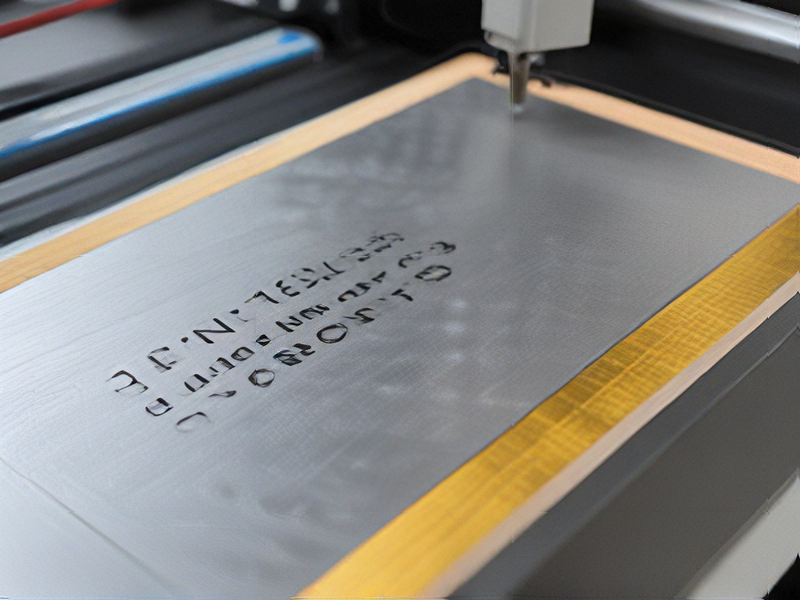

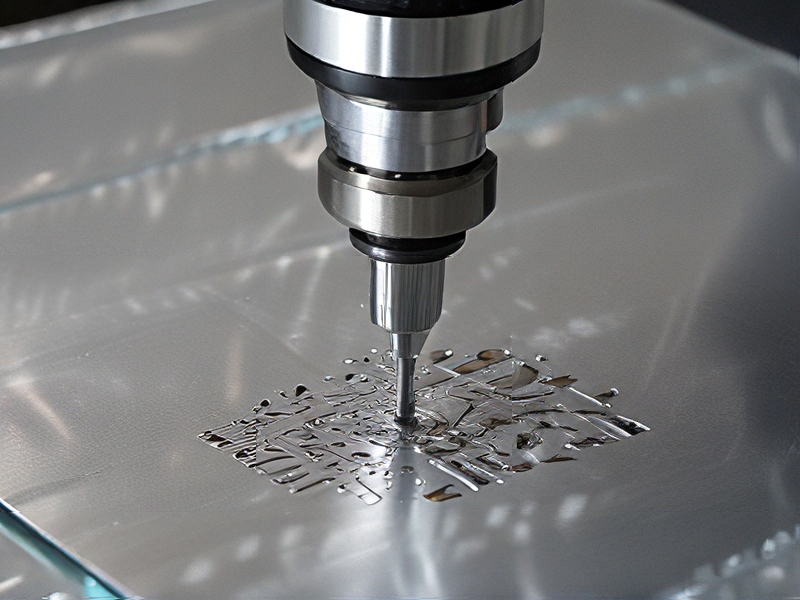

Technology and Applications of laser engraving machine on metal

Laser engraving machines use focused laser beams to etch or mark the surface of metals with high precision and speed. The core technology behind these machines includes fiber lasers, CO2 lasers, and diode-pumped solid-state (DPSS) lasers, each varying in wavelength and suitable for different applications. Fiber lasers are most commonly used for metal engraving due to their high efficiency and ability to produce fine, detailed engravings.

Technology

Fiber Lasers: These use optical fibers doped with rare-earth elements to amplify the laser light. They offer high power density and are ideal for engraving metals like stainless steel, aluminum, and brass.

CO2 Lasers: Although primarily used for non-metal materials, they can engrave coated metals or surface-etch anodized aluminum.

DPSS Lasers: Utilize a solid gain medium and are efficient for marking intricate designs on metals and other materials.

Applications

1. Industrial Marking: Laser engraving is used for serial numbers, barcodes, and logos on metal components, ensuring durability and traceability in automotive, aerospace, and electronics industries.

2. Jewelry: Precise and delicate engraving on precious metals like gold, silver, and platinum, enabling customization and intricate designs.

3. Medical Devices: Engraving critical information like batch numbers and manufacturer details on surgical instruments and implants, complying with regulatory standards.

4. Personalization: Customizing items such as watches, pens, and trophies, enhancing their value and uniqueness.

5. Art and Decoration: Creating detailed artwork on metal surfaces for decorative purposes, blending technology with artistry.

Advantages

Laser engraving offers advantages like non-contact processing, which reduces material wear and deformation. It ensures high precision and repeatability, essential for detailed and consistent results. The process is also fast, efficient, and can be automated, increasing productivity while maintaining high-quality output. Additionally, laser engraving provides permanent markings that are resistant to wear, heat, and corrosion, making it ideal for various applications.

