“Reliable Source for Competitive China Factory Injection Mold Prices: Sourcify Delivers Quality Solutions”

Eager to streamline your manufacturing costs without compromising on quality? Discover the competitive injection mold pricing from China’s top factories, verified and sourced through Sourcify for unparalleled reliability and efficiency in your production process.

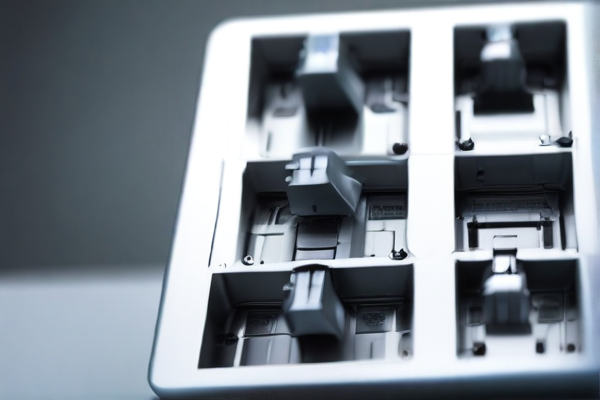

SourcifyChina Factory stands out for its competitive pricing in injection mold manufacturing. By leveraging advanced technology and efficient production processes, they offer buyers cost-effective solutions without compromising on quality.

Moreover, SourcifyChina Factory prioritizes customer satisfaction by providing personalized service and tailored solutions. Their experienced team understands the unique needs of each client and delivers accordingly.

Their robust quality control system ensures that each mold meets stringent standards. This commitment to quality minimizes defects, saving buyers time and money in the long run.

Additionally, SourcifyChina Factory’s extensive network allows for fast turnaround times. Buyers benefit from quicker project completion and reduced lead times, enhancing overall supply chain efficiency.

In conclusion, choosing SourcifyChina Factory for injection mold purchasing in China guarantees cost savings, quality assurance, personalized service, and swift delivery conditions. Their dedicated support and proven track record make them a reliable partner for all your injection molding needs.

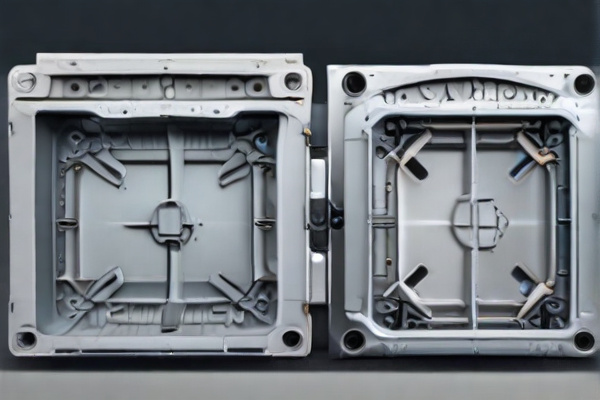

Injection mold price varies based on factors like mold size, complexity, material, and production volume. Different types of molds such as single-cavity, multi-cavity, and family molds cater to diverse manufacturing needs and cost implications.

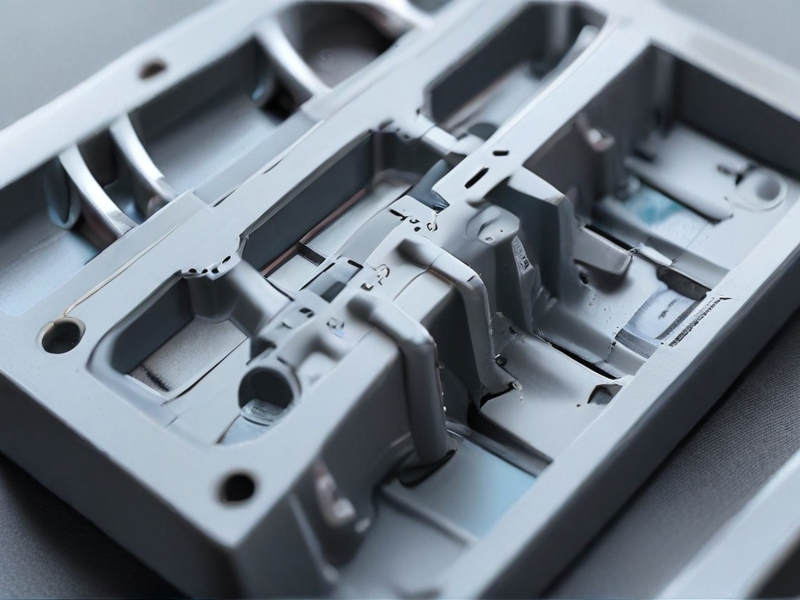

– Mold Size: Larger molds generally incur higher costs due to the increased material and machining required.

