## Reliable Insights: SourcifyChina Factory’s Aluminum Extrusion Process

Discover the intricate and reliable aluminum extrusion process at SourcifyChina factory, showcasing state-of-the-art techniques and quality assurance measures that ensure precision and durability in every product.

Choosing SourcifyChina Factory for aluminum extrusion purchases in China offers expert craftsmanship and superior quality control. Their advanced technology ensures precise, durable extrusions that meet various industry standards, providing buyers with reliable and high-quality products.

The factory prides itself on its sustainable practices, minimizing environmental impact while maximizing efficiency. Their commitment to eco-friendly production differentiates them in the competitive market, appealing to green-conscious buyers.

SourcifyChina Factory provides competitive pricing without compromising on quality. Their well-established supply chain and manufacturing expertise enable cost-effective production, ensuring buyers receive maximum value for their investment.

Customer service is another strong point. The factory’s dedicated team assists buyers throughout the purchasing process, ensuring smooth communication, timely delivery, and post-purchase support. This robust service reinforces trust and satisfaction.

In conclusion, SourcifyChina Factory stands out for its quality, sustainability, affordability, and excellent customer service. Choosing them for aluminum extrusion needs ensures a dependable and advantageous partnership, aligning with both business and environmental priorities.

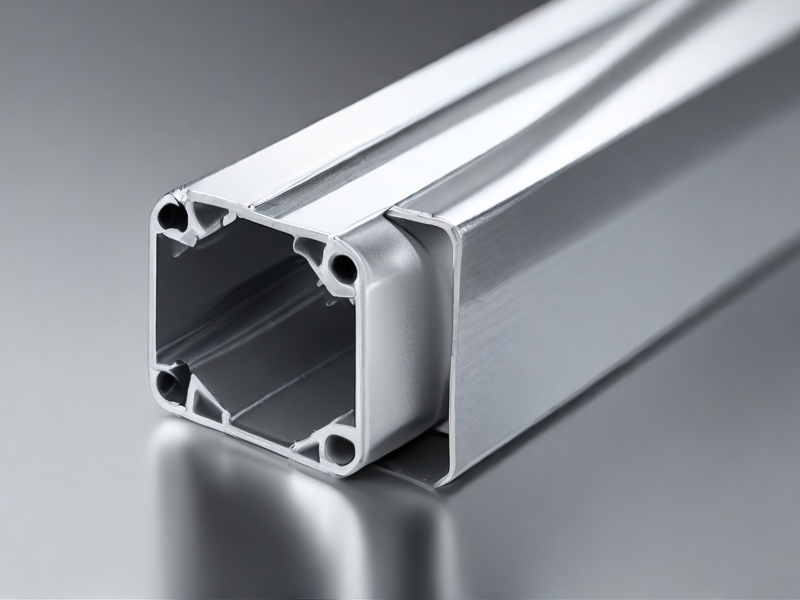

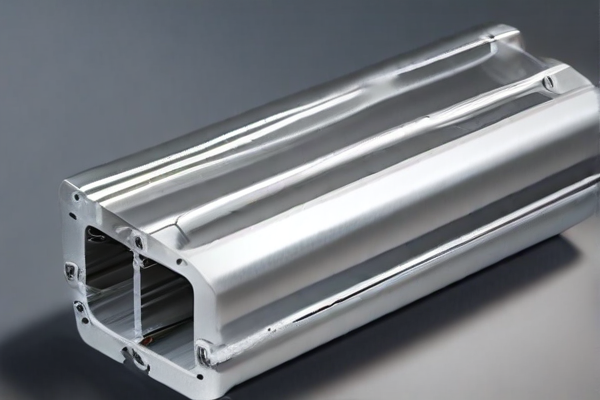

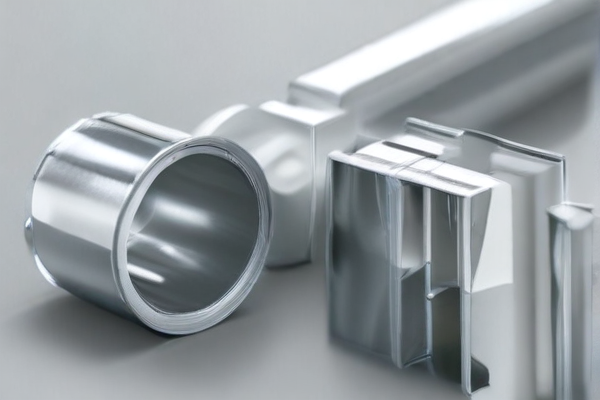

The aluminum extrusion process involves forcing aluminum alloy material through a die to create specific shapes. This method allows for a wide range of complex cross-sectional profiles, making it highly versatile for various applications.

