Choosing SourcifyChina Factory for your EDM service needs in China ensures high-quality manufacturing with advanced technology. They offer precision, reliability, and efficiency, essential for achieving superior results in electrical discharge machining.

Moreover, SourcifyChina Factory provides competitive pricing without compromising quality. Their cost-effective solutions help businesses maximize their budgets, making them an ideal partner for both small and large-scale projects.

The factory’s stringent quality control measures guarantee consistency and adherence to international standards. This dedication to quality ensures that every product meets the exact specifications and requirements of clients.

Additionally, SourcifyChina Factory offers excellent customer service and support. Their experienced team assists clients throughout the purchasing process, from initial inquiry to post-delivery, ensuring a smooth and hassle-free experience.

In summary, SourcifyChina Factory is a top choice for buyers seeking EDM services from China due to their advanced technology, competitive pricing, strict quality control, and exceptional customer service.

EDM service, or Electronic Direct Mail, involves sending marketing messages via email to a targeted audience. It includes various options to tailor the service to specific needs and goals.

– Newsletter Campaigns: Regular updates about company news, product launches, and events.

– Promotional Emails: Special offers, discounts, and exclusive deals aimed at boosting sales.

– Transactional Emails: Order confirmations, shipping notifications, and account updates.

– Personalized Emails: Tailored messages based on customer behavior and preferences.

– Drip Campaigns: Automated series of emails sent based on specific triggers and time intervals.

– Re-engagement Campaigns: Targeted at inactive subscribers to rekindle interest.

– Event Invitations: Invites for webinars, conferences, or any other events.

– Surveys and Feedback Requests: Collecting customer opinions and improving services.

– Product Recommendations: Based on previous purchase history and browsing behavior.

– Welcome Series: Introduce new subscribers to your brand and services.

– Seasonal Campaigns: Emails tailored to holiday seasons or special dates.

– Abandoned Cart Emails: Reminder emails for customers who left items in their shopping cart.

– Upsell/Cross-sell Emails: Suggest additional products customers might be interested in.

– Loyalty Programs: Updates and rewards for repeat customers.

– Content Marketing: Sharing valuable content, like blogs or whitepapers, to engage readers.

– Customer Appreciation: Thank you emails showing gratitude to loyal customers.

– Milestone Emails: Celebrating customer birthdays, anniversaries, or other special dates.

– Security Alerts: Notifications regarding account safety and updates.

Utilizing these various types of EDM services can significantly enhance customer engagement and drive business growth by reaching the right audience with relevant messages.

EDM (Electronic Direct Mail) services are essential for businesses looking to engage with their audience through targeted email campaigns. These services streamline communication, increase brand awareness, and drive sales.

Applications for EDM service include:

– Marketing Campaigns: Promote new products, special offers, and events.

– Customer Retention: Send personalized messages to keep customers engaged.

– Newsletters: Provide updates, news, and valuable content regularly.

– Surveys and Feedback: Collect customer opinions and improve services.

– Transactional Emails: Confirmations, receipts, and other automated messages.

– Lead Nurturing: Convert prospects into customers with tailored content.

– Event Invitations: Inform and invite customers to upcoming events.

– Abandoned Cart Reminders: Encourage customers to complete their purchases.

– Product Recommendations: Suggest products based on customer behavior.

– Brand Building: Enhance brand loyalty through consistent and relevant messaging.

By leveraging EDM services, businesses can foster stronger customer relationships and achieve their marketing objectives effectively.

SourcifyChina’s EDM (Electronic Direct Mail) service utilizes cutting-edge technology to streamline email marketing campaigns. This service integrates advanced analytics and automation to enhance engagement and conversion rates. By leveraging detailed customer insights, businesses can create highly personalized and targeted email content.

The EDM service includes robust A/B testing capabilities, allowing for optimization of subject lines, content, and call-to-action buttons. This ensures maximum effectiveness and response from email recipients. The user-friendly interface also simplifies campaign management, making it accessible for businesses of all sizes.

Data security is a top priority for SourcifyChina. The service complies with international data protection regulations, ensuring that customer information is handled with the utmost care. Encryption and secure servers protect sensitive data from unauthorized access.