– Mold Complexity: More complex mold designs with intricate features or tighter tolerances can increase the price due to the additional engineering and precision involved.

– Mold Material: Durable and high-performance materials like steel tend to be more expensive than aluminum but offer longer lifespan and more consistent product quality.

– Production Volume: High-volume production can justify the expense of more advanced and durable molds, whereas low-volume runs might use simpler, less costly molds.

– Single-Cavity Molds: Typically lower cost but produce one part per cycle, making them suitable for low to moderate production needs.

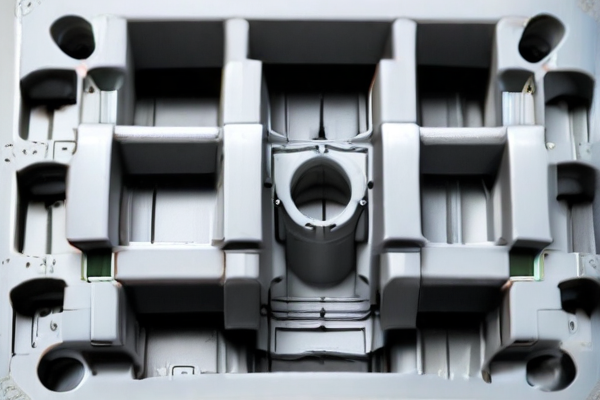

– Multi-Cavity Molds: Higher initial cost but offer cost efficiency in high production runs as they produce multiple parts per cycle.

– Family Molds: Ideal for making different parts of a single assembly in one cycle but can be complex and costly to design.

– Tooling Costs: Initial costs including design, programming, and manufacturing of the mold, which vary significantly based on the aforementioned factors.

– Maintenance Costs: Regular maintenance and potential repairs to ensure mold longevity and consistent production quality.

– Cycle Time: Faster cycle times reduce overall production cost per part but may require more sophisticated molding equipment.

– Customization: Custom molds designed for specific applications might incur higher pricing due to specialized requirements and unique design elements.

– Supplier Location: Geographic location of the mold manufacturer can influence costs due to varying labor rates and shipping expenses.

Understanding these variables helps manufacturers choose the right mold type and manage budget effectively.

Injection mold price is a critical factor in manufacturing, balancing quality with cost-efficiency. Understanding these costs helps optimize production and manage budgets effectively.

– Product Design: Affects size and complexity of the mold.

– Material Selection: Different plastics have varying costs.

– Production Volume: Higher volume can reduce per-unit cost.

– Tooling Costs: Initial cost for creating the mold.

– Cycle Time: Speed of production affects overall cost.

– Maintenance: Regular upkeep to ensure longevity and efficiency.

– Labor Costs: Skilled labor impacts mold pricing.

– Technology: Advanced techniques can streamline the process.

– Geographic Location: Location influences material and labor costs.

– Supplier Experience: Experienced suppliers often offer better pricing through efficiency.

– Customization Needs: Specialized designs can increase price.

– Lead Time: Shorter lead times may come at a premium.

– Quality Control: Ensuring high quality can add to costs.

– Market Demand: Higher demand can drive prices up.

– Energy Costs: Manufacturing processes consume energy, influencing price.

Understanding these variables in injection mold pricing enables manufacturers to make informed decisions, ultimately ensuring a balance between cost and quality.

SourcifyChina provides competitive prices for injection mold manufacturing, utilizing quality materials catered to international standards. They offer a comprehensive range of materials including aluminum, steel, and specialized alloy composites suited for various industries and project specifications.

