Technology and Applications of what is milling machine

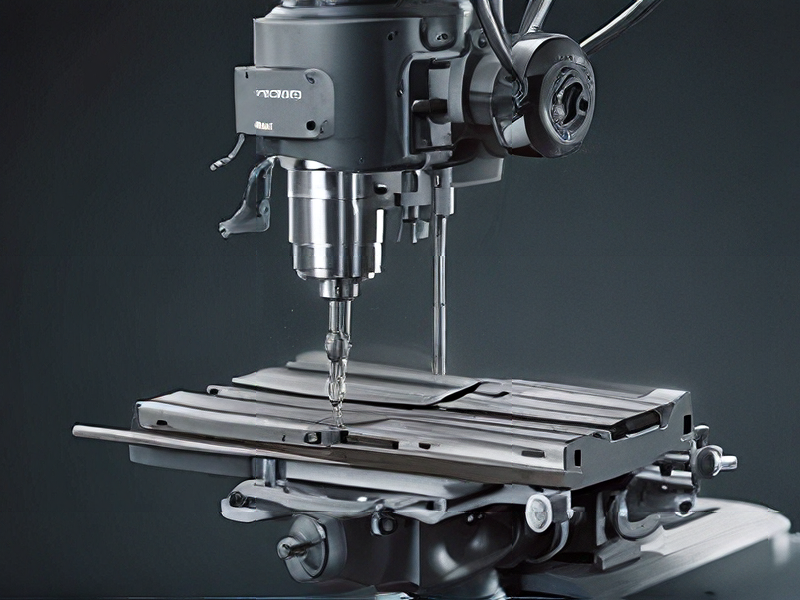

A milling machine is a versatile tool used in machining processes to shape, cut, and drill solid materials like metal, wood, or plastic. It operates with rotary cutters that remove material from a workpiece by advancing in a specific direction. Here are key aspects and applications of milling machines:

Types of Milling Machines:

1. Vertical Milling Machine: The spindle axis is vertically oriented.

2. Horizontal Milling Machine: The spindle axis is horizontally oriented, allowing for more complex parts to be machined.

3. Universal Milling Machine: Combines the features of vertical and horizontal milling machines for enhanced versatility.

Technology and Components:

– Spindle: Rotates the cutter.

– Cutting Tool: Various types (end mills, face mills) for different operations.

– Worktable: Supports the workpiece and can be adjusted for different angles.

– Control Panel: Modern machines often feature digital controls for precise operation.

Applications:

– Metalworking: Used extensively in manufacturing for producing precision parts, molds, and prototypes.

– Woodworking: Shapes wood for furniture, cabinetry, and artistic applications.

– Plastics and Composites: Mills are used to create molds and components in industries like aerospace and automotive.

Advantages:

– Precision: Enables tight tolerances and intricate designs.

– Versatility: Can perform a wide range of operations with different cutting tools.

– Efficiency: Automatable processes increase production rates and consistency.

Conclusion:

Milling machines are crucial in manufacturing and fabrication industries due to their ability to precisely shape materials into desired forms. Advances in CNC technology have further enhanced their capabilities, making them indispensable for complex and high-precision machining tasks across various materials.

Quality Testing Methods for what is milling machine and how to control quality

A milling machine is a versatile tool used to shape and cut solid materials like metal, wood, and plastics. Quality control in milling involves several key methods to ensure precision and performance:

1. Dimensional Inspection: Using precision tools like calipers and micrometers to measure critical dimensions such as length, width, and depth of machined parts against specifications.

2. Surface Finish Evaluation: Employing surface roughness testers to assess the quality of the machined surface, ensuring it meets smoothness requirements without imperfections.

3. Tool Wear Monitoring: Regularly inspecting cutting tools for signs of wear and tear using tool wear indicators or measuring instruments to maintain cutting efficiency and product quality.

4. Accuracy and Alignment Checks: Verifying the alignment of machine components and the accuracy of movements through alignment tools and laser calibration systems.

5. Material Integrity Testing: Ensuring the integrity of the machined material through non-destructive testing methods like ultrasonic testing or magnetic particle inspection to detect defects.

6. Process Monitoring: Utilizing sensors and monitoring systems to track parameters such as cutting speed, feed rate, and coolant flow to maintain consistent machining quality.

7. Operator Training and Skills: Training operators to adhere to standard operating procedures (SOPs) and providing continuous education on quality expectations and techniques.

