SourcifyChina offers unparalleled expertise in sourcing tombstone engraving machines directly from top Chinese manufacturers. With an extensive network of reputable suppliers, they ensure high-quality products that meet global standards.

Their dedicated team provides personalized service, guiding buyers through the entire purchasing process, from initial inquiry to final delivery, ensuring a seamless experience.

SourcifyChina prioritizes customer satisfaction by offering competitive pricing, ensuring that buyers get the best value for their investment. Their transparent pricing models eliminate hidden costs, fostering trust and reliability.

Additionally, they facilitate thorough quality inspections, guaranteeing that every tombstone engraving machine meets rigorous standards before shipment. This commitment to quality reduces risks and builds buyer confidence.

SourcifyChina also excels in logistical support, managing documentation, shipping, and customs clearance efficiently. This comprehensive service saves buyers significant time and effort, making international purchasing hassle-free.

By choosing SourcifyChina, buyers benefit from their extensive industry knowledge, robust supplier relationships, and exceptional customer service, ensuring a successful and rewarding procurement process for tombstone engraving machines from China.

Tombstone engraving machines vary in types and options, providing flexibility in engraving techniques and materials. Common types include laser engravers, rotary engravers, and impact engravers. Options often encompass software compatibility, material versatility, and size adaptability.

– Laser Engravers: Utilize focused laser beams for precise, high-quality engravings on various materials such as granite, marble, and metal.

– Rotary Engravers: Use rotating cutting tools to carve designs into the stone, suitable for creating deep, durable engravings.

– Impact Engravers: Employ a needle-like tool to create indentations, offering a less intricate but efficient engraving method.

– Software Compatibility: Many machines come with user-friendly software that allows custom design creation and easy editing of fonts, images, and patterns.

– Material Versatility: Some machines can handle a wide range of materials, including stone, metal, glass, and wood, adding to their utility.

– Size Adaptability: Engraving machines often come in different sizes to accommodate various tombstone dimensions and intricacy levels of the designs.

– Portability: Certain models are designed to be portable, offering flexibility for on-site engraving services.

– Power Options: Machines can be electric, battery-operated, or even hydraulically powered, catering to different operational environments.

– Speed and Efficiency: Many advanced machines offer high-speed engraving without compromising quality, useful for large-scale operations.

– Safety Features: Enhanced safety mechanisms like protective covers and emergency stop buttons ensure user safety during operation.

– Maintenance Requirements: Easy-to-maintain models reduce downtime and prolong the machine’s life-span, essential for long-term use.

– Cost Variability: Prices range based on complexity, brand, and additional features, providing options for various budget constraints.

– Durability: Machines constructed with robust materials ensure longevity and consistent performance, crucial for professional use.

– Precision: High-end models offer exceptional precision, delivering detailed and accurate engravings ideal for intricate designs.

– Customizability: Advanced options include customizable settings for depth, speed, and power, enhancing flexibility in design and function.

– User Training and Support: Many manufacturers offer training programs and customer support to ensure proficient use and maintenance of the machine.

– Environmental Impact: Machines with eco-friendly options, such as reduced energy consumption and non-toxic engraver mediums, minimize environmental footprint.

A tombstone engraving machine is a specialized tool designed for inscribing personalized messages, names, and dates on gravestones with precision and efficiency. Its applications cover a variety of needs in the memorial industry.

– Customization: Enables the creation of unique and personalized grave markers.

– Efficiency: Speeds up the engraving process compared to traditional methods.

– Accuracy: Offers precise and error-free engravings.

– Versatility: Can engrave a variety of materials including granite, marble, and slate.

– Durability: Ensures long-lasting inscriptions that withstand weather conditions.

– Cost-effectiveness: Reduces labor costs by automating the engraving process.

– Ease of use: User-friendly interfaces and software make it accessible for operators at different skill levels.

– Flexibility: Allows for the inclusion of intricate designs and fonts.

– Consistency: Delivers uniform results across multiple headstones.

– Time-saving: Cuts down the time required to fulfill customer orders.