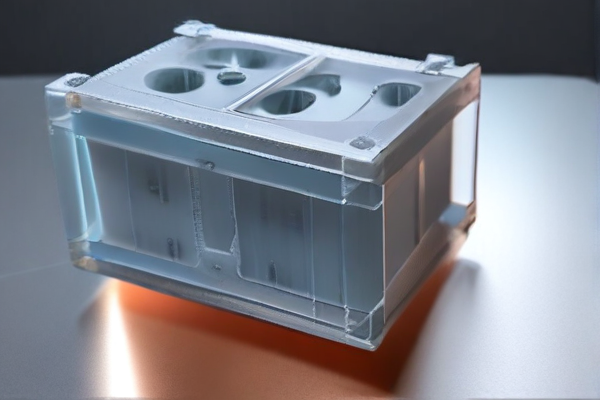

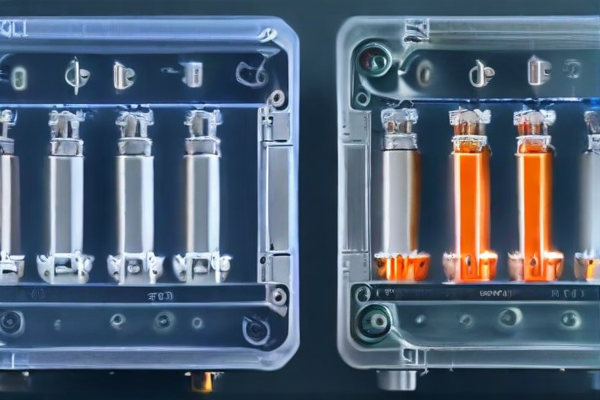

The choice of material directly impacts the cost and durability of the mold. Aluminum, although less expensive, is ideal for prototyping and low-volume production. Steel, particularly hardened tool steel, offers longevity and strength, making it suitable for high-volume manufacturing runs.

SourcifyChina emphasizes precision in mold crafting, ensuring the material chosen aligns with client requirements and production goals. The selection process considers factors like material flow, thermal properties, and resistance to wear and tear.

By providing transparent pricing structures and detailed material recommendations, SourcifyChina helps clients optimize their budget while ensuring high-quality results. They leverage advanced technology and skilled craftsmanship to deliver molds that meet precise specifications, guaranteeing dependable performance and reduced cycle times.

In summary, SourcifyChina’s injection mold pricing reflects a balance of material quality and cost-efficiency. Clients benefit from their expertise in material selection, which translates to reliable, durable molds tailored to specific production needs. Their dedication to transparency and quality makes them a trustworthy partner in the manufacturing sector.

SourcifyChina specializes in providing competitive injection mold prices without compromising on quality. Through an extensive supplier network, they leverage economies of scale to offer affordable rates for high-quality molds. This balanced approach ensures that clients receive both cost-effective and reliable solutions.

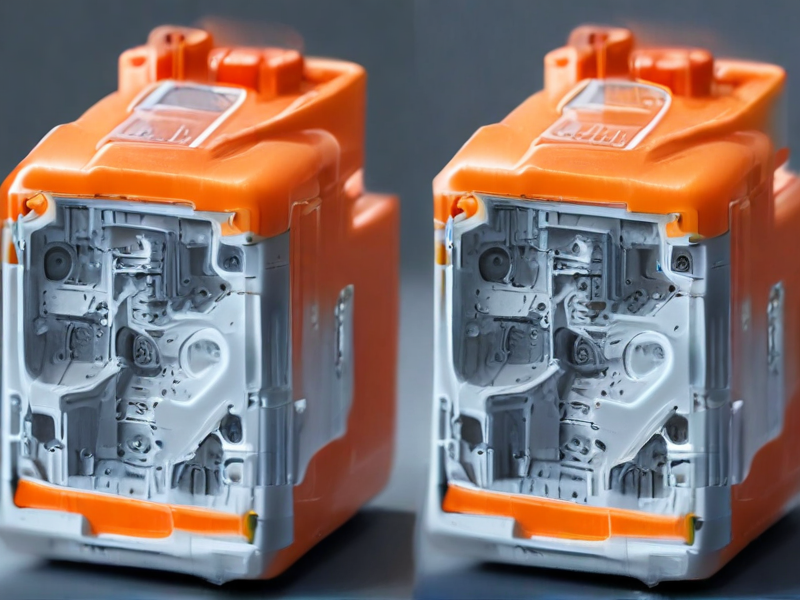

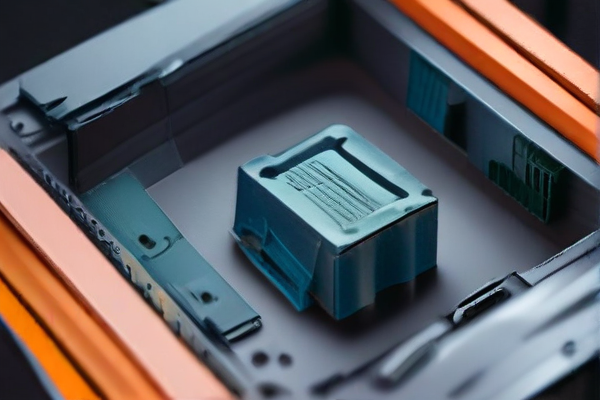

Quality control is a paramount focus in SourcifyChina’s manufacturing process. Each injection mold undergoes rigorous inspection stages, including material verification and dimensional accuracy assessments. Advanced technologies, like 3D scanning and computer-aided design (CAD) software, are employed to ensure precision.