– Direct Extrusion: The most common method where aluminum is pushed through a stationary die.

– Indirect Extrusion: The die moves towards the aluminum billet, reducing friction and force required.

– Hydrostatic Extrusion: Utilizes a hydraulic fluid to apply pressure, ideal for brittle materials.

– Hot Extrusion: Performed at high temperatures, enhancing material flow and shape accuracy.

– Cold Extrusion: Conducted at or near room temperature, providing better surface finish and dimensional control.

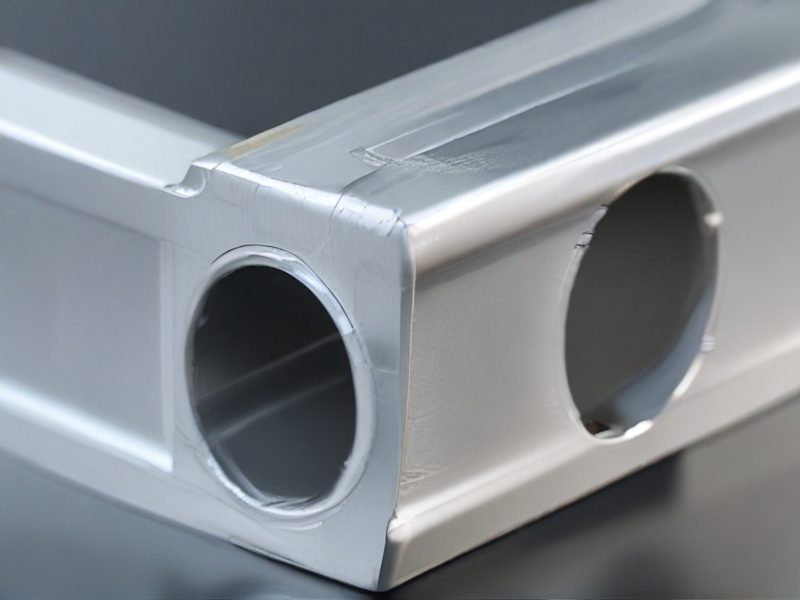

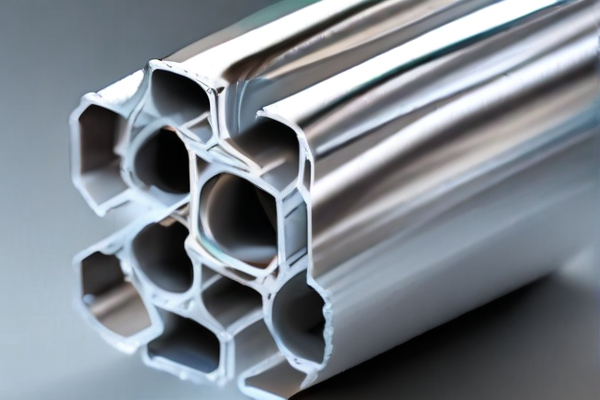

– Seamless Extrusion: Produces hollow profiles without weld seams, ensuring structural integrity.

– Coextrusion: Combines two or more materials to create a single product with multiple properties.

– Multi-Hole Extrusion: Simultaneously extrudes multiple profiles from a single die.

Options for customizing the aluminum extrusion process include varying the alloy composition, modifying die designs, adjusting extrusion temperatures, and applying post-extrusion treatments like anodizing or painting for enhanced surface properties. These variables allow for tailored solutions to meet specific engineering and aesthetic requirements.

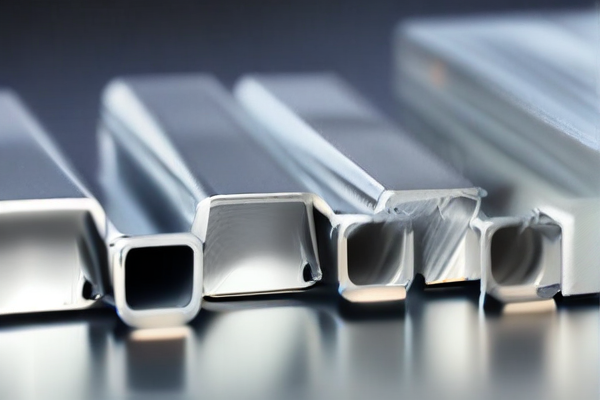

Aluminum extrusion is a versatile process used to create complex cross-sectional profiles, providing lightweight, strong, and malleable solutions across various industries.

