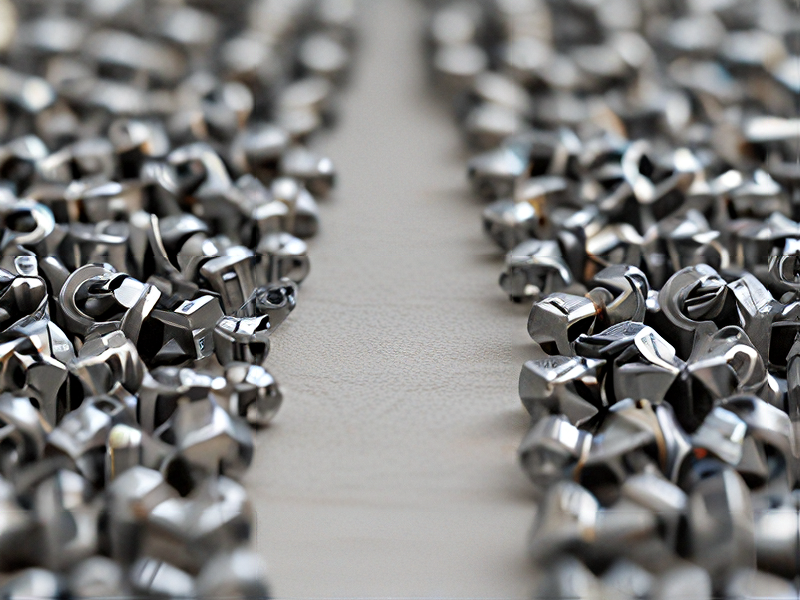

Technology and Applications of metal rivet

Metal rivets are fasteners widely used in various applications due to their strength, reliability, and versatility. They consist of a shaft with a head on one end and are typically made from materials like steel, aluminum, or copper alloys. The technology behind riveting involves deforming the shaft end (known as upsetting) to secure components together permanently.

In construction and manufacturing, rivets are employed where strong and durable joints are essential, such as in aerospace for attaching panels, in automotive for structural integrity, and in shipbuilding for securing hull plates. The process involves drilling matching holes through the materials to be joined, inserting the rivet, and then deforming or “clinching” the tail end to create a tight fit.

The applications of rivets are diverse:

1. Aerospace: Rivets are crucial for assembling aircraft structures due to their ability to withstand high stresses and vibrations.

2. Automotive: Used in chassis assembly and body panels, rivets provide strong joints that can endure the rigors of vehicle operation.

3. Construction: Structural steel and roofing systems often rely on rivets for joining large components securely.

4. Electronics: Small rivets are used in electronic devices for fastening components to circuit boards and casings.

5. Leatherworking: Decorative rivets are used in leather goods such as belts and bags.

Advantages include their mechanical strength, resistance to vibration loosening, and suitability for use in materials where welding may not be feasible or desirable. However, riveting requires access to both sides of the joint and can be labor-intensive compared to other fastening methods. Nonetheless, advancements in rivet design and application continue to expand their utility across various industries, ensuring their relevance in modern manufacturing and construction practices.

Quality Testing Methods for metal rivet and how to control quality

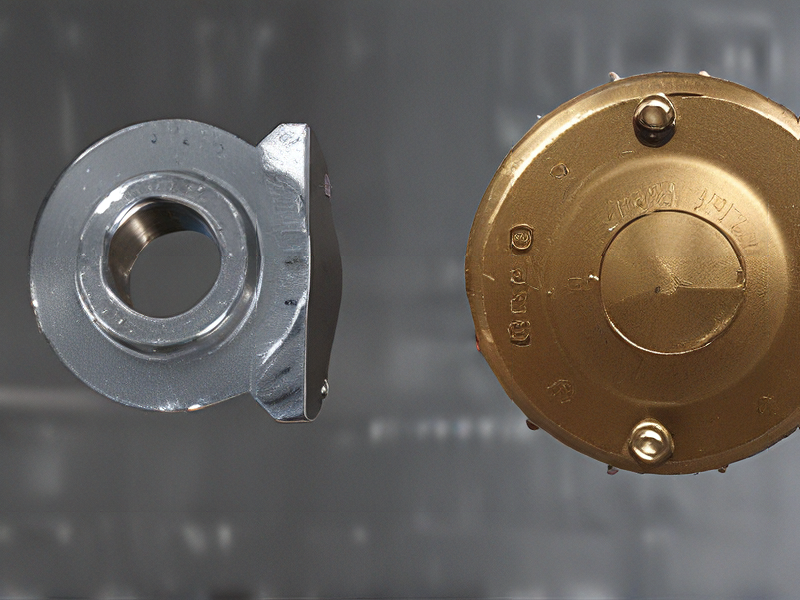

Quality testing methods for metal rivets typically include dimensional checks, mechanical tests, and visual inspections.

1. Dimensional Checks: This ensures the rivet meets specified length, diameter, and head dimensions using calipers or micrometers.