The manufacturing process follows a systematic approach with multiple quality checks at every stage. From initial design to final production, meticulous craftsmanship is maintained. This ensures that the molds not only meet but exceed industry standards. Moreover, highly skilled engineers oversee the process, ensuring that every mold is built to exact specifications.

Client satisfaction is further enhanced through transparent communication and regular updates throughout the manufacturing process. SourcifyChina commits to timely delivery and high product efficacy. They also provide post-production support to address any potential issues, thereby ensuring a seamless customer experience.

In conclusion, SourcifyChina integrates affordable pricing with stringent quality controls to deliver outstanding injection molds. Their meticulous approach, coupled with advanced technology and expert oversight, guarantees that clients receive top-notch products tailored to their specific needs. This commitment to quality and affordability sets SourcifyChina apart in the competitive market of injection mold manufacturing.

SourcifyChina offers competitive injection mold prices that appeal to a broad spectrum of industries. Their transparent pricing strategies ensure clients know exactly what they are paying for without hidden costs. This affordability does not compromise quality; SourcifyChina maintains high standards in delivering durable and precise molds.

Their comprehensive cost analysis helps customers understand the various pricing components, such as material selection, mold configuration, and production volume. Efficient production processes streamline operations, minimizing overhead costs and maximizing value. Clients benefit from reduced lead times, which allows for quicker project turnaround.

SourcifyChina leverages advanced manufacturing technologies and skilled labor, ensuring superior mold accuracy and longevity. Their expertise spans various sectors, including automotive, healthcare, and consumer electronics. This diversity enables them to tailor molds to specific industry requirements, providing customized solutions.

Additionally, SourcifyChina encourages sustainable practices by using eco-friendly materials and efficient production methods. Clients can opt for green manufacturing solutions that do not compromise quality. These environmentally responsible practices align with global sustainability goals and can bolster a company’s eco-friendly reputation.

For businesses seeking reliable and cost-effective mold production, SourcifyChina is an exemplary choice. Their commitment to maintaining affordable prices while delivering high-quality products makes them a standout in the injection molding industry.

Injection molding is a cost-efficient manufacturing process that offers numerous economic and practical benefits, especially for mass production.

– Cost Per Unit: Injection molding significantly reduces the cost per unit when producing large quantities of parts.

– Material Efficiency: The process minimizes material wastage, which lowers raw material costs and benefits the environment.

– Labor Costs: Automation in injection molding reduces labor costs and increases production speed.

– Consistency and Quality: High precision molds ensure consistent part quality and reduce defect rates.

– Design Flexibility: Complex and intricate part designs can be easily achieved, offering flexibility in product development.

– Speed: High production rates allow for meeting tight deadlines and faster turnaround times.

– Scalability: Ideal for scalability, making it easier to ramp up production based on demand.

– Durability: Produces strong and durable parts, reducing the need for frequent replacements and long-term maintenance costs.

– Energy Efficiency: Modern injection molding machines consume less energy, contributing to lower operational costs.

– Material Versatility: Wide range of material options to meet specific performance requirements and price points.

– Waste Reduction: Ability to reuse plastic waste and scraps, contributing to sustainable manufacturing practices.

– Economies of Scale: Larger production batches lead to lower overall costs due to economies of scale.

– Precision and Tolerance: Capable of producing parts with tight tolerances, reducing the need for additional machining or corrections.

– Speed to Market: Decreases time needed from prototype to final product, accelerating market entry.

In summary, the benefits of injection mold pricing are vast and cover cost efficiency, production quality, material use, and overall process sustainability, making it a preferred choice for manufacturers globally.

The price of injection molds is influenced by various factors that contribute to the cost and quality of the final product. Understanding these features can help in optimizing production and managing expenses.

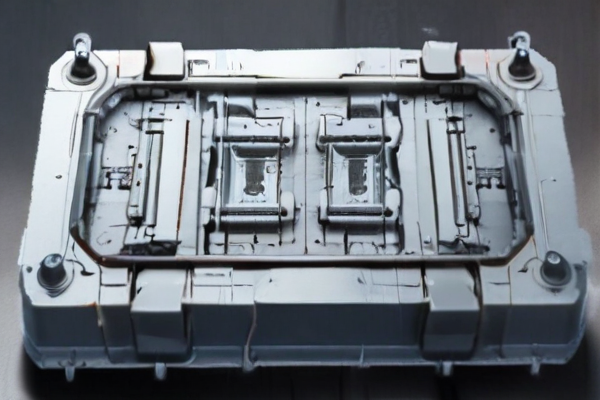

– Material Type: The type of material used, such as steel or aluminum, impacts the cost.

