Choosing SourcifyChina Factory for purchasing Swiss screw machines from China ensures quality and reliability. Their state-of-the-art manufacturing facilities comply with international standards, providing precision engineering that meets the rigorous demands of buyers.

Excellent customer support distinguishes SourcifyChina. Their multilingual team ensures smooth communication, making order placements and clarifications seamless. They understand diverse client needs and provide customized solutions effectively.

Competitive pricing is another attractive feature. SourcifyChina offers Swiss screw machines at highly competitive rates without compromising on quality. Their efficient production processes and bulk purchasing power enable cost savings.

Timely delivery is guaranteed. With an established logistics network, SourcifyChina ensures that orders reach customers punctually. This reliability helps in maintaining continuous business operations for buyers.

To conclude, SourcifyChina Factory is an ideal choice for purchasing Swiss screw machines from China. Their dedication to quality, customer satisfaction, competitive pricing, and reliable delivery make them a preferred partner for global clients.

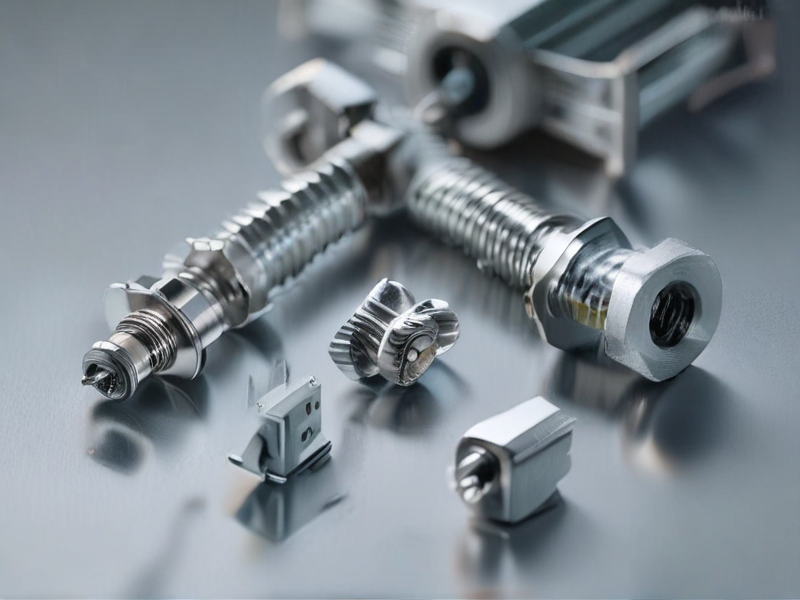

Swiss screw machines are precision lathes used for manufacturing small, intricate parts. These machines excel in high-volume production and ensure tight tolerances. They come in various types with multiple options to suit different manufacturing needs.

– Automatic Swiss Screw Machines: Automatically control multiple tools and parts for high-speed production.

– CNC Swiss Screw Machines: Computer-controlled for complex geometries and high precision.

– Hybrid Swiss Screw Machines: Combine both manual and CNC capabilities for flexible operation.

– Multispindle Swiss Screw Machines: Feature multiple spindles for simultaneous machining of various parts.

Options to consider:

– Bar Feeders: Automatic bar loading systems to increase production efficiency.

– Tool Holders: Various types for different tooling needs; quick-change, rigid, and coolant-through.

– Coolant Systems: High-pressure, standard, and misting systems for heat management.

– Chip Management: Solutions like conveyors and chip bins for effective waste handling.

– Sub-spindles: Offer additional machining capabilities on the rear end of parts.

– Live Tooling: Enables the use of rotating tools for milling, drilling, and tapping operations.

– Back Working: Allows machining on the reverse end of parts without removing them from the machine.

By understanding and selecting the appropriate Swiss screw machine and its options, manufacturers can achieve optimal performance and efficiency in producing small, detailed components.

Swiss screw machines, also known as Swiss-type lathes, are precision tools used for manufacturing small, intricate parts with tight tolerances, making them ideal for various industries.

– Medical Devices: Producing surgical instruments, dental implants, and orthopedic screws with exceptional accuracy.

– Automotive: Manufacturing precision components like fuel injectors, sensor housings, and brake parts.

– Electronics: Creating small, intricate parts for connectors, switches, and enclosures.

– Aerospace: Fabricating high-precision components for navigational instruments and engine parts.

– Watchmaking: Crafting detailed, miniature parts for high-end watches.