– Aesthetic appeal: Creates visually appealing inscriptions with clean lines and detailed artwork.

– Maintenance: Requires minimal upkeep, providing reliable performance over time.

– Safety: Minimizes the risk of injuries associated with manual engraving.

– Professionalism: Enhances the quality and finish of the final product.

– Scalability: Suitable for both small-scale family-owned businesses and large-scale commercial operations.

– Innovation: Incorporates the latest technology to stay ahead in the competitive market.

– Environmental impact: Reduces waste generated compared to manual methods.

– Digital storage: Allows for design templates and customer data to be securely stored and quickly accessed.

– Multiple Languages: Capable of engraving different scripts and languages to cater to diverse client needs.

– Remote Operation: Some advanced machines support remote control and monitoring capabilities.

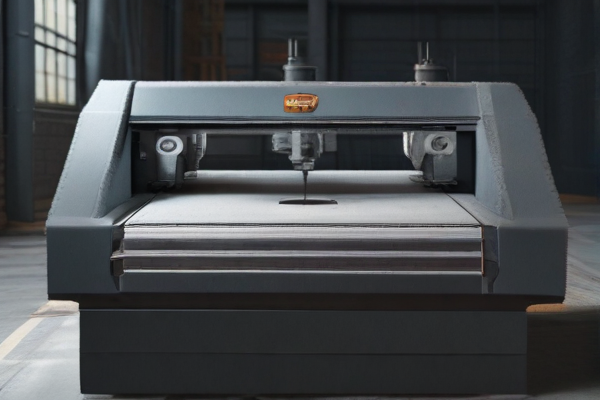

The SourcifyChina tombstone engraving machine is constructed from high-quality materials, ensuring durability and long-term reliability. The primary frame is made from industrial-grade steel, providing a robust structure that can withstand continuous use and maintain stability during high-precision operations.

The machine’s engraving components feature advanced CNC technology, with parts made from hardened aluminum and stainless steel, ensuring precise and detailed engravings. These materials are resistant to corrosion and wear, guaranteeing consistent performance and minimal maintenance over time.

The work surface is covered with a specialized, heat-resistant material designed to securely hold the tombstone in place while engraving. This ensures accuracy and prevents damage to both the machine and the tombstone itself.

High-performance electronic components and cutting-edge software are integrated into the system, providing precise control over engraving processes. These components, sourced from reputable suppliers, ensure the machine’s operational efficiency and consistency.

In conclusion, the combination of robust steel framing, high-precision CNC components, specialized work surfaces, and reliable electronic systems makes the SourcifyChina tombstone engraving machine a top choice for quality engravings. Its design and material selection guarantee excellent performance and durability, meeting the high standards required in the industry.

The quality control manufacturing process for the SourcifyChina tombstone engraving machine begins with stringent raw material inspections. These materials undergo rigorous testing to ensure they meet established quality benchmarks, which is crucial for the durability and performance of the end product.

Next, during the production phase, precision machining tools are employed to achieve high accuracy and consistency. This step is essential for ensuring that each machine component fits perfectly, minimizing operational issues and enhancing overall efficiency.

Following assembly, each machine undergoes stringent functional and endurance tests. These tests simulate real-world conditions to ascertain the machine’s reliability and longevity, ensuring that it can withstand prolonged usage without performance degradation.

Further, advanced software diagnostics are used to verify the electrical and programming aspects of the machine. This stage ensures that all digital systems are functioning optimally, reducing the likelihood of electronic failures and enhancing user experience.

Finally, a thorough inspection and quality assurance audit are conducted before the machines are packaged for delivery. Each engraving machine is meticulously checked for any defects, ensuring that only products meeting the highest standards are shipped to customers.

Continuous feedback loops from customers are incorporated into the quality control process. This information helps identify potential areas of improvement, contributing to ongoing enhancements in product quality and customer satisfaction.

By following this comprehensive quality control process, SourcifyChina ensures that its tombstone engraving machines deliver superior performance, reliability, and durability, thereby meeting the high expectations of their discerning clientele. This meticulous attention to detail and commitment to quality sets SourcifyChina apart in the competitive market of engraving machinery.