– Complexity: More intricate designs require higher precision and longer production times.

– Size and Cavities: Larger molds with multiple cavities increase material and machining costs.

– Production Volume: High-volume orders generally reduce the unit cost through economies of scale.

– Surface Finish: Polishing and texturing for specific finishes can add to the cost.

– Maintenance: Durable molds with higher upkeep standards can be more expensive.

– Lead Time: Shorter deadlines often require expedited services, raising the price.

– Technological Features: Advanced features like automation and intricate cooling systems elevate the cost.

– Tooling Costs: Initial setup and tooling charges can be significant in determining the overall price.

– Supplier Expertise: Experienced manufacturers with a proven track record might charge a premium.

Understanding these features helps streamline the design and manufacturing process, potentially leading to cost savings and efficient production planning.

SourcifyChina is renowned for offering competitive prices for injection molding services. Specializing in custom products, they cater to diverse sectors by producing high-quality molded components efficiently. Their cost-effective solutions are a result of optimized processes and skilled labor, ensuring premium products without breaking the bank.

The company stands out due to its focus on customization. From intricate designs to large-scale production runs, SourcifyChina tailors its services to meet client needs. This flexibility attracts a global clientele seeking unique, reliable products. Their expertise spans various industries, including automotive, consumer electronics, and medical devices.

Quality assurance is a cornerstone of SourcifyChina’s operations. Utilizing advanced machinery and rigorous testing protocols, they guarantee the consistency and durability of their molded parts. This commitment to excellence builds trust and long-term relationships with clients, further enhancing their market reputation.

In addition to cost and quality advantages, SourcifyChina prides itself on efficient project management. They offer end-to-end solutions, from initial design consultations to final product delivery. This streamlined approach minimizes production time and enhances client satisfaction.

Ultimately, SourcifyChina’s competitive injection mold prices, expert customization, and unwavering commitment to quality make them a preferred partner for businesses worldwide. By focusing on their strengths, they continue to deliver exceptional value in the realm of custom molded products and projects.

SourcifyChina is a leading company specializing in the procurement of high-quality injection mold solutions at competitive prices, specifically catering to businesses seeking cost-efficient manufacturing options. With a strong presence in China, the company leverages the region’s advanced industrial capabilities to deliver precision-engineered molds that meet stringent international standards. SourcifyChina’s comprehensive services encompass the entire process from design and development to production and delivery, ensuring that each mold is tailored to the specific needs of their clients. By partnering with a network of vetted, reliable suppliers, they are able to offer robust pricing strategies that make high-quality manufacturing accessible. The company is committed to transparency, efficiency, and customer satisfaction, making it a trusted partner for businesses aiming to optimize their production costs without compromising on quality. Whether for automotive, consumer electronics, or medical devices, SourcifyChina provides tailored solutions that empower companies to achieve their manufacturing goals efficiently.

Injection molding is a critical manufacturing process in the aerospace, defense, and marine industries, attributable to its ability to produce complex components with high precision and repeatability. In aerospace applications, weight reduction and material strength are paramount. Injection molding allows for the use of advanced composite materials and high-performance polymers that meet stringent regulatory standards while reducing weight. The precise production capabilities of injection molding mean that intricate geometries and components with tight tolerances, such as air ducts, housings, and brackets, can be reliably mass-produced, driving down individual unit costs and improving overall efficiency.

In the defense and marine sectors, durability, reliability, and cost-effectiveness are key considerations. Injection molding technology can produce robust parts made from materials that withstand harsh environments, such as extreme temperatures, saline conditions, and mechanical stress. For instance, components like radar housings, cable connectors, and various types of enclosures and fittings are often injection-molded to withstand demanding operational requirements. Furthermore, the ability to scale production without sacrificing quality makes injection molding a cost-effective solution for manufacturing both large and small parts. This scalability is vital for defense and marine applications where quantities may range from limited prototype runs to full-scale production, ensuring that per-part injection mold price remains economical while meeting high safety and performance standards.