– Defense: Producing critical components for firearms and guided systems.

– Consumer Goods: Making parts for appliances, eyeglasses, and writing instruments.

– Telecommunications: Manufacturing connectors and other intricate components for communication devices.

– Custom Components: Enabling production of highly specialized parts across varied industries, thanks to flexibility and precision.

– Prototyping: Allowing the creation of high-precision prototypes for new product development.

Swiss screw machines offer unparalleled precision and versatility, making them indispensable for industries requiring intricate and accurate components. Their ability to handle complex geometries and high production volumes ensures their continued relevance in advanced manufacturing operations.

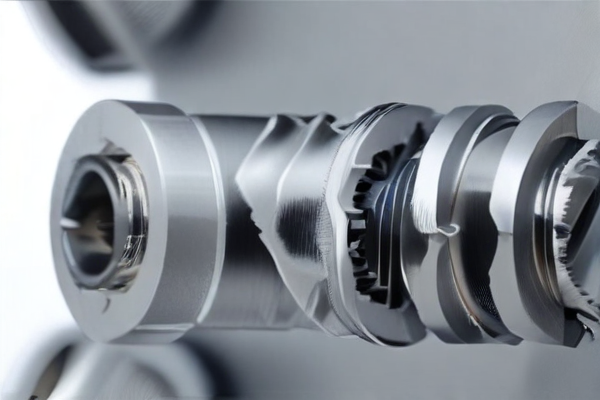

The “SourcifyChina Swiss screw machine” exemplifies precision and durability, primarily constructed of high-grade stainless steel. This material is renowned for its robustness, excellent resistance to corrosion, and impressive lifespan, making it ideal for the exacting demands of high-precision machining.

In addition to stainless steel, critical components may incorporate hardened tool steels. These enhance wear resistance and maintain dimensional accuracy over prolonged use. The combination of these materials ensures the machine’s capability to perform intricate tasks consistently.

Furthermore, the machine’s structural integrity is bolstered using cast iron. Cast iron absorbs vibrations effectively, reducing operational noise and enhancing the machine’s precision. It also offers a rigid framework for the machine’s various mechanical parts.

The blend of stainless steel, hardened tool steels, and cast iron in the “SourcifyChina Swiss screw machine” underscores its superior performance. These materials work synergistically to provide a reliable, durable, and highly accurate machining solution suitable for a variety of industrial applications.

The quality control manufacturing process at “SourcifyChina” for Swiss screw machines begins with rigorous material evaluation to ensure optimal raw materials. Every piece is inspected for conformity to specified tolerances.

Precision is maintained using sophisticated tooling and state-of-the-art machinery. Regular calibration of equipment ensures accurate operation, minimizing errors and defects in the production process.

Operators receive comprehensive training in quality standards and machine operation. This ensures they are equipped to identify and resolve issues that may compromise product quality at any stage of production.

Each finished component undergoes meticulous inspection and testing. Advanced measurement and analysis equipment verify dimensions, surface finish, and other critical attributes.

Quality documentation is thorough, tracking each batch through every stage of production. This traceability ensures accountability and facilitates prompt troubleshooting if issues are identified.

Continuous improvement is a cornerstone of SourcifyChina’s quality control. Feedback loops from customers and internal audits drive refinements in processes and methodologies.

Through these extensive quality control measures, SourcifyChina ensures that every Swiss screw machine component meets the highest standards of precision and reliability. By prioritizing quality at every stage, the company consistently delivers exceptional products to its clients.

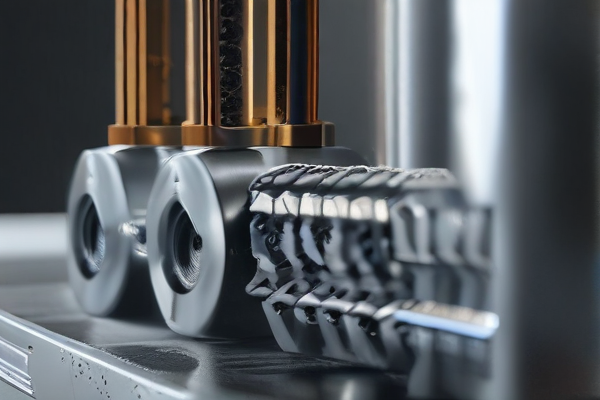

SourcifyChina’s Swiss screw machines offer precise and efficient machining capabilities for small, complex parts. These advanced machines boast high-speed operation, ensuring a rapid production process without sacrificing accuracy. Their multi-axis functionality supports simultaneous cutting operations, reducing time and boosting productivity.

