Technology and Applications of composition of stainless steel

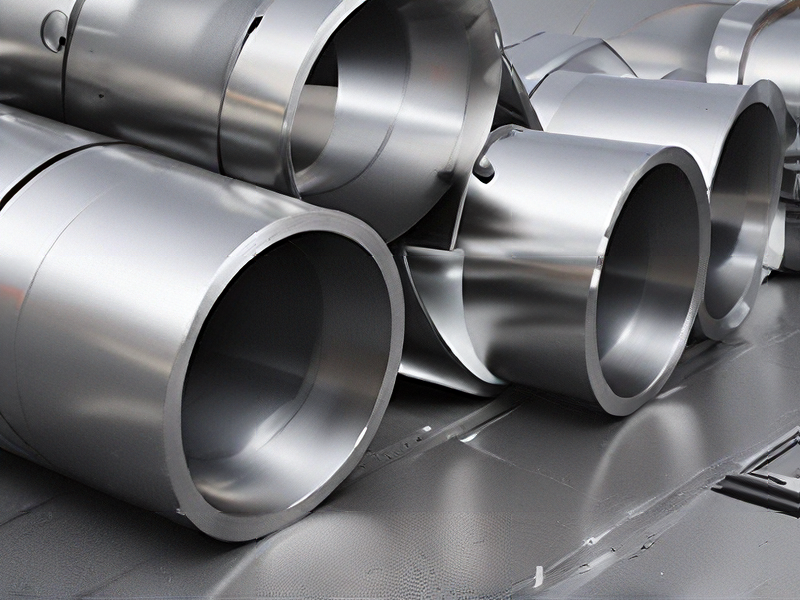

Stainless steel, composed primarily of iron, chromium, nickel, and sometimes other metals like molybdenum, offers exceptional corrosion resistance and durability. Chromium, present in at least 10.5% concentration, forms a passive oxide layer on the steel surface, preventing rust and staining, making it ideal for various applications.

Applications:

1. Construction and Architecture: Widely used in building facades, roofing, and structural components due to its aesthetic appeal, durability, and resistance to weathering.

2. Transportation: Stainless steel finds use in automotive components, such as exhaust systems and trim, due to its resistance to heat and corrosion.

3. Medical: In surgical instruments, implants, and equipment sterilization due to its biocompatibility and ease of cleaning.

4. Food and Beverage: Equipment like storage tanks, brewing vats, and kitchen appliances benefit from stainless steel’s hygienic properties and resistance to corrosion from food acids.

5. Energy: Power generation, including nuclear reactors and solar equipment, utilizes stainless steel for its resistance to extreme temperatures and corrosive environments.

Technological Composition:

1. Austenitic Stainless Steel: Contains high levels of chromium and nickel, non-magnetic, and resistant to corrosion and oxidation. Common in household appliances and industrial equipment.

2. Ferritic Stainless Steel: Chromium-based with low carbon content, magnetic, and suitable for automotive exhausts and decorative applications.

3. Martensitic Stainless Steel: Hardenable stainless steel due to high carbon content, used in cutlery, turbines, and medical instruments.

Advancements in metallurgy continue to enhance stainless steel’s performance, expanding its applications in diverse industries while maintaining its essential properties of durability, corrosion resistance, and aesthetic appeal.

Quality Testing Methods for composition of stainless steel and how to control quality

Quality Testing Methods for Stainless Steel Composition:

1. Spectroscopy:

– X-ray Fluorescence (XRF): Identifies and quantifies elemental composition quickly and non-destructively.

– Optical Emission Spectroscopy (OES): Provides precise measurements of various elements, essential for quality control.

– Inductively Coupled Plasma (ICP): Highly accurate, used for detecting trace elements.

2. Chemical Analysis:

– Wet Chemical Analysis: Involves dissolving the sample and analyzing its components through titration or gravimetric methods.

3. Mechanical Testing:

– Tensile Test: Measures the strength and ductility of the steel.

– Hardness Test: Determines the steel’s hardness using methods like Rockwell, Vickers, or Brinell.

4. Non-Destructive Testing (NDT):

– Ultrasonic Testing: Checks for internal defects without damaging the material.

– Radiographic Testing: Uses X-rays or gamma rays to identify internal flaws.