Quality Testing Methods for laser engraving machine on metal and how to control quality

Quality testing methods for laser engraving machines on metal typically involve several key approaches:

1. Visual Inspection: This involves examining the engraved surface for clarity, depth consistency, and any defects such as burns or uneven markings. A magnifying glass or microscope may be used for detailed inspection.

2. Dimensional Accuracy: Measurements are taken to ensure the engraved dimensions match the specifications. This can be done using precision instruments like calipers or coordinate measuring machines (CMM).

3. Surface Roughness Measurement: Laser engraving can alter the surface texture of metal. Surface roughness testers evaluate the smoothness of the engraved area, ensuring it meets desired standards.

4. Durability Testing: Assessing the durability of the engraved marks involves subjecting them to environmental factors like temperature, humidity, and abrasion. This ensures the marks withstand intended conditions without fading or degradation.

5. Material Composition Verification: For critical applications, verifying the chemical composition of the engraved metal ensures it meets material standards and does not suffer from unintended changes due to the engraving process.

To control quality effectively:

– Calibration: Regular calibration of the laser machine and measuring instruments ensures accuracy in engraving and measurement.

– Standard Operating Procedures (SOPs): Develop SOPs for machine setup, engraving parameters, inspection protocols, and record-keeping to maintain consistency.

– Training: Train operators in proper machine operation, inspection techniques, and quality standards to minimize errors.

– Quality Assurance Checks: Implement regular quality checks at different stages of production to catch issues early.

By integrating these methods and controls, manufacturers can ensure consistent quality in laser engraving on metal, meeting customer expectations and regulatory requirements effectively.

Tips for Procurement and Considerations when Purchasing from laser engraving machine on metal

When purchasing a laser engraving machine for metal, consider the following key factors:

1. Laser Type and Power: Choose between CO2 and fiber lasers based on your specific metal engraving needs. Fiber lasers are typically more suitable for marking and engraving metals due to their high precision and efficiency.

2. Engraving Area and Size: Ensure the machine’s engraving area accommodates the size of the metal parts or products you intend to work with. Consider both the maximum dimensions and the depth of engraving it can achieve.

3. Precision and Speed: Evaluate the machine’s engraving resolution and speed. Higher precision ensures clarity and detail in your engravings, while faster speeds can improve productivity.

4. Software Compatibility and Ease of Use: Check if the machine is compatible with your existing design software. User-friendly interfaces and intuitive controls can simplify operation and training for your staff.

5. Maintenance and Support: Look for a machine that is easy to maintain and comes with reliable customer support. Regular maintenance is crucial to keep the machine in optimal condition for consistent performance.

6. Safety Features: Laser engraving machines involve high-powered lasers, so ensure the machine has adequate safety features such as enclosures, interlocks, and safety sensors to protect operators from potential hazards.

7. Budget and ROI: Determine your budget and consider the return on investment (ROI) based on the machine’s capabilities and expected productivity gains.

8. Reviews and References: Research user reviews and seek references from other businesses using similar machines to gauge reliability, performance, and overall satisfaction.

By carefully evaluating these factors, you can select a laser engraving machine that meets your specific metal engraving requirements efficiently and effectively.

FAQs on Sourcing and Manufacturing from laser engraving machine on metal in China

FAQs on Sourcing and Manufacturing Laser Engraving Machines on Metal in China

1. Why source laser engraving machines from China?

China offers competitive pricing, advanced technology, and a large number of manufacturers specializing in laser engraving machines. This makes it a cost-effective and efficient choice for sourcing.

2. What should I look for in a manufacturer?

Seek manufacturers with a solid reputation, verified certifications (ISO, CE, FDA), positive customer reviews, and robust after-sales support. Visiting the factory or requesting virtual tours can also provide insights into their operations.

3. How do I verify the quality of the machines?

Request samples, technical specifications, and testing videos. Consider third-party inspections and quality checks before shipment to ensure the machines meet your standards.

4. What are the typical lead times for manufacturing?

Lead times can vary based on order size and customization needs but generally range from 2 to 6 weeks. Always confirm the lead time with the manufacturer before placing an order.

5. Are there minimum order quantities (MOQs)?

MOQs can vary significantly between manufacturers. Some may offer flexible MOQs, especially for first-time buyers, while others might require larger orders.

6. What are the common payment terms?

Common payment terms include a 30% deposit upfront with the balance paid before shipment. Letter of Credit (LC) and Trade Assurance on platforms like Alibaba can provide additional security.

7. How can I handle shipping and logistics?

Manufacturers often offer FOB (Free on Board) terms, meaning you’ll need to arrange shipping from the port of origin. Working with a reliable freight forwarder can simplify logistics and ensure smooth delivery.

8. What about after-sales service and support?

Ensure the manufacturer provides comprehensive after-sales support, including remote assistance, spare parts, and maintenance services. Clear communication about warranty terms is also essential.

9. Are there any import duties or taxes?

Import duties and taxes vary by country. It’s crucial to check with local customs authorities to understand any applicable fees and regulations.

10. How do I manage potential risks?

Mitigate risks by conducting thorough research, requesting references, using secure payment methods, and having clear contracts in place. Engaging a sourcing agent can also help navigate complexities.