The SourcifyChina tombstone engraving machine offers high precision for detailed inscriptions on various tombstone materials. Utilizing advanced laser technology, it ensures fine and clear engravings, meeting diverse customization needs.

This machine supports a wide range of materials, including granite, marble, and slate. Its versatility allows for intricate designs and texts, accommodating both traditional and contemporary styles.

Equipped with user-friendly software, the machine simplifies the design process, making it accessible even for beginners. The intuitive interface allows for easy input and editing of text and images.

The engraving machine is built for durability and efficiency, capable of handling large volumes of work with consistent quality. It significantly reduces manual labor and enhances productivity.

In addition, it includes safety features like dust extraction and cooling systems, ensuring a clean and safe working environment. These features protect both the machine and the operator, maintaining optimal working conditions.

Overall, the SourcifyChina tombstone engraving machine combines precision, versatility, and user-friendly operation to deliver high-quality engravings. Its advanced technology and robust build make it a valuable asset for professional engraving services.

Tombstone engraving machines offer precision and efficiency in creating detailed, lasting memorials. These devices streamline the engraving process, providing consistent quality and enabling intricate designs on stone surfaces.

Benefits:

– Precision: Achieve fine details and accuracy not possible with manual engraving.

– Speed: Automates the engraving process, reducing time compared to traditional methods.

– Consistency: Ensures uniformity in repeated patterns or texts, avoiding human errors.

– Versatility: Capable of working on various materials including granite, marble, and sandstone.

– Customization: Allows for personalized designs, fonts, and images.

– Cost-Effective: Reduces labor costs and material wastage.

– Durability: Produces clear and enduring engravings that withstand weathering and time.

– Ease of Use: User-friendly interfaces often require minimal training.

– Scalability: Suitable for both small-scale and high-volume production needs.

A tombstone engraving machine is designed to provide precise and detailed inscriptions on gravestones with efficiency and versatility. Below are some key features of this specialized equipment:

– High Precision: Achieves detailed and intricate designs accurately.

– Versatile Material Compatibility: Works with granite, marble, and other stone materials.

– Computer-Aided Design (CAD) Integration: Easily incorporates custom designs and fonts from digital files.

– Sturdy Build: Constructed with durable components to handle stone cutting.

– Automatic Depth Control: Ensures consistent engraving depth across the surface.

– User-Friendly Interface: Simple controls and software for ease of use, even for beginners.

– Variable Speed Settings: Adjustable speed for different materials and detailed work.

– Dust Collection System: Equipped with a mechanism to minimize dust and debris.

– Safety Features: Includes guards and emergency stop buttons to prevent accidents.

– Compact Design: Space-efficient without compromising on performance capabilities.

– Energy Efficient: Designed to consume minimal power while maximizing output.

– Customizable Settings: Allows for adjustments to suit specific project needs.

– Maintenance Alerts: Integrated notifications for timely machine servicing.

– Long Service Life: Manufactured for extended durability and minimal downtime.

– High Output Capacity: Capable of managing large-scale projects with reduced turnaround time.

– Quiet Operation: Designed to reduce noise pollution for a quieter working environment.

These features collectively make tombstone engraving machines essential in producing quality, lasting memorials with ease and precision.

SourcifyChina specializes in custom tombstone engraving machines, providing precise and high-quality engravings. Their machines cater to both individual and commercial needs, ensuring detailed and durable results.

These engraving machines are designed for a variety of materials, including granite, marble, and stone. They feature advanced technology to produce intricate designs and clear text, enhancing the beauty and personalization of each tombstone.

SourcifyChina’s custom products include tailored machines that meet specific client requirements, from size and power to engraving capabilities. This flexibility allows for unique and meaningful memorials that honor loved ones appropriately.

Projects undertaken by SourcifyChina often involve collaboration with clients to understand their vision and deliver optimal solutions. They focus on efficiency, accuracy, and customer satisfaction, ensuring each project meets high standards.

In addition to standard engravings, SourcifyChina offers machines capable of complex patterns and images. This expands the creative possibilities for memorial design, making each tombstone a unique tribute.