SourcifyChina’s EDM service offers comprehensive reporting tools that provide real-time feedback on campaign performance. Metrics such as open rates, click-through rates, and conversion rates are easily accessible. This enables businesses to make informed decisions and refine their strategies for future campaigns.

Overall, SourcifyChina’s EDM service is designed to deliver high ROI for businesses through effective, secure, and user-friendly email marketing solutions. Whether for small businesses or large enterprises, the service is adaptable to meet varying marketing needs.

SourcifyChina’s EDM service prioritizes stringent quality control measures to ensure exceptional manufacturing outcomes. Each project is initiated with a comprehensive review to validate design specifications and customer requirements.

High-grade raw materials are sourced from validated suppliers, adhering to international standards of quality. This minimizes the risks of material defects, ensuring a solid foundation for the EDM processes.

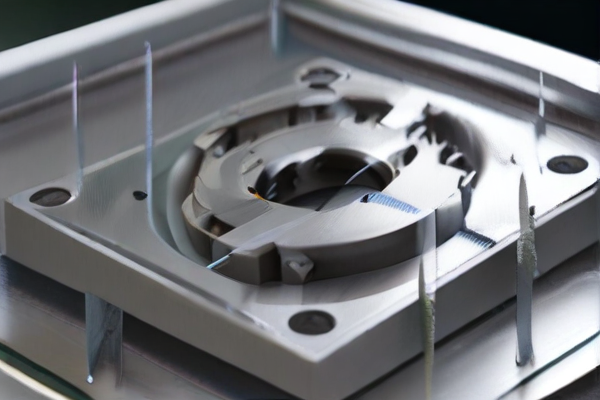

Cutting-edge EDM machinery is employed to achieve precision cuts and intricate designs. Each step in the manufacturing process is closely monitored by experienced technicians to maintain accuracy and consistency.

Final inspection involves rigorous testing protocols including dimensional analysis, surface finish assessments, and functionality checks. Any identified discrepancies are addressed and rectified promptly to maintain the highest standards.

The last step includes thorough documentation and reporting, providing clients with detailed insights into the manufacturing process. This ensures transparency and builds trust in SourcifyChina’s commitment to quality. With meticulous attention to detail at every phase, SourcifyChina guarantees reliable and superior EDM manufacturing services.

SourcifyChina EDM Service Capabilities

SourcifyChina’s EDM (Electronic Direct Mail) service excels in designing compelling email campaigns tailored to the Chinese market. Their expertise ensures high open and conversion rates through visually appealing and culturally relevant content.

The team at SourcifyChina leverages data analytics to scrutinize audience behavior. This allows them to craft targeted, personalized emails that resonate deeply, enhancing engagement and customer loyalty over time.

SourcifyChina also offers seamless integration with various CRM platforms, facilitating real-time tracking and analysis. This ensures campaign effectiveness by continuously optimizing email performance metrics.

Their robust A/B testing methodologies enable businesses to experiment and identify optimal strategies. This constant refinement leads to higher click-through rates and improved ROI for marketing efforts.

Lastly, SourcifyChina provides extensive post-campaign analytics, delivering detailed insights into customer interactions. These comprehensive reports help clients understand what works best, paving the way for future success in email marketing.

Electrical Discharge Machining (EDM) offers unparalleled precision in manufacturing complex components, making it a preferred choice for industries requiring high degrees of accuracy and intricate detailing.

– Precision: EDM can produce parts with tight tolerances, ensuring high accuracy.

– Complex Geometries: Capable of creating intricate shapes that are difficult or impossible with traditional machining.

– Material Versatility: Works with hard materials like tungsten, hardened steel, and carbide.

– Reduced Stress: Minimizes mechanical stress on parts, maintaining material integrity.

– Fine Finish: Achieves superior surface finishes as compared to conventional methods.

– No Direct Contact: Reduces the risk of damage since there’s no direct tool-to-part contact.

– Automation Compatibility: Easily integrated into automated systems for greater efficiency.

– Cost-Effective: Reduces tooling costs, especially for small batches or prototype production.

– Flexibility: Useful for both small-scale projects and large industrial applications.

– Environmentally Friendly: Produces minimal waste and uses fewer resources.

By leveraging the capabilities of EDM services, businesses can enhance their manufacturing processes, ensuring consistency, quality, and cost-effectiveness in producing intricate and high-precision parts.