– Automotive Industry: Lightweight frames and components reducing vehicle weight.

– Construction: Window frames, curtain walls, and structural components.

– Aerospace: Aircraft bodies and structural components for strength without excess weight.

– Electronics: Heat sinks and housings for electrical equipment.

– Renewable Energy: Frames for solar panels and wind turbines.

– Consumer Goods: Frames for furniture, appliances, and sports equipment.

– Transportation: Railway carriages, bus frames, and shipbuilding components.

– Machinery and Equipment: Custom machine parts and extrusion tools.

– Signage: Frames and supports for advertising and directional signs.

– Greenhouses and Agriculture: Structural frames for greenhouses and irrigation systems.

The aluminum extrusion process plays a crucial role in advancing technology and efficiency by offering tailored solutions for myriad applications, making it indispensable in contemporary manufacturing and design.

The aluminum extrusion process involves heating aluminum billet to a softened state and forcing it through a die to create a specific cross-sectional shape. This technique is integral in manufacturing components used across various industries.

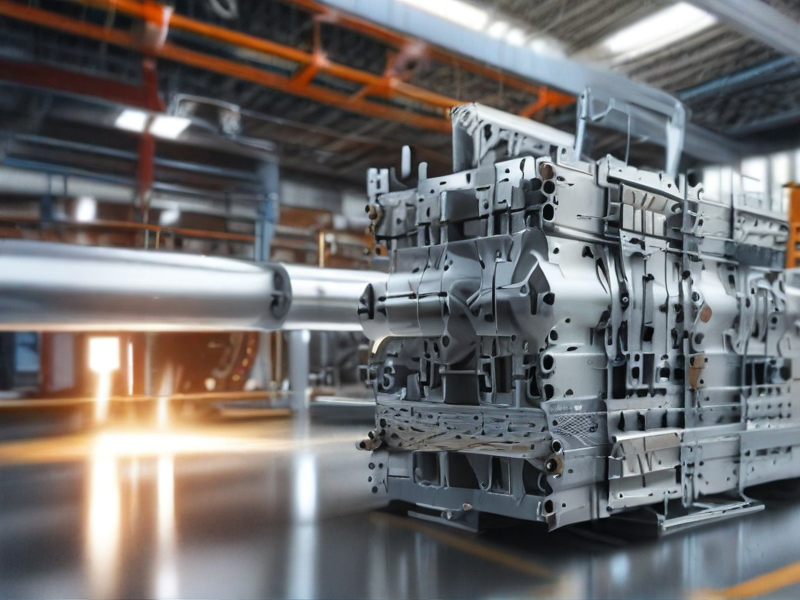

SourcifyChina utilizes state-of-the-art technology to ensure precision in their aluminum extrusion process. They use high-quality dies, ensuring consistent profiles and tight tolerances. The entire process is monitored to maintain the material properties.

The company sources premium aluminum alloys, combining durability with flexibility. These alloys are ideal for creating intricate designs and maintaining structural integrity even under stress, making them suitable for demanding applications.

Their commitment to quality control extends from raw material selection to the final finishing process. Surface treatments such as anodizing and powder coating provide additional protection against environmental effects, enhancing durability and aesthetic appeal.

SourcifyChina’s aluminum extrusion process exemplifies their dedication to engineering excellence, combining advanced technology and high-caliber materials. This meticulous attention to detail ensures superior products that meet stringent industry standards, promising longevity and performance in various demanding applications.

SourcifyChina’s aluminum extrusion process emphasizes stringent quality control procedures to ensure high-grade products. The process begins with selecting premium raw materials, which are meticulously inspected to meet industry standards before they enter production.

Throughout the extrusion process, real-time monitoring systems track critical parameters such as temperature and pressure to ensure consistency. Advanced machinery equipped with sensors detect any deviations, enabling prompt corrective actions to maintain product integrity.

After extrusion, products undergo a rigorous dimensional inspection using precision measuring instruments. This step verifies that the extruded profiles adhere to specified tolerances, ensuring they fit seamlessly into their intended applications.

To further guarantee quality, SourcifyChina conducts mechanical testing, such as tensile and hardness tests, on random samples from each batch. This ensures that the aluminum profiles meet necessary strength and durability requirements.