SourcifyChina’s commitment to innovation and quality makes them a trusted provider in the engraving industry. Their machines are reliable and easy to use, backed by excellent customer support and technical assistance.

Overall, SourcifyChina’s tombstone engraving machines combine advanced technology with customization, allowing for beautiful, lasting memorials. They prioritize client needs, delivering products and projects that stand out in precision and quality.

SourcifyChina is a prominent manufacturer and supplier of tombstone engraving machines, specializing in advanced stone carving technology. Established with a commitment to precision and innovation, SourcifyChina offers a range of high-performance CNC engraving machines designed for the detailed and durable inscription of tombstones and other stone monuments. The company’s equipment is renowned for its reliability, ease of use, and ability to handle various materials including granite, marble, and slate. By integrating the latest advancements in computer numerical control (CNC) technology, SourcifyChina ensures that their machines deliver intricate and consistent results, catering to the specific needs of memorial artisans and stone engravers worldwide. Their dedication to quality and customer satisfaction has positioned them as a trusted partner in the tombstone manufacturing industry, providing both standard and customized solutions to meet diverse engraving requirements. Through continuous innovation and a focus on robust engineering, SourcifyChina remains at the forefront of the market, helping to memorialize lives with precision and care.

In the realms of Aerospace, Defense, and Marine industries, precision, durability, and efficiency are critical factors that can significantly impact operational capabilities and outcomes. A “tombstone engraving machine,” traditionally associated with inscribing texts on gravestones, has found innovative applications within these sectors. For aerospace applications, these machines are repurposed to create highly detailed, engraved components for aircraft, such as complex schematics on control panels or custom identification plates for various parts. The precision of these machines ensures that every engraving is consistent, reliable, and capable of withstanding the harsh conditions encountered at high altitudes, thus maintaining the integrity of critical information that must remain legible under extreme temperatures and pressures.

In the Defense and Marine sectors, the utility of tombstone engraving machines extends to marking essential equipment, weapons, and machinery with identifiers, serial numbers, or intricate symbols that can endure demanding environments. For defense, engraved identification on weapons and gear helps in quick asset management, inventory control, and ensures compliance with strict military regulations. Similarly, in the maritime industry, these machines are employed to engrave vital information on navigation instruments, safety gear, and ship components that are exposed to corrosive saltwater and varying weather conditions. These engravings aid in maintenance cycles, lifespan monitoring, and swift replacements or repairs, crucial for maintaining operational efficiency and crew safety. Thus, the deployment of tombstone engraving technology in these high-stakes industries exemplifies an adaptive, cross-disciplinary utilization of tools to meet stringent demands of accuracy, robustness, and operational readiness.

The tombstone engraving machine, traditionally associated with creating detailed inscriptions on gravestones, has found innovative applications in the automotive industry. This high-precision machine has been adapted to engrave intricate designs and vital information on various car components, ranging from engine parts to dashboard interfaces. Its accuracy ensures that critical specifications, such as serial numbers and manufacturing details, are permanently and clearly marked on each component, facilitating easier tracking and identification. Moreover, the machine’s ability to engrave on complex surfaces and a variety of materials, such as metal and plastic, makes it indispensable in customizing car interiors with personalized logos or intricate decorative elements, significantly enhancing the vehicle’s aesthetic appeal.

In the realm of electronics, the tombstone engraving machine is invaluable for producing precise and durable markings on small, delicate components. These machines can engrave tiny, detailed inscriptions on circuit boards, connectors, and semiconductor surfaces. Such precision is critical in an industry where component identification and quality assurance are paramount. By ensuring permanent and legible labels, the engraving machine helps in maintaining product integrity and facilitates easier troubleshooting and repair. Furthermore, it allows for the customization of electronic devices with personalized engravings or branding logos, adding a layer of uniqueness and sophistication to consumer gadgets. As electronics continue to miniaturize, the demand for such precise engraving solutions is likely to grow, highlighting the expanding versatility of tombstone engraving technology.

