Technology and Applications of wooden laser cut machine

Technology and Applications of Wooden Laser Cut Machines

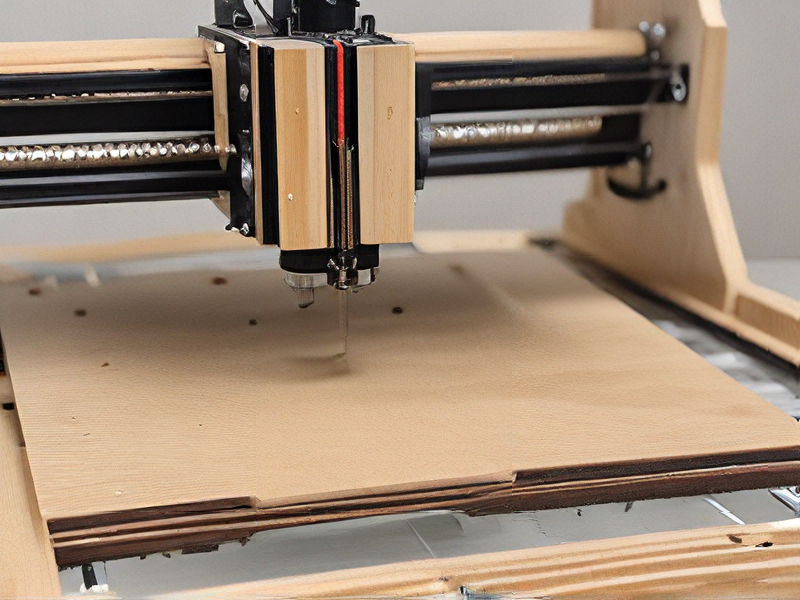

Wooden laser cut machines utilize advanced laser technology to cut, engrave, and shape wood with precision. These machines employ a high-powered laser beam, typically CO2 lasers, which can focus intense energy on a small area of the wood, causing it to vaporize or burn away. The process is controlled by computer-aided design (CAD) software, allowing for intricate and precise patterns that would be difficult to achieve with traditional woodworking tools.

#### Technology

1. Laser Source: The core of the machine, usually a CO2 laser, provides the energy needed for cutting.

2. Motion System: Often guided by stepper or servo motors, ensuring precise movement of the laser head.

3. Cooling System: Maintains optimal temperature of the laser tube and prevents overheating.

4. Control Software: Converts digital designs into instructions for the laser cutter, allowing for detailed customization.

5. Exhaust System: Removes fumes and particulates generated during the cutting process.

#### Applications

1. Art and Craft: Laser cut machines enable artists to create detailed sculptures, decorative items, and intricate designs in wood.

2. Furniture Making: Precision cutting allows for the creation of complex joints and detailed designs in furniture manufacturing.

3. Signage: Custom wooden signs with detailed engravings are popular in both commercial and residential settings.

4. Prototyping: Engineers and designers use laser cutters for creating prototypes, thanks to their ability to produce detailed and accurate models quickly.

5. Architectural Models: Architects use these machines to create precise scale models of buildings and structures.

6. Educational Tools: Schools and universities use laser cut machines for educational projects, providing hands-on experience with design and fabrication.

The precision, versatility, and efficiency of wooden laser cut machines make them indispensable in various industries, from artistic endeavors to industrial applications, revolutionizing how wood is manipulated and enhancing the creative possibilities for designers and manufacturers.

Quality Testing Methods for wooden laser cut machine and how to control quality

To ensure the quality of a wooden laser cutting machine, several testing methods can be employed:

1. Dimensional Accuracy Testing: Measure key dimensions of cut pieces against design specifications using precision instruments like calipers or coordinate measuring machines (CMMs).

2. Material Inspection: Verify the quality and consistency of the wood used, checking for defects such as knots, warping, or inconsistent grain patterns.

3. Cutting Performance Evaluation: Assess the machine’s ability to cut through different types and thicknesses of wood cleanly and accurately. This includes testing edge smoothness and kerf width.

4. Durability Testing: Run the machine through extended operational cycles to evaluate its robustness and longevity under typical usage conditions.