Electronic Direct Mail (EDM) services provide a powerful tool for businesses to engage with their audience through personalized and automated email marketing campaigns.

Key features of EDM services include:

– Personalization: Tailor emails to individual recipients based on their preferences and behaviors.

– Automation: Schedule and send emails automatically at optimal times.

– Segmentation: Group recipients into specific lists based on demographics, purchase history, and more.

– Analytics: Track open rates, click-through rates, and other key metrics to measure campaign performance.

– A/B Testing: Test different email variations to determine the most effective content.

– Integration: Connect with CRM systems, social media, and other marketing tools.

– Templates: Access a variety of pre-designed templates to streamline email creation.

– Mobile Optimization: Ensure emails are responsive and look good on all devices.

– Compliance: Adhere to email marketing regulations, such as GDPR and CAN-SPAM.

SourcifyChina offers an Electronic Direct Mail (EDM) service, specializing in creating custom products tailored to clients’ unique specifications. Their expertise spans various industries, ensuring high-quality, innovative solutions.

Their custom projects include everything from concept development to final production, incorporating cutting-edge technology and design principles. Each project is meticulously managed to meet client expectations and market demands.

SourcifyChina’s EDM service also provides comprehensive support, including sourcing, quality control, and logistics. This ensures a seamless experience from initial idea to product delivery.

By leveraging SourcifyChina’s EDM services, businesses can enhance their product offerings and achieve competitive advantage, driving success in today’s dynamic market environment.

SourcifyChina is a dynamic and innovative EDM (Electronic Direct Mail) service provider based in China, recognized for its tailored solutions that leverage cutting-edge technology to optimize marketing campaigns. By integrating advanced analytics and market insights, SourcifyChina crafts customized EDM strategies that resonate with target audiences, helping businesses foster stronger customer relationships and drive higher engagement rates. Their comprehensive service offerings include expertly designed email templates, precise audience segmentation, and performance-tracking tools, ensuring clients achieve maximal impact with each campaign. Renowned for their professionalism and dedication to excellence, SourcifyChina has established itself as a leader in the EDM industry, helping businesses of all sizes navigate the complexities of digital marketing within the competitive Chinese market.

Electrical Discharge Machining (EDM) has become increasingly vital in aerospace, defense, and marine industries due to its unparalleled precision and ability to handle complex geometries. In aerospace applications, EDM is essential for manufacturing intricate jet engine components, turbine blades, and fuel system parts. These components often require materials like titanium and Inconel, which are difficult to machine using traditional methods. EDM allows engineers to achieve tight tolerances and complex shapes without inducing thermal or mechanical stress, ensuring the integrity and performance of critical aerospace components. This capability is crucial for meeting stringent industry standards and maintaining the safety and efficiency of aircraft systems.

In the defense sector, EDM plays a crucial role in producing high-precision components for weaponry and military vehicles. The process is used to manufacture parts with extreme accuracy, such as firing pins, missile components, and intricately shaped armor pieces. These components need to withstand harsh conditions and perform flawlessly in the field. EDM’s ability to work with hardened materials ensures the durability and reliability required for defense applications. Similarly, in the marine industry, EDM is used to produce parts capable of withstanding corrosive environmental conditions. Components such as propeller shafts, engine parts, and complex pump mechanisms benefit from the precision of EDM, resulting in enhanced performance and longevity. By enabling the production of durable, high-precision parts, EDM service is indispensable across these advanced technology sectors.

Electrical Discharge Machining (EDM) services play a crucial role in the automotive industry by enabling the production of highly precise and complex components that are often difficult to machine using traditional methods. EDM is particularly beneficial for creating intricate parts such as fuel injectors, turbocharger components, and transmission parts, where tight tolerances and fine details are essential. The process utilizes electrical discharges to erode material, allowing for the fabrication of components from hard metals and alloys without inducing thermal stress or deformation. This capability is vital for producing reliable and high-performance automotive parts, leading to enhanced vehicle efficiency and durability.

In the electronics sector, EDM services are indispensable for manufacturing components that require extreme precision and miniaturization. The technique is widely used to create molds and dies for microelectronics, ensuring accurate replication of intricate designs. EDM allows for the machining of conductive materials such as copper, tungsten, and graphite, which are commonly used in electronic applications. Additionally, EDM’s ability to produce fine features and tight tolerances is crucial for the development of connectors, semiconductor components, and intricate circuit board patterns. This precision machining ensures the high performance and reliability of electronic devices, supporting the ever-evolving demands of the consumer electronics, telecommunications, and computing industries.