Quality Control Methods:

1. Standards Compliance:

– Ensure the stainless steel composition meets industry standards such as ASTM, ISO, and EN.

2. Process Control:

– Raw Material Inspection: Test incoming raw materials to ensure they meet required specifications.

– In-Process Monitoring: Continuously monitor the production process to maintain consistent quality.

– Final Product Testing: Perform comprehensive tests on the final product to ensure it meets all specifications.

3. Documentation and Traceability:

– Maintain detailed records of all tests and inspections.

– Ensure traceability of each batch from raw material to final product.

4. Training and Certification:

– Regularly train personnel on the latest testing and quality control methods.

– Obtain certifications from recognized bodies to validate quality control processes.

By integrating these methods, manufacturers can ensure the high quality of stainless steel, maintaining its properties and performance in various applications.

Tips for Procurement and Considerations when Purchasing from composition of stainless steel

When procuring stainless steel, several factors are crucial to consider to ensure quality and suitability for your needs:

1. Grade of Stainless Steel: Different grades (e.g., 304, 316) offer varying levels of corrosion resistance, durability, and suitability for specific environments (e.g., marine, industrial).

2. Intended Application: Identify whether the stainless steel will be exposed to corrosive environments, extreme temperatures, or mechanical stress. This determines the required grade and finish.

3. Finish and Surface Quality: The finish impacts aesthetics, cleanliness (important in food processing or medical applications), and resistance to corrosion. Common finishes include brushed, mirror, and matte.

4. Cost and Budget: Consider the initial cost of procurement as well as long-term maintenance costs. Higher grades and finishes often come with a higher price tag but might offer better longevity and lower maintenance costs.

5. Supplier Reliability: Choose suppliers with a reputation for quality and consistency. Ensure they provide certifications and documentation verifying the grade, composition, and compliance with relevant standards (e.g., ASTM).

6. Environmental Factors: Assess the environmental impact of production and disposal. Opt for suppliers who adhere to sustainable practices and offer recycled stainless steel options if applicable.

7. Customization Needs: If specific dimensions, shapes, or tolerances are required, ensure the supplier can meet these specifications.

8. Testing and Inspection: Consider conducting tests or inspections to verify material properties and quality before acceptance.

9. Logistics and Lead Times: Plan for shipping logistics, lead times, and any potential delays to ensure timely delivery.

10. Regulatory Compliance: Ensure compliance with industry standards (e.g., ASTM, ISO) and regulatory requirements (e.g., REACH, RoHS) applicable to your industry or region.

By carefully considering these factors, you can make informed decisions when procuring stainless steel that align with your project requirements, budget constraints, and environmental considerations.

FAQs on Sourcing and Manufacturing from composition of stainless steel in China

When sourcing stainless steel from China, understanding the composition and manufacturing processes is crucial. Here are some FAQs:

1. What are the common grades of stainless steel available in China?

China produces a wide range of stainless steel grades, including 304 (18-8 stainless, most common), 316 (marine grade with added molybdenum), and 430 (lower cost, less corrosion-resistant).

2. How can I ensure the quality of stainless steel sourced from China?

Quality assurance can be ensured through supplier audits, certifications (like ISO 9001), and requesting samples for testing prior to bulk orders.

3. What are the typical manufacturing processes used in China for stainless steel?

Processes include melting and refining, hot rolling, cold rolling, and finishing (such as annealing, pickling, and polishing). Chinese manufacturers often have advanced facilities for these processes.

4. Are there environmental considerations when sourcing stainless steel from China?

Yes, environmental standards vary. Look for manufacturers adhering to local environmental regulations and certifications like ISO 14001 to ensure responsible sourcing practices.

5. What are the lead times and MOQs (Minimum Order Quantities) usually like?

Lead times can vary widely depending on the complexity and volume of the order. MOQs also vary by supplier and product type, so it’s important to clarify these early in negotiations.

6. What support can I expect regarding customization and technical specifications?

Chinese manufacturers often offer customization options and support for meeting technical specifications. Clear communication and detailed technical drawings are essential.

7. How do tariffs and trade agreements impact sourcing stainless steel from China?

Stay informed about tariffs and trade policies that may affect import costs and lead times. Utilizing trade agreements where applicable can help mitigate costs.

Understanding these factors will help in effectively sourcing stainless steel from China while ensuring quality, compliance, and cost-efficiency.