Technology and Applications of shearing metal sheet

Technology and Applications of Shearing Metal Sheet

Technology:

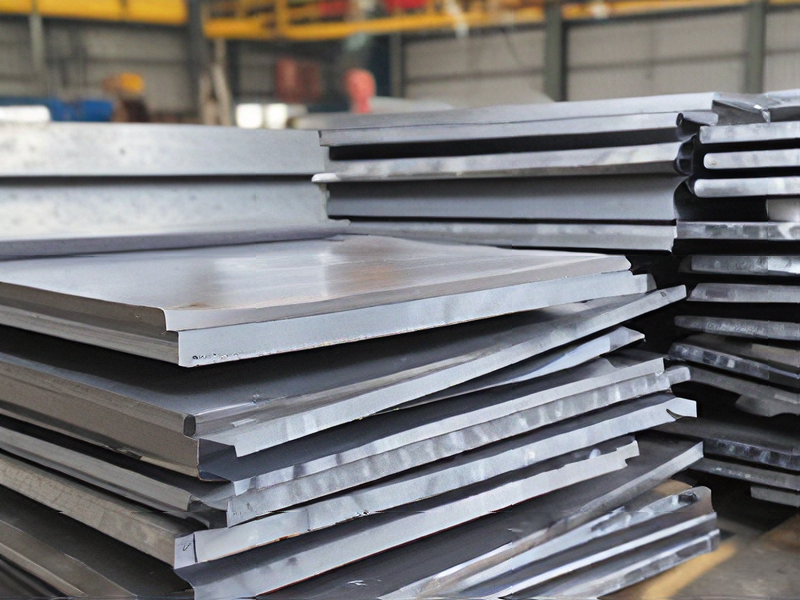

Shearing is a cutting process that produces straight cuts in metal sheets without forming chips or using burning or melting processes. This is achieved through the application of a high force or stress on the material, often using a punch and die mechanism. The main types of shearing equipment include mechanical, hydraulic, and pneumatic shears.

1. Mechanical Shears: These use a motor-driven flywheel to store energy and deliver it rapidly to the shearing blade. They’re suited for high-speed, continuous operations.

2. Hydraulic Shears: Utilizing hydraulic cylinders, these provide greater force and precision, ideal for thicker materials and more intricate cuts.

3. Pneumatic Shears: Powered by compressed air, these are typically used for lighter gauge materials and offer fast, clean cuts.

Applications:

1. Manufacturing and Fabrication: Shearing is widely used in manufacturing industries to cut large sheets into smaller sizes, which can be further processed into various components. It is essential in the automotive, aerospace, and appliance industries.

2. Construction: In construction, shearing is used to cut metal sheets for structural components, roofing, and cladding materials. It’s crucial for creating uniform, precise parts required in building structures.

3. Shipbuilding: The shipbuilding industry employs shearing for cutting metal plates used in the hulls and other structural parts of ships, where large and thick metal sheets are common.

4. Electronics: Shearing is used to manufacture components for electronic devices, such as casings and chassis, requiring high precision and fine cuts.

The shearing process is advantageous for its speed, cost-effectiveness, and ability to produce clean, accurate cuts, making it indispensable in numerous industries where metal sheet processing is fundamental.

Quality Testing Methods for shearing metal sheet and how to control quality

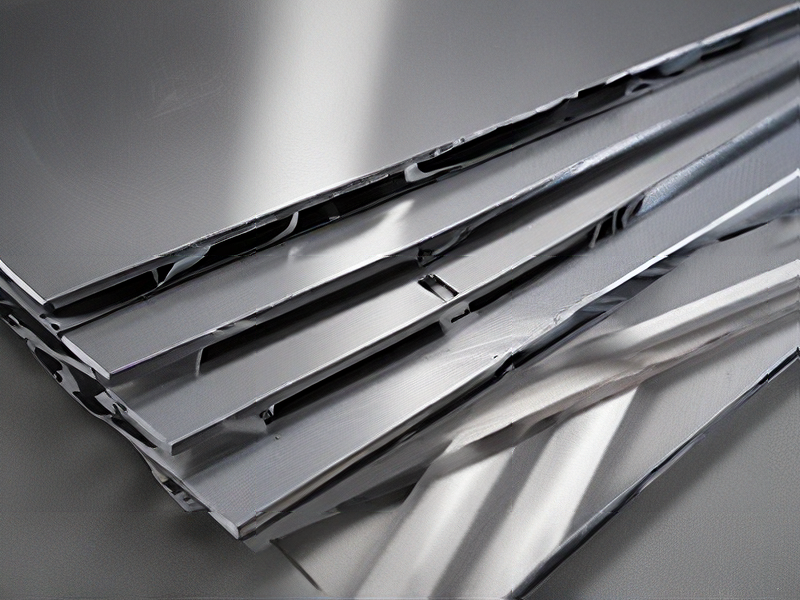

Quality testing methods for shearing metal sheets focus on ensuring accurate cuts, smooth edges, and minimal burrs.

