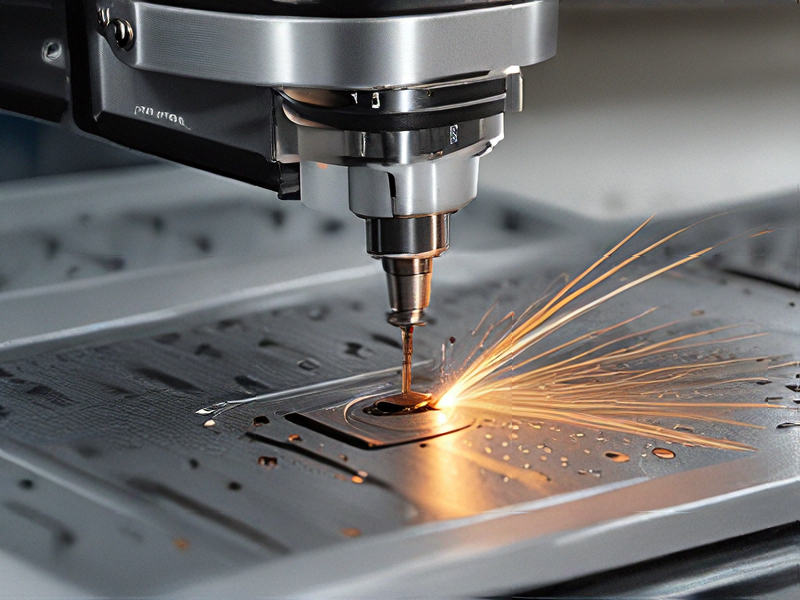

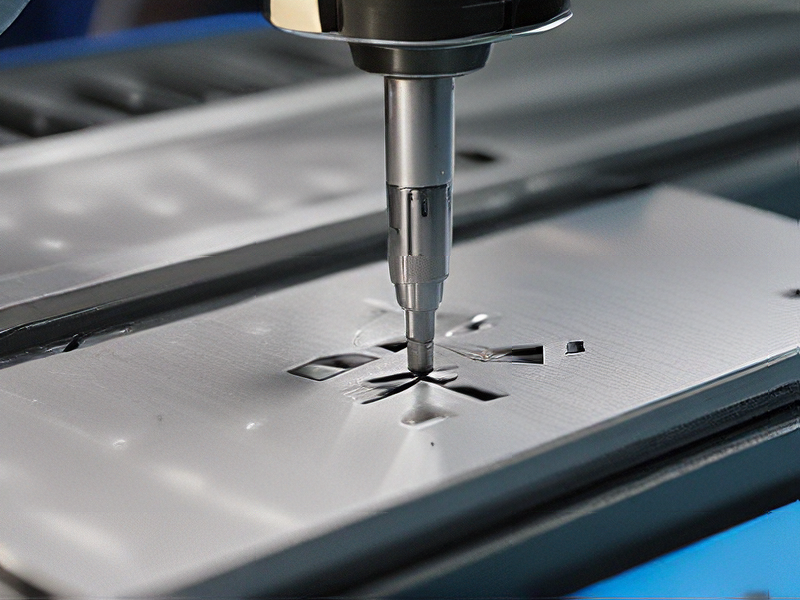

Technology and Applications of laser etching machine metal

Laser etching machines for metal use focused laser beams to create precise, permanent marks on various metal surfaces. This technology leverages high-intensity laser light to vaporize material from the metal surface, producing clean, high-resolution designs, logos, barcodes, or text.

Technology

1. Laser Source: Commonly used lasers include fiber lasers, CO2 lasers, and Nd:YAG lasers, each suited for different types of metals and applications. Fiber lasers are particularly efficient for metals.

2. Optics: Galvanometer scanners or fixed optics direct the laser beam with high precision, allowing for intricate patterns and detailed marks.

3. Control Software: Advanced software controls the laser parameters (such as power, speed, and frequency) and the movement of the laser head, ensuring accurate and repeatable etching.

4. Cooling Systems: Integrated cooling systems prevent overheating and ensure consistent performance.

Applications

1. Industrial Manufacturing: Laser etching is widely used in automotive, aerospace, and electronics industries for marking serial numbers, batch numbers, and QR codes on parts for traceability.

2. Jewelry and Personalization: Fine and detailed designs on jewelry, custom engraving of names or messages on watches, rings, and other accessories.

3. Medical Devices: Marking of surgical instruments and implants with unique identifiers for tracking and compliance with regulations.

4. Tooling and Machining: Creating durable, wear-resistant marks on tools, dies, and machine parts.

5. Consumer Products: Custom etching on consumer electronics, promotional items, and household goods.

Laser etching machines offer significant advantages, including high precision, speed, and flexibility. They provide a non-contact process, reducing the risk of mechanical damage and wear. Furthermore, the marks are permanent, resistant to wear, corrosion, and high temperatures, ensuring durability in various environmental conditions.

This technology continues to evolve, with innovations aimed at enhancing efficiency, reducing costs, and expanding the range of materials and applications.