5. Safety and Compliance Checks: Ensure the machine adheres to safety standards for laser devices and woodworking equipment, including emissions testing and electrical safety certifications.

To control quality effectively:

1. Establish Standard Operating Procedures (SOPs): Define clear protocols for machine setup, operation, maintenance, and testing procedures.

2. Implement Quality Control Checks: Integrate regular inspections and testing checkpoints throughout the manufacturing process.

3. Training and Skill Development: Provide training to operators and quality assurance personnel on proper machine operation, testing methods, and quality standards.

4. Feedback Loop: Establish mechanisms for gathering feedback from users and stakeholders to continually improve machine design and performance.

5. Documentation and Traceability: Maintain comprehensive records of testing results, machine configurations, and any quality issues encountered for traceability and continuous improvement purposes.

By systematically applying these methods and controls, manufacturers can ensure that their wooden laser cutting machines consistently meet high-quality standards and customer expectations.

Tips for Procurement and Considerations when Purchasing from wooden laser cut machine

When purchasing a wooden laser cut machine for procurement purposes, several key considerations can ensure you make an informed decision:

1. Machine Specifications: Evaluate the laser power, cutting bed size, and maximum material thickness the machine can handle. Ensure these specifications align with your intended use and production needs.

2. Quality and Durability: Research the build quality, materials used, and reliability of the machine. Look for reviews or testimonials from other users to gauge its performance over time.

3. Ease of Use and Software Compatibility: User-friendly interfaces and compatible software are crucial for seamless operation. Check if the machine supports common file formats (e.g., DXF, AI) and integrates with your existing workflow.

4. Safety Features: Laser machines pose safety risks. Ensure the machine has necessary safety features like emergency stop buttons, enclosed laser area, and compliance with safety standards (e.g., CE certification).

5. After-Sales Support and Training: Verify what after-sales support the supplier offers. Training on machine operation and troubleshooting can prevent downtime and maximize productivity.

6. Cost and Return on Investment (ROI): Compare prices among different suppliers, but also consider long-term costs such as maintenance, energy consumption, and consumables like laser tubes and lenses. Calculate potential ROI based on your production volume and efficiency gains.

7. Supplier Reputation and Service: Choose a reputable supplier with a history of delivering quality products and responsive customer service. Warranty terms and repair services are essential considerations.

8. Environmental Considerations: Laser cutting can generate fumes and waste materials. Assess whether the machine includes exhaust systems or other environmental controls to minimize impact.

By thoroughly assessing these factors, you can make a well-informed procurement decision that aligns with your operational needs and budget constraints.

FAQs on Sourcing and Manufacturing from wooden laser cut machine in China

FAQs on Sourcing and Manufacturing with Wooden Laser Cut Machines in China

1. What is a wooden laser cut machine?

A wooden laser cut machine uses laser technology to cut, engrave, and design wood materials with high precision. It’s widely used for making intricate designs in various applications, including crafts, furniture, and signage.

2. Why source from China?

China offers competitive pricing, advanced technology, and a vast network of manufacturers. The country has a well-established supply chain, allowing for efficient production and rapid delivery.

3. How do I find a reliable manufacturer?

Research potential manufacturers through platforms like Alibaba or Made-in-China. Check reviews, ask for samples, and verify certifications. Additionally, consider visiting factories or hiring a sourcing agent.

4. What should I consider regarding quality control?

Establish clear quality standards and conduct inspections before shipment. You can hire third-party inspection services to ensure the products meet your specifications.

5. What materials can be used with laser cut machines?

While the focus is on wood, many laser machines can also cut or engrave materials like acrylic, leather, and cardboard. Confirm compatibility with your manufacturer.

6. What are typical lead times for production?

Lead times vary based on order size and complexity but typically range from 2 to 6 weeks. Communicate your timeline with the manufacturer early in the process.

7. What are the shipping options available?

Common shipping methods include sea freight, air freight, and express delivery. Your choice will depend on your budget and urgency.

8. Are there any import duties I should be aware of?

Yes, import duties vary by country. Check with your local customs office for specific regulations and rates.

By understanding these key aspects, you can effectively navigate sourcing and manufacturing using wooden laser cut machines in China.