2. Mechanical Tests: These assess the strength and durability of the rivet. Common tests include:

– Tensile Strength: Measures the maximum load the rivet can bear before breaking.

– Shear Strength: Evaluates the rivet’s resistance to forces applied parallel to its axis.

– Pull-out Test: Determines how much force is required to pull the rivet out of its joint.

3. Visual Inspections: Crucial for detecting surface defects, improper forming, cracks, or corrosion that could compromise integrity.

To control quality:

– Establish Specifications: Define tolerances and performance criteria for each type of rivet.

– Supplier Quality Assurance: Ensure suppliers meet quality standards through audits and inspections.

– In-process Inspections: Regular checks during manufacturing to catch defects early.

– Final Inspection: Comprehensive review of finished rivets before distribution.

– Continuous Improvement: Feedback loops from testing results to refine processes and enhance product quality.

Implementing these methods ensures that metal rivets meet design requirements, perform reliably in applications, and maintain safety standards.

Tips for Procurement and Considerations when Purchasing from metal rivet

Tips for Procurement of Metal Rivets

1. Quality Standards:

Ensure the rivets meet industry standards and specifications (ISO, ASTM, DIN). High-quality materials prevent failures in applications.

2. Supplier Reliability:

Choose reputable suppliers with proven track records. Check reviews, request samples, and verify certifications to ensure reliability.

3. Material Type:

Select rivets made from materials suitable for the application (e.g., aluminum, steel, stainless steel). Consider factors like corrosion resistance and strength.

4. Cost Consideration:

Compare prices from different suppliers, but don’t compromise on quality. Bulk purchasing can often lead to cost savings.

5. Lead Time:

Confirm the lead time and ensure it aligns with your project schedule. Delays in delivery can halt your operations.

6. Custom Specifications:

If standard rivets don’t meet your requirements, discuss custom options with your supplier. Customization may come at a higher cost but ensures perfect fit and performance.

7. Volume Requirements:

Assess your volume needs. Large orders may qualify for discounts but consider storage space and inventory management.

8. Technical Support:

Choose suppliers who offer technical support and after-sales service. This is crucial for troubleshooting and ensuring proper application.

9. Sustainability:

Consider environmentally friendly options. Suppliers who follow sustainable practices and offer recyclable materials contribute positively to your company’s green initiatives.

10. Regulatory Compliance:

Ensure the rivets comply with local and international regulations, especially if they are used in safety-critical applications.

Considerations When Purchasing

1. Application Needs:

Understand the specific requirements of your application, including load-bearing capacity, environmental exposure, and thermal conditions.

2. Design Compatibility:

Ensure the rivet design (e.g., blind, solid, semi-tubular) matches your assembly needs.

3. Installation Method:

Consider the tools and techniques required for installation. Some rivets may need specialized equipment.

4. Lifecycle Costs:

Evaluate the total cost of ownership, including installation, maintenance, and potential replacements.

By adhering to these tips and considerations, you can ensure efficient procurement and effective use of metal rivets in your projects.

FAQs on Sourcing and Manufacturing from metal rivet in China

FAQs on Sourcing and Manufacturing Metal Rivets in China

1. Why source metal rivets from China?

China offers competitive pricing, a vast selection of manufacturers, and advanced manufacturing capabilities, making it a cost-effective option for high-quality rivets.

2. How to find reliable manufacturers?

Utilize platforms like Alibaba, Made-in-China, and Global Sources. Look for suppliers with good reviews, high transaction volumes, and verified status. Factory visits and third-party audits are also recommended.

3. What are the common types of metal rivets available?

Common types include solid rivets, blind rivets, semi-tubular rivets, and drive rivets, available in materials like aluminum, steel, copper, and stainless steel.

4. What is the typical lead time for production?

Lead times can vary but generally range from 2 to 6 weeks depending on order size, customization requirements, and the manufacturer’s capacity.

5. How can I ensure the quality of rivets?

Request samples before placing large orders. Specify quality standards and use third-party inspection services to check product quality before shipment.

6. What are the payment terms usually offered?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and D/P (Documents Against Payment). It’s common to pay a 30% deposit upfront and the balance before shipment.

7. Are there any import regulations to be aware of?

Ensure compliance with your country’s import regulations, including necessary certifications and customs duties. Working with a customs broker can help navigate these requirements.

8. How can I handle shipping and logistics?

Manufacturers often offer FOB (Free On Board) terms. Work with freight forwarders to manage shipping, and consider insurance to cover potential transit risks.

9. What should I include in my purchase order?

Detail specifications such as material, size, finish, quantity, packaging requirements, and delivery timelines. Clear communication helps avoid misunderstandings.

10. How to handle intellectual property protection?

Sign non-disclosure agreements (NDAs) and contracts that include clauses for IP protection. Register patents and trademarks in China if necessary.

By addressing these FAQs, you can navigate the complexities of sourcing and manufacturing metal rivets in China more effectively.