Technology and Applications of laser engraving machine steel

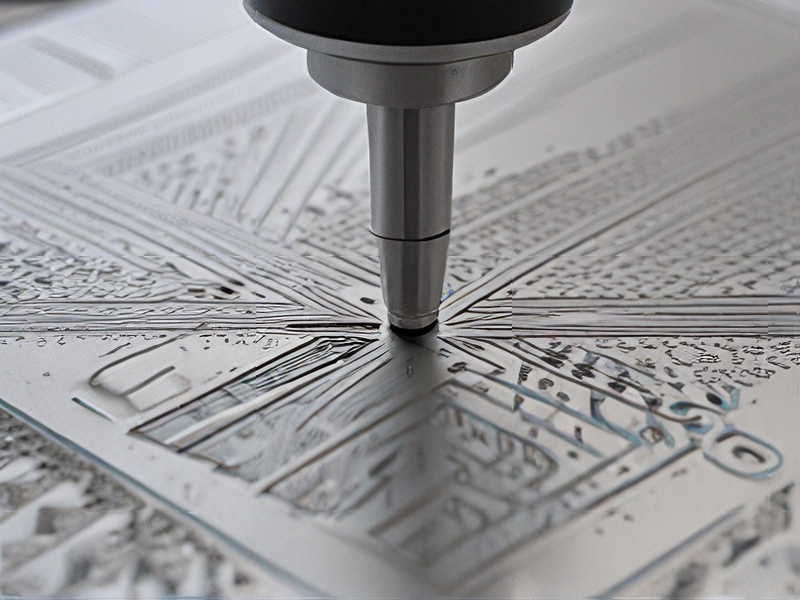

Laser engraving on steel is a technology that utilizes focused laser beams to etch designs, text, or patterns onto steel surfaces. This method is highly precise and versatile, making it ideal for a range of industrial and artistic applications.

Technology

Laser engraving machines operate using various laser types, including CO2, fiber, and Nd:YAG lasers. Each type has unique properties suited for different tasks:

– Fiber lasers: These are preferred for metal engraving due to their high intensity and efficiency. They can create fine details and are suitable for high-speed engraving.

– CO2 lasers: Though primarily used for non-metals, CO2 lasers can engrave metals if the material is coated or treated.

– Nd:YAG lasers: These are effective for deep engraving and are often used in applications requiring high power.

Process

The laser engraving process involves directing the laser beam onto the steel surface, where the intense heat causes the material to vaporize, leaving behind a permanent mark. The laser is controlled by software that dictates the pattern, depth, and speed of the engraving.

Applications

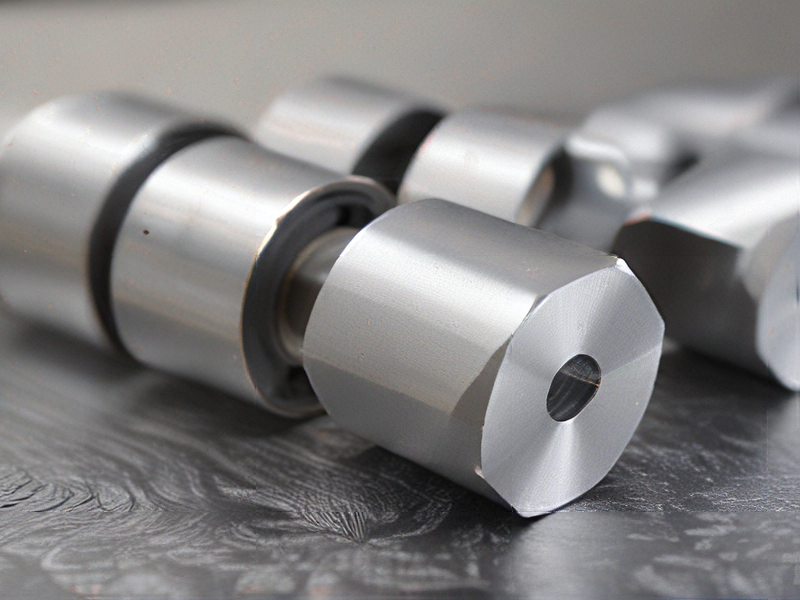

1. Industrial Marking: Laser engraving is used for marking serial numbers, barcodes, and logos on tools, machinery parts, and consumer products. This ensures traceability and authenticity.

2. Jewelry and Art: Artists and jewelers use laser engraving for intricate designs on rings, bracelets, and other metal art pieces, offering customization and precision that traditional methods cannot match.

3. Manufacturing: In manufacturing, laser engraving is employed to create detailed molds, engrave machine components, and produce custom parts with high accuracy.

4. Medical Devices: The medical industry uses laser engraving for marking surgical instruments and implants with vital information without compromising their integrity.

Advantages

– Precision: Laser engraving provides high accuracy and can produce very fine details.

– Durability: Engraved marks are permanent and resistant to wear and corrosion.

– Speed: The process is faster than many traditional engraving methods.

– Flexibility: It can handle complex designs and a wide range of steel types and thicknesses.

Overall, laser engraving on steel is a robust and versatile technology that enhances precision, durability, and efficiency across various fields.

Quality Testing Methods for laser engraving machine steel and how to control quality

Quality Testing Methods for Laser Engraving on Steel:

1. Visual Inspection: Examine the engraved surface for clarity, sharpness, and consistency. Any signs of burn marks, incomplete engraving, or irregular lines indicate a quality issue.

2. Microscopic Analysis: Use a microscope to inspect the engraving details closely. This method helps identify minute flaws not visible to the naked eye, such as micro-cracks or rough edges.

3. Depth Measurement: Utilize depth gauges or profilometers to measure the engraving depth. Ensure it meets the required specifications for uniformity and precision.