The construction industry consistently looks for innovations that can optimize processes and enhance precision, and the tombstone engraving machine has emerged as a valuable tool in this regard. Primarily used for engraving intricate designs and inscriptions on tombstones, this technology has diverse applications in construction projects requiring detailed stonework. For instance, architects and designers can utilize these machines to carve precise patterns, logos, or text on building facades, monuments, or interior stone elements, thereby adding a bespoke touch to structural designs. The accuracy and speed of tombstone engraving machines reduce manual labor, minimizing errors and expediting project timelines. Consequently, these machines contribute significantly to both aesthetic and functional aspects of construction, streamlining workflows while ensuring high-quality, durable engravings that enhance the appeal and integrity of stone structures.

In the energy sector, tombstone engraving machines find a niche application, particularly involving renewable energy infrastructure. Many solar and wind farms contain memorial plaques or informational displays that require durable, weather-resistant engravings on stone or metal surfaces. These machines ensure that such engravings maintain clarity and legibility over prolonged periods under harsh environmental conditions. Additionally, energy facilities often use these machines for creating precise, permanent labels on crucial equipment parts, ensuring efficient maintenance and operation. For instance, in hydroelectric plants, engraved markers on turbines or control units can provide vital operational data, which remains readable despite exposure to water and wear. Overall, the utilization of tombstone engraving machines in energy applications underscores their versatility and the critical role they play in enhancing operational efficacy and sustainability across various sectors.

The industrial equipment industry has increasingly integrated tombstone engraving machines to enhance precision, efficiency, and customization in the production of commemorative plaques and monuments. These machines, equipped with advanced CNC (Computer Numerical Control) technology, offer unparalleled accuracy and speed in engraving intricate designs, texts, and images onto various materials such as granite, marble, and metal. The automation provided by these machines significantly reduces the labor-intensive nature of traditional hand engraving, ensuring consistent quality and allowing for complex patterns that were previously challenging to achieve. This technological advancement has not only streamlined production processes but also broadened the scope of artistic expression in the memorialization industry.

Furthermore, tombstone engraving machines cater to the growing demand for personalized and detailed memorials. With their ability to precisely replicate digital designs, customers can request highly customized engravings that reflect the unique personalities and stories of their loved ones. The integration of software solutions enables operators to easily adjust designs and make real-time modifications, enhancing customer satisfaction through a more interactive design process. Additionally, the use of durable materials combined with precise engraving techniques ensures the longevity of the inscriptions, making these machines a vital asset in producing high-quality, lasting memorials. Overall, the adoption of tombstone engraving machines in the industrial equipment sector underscores a significant shift towards greater efficiency, personalization, and durability in the memorialization process.

The “tombstone engraving machine,” typically used for inscribing memorials, has potential applications in the medical device industry, particularly in the labeling and customization of medical implants and devices. In a healthcare setting, precision and durability in marking are crucial for compliance, traceability, and patient safety. These engraving machines can provide permanent, corrosion-resistant markings on a variety of materials such as titanium, stainless steel, and ceramics, which are commonly used in medical devices like surgical instruments, orthopedic implants, and dental appliances. This ensures that vital information, including serial numbers, batch codes, or manufacturer details, remains legible throughout the device’s lifecycle, even in harsh physiological environments or during repeated sterilization processes.

Additionally, tombstone engraving machines can enhance the personalization of medical devices, contributing to the customization trend in modern medicine. For instance, in prosthetics or dental implants, personalized engravings can include patient identifiers or specific design features tailored to an individual’s anatomy or medical history. This level of customization not only improves the fit and functionality of the devices but also supports advanced medical practices such as personalized medicine. The precision and versatility of these engraving machines make them valuable tools for manufacturers aiming to meet stringent regulatory requirements while providing high-quality, patient-specific medical solutions.