Finally, the extruded profiles are subjected to surface treatments like anodizing or powder coating. Each finished product is visually inspected for surface defects, ensuring an aesthetically pleasing and functional end product. Quality control documentation is meticulously maintained throughout the process, ensuring traceability and accountability.

SourcifyChina’s comprehensive quality control manufacturing process ensures that their aluminum extrusions consistently meet and exceed customer expectations. Their commitment to quality and precision is at the core of their manufacturing philosophy, guaranteeing superior products and customer satisfaction.

SourcifyChina specializes in precision aluminum extrusion, catering to diverse industrial needs. Their advanced machinery ensures accurate dimensions, superior strength, and consistent quality in every product. Customization is paramount, enabling bespoke shapes tailored to client specifications.

Their process starts with selecting high-grade aluminum alloys, maximizing durability and performance. Following precise heating, the material is pushed through meticulously designed dies, forming complex cross-sectional profiles. This method affords flexibility in design without compromising structural integrity.

Post-extrusion, SourcifyChina implements rigorous quality control, employing cutting-edge technology for inspection. This step ensures each extrusion meets stringent international standards, resulting in reliable products for various applications.

SourcifyChina’s aluminum extrusion capabilities are complemented by their finishing services. Anodizing or powder coating options enhance both aesthetics and corrosion resistance. This attention to detail solidifies their position as a leading aluminum extrusion provider, combining tradition with technological advancements to achieve excellence.

Overall, SourcifyChina is dedicated to delivering high-quality aluminum extrusions, ensuring customer satisfaction through innovation, precision, and extensive industry knowledge. They offer a one-stop solution for all aluminum extrusion needs, maintaining a commitment to excellence in every project.

The aluminum extrusion process offers numerous advantages, from cost efficiency to enhanced material properties. Here are the key benefits:

– Cost Efficiency: Aluminum extrusion is a cost-effective manufacturing process, particularly for creating complex cross-sections and minimizing material wastage.

– Versatility: This process supports a wide range of shapes and designs, enabling the production of components with intricate profiles and varying thicknesses.

– Strength and Weight Ratio: Extruded aluminum has a high strength-to-weight ratio, making it ideal for applications where durability and lightweight materials are essential.

– Corrosion Resistance: Aluminum’s natural oxidation layer provides excellent corrosion resistance, reducing the need for additional coatings or treatments.

– Thermal Conductivity: Aluminum extrusion is excellent for applications requiring high thermal conductivity, such as heat sinks and radiators.

– Recyclability: Aluminum is 100% recyclable without loss of properties, making the extrusion process environmentally friendly and sustainable.

– Customization: It allows for extensive customization, accommodating specific design requirements, including various finishes and coatings.

– Ease of Assembly: Extruded aluminum parts typically feature designs that facilitate easy assembly, often reducing the need for additional fasteners.

– Mechanical Properties: The process enhances mechanical properties such as tensile strength, making it suitable for structural applications.

– Aesthetic Appeal: Aluminum extrusions can be anodized or coated, providing an attractive finish for consumer products and architectural elements.

This combination of benefits makes aluminum extrusion a highly advantageous process across various industries, from automotive to construction.

The aluminum extrusion process involves forcing aluminum alloy material through a specifically designed die to shape it into a predetermined cross-sectional profile.

– Customization: Allows for the creation of complex cross-sectional shapes tailored to specific applications.

– Lightweight: Produces lightweight structures, ideal for applications requiring strength and reduced weight.

– Durability: Generates products with excellent strength and rigidity.

– Corrosion Resistance: Extruded aluminum profiles exhibit high resistance to corrosion and environmental wear.

– Thermal Conductivity: Beneficial for applications requiring efficient heat dissipation.

– Recyclability: Aluminum is 100% recyclable, making the process environmentally friendly.

– Cost-Effectiveness: Offers economical production for high-volume or custom profiles.

– Versatility: Suitable for a wide range of industries, including aerospace, automotive, and construction.

– Surface Finish: Provides smooth and appealing surface finishes, reducing the need for additional treatments.

– Precision: Ensures high dimensional accuracy and consistency across production batches.

– Mechanical Properties: Enhances the mechanical properties of aluminum, making it suitable for demanding applications.

– Speed and Efficiency: Capable of producing large quantities in a relatively short time frame.

– Energy Efficiency: The process requires less energy compared to other metal-forming techniques.

– Fabrication Ease: Facilitates post-extrusion processes such as cutting, machining, and welding.