Quality Testing Methods for laser etching machine metal and how to control quality

Quality testing for laser etching on metal involves several methods to ensure precision and consistency. Key techniques include:

1. Visual Inspection: Examining the etched surface for clarity, sharpness, and any signs of defects like burn marks or incomplete etching. This is often the first and simplest step.

2. Microscopy: Using microscopes to check the fine details of the etching, ensuring that all lines and patterns meet the required specifications.

3. Surface Profilometry: Measuring the etched surface’s topography to assess depth and uniformity. This ensures the etching meets specific dimensional tolerances.

4. Spectroscopy: Analyzing the chemical composition of the etched area to ensure no unwanted changes occurred during the laser etching process.

5. Hardness Testing: Evaluating the metal’s hardness post-etching to confirm that the laser process hasn’t adversely affected the material properties.

To control the quality of laser etching on metal, consider the following strategies:

1. Calibration and Maintenance: Regularly calibrate the laser etching machine and maintain it according to the manufacturer’s guidelines to ensure consistent performance.

2. Process Parameters: Carefully control parameters such as laser power, speed, frequency, and focus. These settings significantly impact the quality and precision of the etching.

3. Material Consistency: Use metals with consistent properties and surface finishes to reduce variability in etching results.

4. Environmental Control: Maintain a stable environment around the laser etching machine, controlling factors like temperature and humidity, which can affect the process.

5. Training and Protocols: Ensure operators are well-trained and follow standardized protocols. Consistent handling and operation reduce the chances of human error.

6. Automated Monitoring: Implement systems that monitor the etching process in real-time, using sensors and software to detect deviations and make adjustments on the fly.

By integrating these testing methods and control strategies, the quality of laser etching on metal can be maintained at a high standard, ensuring reliable and precise outcomes.

Tips for Procurement and Considerations when Purchasing from laser etching machine metal

When procuring a laser etching machine for metal, consider several key factors to ensure you make an informed decision:

1. Laser Type and Power: Choose a machine with the appropriate laser type (fiber, CO2) and power suitable for your materials and application needs. Fiber lasers are typically better for metal etching due to their wavelength and efficiency.

2. Precision and Speed: Evaluate the machine’s capability for high precision and speed. This is crucial for intricate designs and large production volumes.

3. Software and Compatibility: Check the compatibility of the machine’s software with your existing systems or design software. User-friendly software can streamline operations and enhance productivity.

4. Maintenance and Support: Consider the availability of technical support, training, and maintenance services from the supplier. This ensures minimal downtime and efficient troubleshooting.

5. Safety Features: Ensure the machine complies with safety standards and has features like fume extraction systems for safe operation in your workspace.

6. Cost and Return on Investment (ROI): Compare costs across different suppliers and consider the long-term ROI. A higher initial investment may be justified by lower operating costs and increased productivity.

7. References and Reviews: Research supplier reputation and customer reviews to gauge reliability, service quality, and machine performance.

8. Future Scalability: Choose a machine that can accommodate future business growth or changes in production requirements.

9. Material Handling: Consider the machine’s capabilities for handling various metal types, thicknesses, and sizes that align with your production needs.

10. Warranty and Terms: Review warranty terms, service agreements, and delivery timelines to ensure they meet your expectations and business continuity needs.

By carefully evaluating these factors and aligning them with your specific requirements, you can select a laser etching machine that enhances productivity, meets safety standards, and delivers quality results for metal etching applications.

FAQs on Sourcing and Manufacturing from laser etching machine metal in China

Certainly! When sourcing and manufacturing laser etching machines from China, it’s essential to address key FAQs:

1. Quality Assurance: How can I ensure the quality of laser etching machines from Chinese manufacturers?

– Answer: Conduct thorough supplier audits, request product samples, and establish clear quality control measures in your contract.

2. Cost Considerations: What are the typical costs involved in manufacturing laser etching machines in China?

– Answer: Costs vary based on specifications, materials, and production volumes. Negotiate pricing and clarify all included costs (e.g., shipping, tariffs).

3. Lead Times: What are the expected lead times for manufacturing and shipping laser etching machines from China?

– Answer: Lead times can range from weeks to months depending on production schedules and shipping methods. Plan accordingly and maintain communication with suppliers.

4. Customization Options: Can I customize laser etching machines according to specific requirements?

– Answer: Yes, many Chinese manufacturers offer customization options for hardware, software, and design. Provide detailed specifications and discuss feasibility with suppliers.

5. Intellectual Property Protection: How can I protect my designs and intellectual property when manufacturing in China?

– Answer: Ensure robust contracts with clear intellectual property clauses. Consider legal advice and utilize NDAs (Non-Disclosure Agreements) where necessary.

6. Support and Maintenance: What support and maintenance options are available post-purchase?

– Answer: Clarify warranty terms, technical support availability, and potential servicing arrangements with the manufacturer.

By addressing these FAQs, you can navigate the process of sourcing and manufacturing laser etching machines from China effectively, ensuring quality, cost-efficiency, and protection of intellectual property.