By employing these methods, manufacturers can effectively control the quality of milling machine operations, ensuring precise and reliable production of components across various industries.

Tips for Procurement and Considerations when Purchasing from what is milling machine

When procuring a milling machine, several key factors should be considered to ensure the purchase aligns with your needs and objectives.

Tips for Procurement

1. Define Requirements: Clearly outline the intended use of the milling machine. Consider the types of materials you’ll be working with, the required precision, and the production volume.

2. Budget: Determine your budget, including not just the purchase price but also the costs of installation, maintenance, and potential upgrades.

3. Research Suppliers: Look for reputable suppliers with good reviews and a track record of providing reliable machines and excellent after-sales support.

4. Machine Specifications: Compare specifications like spindle speed, feed rate, and power. Ensure the machine meets your performance requirements.

5. Evaluate Software Compatibility: Modern milling machines often come with software for CAD/CAM integration. Ensure the software is user-friendly and compatible with your existing systems.

6. Check for Automation: Depending on your production needs, consider machines with automation features for increased efficiency and reduced labor costs.

7. Quality and Durability: Opt for machines made from high-quality materials and components to ensure longevity and minimal downtime.

8. Warranty and Support: Check the warranty terms and the availability of technical support and spare parts.

9. Safety Features: Ensure the machine has adequate safety features to protect operators and comply with workplace safety regulations.

Considerations

– Type of Milling Machine: Choose between vertical, horizontal, or CNC milling machines based on your specific needs. Vertical machines are versatile, horizontal machines are good for heavy-duty tasks, and CNC machines offer high precision and automation.

– Size and Space: Ensure the machine fits within your workspace and that there is enough room for operation and maintenance.

– Operator Skill Level: Consider the skill level of your operators. CNC machines, for instance, require more technical know-how compared to manual machines.

– Future Proofing: Consider potential future needs and whether the machine can be upgraded or adapted as your business grows.

By carefully evaluating these factors, you can make an informed decision that balances cost, performance, and long-term value.

FAQs on Sourcing and Manufacturing from what is milling machine in China

FAQs on Sourcing and Manufacturing Milling Machines in China

1. What is a milling machine?

A milling machine is a device used in machining solid materials. It can perform various operations such as cutting, drilling, and shaping parts made from metal or other materials.

2. Why source milling machines from China?

China is a leading manufacturer of milling machines, offering a wide range of products at competitive prices. The country has advanced manufacturing capabilities and a robust supply chain, making it an attractive option for sourcing machinery.

3. How to find reliable manufacturers in China?

To find reliable manufacturers:

– Use online platforms like Alibaba, Made-in-China, and Global Sources.

– Attend trade shows such as the China International Machine Tool Show (CIMT).

– Utilize sourcing agents and consultants with experience in the industry.

4. What factors should I consider when choosing a manufacturer?

Key factors include:

– Quality and certifications (ISO, CE).

– Production capacity and lead times.

– Customer reviews and testimonials.

– After-sales support and warranty policies.

5. What are the common types of milling machines available in China?

Common types include:

– Vertical milling machines.

– Horizontal milling machines.

– CNC (Computer Numerical Control) milling machines.

– Universal milling machines.

6. How can I ensure the quality of the milling machines?

– Request samples or visit the factory for a firsthand inspection.

– Check for certifications and compliance with international standards.

– Conduct third-party inspections and quality audits.

7. What is the typical lead time for manufacturing and shipping?

Lead times vary based on the complexity of the machine and the manufacturer’s schedule. Typically, it ranges from a few weeks to a few months. Shipping times depend on the destination and shipping method (air or sea freight).

8. Are there any risks involved in sourcing from China?

Potential risks include:

– Quality inconsistencies.

– Communication barriers.

– Intellectual property issues.

– Logistical challenges.

9. How can I mitigate these risks?

– Establish clear contracts and agreements.

– Maintain regular communication with suppliers.

– Use trusted logistics partners.

– Protect intellectual property through patents and trademarks.

10. What are the payment terms usually offered by Chinese manufacturers?

Common payment terms include:

– 30% deposit before production and 70% balance before shipment.

– Letter of Credit (L/C).

– Escrow services for added security.

By understanding these aspects, businesses can effectively source and manufacture milling machines from China, ensuring high-quality products and smooth operations.