– Design Flexibility: Enables designers to incorporate intricate details and functional features directly into the profiles.

By leveraging these features, the aluminum extrusion process meets diverse industry needs efficiently and sustainably.

SourcifyChina specializes in the aluminum extrusion process, catering to custom products and projects with precision and efficiency. Utilizing state-of-the-art technology, they ensure high-quality extrusions that meet specific design and tolerance requirements.

Their custom aluminum extrusions are ideal for various industries, offering solutions for automotive, aerospace, architecture, and consumer products. By adapting to unique project requirements, SourcifyChina delivers tailored results with exceptional attention to detail.

The process begins with creating precise dies, followed by heated aluminum billets being forced through these dies to form unique cross-sectional profiles. This ensures uniformity and consistency in the final extrusions.

Quality control is paramount at SourcifyChina, involving rigorous testing and inspection throughout the production process. This guarantees that each product not only meets but often exceeds industry standards.

SourcifyChina places a strong emphasis on customer collaboration, working closely with clients to understand their needs and deliver bespoke solutions. This client-centric approach results in projects that are not only functional but also innovative.

The versatility of aluminum allows for lightweight yet durable custom extrusions, proving indispensable in modern engineering and design. SourcifyChina capitalizes on these properties, providing robust and reliable solutions.

In conclusion, SourcifyChina’s expertise in the aluminum extrusion process ensures the delivery of high-quality, custom products and projects. Their commitment to precision, quality, and customer satisfaction makes them a leader in the field, capable of meeting diverse industry needs efficiently.

SourcifyChina is a prominent company specializing in aluminum extrusion processes, catering to a wide array of industries with precision-engineered solutions. Renowned for their meticulous attention to quality and efficiency, SourcifyChina leverages cutting-edge technology and state-of-the-art machinery to produce custom aluminum profiles that meet the exacting standards of clients globally. Their comprehensive process encompasses everything from design consultation and material selection to extrusion, finishing, and assembly. By maintaining stringent quality control measures and adhering to international standards, they ensure durability, consistency, and performance in every product. The company’s commitment to sustainability is evidenced by their eco-friendly practices, including recycling scrap aluminum and optimizing energy usage throughout production. With a robust supply chain network and a customer-centric approach, SourcifyChina not only delivers superior products but also fosters long-term partnerships, making them a trusted name in the aluminum extrusion industry.

The aluminum extrusion process has revolutionized the aerospace, defense, and marine industries by providing a method to create lightweight, strong, and corrosion-resistant components. In aerospace applications, extruded aluminum shapes are critical due to their excellent strength-to-weight ratio. Aircraft frames, fuselage sections, wing components, and various other structural parts are commonly produced through extrusion. This process allows for precise control over the dimensions and intricacies of each piece, ensuring optimal aerodynamic performance and fuel efficiency. Moreover, the ability to integrate complex features into a single extrusion reduces the need for additional joining processes, thereby enhancing overall structural integrity and reducing manufacturing costs.

In the defense and marine sectors, aluminum extrusions offer similar advantages, contributing to the development of robust and durable military vehicles, naval vessels, and submarines. The anti-corrosive properties of aluminum make it particularly valuable in marine environments where saltwater exposure is a constant concern. This ensures longevity and reduces maintenance needs for watercraft hulls, decks, and superstructures. In defense, armored vehicles and weaponry benefit from the customizability and resilience of extruded aluminum parts, which can be designed to meet specific ballistic or structural requirements. The versatility of the extrusion process allows for rapid prototyping and production, which is crucial for mission-specific adaptations and quick deployment in response to emerging threats. Thus, aluminum extrusion stands as a cornerstone technology across these critical industries, driving innovation and enhancing performance while maintaining cost-effectiveness.

Aluminum extrusion plays a pivotal role in the automotive industry, offering a versatile solution to meet the high demands for lightweight, high-strength, and corrosion-resistant components. Extruded aluminum is often used to manufacture structural components such as crash management systems, chassis, and body frames, which contribute significantly to improving the overall fuel efficiency and performance of vehicles. The process involves pushing aluminum through a shaped die to create long pieces with consistent cross-sectional profiles, which can be customized to fit various design requirements. This method not only allows for the production of complex shapes with tight tolerances but also enhances the recyclability of automotive parts, aligning with the industry’s push towards sustainability. As electric vehicles gain traction, the need for lightweighting to offset the weight of batteries makes aluminum extrusion even more indispensable, supporting advancements in range and energy efficiency.

