Technology and Applications of tensile strength for steel

Tensile strength is a critical property of steel, defining its ability to withstand tension without breaking. It is determined through standardized testing methods that stretch a steel specimen until it fractures, measuring the maximum stress it can endure.

Technological Applications:

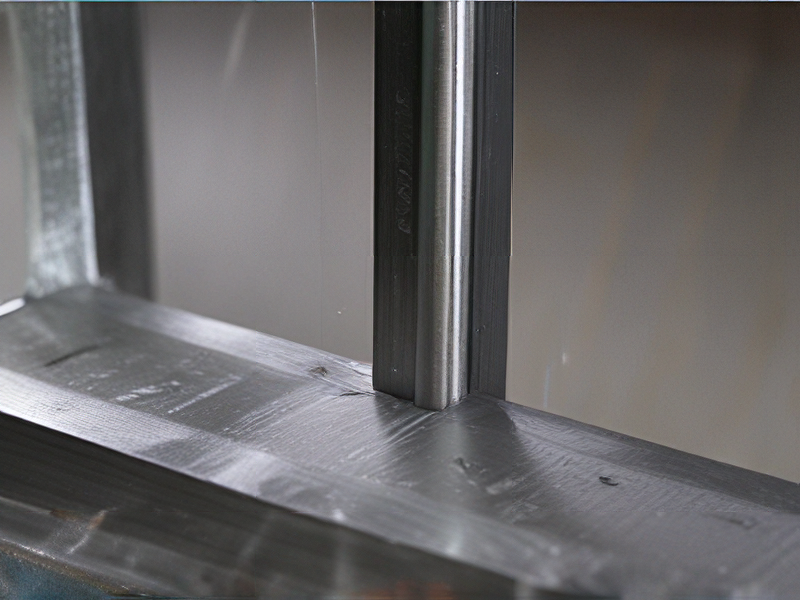

1. Structural Engineering: Steel’s high tensile strength makes it ideal for constructing buildings, bridges, and infrastructure where durability and safety are paramount. Engineers can design lighter structures that can bear heavy loads due to steel’s ability to resist stretching under tension.

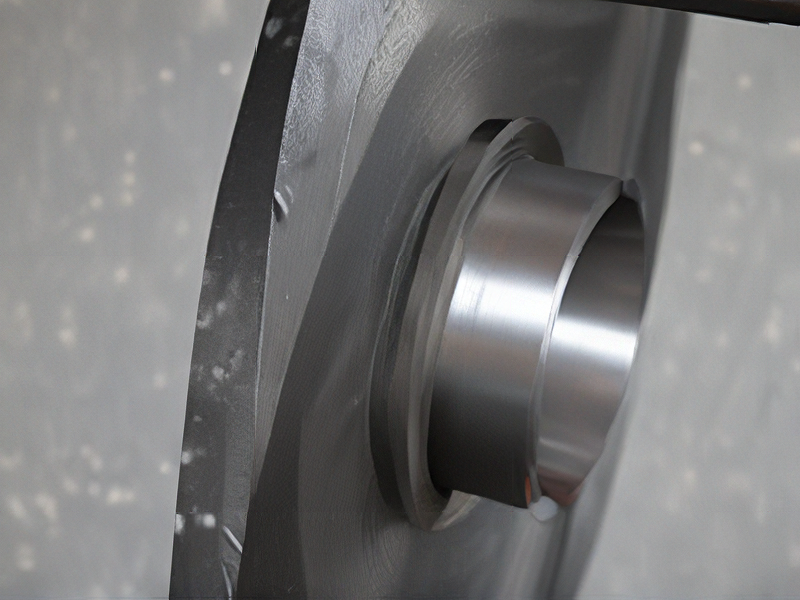

2. Manufacturing: In manufacturing, steel’s tensile strength ensures the reliability of components and machinery subjected to dynamic forces. It is used in automotive, aerospace, and machinery industries for parts that endure stress and strain.

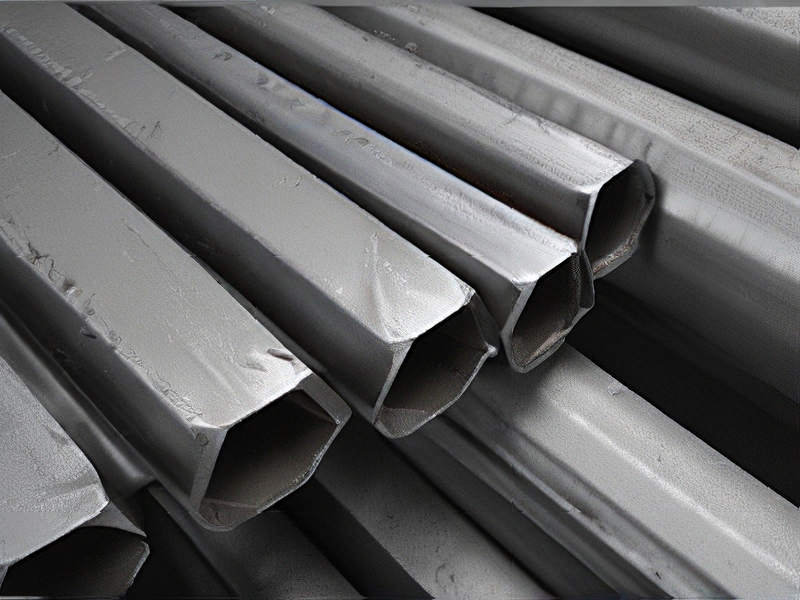

3. Energy Sector: Steel’s tensile strength is crucial in the energy sector, where it is used in pipelines, offshore platforms, and power transmission lines. These applications require materials that can withstand environmental stresses and operational loads over long periods.