Injection mold pricing is a critical consideration in the automotive industry, where complex, high-precision parts are essential for vehicle performance and safety. Automotive manufacturers rely on injection molding to produce a wide range of components, from large structural parts like bumpers to small, intricate elements such as clips and fasteners. The cost of an injection mold in this sector is influenced by factors like material selection, mold complexity, part volume, and production speed. High-grade materials and intricate designs typically incur higher costs, but these expenses are justified by the durability and precision required in automotive applications. Accurate injection mold pricing allows manufacturers to budget effectively, ensuring they can meet stringent industry standards without compromising on quality or performance. Ultimately, cost-effective molding solutions help maintain the balance between innovation, safety, and affordability in automotive production.

In the electronics industry, injection mold pricing is equally significant due to the demand for small, precise, and often highly complex components. Electronic devices such as smartphones, laptops, and wearable technology rely on injection molding for parts like casings, connectors, and insulation components. The cost of molds in this field is primarily driven by the intricacy of the designs and the precision required to meet electronic device specifications. As electronic components continue to shrink and integrate more functionality, the demand for highly detailed and accurate molds increases, which can elevate mold costs. However, investment in high-quality molds ensures the production of parts that meet the rigorous durability and performance standards of modern electronics. Properly managed mold pricing ensures that electronics manufacturers can maintain efficient production cycles, reduce waste, and deliver increasingly sophisticated products to the market. The careful balance of cost and precision in injection mold pricing is essential for sustaining innovation and competitiveness in the fast-evolving electronics landscape.

Injection mold price plays a critical role in the construction industry, particularly in the production of customized components and materials. High-quality molds that can produce durable, precision-engineered elements are essential for building infrastructure, where consistency and reliability are paramount. For instance, components such as window frames, wall panels, and various fixtures can be mass-produced with injection molding, significantly reducing crafting time and labor costs. The investment in quality molds can lead to substantial cost savings over time, despite the initially high injection mold prices, as the longevity and efficiency of the molds ensure a lower cost per unit. Accurate mold engineering also minimizes material wastage and guarantees that each piece meets stringent safety and regulatory requirements, making it a preferred choice for large-scale construction projects.

In the energy sector, particularly for sustainable and renewable energy solutions, injection mold prices impact the feasibility and scalability of production. Precision molds are used to manufacture components for solar panels, wind turbines, and other green technology devices. For example, producing high-quality, durable wind turbine blades requires molds that can withstand significant stress and wear, ensuring reliability and longevity in harsh environmental conditions. Although the initial mold cost can be high, the benefits of mass production, reduced material waste, and enhanced component performance justify the expense. Furthermore, the cost of molds influences the affordability of solar energy products, directly affecting the broader adoption and implementation of renewable energy solutions. Thus, investing in quality injection molds is essential for the energy sector to maintain a balance between efficiency, innovation, and cost, driving the global move towards sustainable energy practices.

The industrial equipment industry heavily relies on the precision and cost-effectiveness of injection molding to manufacture various components, making the calculation of injection mold prices a critical aspect of production planning. Injection molding provides a high degree of accuracy and repeatability, which is essential for producing complex parts with tight tolerances. The cost of creating these molds is influenced by factors such as the complexity of the design, the type of materials used, and the expected production volume. A well-calculated injection mold price not only ensures that production runs are economically feasible but also helps in maintaining competitive pricing for the final products in the market. Additionally, the upfront cost of the mold can be amortized over large production runs, reducing the per-unit cost and enhancing the profitability of projects.

Moreover, understanding the injection mold price is vital for budgeting and financial forecasting within the industrial equipment sector. Companies need to account for these costs early in the product development cycle to avoid budget overruns and ensure timely delivery of high-quality parts. Choosing the right materials for the mold, whether it be steel or aluminum, can also impact both the initial investment and the longevity of the mold, further affecting long-term production costs. Advanced simulation technologies can assist in predicting wear and optimizing mold designs to extend their lifespan, offering a better return on investment. By accurately assessing and managing mold expenses, companies can enhance their operational efficiency, align with financial goals, and meet market demands effectively, thus sustaining their competitive edge in the industry.

Medical devices often require precision, durability, and adherence to stringent safety standards, making the production process a critical factor. Injection molding stands out as a preferred method for manufacturing these devices due to its ability to produce high-quality, complex components at scale. The injection mold price directly impacts the cost-effectiveness and feasibility of producing a large volume of medical devices. Despite the potentially high initial cost of creating the injection mold, the long-term benefits include consistency in part reproduction, reduced labor costs, and minimized material waste. For instance, components like syringe bodies, inhalers, and IV components benefit from injection molding’s precision and repeatability, enabling manufacturers to meet regulatory standards and deliver reliable products.