In electronics, aluminum extrusion is equally transformative, providing innovative solutions for heat dissipation, structural integrity, and aesthetic design. One of the most prominent applications is in the creation of heat sinks and enclosures for electronic devices. The high thermal conductivity of aluminum, combined with the ability to extrude complex fin profiles, ensures efficient heat management for devices such as CPUs, GPUs, and power electronics, thus enhancing performance and longevity. Additionally, extruded aluminum enclosures serve as robust and lightweight protective housings for sensitive electronics, ensuring durability while maintaining an attractive finish that can be anodized or coated in various colors. In the rapidly evolving realm of consumer electronics, the adaptability of aluminum extrusion supports the continuous push for sleeker, more compact, and more efficient devices, meeting the ever-growing demands for technological advancement and user experience.

Aluminum extrusion is a versatile and efficient process widely utilized in the construction industry due to its ability to create complex cross-sectional profiles with high structural integrity. The process involves heating aluminum billets to a malleable state and then forcing them through a die to create the desired shape. This results in components such as window frames, curtain walls, and structural beams that exhibit excellent strength-to-weight ratios, corrosion resistance, and ease of assembly. These benefits make aluminum extrusions a preferred choice for modern architectural projects, where sustainability and energy efficiency are paramount. Moreover, the high recyclability of aluminum contributes to the eco-friendly credentials of construction projects while reducing material wastage and overall construction costs.

In the energy sector, aluminum extrusion plays a critical role in enhancing the performance and efficiency of various applications, ranging from power distribution to renewable energy solutions. For instance, aluminum extruded components are essential in the construction of heat sinks for electronic devices and power systems, owing to aluminum’s superior thermal conductivity and ability to dissipate heat effectively. Additionally, in the realm of renewable energy, aluminum extrusions are integral to the manufacturing of solar panel frames and support structures, where their lightweight yet robust nature facilitates easier installation and maintenance. The process also supports the production of components for wind turbines and electric vehicles, contributing to the shift towards more sustainable and efficient energy systems. The adaptability of aluminum extrusions thus fosters innovation and progress in energy technologies, ensuring more sustainable and resilient energy infrastructures for the future.

The industrial equipment industry heavily relies on the aluminum extrusion process due to its ability to produce strong, lightweight, and precise components. Aluminum extrusion involves forcing heated aluminum through a die to create long shapes with consistent cross-sections. This process is particularly advantageous for manufacturing components that require complex profiles, such as structural frames, heat sinks, and conduits. The resulting products benefit from aluminum’s inherent properties, including high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. These characteristics are crucial for industrial applications where durability and efficiency are paramount, such as in the construction of machinery, transportation equipment, and energy systems.

Moreover, the aluminum extrusion process supports customization and scalability, which are essential for the diverse needs of the industrial equipment sector. Manufacturers can design extrusions to meet specific requirements, incorporating features like grooves, channels, and varying wall thicknesses directly into the extruded shape. This flexibility reduces the need for additional machining and assembly, lowering production costs and lead times. Additionally, the recyclability of aluminum aligns with the industry’s growing emphasis on sustainability, offering an eco-friendly solution without compromising performance. Overall, the aluminum extrusion process provides a versatile, cost-effective method to produce high-quality components, driving innovation and efficiency in industrial equipment manufacturing.

The aluminum extrusion process is pivotal in the manufacturing of medical devices due to its ability to create precise and complex shapes necessary for various applications. This process involves forcing aluminum alloy material through a die with a specific cross-sectional profile, enabling the production of components with high strength-to-weight ratios and excellent thermal and electrical conductivity. For instance, in the construction of medical imaging devices such as MRI and CT scanners, aluminum extrusions are used for frames and structural supports due to their durability and lightweight properties. Additionally, their corrosion resistance ensures longevity and reliability, which are critical in a healthcare setting where device failure is not an option.

Moreover, aluminum extrusions find extensive use in the development of surgical instruments and hospital equipment. The versatility of the extrusion process allows for the creation of custom profiles that can be tailored to the ergonomic requirements of surgeons, thereby enhancing the precision and comfort during procedures. Aluminum’s biocompatibility also makes it suitable for components in direct contact with patients, such as those found in implantable devices. Heat sinks for medical electronics, patient mobility aids like wheelchairs, and even intricate parts of diagnostic machinery are other examples where aluminum extrusions are employed. This process not only supports the high standards of hygiene and performance in medical settings but also contributes to the overall innovation and effectiveness of medical technology.