In the construction industry, Electrical Discharge Machining (EDM) services play a crucial role in manufacturing precision components that are essential for modern building projects. EDM is a non-traditional machining method that uses electrical discharges to shape materials, often used for complex geometries and hard metals that are difficult to machine with traditional methods. In construction, EDM is utilized to create intricate parts for heavy machinery, customized tools, and specialized fixtures that ensure precision and efficiency on the job site. For instance, components for cranes, excavators, and other heavy equipment are often produced using EDM due to its ability to achieve tight tolerances and high levels of detail. Additionally, EDM is employed in the fabrication of high-strength steel structures and architectural elements that demand exceptional accuracy and durability.

In the energy sector, EDM services are indispensable for the production and maintenance of critical components used in power generation and distribution. This includes parts for turbines, both in traditional power plants and renewable energy installations like wind and hydroelectric systems. The precision of EDM allows for the creation of complex turbine blades and intricate cooling channels, which are essential for optimizing performance and efficiency. Furthermore, EDM is vital in the manufacturing of components for nuclear reactors, where the need for exacting standards and resistance to extreme conditions is paramount. The ability to machine hard and exotic materials, such as Inconel and titanium, makes EDM an invaluable tool in the energy industry, supporting the development of reliable and efficient energy infrastructure.

Electrical Discharge Machining (EDM) services have revolutionized the industrial equipment sector by offering precise, efficient, and flexible machining solutions for creating complex and intricate parts. In industries such as aerospace, automotive, and heavy machinery, where precision and durability are paramount, EDM technology ensures the accurate shaping of hard metals, including titanium, tool steel, and other high-performance alloys. Traditional machining methods often struggle with materials that have high hardness or intricate geometries, but EDM excels by using electrical discharges to erode the material with remarkable precision. This ability to produce components with fine tolerances and intricate details significantly improves the performance and reliability of industrial equipment, ensuring minimum wear and tear and extending the equipment’s operational life.

Additionally, EDM services contribute to cost-effectiveness and efficiency in the industrial equipment industry. The non-contact nature of the EDM process reduces mechanical stresses on the workpiece, minimizing the risks of deformation and damage. This leads to higher yields and less material wastage, ultimately lowering production costs. Moreover, EDM is highly versatile and compatible with automation technologies, enabling batch processing and integration into smart manufacturing systems. This not only accelerates production timelines but also ensures consistency and repeatability, critical for maintaining quality standards in high-precision industries. By harnessing the capabilities of EDM services, companies can enhance their manufacturing processes, achieve superior product quality, and maintain a competitive edge in the rapidly evolving industrial equipment landscape.

Electrical Discharge Machining (EDM) service is revolutionizing the medical devices industry by enabling the production of intricate, high-precision components essential for modern healthcare solutions. EDM, a non-conventional machining process, uses electrical discharges or sparks to shape materials with exceptional accuracy, regardless of hardness. This capability is crucial in creating complex geometries and fine features required in medical devices such as stents, orthopedic implants, and surgical instruments. The precision offered by EDM ensures that these components meet stringent quality standards, enhancing their performance and reliability. By producing smooth surface finishes and intricate designs that would be challenging or impossible to achieve with traditional machining methods, EDM contributes significantly to advancing medical technology and patient care.

Furthermore, the flexibility of EDM allows for the effective machining of biocompatible materials like titanium and stainless steel, commonly used in medical devices. Customized implants and patient-specific instruments benefit greatly from EDM, as the process facilitates rapid prototyping and intricate customization without compromising quality. Additionally, EDM minimizes thermal damage and residual stresses, which are critical in maintaining the integrity of medical parts and ensuring their longevity. As the demand for advanced medical devices continues to grow, the integration of EDM service in the manufacturing process stands as a pivotal innovation, driving forward the capabilities of medical engineering and improving patient outcomes.