The machines are highly versatile, suitable for various materials including metals, plastics, and composites. They are perfect for industries such as aerospace, automotive, and medical devices, where intricate component requirements are standard. This versatility ensures that manufacturers can meet diverse customer demands with ease.

SourcifyChina’s Swiss screw machines integrate automated systems and advanced software, further enhancing precision and consistency. These features minimize human error and ensure repetitive tasks are completed to exact specifications. The user-friendly interface streamlines setup and programming, enabling operators to achieve optimal performance quickly.

Maintenance and downtime are significantly reduced due to the robust design and quality components. The machines are designed for longevity, keeping production lines running smoothly and efficiently over long periods. This durability translates into lower operational costs and higher return on investment.

In conclusion, SourcifyChina’s Swiss screw machines provide unmatched precision, versatility, and efficiency in small parts manufacturing. Their advanced features and robust design make them an invaluable asset across multiple industries.

Swiss screw machines, renowned for their precision and efficiency, are indispensable in modern manufacturing. They offer numerous benefits that enhance production quality and speed.

– High Precision: Swiss screw machines are capable of achieving tight tolerances, which is crucial for industries requiring high-precision parts like aerospace, medical, and electronics.

– Increased Efficiency: These machines can perform multiple operations simultaneously, significantly reducing cycle times and boosting productivity.

– Versatility: They are compatible with various materials, including metals and plastics, allowing for diverse application across industries.

– Reduced Waste: Swiss screw machines minimize material waste, leading to cost savings and more environmentally friendly production processes.

– Automation Capabilities: Many modern Swiss screw machines come with advanced automation features, reducing the need for manual intervention and decreasing labor costs.

– Complex Geometries: These machines excel at producing complex geometrical parts, enabling the manufacture of intricate components that would be difficult or impossible with other machining methods.

– Enhanced Production Rates: The speed and efficiency of Swiss screw machines make them ideal for high-volume production environments.

– Longevity and Durability: These machines are built to last, providing a long-term investment that continues to deliver value over time.

– Consistent Quality: The repeatability of Swiss screw machines ensures that parts produced are consistent in quality, which is crucial for industries where uniformity is key.

– Space Efficiency: Despite their powerful capabilities, Swiss screw machines are typically compact, making them suitable for businesses with limited floor space.

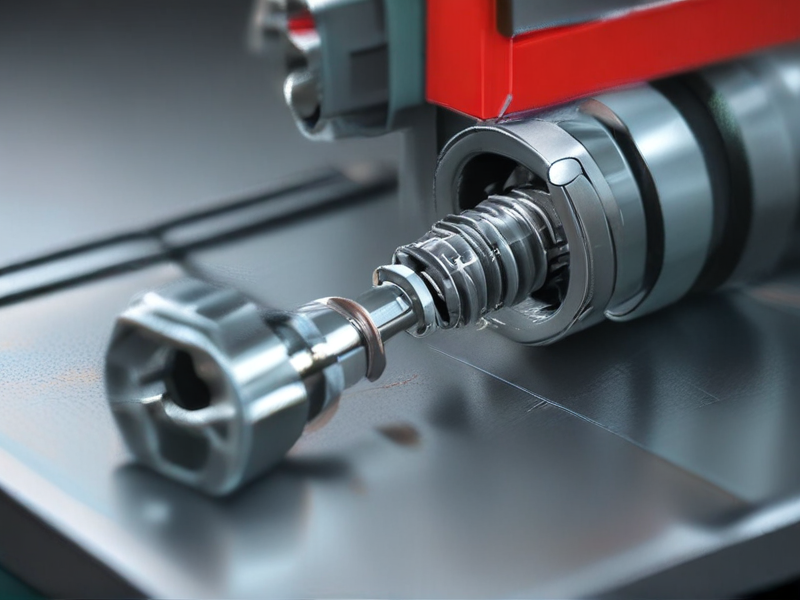

Swiss screw machines are precision tools used for producing small, intricate parts with great accuracy. These machines are known for their distinctive guide bushing, which supports the material close to the cutting tool, ensuring high precision.

Features of Swiss Screw Machine:

– Guide Bushing: Provides support close to the cutting area, reducing deflection.

– Multiple Tools: Capable of holding multiple tools, allowing for complex operations in a single setup.