A tombstone engraving machine plays an integral role in the machining and manufacturing industry by specializing in the precise engraving of memorial markers, plaques, and tombstones. These machines utilize advanced CNC (Computer Numerical Control) technology, allowing for highly detailed and intricate designs to be carved into materials such as granite, marble, and other types of stone. The precision offered by CNC technology ensures consistent, high-quality output that meets the strict standards required for memorial products. This capability significantly reduces manual labor and the potential for human error, thereby increasing efficiency and throughput in the manufacturing process. Moreover, the machinist can easily input custom designs or text into the machine’s software, enabling personalized engravings that cater to individual customer specifications.

Beyond the memorial industry, tombstone engraving machines have applications in other manufacturing sectors where detailed stone engravings are required. For instance, they are utilized in architectural projects to create ornate stonework for buildings, monuments, and public spaces. The versatility of these machines allows them to handle various stone types, making them invaluable for intricate detailing and batch production of uniform components. Additionally, the combination of robust mechanical design and sophisticated software in these machines enables rapid prototyping and short production runs, which are essential in custom stonework projects. Their ability to execute complex designs with high precision also makes them suitable for creating decorative elements and artistic sculptures, broadening their application beyond traditional tombstone engraving. This adaptability and precision make tombstone engraving machines an essential asset in both specialized memorial production and broader machining and manufacturing contexts.

Sure, here is a list of frequently asked questions (FAQ) along with their answers for the manufacturing of tombstone engraving machines, from SourcifyChina factory:

Q1: What materials can the tombstone engraving machine from SourcifyChina handle?

A1: Our tombstone engraving machines are designed to handle a variety of materials including granite, marble, sandstone, limestone, and other natural stones. The equipment is robust and reliable for high-precision engraving on tough surfaces.

Q2: What is the delivery time for a tombstone engraving machine?

A2: The standard delivery time for our tombstone engraving machines is typically 4-6 weeks from the date of order confirmation. This includes manufacturing, quality checks, and shipping arrangements.

Q3: How does SourcifyChina ensure the quality of their engraving machines?

A3: SourcifyChina adheres to stringent quality control standards. Our machines undergo multiple checks during the manufacturing process, including performance testing and calibration to ensure they meet industry requirements.

Q4: Can I get customization options for the engraving machine?

A4: Yes, we offer customization options to meet specific needs such as size, power requirements, and engraving capabilities. Please discuss your requirements with our sales team to get a tailored solution.

Q5: What kind of after-sales support does SourcifyChina provide?

A5: We provide comprehensive after-sales support, including installation assistance, user training, and technical support. Our customer service team is available to address any issues and ensure smooth operation of the machines.

Q6: Are there any warranties on the engraving machines?

A6: Yes, SourcifyChina offers a one-year warranty on all our tombstone engraving machines. This covers manufacturing defects and ensures you get a reliable and durable product.

Q7: How do I maintain and ensure the longevity of the engraving machine?

A7: Regular maintenance is key to the longevity of the machine. This includes periodic cleaning, lubrication of moving parts, and routine checks as per the user manual. Our team can provide detailed maintenance guidelines and tips.

When sourcing tombstone engraving machines from SourcifyChina factory, consider the following tips to ensure you get high-quality products that meet your needs:

1. Understand Your Requirements:

– Determine the specific type of engraving machine needed (e.g., laser, CNC, rotary).

– Assess the material types (granite, marble, etc.) and the size of the tombstones you’ll be working with.

2. Factory Credentials:

– Verify the factory’s certifications and compliance with international standards.

– Check for ISO certification and any specific industry-related quality assurances.

3. Product Quality:

– Request detailed product specifications and materials used in the machine.

– Ask for samples or demonstration videos of the machine in action.

– Look for reviews or testimonials from previous customers.

4. Customization Options:

– Inquire about the possibility of custom modifications to suit specific needs.

– Ensure that the factory can accommodate your required customizations in terms of design, software, and functionality.

5. Technology and Features:

– Ensure the machine has user-friendly software and robust technical support.

– Check for advanced features like automated operation, precision controls, and durability under continuous use.

6. After-Sales Support:

– Confirm the availability of after-sales service and technical support.

– Ask about warranty terms and the availability of spare parts.

7. Logistics and Delivery:

– Discuss shipping terms, delivery timelines, and associated costs.