Electrical Discharge Machining (EDM) is a versatile manufacturing process that excels in creating intricate and precise components that would be difficult or impossible to produce using traditional machining methods. EDM is particularly beneficial for machining hard materials such as tool steels, titanium, and superalloys. This non-conventional machining process utilizes electrical discharges or sparks to erode material from the workpiece, allowing for the high-precision cutting of complex shapes and fine details. EDM is widely used in industries such as aerospace, automotive, and medical device manufacturing where accuracy and surface finish are paramount. With the ability to achieve tolerances within microns and produce smooth surface finishes, EDM service is crucial for creating molds, dies, and high-precision components.

In manufacturing applications, EDM offers significant advantages, including the capability to machine intricate geometries with high repeatability and minimal material stress. This makes it ideal for producing small, delicate parts like those required in the electronics industry, as well as for large-scale manufacturing of components with complex profiles. EDM is also effective for machining components with internal cavities, thin walls, and other features that are challenging to achieve with conventional cutting tools. Additionally, EDM can be used to create prototype parts as well as high-volume production runs, making it a flexible option for various manufacturing needs. When integrated into production lines, EDM services can enhance efficiency, reduce lead times, and contribute to the overall quality and performance of the final product.

Sure! Here is a concise list of Frequently Asked Questions (FAQ) with answers related to the manufacturing of EDM (Electrical Discharge Machining) service quality work from SourcifyChina factory:

1. What is EDM service offered by SourcifyChina?

EDM (Electrical Discharge Machining) is a manufacturing process offered by SourcifyChina that uses electrical discharges or sparks to shape metals. This process is ideal for producing intricate and precise components that conventional machining can’t achieve.

2. What kinds of materials can SourcifyChina’s EDM service work with?

SourcifyChina’s EDM service can work with a wide range of conductive materials including steel, aluminum, titanium, copper, and various alloys, ensuring versatility for different project needs.

3. How accurate are the EDM services from SourcifyChina?

The EDM services from SourcifyChina are highly accurate, with tolerances typically within ±0.005 mm. This level of precision ensures that the end products meet stringent quality standards.

4. What industries does SourcifyChina serve with its EDM capabilities?

SourcifyChina’s EDM services cater to various industries including automotive, aerospace, medical, electronics, and mold making, among others.

5. How long does it take to complete an EDM project at SourcifyChina?

Turnaround time for EDM projects at SourcifyChina varies based on project complexity and volume. However, they are committed to timely deliveries and can often complete jobs within a few days to a couple of weeks.

6. What quality control measures are in place for EDM services?

SourcifyChina employs rigorous quality control measures including in-process inspections, final inspections, and advanced measurement tools to ensure each product meets client specifications and industry standards.

7. Can SourcifyChina provide custom EDM solutions?

Yes, SourcifyChina offers custom EDM solutions tailored to customer requirements, ensuring bespoke components that fit unique project specifications.

8. How can one request a quote for EDM services from SourcifyChina?

To request a quote for EDM services, you can contact SourcifyChina directly through their website or customer service email, providing details such as material type, project specifications, and timeline.

9. Do they offer post-processing services?

Yes, SourcifyChina can provide additional post-processing services such as polishing, coating, and assembly to ensure the finished product meets all client needs.

When partnering with SourcifyChina for EDM (Electrical Discharge Machining) service manufacturing, effective collaboration can significantly enhance your outcomes. Here are some essential tips:

1. Define Requirements Clearly:

Provide detailed specifications and CAD drawings to ensure precision in manufacturing. Clearly outline tolerances, materials, and finish requirements to avoid ambiguities.

2. Evaluate Capabilities:

Assess the factory’s EDM equipment and technology to confirm they meet your project needs. SourcifyChina should have advanced machinery capable of handling complex geometries and high-precision demands.

3. Material Selection:

Consult with SourcifyChina on the best materials for your project. Different materials respond uniquely to EDM, affecting the machining efficiency and final product quality.

4. Quality Assurance:

Establish quality control benchmarks. Ensure SourcifyChina has robust inspection processes, such as coordinate measuring machines (CMM), to verify tolerances and surface finishes.

5. Prototyping:

Start with a prototype to validate designs and processes. This step allows adjustments before full-scale production, saving time and costs in the long run.

6. Communication:

Maintain open and frequent communication. Regular updates and feedback loops with SourcifyChina will help address issues promptly and keep the project on track.

7. Costing:

Request detailed quotes, including setup fees, material costs, and unit prices. Clarify any potential hidden costs early to manage the budget effectively.