– Automatic Bar Feed: Continuous feeding of material for uninterrupted production.

– Sub-Spindle: Facilitates back-end machining and complex part manufacturing.

– High-Speed Operations: Capable of high-speed cutting, improving efficiency.

– Reduced Setup Time: Quick-change tool holders reduce downtime.

– Precision Machining: Ideal for producing complex, high-precision parts.

– Multi-Axis Control: Enhanced versatility for intricate geometries.

– Computer Numerical Control (CNC): Advanced models feature CNC for automated, precision control.

– Compact Design: Typically designed to save space in a workshop.

– Tool Life Management: Systems to monitor and manage tool wear.

– Coolant Systems: Integrated systems to manage heat and extend tool life.

Swiss screw machines excel in applications requiring tight tolerances, complex geometries, and high-volume production, making them essential in industries like medical, aerospace, and electronics. They blend efficiency with precision, delivering superior quality for small-part manufacturing.

SourcifyChina specializes in custom products and projects using Swiss screw machines. These precision tools are ideal for creating intricate parts with unparalleled accuracy and efficiency. Swiss screw machines are renowned for their ability to handle complex geometries and tight tolerances, which is particularly useful in industries like aerospace, medical, and electronics.

Customized products are crafted by skilled technicians who leverage state-of-the-art Swiss screw machines. From prototype to production, SourcifyChina ensures every product meets rigorous quality standards. Their expertise allows for the manufacture of components that range from simple to highly complex.

Projects undertaken by SourcifyChina span various sectors requiring high precision and reliability. Whether you need small batches or large-scale production, their Swiss screw machines offer unmatched versatility and consistency. This ensures your projects not only meet but exceed specifications.

In addition to quality, SourcifyChina emphasizes timely delivery and cost-effectiveness. By utilizing the latest technology and optimal processes, they minimize lead times and reduce costs, providing immense value to customers. This dedication to excellence ensures your custom products are delivered on time and within budget.

Overall, SourcifyChina’s use of Swiss screw machines is a cornerstone of their commitment to precision and quality in custom manufacturing. By combining advanced machinery with skilled craftsmanship, they deliver superior custom products and successful projects that set them apart in the industry.

SourcifyChina is an esteemed company specializing in the production and supply of Swiss screw machines, also known as CNC (Computer Numerical Control) Swiss-type lathes or automatic lathes. Renowned for their precision engineering and exceptional quality, these machines play a pivotal role in manufacturing intricate components for industries such as aerospace, medical devices, electronics, and automotive sectors. SourcifyChina seamlessly integrates advanced technology with rigorous quality control measures, ensuring that each machine delivers unparalleled accuracy, efficiency, and durability. The company prides itself on its robust customer support and tailored solutions, catering to the specific needs of clients worldwide. By leveraging a blend of experienced craftsmanship and state-of-the-art machinery, SourcifyChina remains a trusted name in the global market, driving innovation and excellence in precision machining.

Swiss screw machines, renowned for their precision and efficiency, play a critical role in producing intricate components for the aerospace, defense, and marine industries. In aerospace applications, these machines fabricate high-precision parts required for engines, instrumentation, and control systems. The stringent tolerances and dependable repeatability of Swiss screw machines ensure the reliability and performance of aircraft components, which are paramount in an industry where safety and precision are non-negotiable. For instance, producing small, complex parts such as fuel injector nozzles, electrical connectors, and other engine components is streamlined with Swiss screw machines, contributing to the overall robustness and efficiency of aircraft systems.

In the defense and marine sectors, Swiss screw machines are equally indispensable. In defense, the machines manufacture components for various weaponry and surveillance systems where precision is crucial. Parts such as firing pins, missile components, and electronic connectors demand impeccable accuracy and consistency, which Swiss screw machines deliver. Similarly, in the marine industry, Swiss screw machines produce parts for navigation instruments, propulsion systems, and other critical marine machinery. The ability to work with a wide range of materials, from lightweight aluminum to robust stainless steel, makes Swiss screw machines versatile for diverse operational requirements. Thus, these machines underpin the production of high-quality, reliable parts essential for the demanding environments encountered in aerospace, defense, and marine applications.