4. Surface Roughness Testing: Employ surface roughness testers to check the smoothness of the engraved areas. Consistent roughness levels indicate a uniform engraving process.

5. Hardness Testing: Perform hardness tests on the engraved areas using methods like Rockwell or Vickers hardness tests. Changes in hardness can indicate improper laser settings or material issues.

6. Dimensional Accuracy: Use calipers or coordinate measuring machines (CMM) to verify the dimensions of the engraved patterns against design specifications.

7. Contrast and Readability Tests: Ensure that text or designs have sufficient contrast and are readable. This is crucial for applications involving serial numbers or barcodes.

Quality Control Methods:

1. Calibration and Maintenance: Regularly calibrate the laser engraving machine to ensure precision. Perform routine maintenance to keep the machine in optimal working condition.

2. Standard Operating Procedures (SOPs): Develop and adhere to SOPs for the engraving process, including laser settings, material handling, and inspection protocols.

3. Training and Skill Development: Ensure operators are well-trained and knowledgeable about the machine settings, material properties, and troubleshooting techniques.

4. Process Monitoring: Implement real-time monitoring systems to track the engraving process. Use sensors and cameras to detect deviations and take corrective actions promptly.

5. Sample Testing: Conduct regular sample tests on materials before full-scale production to verify settings and ensure consistent quality.

6. Feedback Loop: Establish a feedback loop from the inspection team to the production team. Use inspection results to adjust and improve the engraving process continually.

By combining these testing and control methods, the quality of laser engraving on steel can be effectively monitored and maintained.

Tips for Procurement and Considerations when Purchasing from laser engraving machine steel

When purchasing a laser engraving machine for steel, several key considerations can ensure you make an informed procurement decision:

1. Power and Capability: Ensure the laser machine is equipped with sufficient power to effectively engrave on steel. Fiber laser machines are highly recommended for their capability to engrave on metals with precision and speed.

2. Laser Source: Choose between fiber lasers and CO2 lasers based on your specific needs. Fiber lasers are ideal for marking and engraving metals due to their high beam quality and reliability.

3. Software Compatibility: Verify that the machine’s software supports the file formats you typically work with (e.g., CAD files, vector graphics). User-friendly software with intuitive interfaces can enhance productivity.

4. Ease of Use and Maintenance: Consider machines that are easy to operate and maintain. Look for features like automatic focus adjustment and minimal consumable requirements to streamline operations.

5. Bed Size and Configuration: Ensure the machine’s bed size accommodates the dimensions of steel components you intend to engrave. Adjustable bed heights and rotary attachments can enhance versatility.

6. Speed and Efficiency: Evaluate engraving speed and throughput rates to match your production requirements. High-speed engraving capabilities can significantly impact productivity.

7. Quality and Precision: Seek machines known for producing high-quality engravings with fine details. Reviews and demonstrations can provide insights into the machine’s performance.

8. Safety Features: Prioritize machines equipped with safety features such as enclosed laser systems, interlock mechanisms, and exhaust systems to ensure operator safety and regulatory compliance.

9. Technical Support and Training: Opt for suppliers that offer comprehensive technical support, training, and warranties. Adequate training ensures your team can operate the machine effectively and troubleshoot minor issues.

10. Cost Considerations: Balance your budget with the machine’s capabilities and long-term operational costs (e.g., maintenance, consumables). Consider total cost of ownership rather than initial purchase price alone.

By carefully evaluating these factors, you can select a laser engraving machine that meets your steel engraving requirements effectively and efficiently.

FAQs on Sourcing and Manufacturing from laser engraving machine steel in China

FAQs on Sourcing and Manufacturing Laser Engraving Machine Steel in China

#### 1. Why source laser engraving machine steel from China?

China offers competitive pricing, a broad selection of manufacturers, advanced technology, and substantial production capacity, making it a prime location for sourcing laser engraving machine steel.

#### 2. What are the key considerations when selecting a manufacturer?

Evaluate the manufacturer’s experience, production capacity, quality control measures, certifications (such as ISO 9001), and customer reviews. Visiting the facility or requesting samples can also provide insights into their capabilities.

#### 3. How can I ensure the quality of the steel used in laser engraving machines?

Request material certifications, conduct third-party inspections, and verify the supplier’s compliance with international standards. Regular communication and clear quality expectations are essential.

#### 4. What types of steel are commonly used for laser engraving machines?

Stainless steel and carbon steel are frequently used due to their durability, corrosion resistance, and suitability for precision engraving.

#### 5. What are the typical lead times for manufacturing?

Lead times can vary based on order size and complexity but typically range from 30 to 60 days. Custom orders may require longer timeframes.

#### 6. Are there minimum order quantities (MOQs) for manufacturing?

Yes, most manufacturers have MOQs that can range from small batch orders to large-scale productions. It’s important to negotiate MOQs that align with your needs.

#### 7. How is shipping and logistics handled?

Manufacturers often provide FOB (Free On Board) terms, but it’s crucial to clarify shipping responsibilities. Using freight forwarders can simplify logistics, ensuring smooth transportation and customs clearance.

#### 8. What payment terms are common when dealing with Chinese manufacturers?

Common payment terms include a deposit (usually 30%) before production starts, with the balance paid upon completion or before shipment. Letters of credit (LC) and trade assurance services from platforms like Alibaba are also used.

#### 9. Can manufacturers in China provide customization?

Yes, many Chinese manufacturers offer customization services, including specific steel grades, dimensions, and laser engraving specifications to meet client requirements.

#### 10. What are the risks and how can they be mitigated?

Risks include quality issues, communication barriers, and delays. Mitigation strategies include thorough vetting of suppliers, clear contracts, regular updates, and quality inspections.

This concise FAQ should help streamline the process of sourcing and manufacturing laser engraving machine steel in China.