Technological Advances:

1. Alloying: Advances in metallurgy have produced high-strength steels through alloying with elements like chromium, nickel, and manganese. These alloys enhance tensile strength and other properties, expanding steel’s applications in high-stress environments.

2. Heat Treatment: Controlled heating and cooling processes refine steel’s microstructure, enhancing its tensile strength. Techniques like quenching and tempering produce hardened steels suitable for diverse industrial applications.

3. Nanostructuring: Emerging technologies involve nanostructuring steel to enhance its mechanical properties, including tensile strength. Nanostructured steels exhibit superior strength-to-weight ratios and resilience against fatigue.

In conclusion, steel’s tensile strength underpins its versatility across industries, driving advancements in structural design, manufacturing efficiency, and energy infrastructure. Ongoing innovations continue to expand its capabilities, ensuring steel remains integral to modern technological progress.

Quality Testing Methods for tensile strength for steel and how to control quality

To test the tensile strength of steel effectively, several methods can be employed:

1. Tensile Testing Machine: Utilizes a calibrated machine to apply tension until the steel specimen fractures. This provides the ultimate tensile strength (UTS) and yield strength (YS).

2. Impact Testing: Determines how much energy is absorbed during fracture, indicating toughness.

3. Hardness Testing: Measures the material’s resistance to penetration or indentation, correlating with tensile strength.

4. Chemical Analysis: Verifies steel composition, ensuring it meets specifications affecting strength.

5. Non-Destructive Testing (NDT): Techniques like ultrasound or magnetic particle inspection detect internal defects without damaging the material.

To control quality:

1. Standardized Testing Protocols: Follow established standards (ASTM, ISO) for testing methods and parameters.

2. Regular Calibration: Ensure testing machines are calibrated to maintain accuracy.

3. Material Traceability: Track steel sources and batches to identify any quality issues.

4. Process Control: Monitor and adjust manufacturing processes to minimize variability in steel properties.

5. Quality Assurance: Implement robust quality management systems to oversee all stages from raw material to finished product.

By integrating these methods and controls, manufacturers can reliably assess and maintain the tensile strength of steel, ensuring consistency and meeting quality standards.

Tips for Procurement and Considerations when Purchasing from tensile strength for steel

When procuring steel based on tensile strength, consider the following tips to make informed purchasing decisions:

1. Define Requirements: Clearly outline your project specifications, including the required tensile strength of the steel. Tensile strength indicates how much stress a material can withstand before breaking, crucial for structural integrity.

2. Quality Standards: Ensure the steel meets relevant quality standards (e.g., ASTM, ISO). Verify certifications and test reports to confirm compliance with your project’s needs.

3. Material Composition: Understand the chemical composition of the steel, as it affects its mechanical properties. Elements like carbon, manganese, and others influence tensile strength and suitability for specific applications.

4. Supplier Reputation: Choose reputable suppliers known for consistent quality and reliability. Check references, previous projects, and customer reviews to gauge their performance.

5. Cost Efficiency: Balance quality with cost-effectiveness. Evaluate quotes from multiple suppliers while considering factors like shipping, handling, and potential long-term savings from durable materials.

6. Customization Options: Some projects may require customized steel grades or dimensions. Discuss customization options with suppliers to ensure they can meet your exact specifications.

7. Logistics and Lead Times: Consider logistics aspects such as delivery schedules and lead times. Plan procurement timelines to avoid delays in your project schedule.

8. Technical Support: Opt for suppliers who offer technical support and expertise. They can assist in selecting the right steel grade based on your application requirements.

By following these considerations, you can effectively procure steel based on tensile strength that aligns with your project’s needs, ensuring durability and performance in its intended application.

FAQs on Sourcing and Manufacturing from tensile strength for steel in China

When sourcing steel in China, ensuring high tensile strength is crucial. Here are some FAQs to consider:

1. What is tensile strength, and why is it important?

Tensile strength measures a material’s ability to withstand tension forces without breaking. For steel, it indicates durability and reliability in applications.

2. How can I ensure high tensile strength in steel sourced from China?

Opt for reputable suppliers with proven track records and certifications like ISO 9001. Conducting quality inspections and requesting material test reports (MTRs) can also verify the specified tensile strength.

3. What are common standards or grades for high tensile steel in China?

Standards such as GB/T 700, GB/T 1591, and ASTM A572 specify grades suitable for high tensile applications. Ensure your supplier adheres to these standards.

4. What are the typical lead times for manufacturing high tensile steel in China?

Lead times vary based on order size, complexity, and supplier capacity. Generally, it’s advisable to plan for longer lead times to accommodate production and shipping.

5. How do I address quality control concerns when manufacturing high tensile steel in China?

Implementing a comprehensive quality control plan with onsite inspections, third-party audits, and clear communication with suppliers is essential. This helps mitigate risks and ensures compliance with specifications.

6. What are the logistics and shipping considerations?

Factor in shipping costs, customs procedures, and transportation logistics when sourcing steel from China. Working with experienced freight forwarders can streamline the process.

By addressing these FAQs, you can navigate sourcing and manufacturing challenges effectively while ensuring high tensile strength standards for steel sourced from China.