Swiss screw machines, known for their unparalleled precision and efficiency, play a crucial role in the automotive industry. These machines, designed for manufacturing small, intricate, and high-tolerance parts, are ideally suited for producing components such as fuel injector nozzles, valve components, and custom fasteners. The high level of precision offered by Swiss screw machines ensures that each component meets the stringent quality and performance standards required in modern vehicles. Furthermore, the ability to produce complex geometries with tight tolerances aids in the production of lightweight and compact parts, which is vital for enhancing vehicle efficiency and performance. The automotive industry’s ongoing drive towards automation and precision manufacturing ensures that Swiss screw machines remain indispensable in the production of high-quality automotive components.

In the electronics sector, Swiss screw machines are equally vital, providing the capability to produce miniature parts with exceptional accuracy. These machines are commonly used to manufacture connectors, pins, and other micro-components critical for electronic devices, from smartphones to medical instruments. The demand for miniaturization and the integration of complex functionalities in electronic devices necessitate the high precision that Swiss screw machines offer. Additionally, the machines’ ability to work with a variety of materials, including metals and specialized polymers, supports the creation of durable and reliable electronic parts. The versatility and precision of Swiss screw machines make them invaluable in the fast-evolving electronics industry, where the smallest components can significantly impact overall device performance and reliability.

The Swiss screw machine, known for its precision and efficiency, has marked its significance in the construction industry by enabling the production of highly accurate and durable components. Its capability to manufacture small, intricate parts with tight tolerances is crucial for the development of reliable architectural fasteners, hinges, and brackets. These components play a vital role in assembling diverse structural elements, from steel frameworks to modular buildings, ensuring stability and safety. Furthermore, the Swiss screw machine’s versatility in working with various metals and alloys facilitates the creation of custom fittings that adhere to specific architectural designs and engineering requirements, thus promoting innovation and flexibility in construction projects.

In the realm of energy applications, Swiss screw machines are instrumental in fabricating essential parts for renewable energy systems and traditional power generation equipment. The precision machining allows for the mass production of components used in wind turbines, solar panel mounts, and energy storage systems, ensuring optimal performance and longevity. For example, these machines can produce gears, bearings, and connectors with exact specifications, enhancing the efficiency of wind turbines and reducing maintenance costs. In the oil and gas industry, Swiss screw machines create high-quality, reliable components for drilling and extraction equipment, supporting safe and efficient energy production. The machine’s ability to consistently deliver parts with exacting standards ensures the smooth operation and reliability of energy infrastructures across various sectors.

The industrial equipment industry significantly benefits from the application of Swiss screw machines, renowned for their precision and efficiency in manufacturing intricate parts. These machines are particularly advantageous for producing components that require tight tolerances and complex geometries, such as those found in aerospace, automotive, and medical devices. Swiss screw machines are engineered to operate continuously, often unattended, facilitating large-scale production runs without sacrificing quality. Their ability to machine materials ranging from stainless steel to high-performance plastics ensures versatility across various sectors. By employing Swiss screw machines, manufacturers achieve higher precision, improve productivity, and reduce the time-to-market for critical components.

Moreover, Swiss screw machines contribute to cost-efficiency in the industrial equipment industry by minimizing material waste and optimizing cycle times. Their design allows for simultaneous multi-axis operations, where multiple tools can work on a single piece concurrently, significantly reducing the machining time. This capability is crucial for industries where the rapid production of high-quality parts directly impacts operational efficiency and competitiveness. Additionally, the integration of CNC (Computer Numerical Control) technology with Swiss screw machines enhances their adaptability and ease of programming, allowing more complex part designs and quick adjustments to production processes. Through these advancements, the Swiss screw machine stands as a pivotal tool, driving innovation and maintaining the rigorous standards demanded by modern industrial applications.

The medical device industry has significantly benefited from the precision and efficiency offered by Swiss screw machines. These automated lathes are renowned for their ability to produce small, intricate components with tight tolerances, making them ideal for manufacturing medical devices. For example, the production of bone screws, stents, and catheter tips relies heavily on the high precision and consistency that Swiss screw machines provide. The ability to machine components from difficult-to-cut materials like titanium and various surgical-grade stainless steels is particularly beneficial, ensuring that the end products meet stringent medical standards for safety and durability.

Beyond their precision, Swiss screw machines are highly versatile, capable of performing multiple operations on a single setup, such as turning, milling, and threading. This multi-functionality not only speeds up production times but also reduces the need for secondary operations, leading to cost savings and reducing the potential for human error. In a field where precision and reliability can directly impact patient outcomes, the utilization of Swiss screw machines is integral. By enabling the production of complex, high-quality components efficiently and accurately, these machines help medical device manufacturers innovate and keep pace with the evolving demands of modern medicine.