Additionally, the injection mold price encompasses several factors such as mold design, material selection, and manufacturing complexity. Medical device manufacturers often require molds made from high-grade stainless steel or aluminum to ensure durability and compliance with health standards. Advanced molds with multiple cavities can produce several parts in one cycle, increasing throughput and reducing per-unit costs, thus justifying the higher upfront investment. It’s crucial for manufacturers to balance the initial mold cost with the projected production volume and lifecycle of the device. An investment in higher-quality molds can lead to lower maintenance costs and longer mold lifespans, ultimately enhancing the overall cost efficiency and product quality in the competitive medical devices market.

Injection mold pricing plays a critical role in the machining and manufacturing sector, where precision and cost-efficiency are paramount. In machining processes, the initial price of an injection mold can significantly impact the overall production budget. The cost is influenced by factors such as mold complexity, material selection, and the anticipated longevity of the mold. High-quality materials and intricate designs naturally demand higher prices due to the advanced machining techniques required during the mold-making process. However, investing in superior molds can lead to enhanced durability and fewer defects in the final products, ultimately translating to long-term savings and higher quality outputs. This initial investment is, therefore, a strategic decision that greatly affects the operational dynamics of a manufacturing unit.

In the broader manufacturing application, understanding injection mold pricing is key for project feasibility and pricing strategies. Companies must consider not only the upfront mold cost but also the lifecycle costs, which include maintenance, repair, and potential modifications. Accurately estimating these expenses helps in setting realistic product prices, ensuring competitive advantage and market profitability. Moreover, the injection mold price can affect the speed of market entry; lower-cost molds might allow for quicker production ramp-ups but could also result in compromises on product quality or durability. Hence, manufacturers often conduct a detailed cost-benefit analysis to decide the optimal balance between mold investment and expected production quality, ensuring that they remain efficient and competitive in a fast-paced market environment.

FAQ for Manufacturing Injection Mold Price Quality Work from SourcifyChina Factory

Q1: What factors influence the cost of injection molds at SourcifyChina?

A1: The cost of injection molds is influenced by several factors including the complexity of the mold design, size, the material used, number of cavities, production volume, and any additional features such as inserts or texturing.

Q2: How does SourcifyChina ensure the quality of injection molds?

A2: SourcifyChina ensures quality through rigorous material selection, precision machining, and thorough testing processes. Our QC team conducts multiple inspections including first article inspections, in-process checks, and final product evaluations.

Q3: What is the typical lead time for producing injection molds?

A3: The lead time can vary depending on the complexity and size of the mold. However, for standard molds, the typical lead time is between 4 to 6 weeks. For more complex projects, it could extend to 8 to 12 weeks.

Q4: Can SourcifyChina accommodate custom mold designs?

A4: Yes, SourcifyChina specializes in custom mold designs. Our experienced engineers work closely with clients to develop molds that meet their specific requirements and production needs.

Q5: What materials are used in the construction of your injection molds?

A5: We use high-quality materials such as P20, H13, S7, and stainless steel to construct our injection molds, ensuring durability and precision in your production processes.

Q6: Does SourcifyChina offer design assistance or consultation services?

A6: Yes, we offer design assistance and consultation services to help optimize your mold design for manufacturability, cost efficiency, and performance.

Q7: Are there any volume requirements for placing an order?

A7: While we handle projects of various sizes, we generally recommend a minimum production volume to ensure cost efficiency. Please contact our sales team for specific volume requirements.

Q8: How does SourcifyChina handle after-sales support?

A8: We provide comprehensive after-sales support, including maintenance services and prompt troubleshooting assistance to ensure your production line runs smoothly.

Q9: Can I get a quote before proceeding with the mold production?

A9: Absolutely. We offer free, no-obligation quotes based on your specific mold design and production requirements. Contact us with your details to receive an accurate estimate.

When considering injection mold price manufacturing from a SourcifyChina factory, several key tips can help ensure you get the best value and quality:

1. Define Requirements Clearly: Provide detailed specifications for your mold, including material type, part geometry, surface finish, and expected production volume. Clear documentation helps avoid misunderstandings and misquotes.

2. Material Selection: Different materials have varying costs and properties. Discuss available options with the manufacturer to choose the best material balancing cost and durability.

3. Tooling Complexity: Simpler designs cost less. Complex features like undercuts, threads, and tight tolerances increase manufacturing difficulty and expense. Streamline your design if possible.

4. Mold Type: Determine whether you need a prototype mold, low-volume production mold, or high-volume production mold. Each type has different cost implications and lifespan.