– Ensure the factory has experience in handling international shipments to avoid customs or logistical issues.

8. Cost and Payment Terms:

– Compare prices with other suppliers to ensure competitive pricing.

– Understand payment terms, and consider using secure payment methods to protect your investment.

9. Factory Visit:

– If possible, visit the factory to assess the production environment and quality control measures.

By focusing on these aspects, you can ensure a smooth and reliable sourcing experience for tombstone engraving machines from SourcifyChina factory.

Certainly! Here are some frequently asked questions (FAQs) about sourcing a tombstone engraving machine from the SourcifyChina factory:

1. What types of tombstone engraving machines does SourcifyChina offer?

SourcifyChina offers a range of tombstone engraving machines suitable for different materials such as granite, marble, and stone. The options include CNC routers, laser engraving machines, and portable engraving tools for detailed work.

2. How can I place an order with SourcifyChina?

To place an order, you can contact SourcifyChina directly through their website or sales email. Make sure to specify your requirements, such as the type of machine, quantity, and special features needed.

3. What is the typical lead time for delivery?

The lead time varies depending on the complexity and customization of the machine. Standard models usually ship within 15-30 days, while custom-built machines may take up to 60 days.

4. Can I customize the engraving machine to meet specific requirements?

Yes, SourcifyChina offers customization options. You can choose specific features such as machine size, power, and design elements to fit your unique needs. Discuss your requirements with their sales team for detailed information.

5. Does SourcifyChina provide after-sales support and training?

Yes, SourcifyChina provides comprehensive after-sales support, including machine installation, operational training, and ongoing technical support. They also offer online resources and documentation for troubleshooting.

6. What is the warranty period for these machines?

The warranty period for SourcifyChina tombstone engraving machines is typically one year. This covers parts and labor for any manufacturing defects. Extended warranties may also be available upon request.

7. How do I handle shipping and customs clearance?

SourcifyChina can arrange shipping to your specified location. They can also assist with the necessary documentation for customs clearance. It is advisable to consult with a local customs broker for smooth processing.

8. What are the payment terms?

Common payment terms include a 30% deposit upon order confirmation and the remaining balance before shipment. Options like T/T (Telegraphic Transfer), L/C (Letter of Credit), and other secure payment methods are accepted.

9. Can I arrange a factory visit before placing an order?

When sourcing a tombstone engraving machine from a factory on SourcifyChina, follow these tips:

1. Research and Compare:

– Use SourcifyChina’s search function to find multiple suppliers of tombstone engraving machines.

– Compare product specifications, features, and prices to find the best match for your needs.

2. Check Supplier Credentials:

– Look for verified suppliers and check their ratings and reviews.

– Ensure the supplier has experience in manufacturing tombstone engraving machines.

3. Request Detailed Information:

– Ask for detailed product catalogs, technical specifications, and customization options.

– Request case studies or references from previous customers to gauge product performance and reliability.

4. Verify Quality Standards:

– Confirm that the machines comply with relevant industry standards and certifications (e.g., CE, ISO).

– Inquire about the quality control processes in place at the factory.

5. Sample and Prototype:

– If possible, request a sample or prototype to test the machine’s performance and quality.

– Assess the sample’s functionality, ease of use, and engraving precision.

6. Negotiate Terms:

– Discuss pricing, payment terms, minimum order quantities, and delivery timelines.

– Clarify warranty and after-sales service terms to ensure support post-purchase.

7. Factory Visit:

– If feasible, visit the factory to inspect the manufacturing process and ensure the facility meets your standards.

– Alternatively, request a virtual tour if an in-person visit is not possible.

8. Logistics and Shipping:

– Plan for logistics, including shipping methods and costs.

– Ensure the supplier can handle export requirements and documentation.

9. Contracts and Agreements:

– Draft a clear contract outlining all terms and conditions to protect both parties.

– Include clauses for quality assurance, delivery schedules, and dispute resolution.

10. Continuous Communication:

– Maintain regular communication with the supplier throughout the sourcing process to address any issues promptly.

By following these steps, you can effectively source a reliable tombstone engraving machine from a SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.