The Swiss screw machine, also known as a Swiss-type lathe or Swiss automatic lathe, is an essential tool in the realm of machining and manufacturing, particularly for producing high-precision small parts. Originally developed for the watchmaking industry in Switzerland, these machines are adept at creating intricate components with tight tolerances. The primary advantage of Swiss screw machines lies in their ability to move the workpiece in both rotational and longitudinal axes, allowing for exceptional precision and reduced deflection, even with long and slender parts. By mounting the workpiece on a collet and supporting it near the cutting tool, Swiss screw machines can achieve unparalleled accuracy, making them indispensable for industries such as aerospace, medical, and electronics, where tiny, complex parts are paramount.

In the manufacturing application, Swiss screw machines streamline production by automating and optimizing repetitive tasks, enhancing efficiency, and reducing labor costs. These machines can perform multiple operations—turning, drilling, threading, and milling—without the need for secondary processes, thereby minimizing production time and costs. The versatility of Swiss screw machines extends to various materials such as metals, plastics, and composites, demonstrating their adaptability in producing components like screws, shafts, and intricate medical devices. Furthermore, their integration with modern CNC (Computer Numerical Control) technology facilitates high-volume production runs while maintaining consistent quality. As manufacturing continues to evolve, the role of Swiss screw machines remains pivotal, offering a blend of precision, efficiency, and versatility necessary to meet the demands of today’s complex production environments.

Certainly! Here’s a concise FAQ for “Swiss Screw Machine Quality Work from SourcifyChina Factory”:

1. What is Swiss screw machining?

Swiss screw machining is a precision manufacturing process used to fabricate small, intricate parts with high accuracy. It’s ideal for complex geometries and tight tolerances.

2. Why choose SourcifyChina for Swiss screw machine work?

SourcifyChina offers advanced technology, skilled technicians, and rigorous quality control to ensure all parts meet stringent specifications. Our competitive pricing and timely delivery make us a reliable partner.

3. What materials can SourcifyChina work with?

We handle a wide range of materials including stainless steel, aluminum, brass, titanium, and various plastics. Custom material requests are also accommodated.

4. What industries do you serve?

We serve diverse sectors such as medical devices, aerospace, automotive, electronics, and consumer goods, among others.

5. What tolerances can you achieve?

Our Swiss screw machines can achieve tolerances as tight as +/- 0.0002 inches, ensuring exceptional precision for demanding applications.

6. What is your minimum order quantity (MOQ)?

Our MOQs vary depending on the complexity and material of the parts. However, we strive to accommodate both small and large orders to meet our customers’ needs.

7. How does your quality assurance process work?

Our quality assurance includes in-process inspections, final inspections, and utilizing advanced metrology equipment such as CMMs (Coordinate Measuring Machines) to ensure every part meets standards.

8. Can you provide prototyping services?

Yes, we offer rapid prototyping to help clients validate designs before committing to full-scale production.

9. What is your typical lead time?

Lead times depend on the order size and complexity, but typical production runs can be completed within 2-6 weeks. Expedited options are available upon request.

10. How do I get a quote?

You can contact us via email or through our website with your part specifications, drawings, and quantity requirements. We’ll provide a detailed quote within 48 hours.

11. Do you offer any finishing services?

Yes, we provide a variety of finishing options including anodizing, plating, heat treatment, and custom surface finishes to meet specific requirements.

12. How do you handle shipping and logistics?

Sourcing Swiss screw machine manufacturing from SourcifyChina factory can be a strategic move for precision parts. Swiss screw machines are renowned for their ability to produce high-precision, complex components. Here are some tips to optimize your collaboration:

1. Specify Requirements Clearly:

Ensure all technical specifications, tolerances, and materials are clearly defined. Swiss screw machines are highly precise, but they require detailed instructions for optimal results.

2. Prototype First:

Request a prototype before mass production. This validates the factory’s capability and the fidelity of your part’s design.

3. Quality Assurance:

Check if the factory adheres to international quality standards such as ISO 9001. On-site inspections or third-party audits can be beneficial.

4. Communication:

Establish strong communication channels. Frequent updates via email, video calls, or project management tools ensure alignment and transparency.

5. Lead Time:

Clarify production and shipping lead times upfront. Account for potential delays, especially for highly intricate parts.