The aluminum extrusion process is pivotal in machining and manufacturing due to its ability to produce complex cross-sectional profiles that are strong, lightweight, and durable. During the extrusion process, aluminum billets are heated to a malleable state and forced through a die, resulting in long, continuous shapes with consistent cross-sections. This makes aluminum extrusion ideal for creating components used in diverse applications such as automotive frames, aerospace structures, and architectural elements. The process is highly adaptable, allowing for the customization of shapes and sizes to meet specific design requirements, thus enhancing the structural integrity and functionality of the final products. The ability to produce intricate shapes with tight tolerances ensures that machined parts fit precisely and perform reliably in their intended applications.

Moreover, the aluminum extrusion process adds significant value in terms of material efficiency and sustainability. Extrusion produces minimal waste, and the scraps generated can be easily recycled, aligning with the increasing industry focus on sustainable manufacturing practices. The process also facilitates the creation of hollow structures and complex geometries that would be difficult or impossible to achieve with other manufacturing methods such as casting or forging. Post-extrusion, the aluminum can be further machined, anodized, or treated to enhance its surface properties and corrosion resistance, broadening its applicability in harsh environments. This seamless integration of extrusion with other machining and finishing techniques underscores its indispensable role in modern manufacturing, where precision, performance, and sustainability are paramount.

Sure, here are some frequently asked questions (FAQs) about the aluminum extrusion process quality work at SourcifyChina Factory:

What is aluminum extrusion?

Aluminum extrusion is a process where aluminum is forced through a die with a specific cross-sectional profile. This process results in a long piece of aluminum with a consistent shape that can be used for various applications.

Why should I choose SourcifyChina Factory for aluminum extrusions?

SourcifyChina Factory is known for its high-quality aluminum extrusion processes, advanced machinery, and experienced workforce. We ensure stringent quality control measures and efficient production timelines to meet your requirements.

What are the quality control measures in place?

We implement numerous quality control measures such as dimensional verification, surface finish inspection, hardness testing, and tensile strength assessments to ensure the final product meets industry standards and customer specifications.

What types of aluminum alloys do you use?

We typically use a range of aluminum alloys, including 6061, 6063, 6005, and others. The selection of the alloy depends on the mechanical and thermal properties required for your specific application.

Can you create custom profiles?

Absolutely! We specialize in producing custom aluminum extrusion profiles tailored to your design specifications. Our expert team works with you from design to final production to ensure your unique requirements are met.

What is the typical lead time for orders?

Lead times vary depending on the complexity and volume of the order, but typically range from 2 to 6 weeks. For precise timelines, please contact our customer service team.

Is there a minimum order quantity (MOQ)?

Yes, the MOQ depends on the specific project. We encourage you to discuss your needs with our sales team to get a tailored solution that suits your budget and project scope.

What surface finishes do you offer?

We offer a variety of surface finishes including anodizing, powder coating, sandblasting, and polishing. Each finish provides different aesthetic and protective properties.

Do you provide secondary processing services?

Yes, we offer an array of secondary processing services such as cutting, drilling, punching, and CNC machining to deliver a finished product that meets your precise needs.

How do you ensure timely delivery?

We prioritize strategic planning, efficient production schedules, and reliable logistics partners to ensure timely delivery of your orders. Real-time tracking and ongoing communication keep you updated throughout the process.

When it comes to aluminum extrusion process manufacturing, SourcifyChina factory offers notable expertise. Here are some tips to maximize the quality and efficiency of your aluminum extrusion projects:

1. Material Selection: Choose the appropriate aluminum alloy depending on your product’s requirements for strength, corrosion resistance, and malleability. Common alloys include 6061 for general purposes and 6063 for architectural applications.

2. Design Efficiency: Work closely with SourcifyChina’s engineering team to design extrusion profiles that reduce material waste while maintaining structural integrity. Consider features such as hollow sections and thin walls.

3. Tooling Precision: Ensure that extrusion dies are manufactured with high precision and maintained regularly. SourcifyChina utilizes advanced CNC machining for tooling, which guarantees accurate and consistent output.

4. Temperature Control: Monitor the billet temperature and extrusion speed carefully. Precise temperature control is essential for achieving optimal mechanical properties and surface finish.

5. Quenching and Aging: Implement rapid cooling (quenching) of the extruded aluminum to enhance strength, followed by aging treatments to reach the desired mechanical properties.

