service team is always available to address any issues or provide further assistance.

These FAQs offer insight into how SourcifyChina handles plastic mold manufacturing, ensuring quality and cost-efficiency for their clients.

When considering plastic mold cost manufacturing from SourcifyChina factory, there are several tips to ensure cost-efficiency and quality:

1. Initial Consultation: Engage in detailed discussions with SourcifyChina to understand their capabilities, the types of molds they manufacture, and their past project experience.

2. Design Optimization: Work closely with the design team to optimize the mold design. Simple designs with fewer complex features often cost less. Ensure the design is finalized before manufacturing to avoid costly modifications later.

3. Material Selection: Choose suitable materials for the mold. While high-quality steel molds offer durability, aluminum molds are a cost-effective alternative for lower production volumes.

4. Quantity and Volume: Higher production volumes can reduce the per-unit cost. Discuss batch size and production volume to get the best pricing from SourcifyChina.

5. Precision and Tolerances: Define the required tolerances clearly. Higher precision molds increase costs, so balance requirements with budget constraints.

6. Lead Time: Understand the lead time for mold manufacturing. Longer lead times can sometimes offer cost savings compared to expedited orders.

7. Quality Control: Request for detailed quality control processes. Ensure that the factory follows rigorous testing to prevent defects and ensure consistency.

8. After-Sales Support: Inquire about post-manufacturing support for mold maintenance and potential modifications. Having a reliable support system can save costs in the long run.

9. Quotes and Comparisons: Obtain detailed quotes and compare them with other manufacturers. Transparent pricing helps identify hidden costs and ensures better budgeting.

10. Logistics and Shipping: Factor in logistics and shipping costs. SourcifyChina might offer bundled services, which can reduce overall expenses.

By focusing on these areas, you can effectively manage the costs associated with plastic mold manufacturing while ensuring quality production from SourcifyChina.

Sure, here are some frequently asked questions (FAQ) with answers regarding sourcing plastic mold costs from SourcifyChina factory:

1. What factors affect the cost of plastic molds at SourcifyChina factory?

The cost of plastic molds depends on various factors including the complexity of the design, the type of plastic material, mold size, the number of cavities, production volume, and surface finish requirements.

2. How can I get a quote for my plastic mold project?

You can get a quote by submitting your detailed project specifications, including design files (CAD), material preferences, and production volumes, directly to SourcifyChina’s sales team via email or through their online request form.

3. What type of file formats does SourcifyChina accept for design submissions?

SourcifyChina typically accepts standard file formats like STL, STEP, IGES, and DWG for 3D models and designs. It’s best to confirm with them directly for any specific requirements.

4. Are there any minimum order quantity (MOQ) requirements?

The MOQ can vary depending on the complexity and type of the mold. It’s recommended to ask SourcifyChina directly for the MOQ related to your specific project.

5. How long does it take to manufacture and deliver the mold?

Lead times for mold manufacturing can range from a few weeks to a few months depending on the mold’s complexity and the current workload of the factory. It’s advisable to discuss timelines at the quoting stage.

6. What is the warranty or guarantee provided by SourcifyChina for their molds?

SourcifyChina typically offers a warranty on the molds, covering manufacturing defects and ensuring a certain number of shots or cycles. Specific warranty terms can be confirmed directly with their sales representatives.

7. Can SourcifyChina provide prototype molds before mass production?

Yes, SourcifyChina can create prototype molds to validate designs and functionalities before moving on to mass production. This can help in identifying any design adjustments needed and ensuring quality.

8. What payment methods does SourcifyChina accept?

SourcifyChina accepts various payment methods including wire transfers, credit cards, and possibly other options. It is best to confirm the available payment methods directly with their team.

9. Does SourcifyChina offer services beyond mold manufacturing?

Yes, SourcifyChina often provides additional services such as product assembly, post-processing, packaging, and shipping to offer a comprehensive manufacturing solution.

Sourcing competitive plastic mold costs from factories like SourcifyChina involves careful planning and strategic communication. Here are some tips to help you achieve the best results:

1. Research Factories: Begin by researching SourcifyChina and similar factories to ensure they have the expertise and resources to meet your needs. Look for reviews, testimonials, and case studies.

2. Clarify Requirements: Provide detailed information about your project. This includes the type of plastic, mold complexity, production volume, and any specific quality standards or certifications required.

3. Request Detailed Quotes: Ask for comprehensive quotes that break down costs, including material, labor, design, and any additional fees. Ensure quotes are for similar specifications to make accurate comparisons.

4. Negotiate: Use the information you gather to negotiate better terms. Highlight the potential for long-term business to secure favorable pricing.

5. Evaluate Total Cost of Ownership: Consider not just the initial mold cost but also factors like shipping, lead times, and potential maintenance or repair costs.

6. Sample Testing: Prior to full-scale production, request sample molds or prototypes to evaluate quality. This helps in verifying the factory’s capability to meet your standards.

7. Verify Compliance: Ensure the factory complies with all relevant regulations and standards, which can impact cost and quality.

8. Check Lead Times: Confirm the production and delivery timelines to ensure they align with your project schedule.

9. Communication: Maintain clear and regular communication with the factory. Good relationships can lead to better pricing and service.

10. Payment Terms: Discuss and agree on favorable payment terms. Options might include phased payments tied to project milestones.

By following these steps, you can effectively manage and reduce the costs associated with sourcing plastic molds from SourcifyChina or similar factories.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.