6. Cost Management:

Understand the cost structure, including material costs, machine setup fees, and labor. Bulk orders can often reduce the per-unit cost.

7. Technology and Equipment:

Verify the factory has modern, well-maintained Swiss screw machines and experienced operators to handle your specific requirements.

8. Supply Chain Reliability:

Evaluate their supply chain for consistency in raw material availability. Unchecked supply chains can lead to delays.

9. Intellectual Property (IP) Protection:

Ensure there are strong measures in place to protect your design and IP rights.

10. Reviews and References:

Research reviews or ask for references from other clients to gauge the factory’s reliability and quality.

By focusing on these aspects, you can leverage SourcifyChina’s advanced manufacturing capabilities to produce high-quality Swiss screw machine parts efficiently.

Q: What is a Swiss screw machine, and why should I source it from SourcifyChina factory?

A: A Swiss screw machine, also known as a Swiss-type lathe, is a precision tool used for manufacturing small, complex components. Sourcing from SourcifyChina factory ensures high-quality standards, competitive pricing, and reliable delivery directly from a reputable Chinese manufacturing hub.

Q: How can I trust the quality of the Swiss screw machines from SourcifyChina factory?

A: SourcifyChina factory adheres to stringent international quality standards and certifications like ISO 9001. They conduct rigorous quality inspections and testing to ensure machines meet or exceed expectations.

Q: What customization options are available for Swiss screw machines at SourcifyChina factory?

A: SourcifyChina factory offers customization in terms of machine specifications, tooling options, and even software integrations to meet specific production needs. Consult their technical team for personalized solutions.

Q: What is the lead time for delivery after placing an order?

A: The standard lead time ranges from 4 to 8 weeks, depending on the complexity and customization of the machine. SourcifyChina factory ensures timely updates and tracking information throughout the process.

Q: Are there minimum order requirements when purchasing from SourcifyChina factory?

A: There are no strict minimum order requirements, making it convenient for businesses of all sizes to source the machines they need. However, bulk orders may attract additional discounts.

Q: What kind of after-sales support is available?

A: SourcifyChina factory provides comprehensive after-sales support, including technical assistance, parts replacement, and maintenance services. Their customer service team is available 24/7 to assist with any issues.

Q: How do I get a quote for a Swiss screw machine from SourcifyChina factory?

A: To get a quote, visit the SourcifyChina factory website and fill out the inquiry form with your specific requirements. Alternatively, you can contact their sales team directly via email or phone for a detailed estimate.

Q: What payment options are available for international buyers?

A: SourcifyChina factory accepts various payment methods including wire transfers, credit cards, and letters of credit (L/C). Payment terms are usually negotiable based on the order volume and customer relationship.

Q: Do they provide installation and training services for the Swiss screw machines?

Sourcing a Swiss screw machine from SourcifyChina can be streamlined by following these steps:

1. Research: Understand your exact requirements in terms of machine size, capabilities, and specifications. Determine the volume of production you anticipate and any special features you need.

2. Supplier Verification: SourcifyChina offers vetted suppliers, but double-check their authenticity. Look for reviews, ask for client references, and verify their manufacturing capabilities.

3. Request a Quote: Clearly outline your specifications and request quotes from several suppliers. Include details like machine type, precision requirements, and any customizations needed. This helps in comparing capabilities and pricing.

4. Technical Details: Ensure that the supplier can provide detailed technical drawings, machine manuals, and operational training if necessary. Verify whether they comply with international standards.

5. Quality Assurance: Inquire about the supplier’s quality control processes. Ask for documentation of previous quality checks and, if possible, arrange an on-site inspection or a virtual tour of their production facility.

6. Payment Terms and Warranty: Negotiate payment terms that mitigate risks, such as a staggered payment plan. Ensure a comprehensive warranty covers parts and labor for a specified period.

7. Shipping and Logistics: Discuss shipping arrangements and lead times. Validate the total cost, including transportation, customs duties, and potential tariffs.

8. After-Sales Support: Confirm the availability of after-sales support, such as maintenance services, spare parts supply, and technical assistance.

9. Contract Review: Before finalizing, thoroughly review all contractual terms, including compliance with your local regulations, and consider having a legal expert look over the agreement.

10. Build Relationships: Maintain open communication lines with the supplier for future collaborations and support.

By following these steps, you can efficiently source a reliable Swiss screw machine through SourcifyChina, ensuring quality, cost-efficiency, and long-term support.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.