6. Surface Finishing: Depending on your needs, employ anodizing, powder coating, or polishing to enhance corrosion resistance and aesthetic appeal. SourcifyChina offers a variety of surface treatment options.

7. Quality Assurance: Utilize rigorous quality control protocols, including dimensional inspections, tensile testing, and surface quality checks, to ensure each product meets the specified standards.

8. Sustainability Practices: Sophisticated recycling practices and efficient scrap management can significantly lower costs and environmental impact. SourcifyChina is committed to sustainable manufacturing processes.

By leveraging these tips, you can optimize your aluminum extrusion manufacturing process through SourcifyChina, ensuring high-quality, cost-efficient, and reliable products.

Sure, here are some frequently asked questions (FAQ) and their answers regarding sourcing aluminum extrusion processes from SourcifyChina factory:

Q: What is the minimum order quantity (MOQ) for aluminum extrusion?

A: The MOQ for aluminum extrusion at SourcifyChina typically ranges from 500 to 1,000 kilograms, depending on the complexity and customization of the profiles.

Q: What types of aluminum alloys are available for extrusion?

A: SourcifyChina offers a wide range of aluminum alloys including but not limited to 6061, 6063, 6005, and 7075 to meet different strength, corrosion resistance, and workability requirements.

Q: Can SourcifyChina handle customized designs and specific dimensions?

A: Yes, SourcifyChina specializes in customized aluminum extrusion profiles. Clients can provide detailed drawings and specifications, and the factory can produce extrusions as per those requirements.

Q: What surface finishes can SourcifyChina provide?

A: SourcifyChina offers various surface treatment options such as anodizing, powder coating, painting, and mechanical finishes including polishing and brushing to meet aesthetic and functional needs.

Q: What certifications does SourcifyChina hold for quality assurance?

A: SourcifyChina is certified with ISO 9001 for quality management systems and can comply with other standards such as RoHS, REACH, and specific customer requirements.

Q: How long does it take to receive a quote?

A: Quotes are typically provided within 24 to 48 hours after submitting an inquiry with detailed requirements, including CAD drawings if available.

Q: What is the typical lead time for production and delivery?

A: The lead time for aluminum extrusion production is generally 2 to 4 weeks, with shipping depending on the transportation method chosen. Air freight is faster but more expensive, while sea freight might take longer but is more cost-effective.

Q: Are samples available before full production?

A: Yes, SourcifyChina can provide samples for approval before beginning full-scale production to ensure that client specifications and quality standards are met.

Q: How does SourcifyChina ensure product quality?

A: SourcifyChina employs strict quality control measures including material inspection, in-process quality checks, and final inspection before shipping. They also use advanced testing equipment to ensure product consistency and reliability.

Q: What payment terms does SourcifyChina offer?

Sourcing aluminum extrusions from SourcifyChina factory involves several key steps:

1. Research and Identify Needs: Determine the exact specifications of the aluminum extrusions you need, including size, shape, alloy type, surface finish, and tolerances. This helps in communicating your requirements clearly.

2. Contact SourcifyChina: Reach out to SourcifyChina via their website, email, or phone. Provide detailed specifications and any technical drawings. Ask for a quote and lead time.

3. Evaluate Quotes: Compare the quotes received based on cost, quality, lead time, and any additional services such as packaging or shipping. Ensure that the quote includes all costs to avoid surprises later.

4. Request Samples: Before placing a bulk order, request samples to verify the quality and conformity to your specifications. This step helps in avoiding costly errors.

5. Verify Factory Credentials: Check the factory’s certifications (such as ISO 9001), production capacity, and past client reviews. This ensures reliability and quality assurance.

6. Negotiate Terms: Discuss and negotiate payment terms, shipping arrangements, and any other contractual details. Ensure clarity on delivery schedules and after-sales support.

7. Place Order: Once satisfied with the terms, place a formal purchase order. Ensure that all specifications and terms are clearly documented.

8. Quality Control: Implement a quality control process. This can include third-party inspections before shipping or on-site inspections at the factory.

9. Shipping and Logistics: Coordinate shipping logistics, ensuring proper packaging to prevent damage during transit. Confirm shipping schedules and tracking details.

10. Post-Purchase Support: After receiving the goods, conduct a final quality inspection. Provide feedback to the supplier and address any issues promptly.

By following these steps, you can effectively source aluminum extrusions from SourcifyChina, ensuring quality and reliability in your supply chain.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.