5. Supplier Verification: Verify the credibility and reliability of the SourcifyChina factory. Check reviews, request case studies, and, if possible, visit the facility to assess their manufacturing capabilities.

6. Quotation Comparison: Obtain and compare quotes from multiple suppliers. Ensure each quote covers all aspects of the project, including design, production, finishing, and shipping.

7. Negotiate Terms: Don’t hesitate to negotiate terms, including price, payment schedules, lead times, and quality assurance processes.

8. Prototype Testing: Before full-scale production, consider creating a prototype to test the mold’s performance. This can save costs by identifying and correcting issues early.

9. Quality Control: Establish quality control measures to ensure the molds meet your standards. Request inspection reports and consider third-party audits if needed.

10. After-sales Support: Ensure the supplier provides robust after-sales support, including maintenance, repairs, and any adjustments required during production.

Prioritize communication and collaboration with your chosen supplier to achieve a cost-effective and high-quality injection mold manufacturing experience.

Sure, here are some frequently asked questions (FAQ) with answers about sourcing injection mold prices from SourcifyChina Factory.

Q1: What information do I need to provide to get an accurate injection mold price?

A1: To obtain an accurate price, provide detailed specifications such as CAD drawings, material preferences, estimated production volume, mold complexity, and any specific quality requirements.

Q2: How long does it take to receive a quote for an injection mold?

A2: Typically, you can expect to receive a quote within 3 to 5 business days after submitting all necessary details.

Q3: What factors affect the cost of an injection mold at SourcifyChina?

A3: The cost is influenced by mold complexity, size, material, precision requirements, expected production volume, and additional services like prototyping and testing.

Q4: Can SourcifyChina handle both low-volume and high-volume production runs?

A4: Yes, SourcifyChina is equipped to manage both low-volume and high-volume production, ensuring flexibility to meet diverse project needs.

Q5: Are there any hidden costs involved in the pricing?

A5: SourcifyChina provides transparent pricing. However, additional costs may arise for special materials, expedited services, and post-processing requirements. Make sure to discuss all possible costs upfront.

Q6: What is the typical lead time for producing an injection mold?

A6: Lead times can vary based on mold complexity and factory workload, but it’s usually between 4 to 8 weeks from order confirmation to mold completion.

Q7: Do you offer any guarantees or warranties for the molds produced?

A7: Yes, SourcifyChina offers warranties covering mold defects and production quality, although specific terms may depend on the agreement made during the order process.

Q8: Can I visit the factory to see the mold-making process?

A8: Yes, factory visits can be arranged. Contact SourcifyChina to schedule a visit and ensure all necessary permissions and safety protocols are in place.

Q9: What payment options are available?

A9: Payment options typically include T/T (telegraphic transfer), L/C (letter of credit), and other negotiable terms depending on the order size and customer relationship.

Q10: How do you ensure consistent quality in mold production?

Sourcing injection mold prices from SourcifyChina factory can be streamlined by following these strategic tips:

1. Detailed Specifications: Clearly define and provide detailed specifications of the injection mold you need. This includes dimensions, material, complexity, and tolerances. Well-defined specs ensure accurate quotes.

2. Volume and Usage: State the expected production volume and how the molds will be used. This helps the factory offer appropriate materials and techniques, influencing cost.

3. Quality Standards: Specify the quality standards and certifications you require (e.g., ISO). This impacts the type of materials and processes, which in turn affects pricing.

4. Sample or Prototype: If possible, provide a sample or prototype. This gives the factory a tangible reference, ensuring they understand your needs more clearly.

5. Request for Quote (RFQ): Draft a comprehensive RFQ document. Include all the details and ask for itemized quotes to understand cost breakdowns.

6. Lead Time: Indicate your timeline and any flexibility. Rush orders may incur higher costs.

7. Shipping Costs: Clarify whether the quoted price includes shipping. Factor in logistics to get a complete cost picture.

8. Supplier Audit: Conduct a background check on SourcifyChina. Look for reviews, check their previous work, and possibly conduct a virtual or physical audit if feasible.

9. Negotiation: Be prepared to negotiate. Often, prices can be adjusted based on volume commitments or long-term agreements.

10. Payment Terms: Discuss payment terms upfront. Understanding their payment schedule (e.g., deposits, milestones) helps manage cash flow and expectations.

11. Communication: Maintain clear and regular communication to avoid misunderstandings and ensure smooth transactions.

By thoroughly preparing and engaging with SourcifyChina factory using these tips, you can effectively source competitive injection mold prices.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.