8. Lead Time:

Discuss realistic lead times and factor in potential delays. SourcifyChina’s ability to deliver on time is crucial for keeping your project timeline intact.

9. Review Samples:

Thoroughly inspect initial samples for adherence to specifications. Any deviations should be promptly communicated to SourcifyChina for correction before mass production.

10. Compliance and Standards:

Ensure the factory complies with international standards and certifications relevant to your industry, such as ISO 9001, to guarantee high quality and reliability in the production process.

Following these tips can streamline your EDM service manufacturing collaboration with SourcifyChina, ensuring high-quality production and timely delivery.

What is EDM service provided by SourcifyChina factory?

Electrical Discharge Machining (EDM) service at SourcifyChina factory involves precision machining processes that use electrical discharges to shape metal materials. It’s ideal for creating complex geometries and fine details in hard metals.

Why should I choose SourcifyChina for EDM services?

SourcifyChina offers state-of-the-art EDM technology, skilled technicians, and a commitment to quality. We ensure high precision, reduced lead times, and competitive pricing for all our clients.

What types of EDM processes does SourcifyChina provide?

We offer a variety of EDM processes including Wire EDM, Sinker EDM, and Hole Drilling EDM, catering to different project requirements from simple cuts to intricate shapes.

What materials can be machined using EDM at SourcifyChina?

Our EDM services can handle a wide range of conductive materials such as stainless steel, titanium, aluminum, brass, and exotic alloys.

How do I get a quote for an EDM project?

To get a quote, you can contact our sales team with your project specifications, including material type, design files, and any special requirements. We’ll provide a detailed quote promptly.

What is the typical lead time for an EDM project?

Lead time varies based on project complexity and volume. Generally, we aim for a rapid turnaround while maintaining high-quality standards. Specific timelines can be discussed during the quotation process.

Can SourcifyChina handle large volume EDM orders?

Yes, we have the capacity to manage both small-scale and large-scale production runs. Our advanced equipment and efficient processes ensure timely delivery of large volume orders.

Is there a minimum order quantity (MOQ) for EDM services?

We are flexible with order quantities and cater to both small and large orders. You can discuss your specific needs with our sales team.

How does SourcifyChina ensure the quality of EDM machined parts?

Quality is ensured through rigorous inspection processes, adherence to international standards, and the use of advanced measurement tools. We provide quality reports with every order.

Can I visit the SourcifyChina factory to inspect the production process?

Yes, client visits are welcome. Please schedule an appointment with our team to ensure we can provide you with a comprehensive tour and discussion.

Sourcing EDM (Electronic Dance Music) services from SourcifyChina can be a strategic move for producing high-quality music at competitive prices. Here are some concise tips to guide you through the process:

1. Define Your Needs:

– Clearly outline your requirements, including genre specificity, production elements, and any unique features.

– Determine the level of service needed (e.g., full production, mixing, mastering).

2. Research and Reference:

– Look at SourcifyChina’s portfolio and past EDM projects.

– Gather references and contact past clients for feedback on their experience.

3. Check Credentials:

– Verify the credentials of SourcifyChina’s team members, focusing on their expertise and experience in EDM production.

– Ensure they use up-to-date software and high-quality equipment.

4. Communication:

– Establish clear and open lines of communication.

– Use detailed briefs, project timelines, and regular updates to keep the process smooth.

5. Trial Project:

– Start with a smaller trial project to assess quality, turnaround time, and compatibility.

– This helps build trust and understanding before committing to larger projects.

6. Budget and Payments:

– Discuss and finalize the budget upfront to avoid hidden costs.

– Agree on payment terms that might include deposits, milestones, and final payments upon delivery.

7. Intellectual Property:

– Ensure clarity on intellectual property rights and ownership of the final product.

– Sign a detailed contract outlining these terms to protect your interests.

8. Quality Assurance:

– Set quality benchmarks and review processes.

– Ask for sample revisions if the initial outputs do not meet your expectations.

9. Logistics:

– Factor in time zone differences for communication and deadlines.

– Plan for potential shipping needs if physical items are involved.

10. Reviews and Improvements:

– After completion, review the service and provide feedback.

– Discuss any areas of improvement for future collaborations.

Following these tips can help streamline your sourcing process and ensure a successful partnership with SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.