Visual inspection: This involves examining the cut edge for jaggedness, burrs, or distortions. A magnifying glass can help identify minute imperfections.

Measurement tools: Calipers and rulers are used to verify cut length and width against specifications.

Profile measurement: Specialized tools like a profile projector can create a 3D image of the cut edge, revealing any deviations from the intended shape.

Edge quality testing:

* Burr measurement: Gauges or microscopes can quantify burr height and width.

* Surface finish testing: A profilometer measures surface roughness to ensure a smooth, defect-free edge.

Controlling quality:

* Proper tooling: Sharp, well-maintained blades are crucial for clean cuts.

* Machine calibration: Regular calibration of the shearing machine ensures accurate dimensions and consistent cuts.

* Material handling: Correct handling and storage of metal sheets prevent damage and warping before shearing.

* Process control: Monitoring cutting parameters like speed and pressure helps maintain consistent quality.

* Operator training: Skilled operators can minimize human error and optimize cutting techniques.

By implementing these testing methods and control measures, manufacturers can ensure the production of high-quality sheared metal sheets that meet the required specifications.

Tips for Procurement and Considerations when Purchasing from shearing metal sheet

When procuring metal sheet shearing services, it is essential to focus on key considerations to ensure quality, efficiency, and cost-effectiveness. Here are some critical tips:

1. Quality and Precision: Verify the shearing machine’s capability to meet your specifications, including tolerances and finishes. Ensure the service provider uses high-quality blades and equipment to achieve clean cuts without burrs.

2. Material Compatibility: Confirm that the shearing service can handle the specific type of metal and thickness you require. Different metals (e.g., aluminum, steel, stainless steel) and thicknesses may need specialized machines and techniques.

3. Provider Experience: Select a provider with a proven track record in metal sheet shearing. Experienced operators are more likely to deliver precise and consistent results, reducing material waste and rework.

4. Production Capacity: Assess the provider’s capacity to handle your order volume within the required timeframe. This includes considering the availability of machines, workforce, and any potential downtime.

5. Cost: Compare quotes from multiple providers, but do not base your decision solely on price. Consider the overall value, including quality, turnaround time, and additional services like delivery or post-shearing treatments.

6. Technology: Modern shearing machines equipped with CNC (Computer Numerical Control) offer higher precision and efficiency. Providers with up-to-date technology can often deliver better results and adapt to complex designs.

7. Customer Support: Evaluate the provider’s customer service, including communication, problem resolution, and flexibility. A responsive and supportive provider can significantly ease the procurement process.

8. Sustainability: Consider providers that implement sustainable practices, such as recycling scrap metal and using energy-efficient machines. This can align with your company’s environmental goals and potentially reduce costs.

By focusing on these considerations, you can make informed decisions that ensure high-quality sheared metal sheets, optimized costs, and reliable service.

FAQs on Sourcing and Manufacturing from shearing metal sheet in China

FAQs on Sourcing and Manufacturing Shearing Metal Sheets in China

1. Why source metal sheets from China?

China is a global leader in metal production, offering high-quality materials at competitive prices. Advanced technology and large-scale production capabilities make China an attractive option for sourcing metal sheets.

2. What are the common types of metal sheets available?

China manufactures a wide range of metal sheets, including stainless steel, aluminum, galvanized steel, and carbon steel. Each type offers specific benefits depending on the application.

3. How do I find a reliable supplier?

Use online platforms like Alibaba, Global Sources, or Made-in-China. Check supplier credentials, customer reviews, and request samples. Visiting factories or hiring third-party inspection services can also ensure reliability.

4. What is the typical lead time for orders?

Lead times vary based on order size and customization requirements, typically ranging from 2 to 8 weeks. Always confirm lead times directly with the supplier.

5. How can I ensure the quality of metal sheets?

Specify your quality requirements clearly in contracts. Request material certificates, conduct factory audits, and use third-party quality inspection services to verify product quality before shipment.

6. What are the common shipping methods and costs?

Shipping methods include sea freight, air freight, and express courier. Sea freight is the most economical for bulk orders. Costs depend on weight, volume, and destination. It’s crucial to compare quotes from multiple freight forwarders.

7. Are there any specific import regulations?

Yes, each country has its own import regulations. Ensure compliance with local import duties, taxes, and standards. Hiring a customs broker can simplify the process.

8. What are the payment terms typically used?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and D/P (Documents against Payment). Negotiate terms that protect your interests and minimize risk.

9. How can I handle communication barriers?

Clear communication is key. Use bilingual staff or professional translators. Confirm all details in writing to avoid misunderstandings.

10. What are the potential risks and how can I mitigate them?

Risks include quality issues, delays, and logistical challenges. Mitigate these by selecting reputable suppliers, maintaining clear communication, and using third-party inspection and logistics services.