Technology and Applications of legacy metals

Legacy metals, such as iron, copper, silver, and gold, have been integral to human civilization for thousands of years. Despite advancements in materials science, these metals continue to be crucial in various modern technologies and applications.

Iron is a fundamental component in construction and manufacturing due to its strength and versatility. Steel, an alloy of iron and carbon, remains the backbone of the construction industry, used in buildings, infrastructure, and transportation. Iron’s magnetic properties are essential in electric motors and transformers.

Copper is indispensable in electrical and electronic industries due to its excellent electrical conductivity. It is widely used in wiring, motors, generators, and electronic devices. Copper’s thermal conductivity also makes it ideal for heat exchangers and refrigeration systems. Additionally, copper’s antimicrobial properties find applications in medical equipment and water purification systems.

Silver has the highest electrical conductivity of all metals, making it vital in electronics, batteries, and solar panels. Its reflective properties are used in mirrors and coatings for windows and optical devices. Silver’s antimicrobial qualities are exploited in medical applications, including wound dressings and coatings for medical devices.

Gold is renowned for its resistance to corrosion and excellent conductivity. It is extensively used in electronics, especially in connectors, switches, and relays, where reliability is paramount. Gold’s biocompatibility makes it valuable in medical devices and dentistry. Additionally, gold’s catalytic properties are leveraged in industrial processes, including pollution control and chemical manufacturing.

These legacy metals continue to evolve with advancements in technology, finding new applications in emerging fields such as nanotechnology, renewable energy, and biotechnology. Their enduring utility underscores their importance in both historical and contemporary contexts.

Quality Testing Methods for legacy metals and how to control quality

Quality testing for legacy metals involves various methods to ensure their properties meet specific standards. Here are key techniques and controls:

1. Chemical Analysis:

– Spectrometry (e.g., XRF, OES): Determines elemental composition.

– Wet Chemical Analysis: Traditional method using chemical reactions to identify constituents.

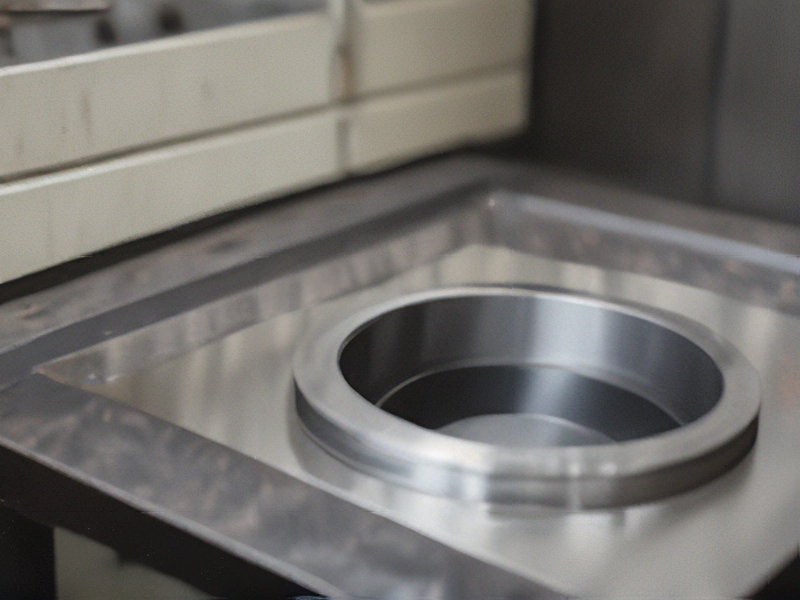

2. Mechanical Testing:

– Tensile Testing: Measures strength and ductility.

– Hardness Testing: Assesses resistance to deformation (e.g., Rockwell, Vickers).

– Impact Testing: Evaluates toughness, usually with a Charpy impact test.

3. Non-Destructive Testing (NDT):

– Ultrasonic Testing: Uses sound waves to detect internal flaws.

– Radiographic Testing: Employs X-rays or gamma rays to visualize internal defects.

– Magnetic Particle Testing: Detects surface and near-surface discontinuities in ferromagnetic materials.

– Dye Penetrant Testing: Reveals surface cracks in non-porous materials.

4. Metallographic Analysis:

– Microscopy: Examines microstructure using optical or electron microscopes.

– Grain Size Analysis: Determines grain size which affects mechanical properties.

Quality Control Methods

1. Standardization:

– Implement standards like ASTM, ISO, or DIN to ensure consistency in testing procedures.

2. Process Control:

– Use Statistical Process Control (SPC) to monitor and control manufacturing processes.

– Implement quality management systems such as ISO 9001 to maintain high standards.

3. Regular Audits and Inspections:

– Conduct regular internal and external audits to ensure compliance with quality standards.

4. Documentation and Traceability:

– Maintain detailed records of test results and material origins to trace back any issues.

5. Training and Certification:

– Ensure personnel are trained and certified in relevant testing methods and quality control procedures.

By combining these testing methods with stringent quality control practices, the integrity and reliability of legacy metals can be effectively ensured.

Tips for Procurement and Considerations when Purchasing from legacy metals

When procuring from legacy metals, which typically include precious metals like gold, silver, and platinum, as well as other valuable materials such as copper or rare earth elements, several key considerations are essential:

1. Supplier Verification: Ensure suppliers are reputable and adhere to ethical and environmental standards. Verify their certifications (e.g., Responsible Jewellery Council for gold and diamonds) to mitigate risks of sourcing from conflict zones or unethical practices.

2. Quality and Purity: Specify quality standards and purity levels required for your application. Conduct assays or demand certificates of purity to guarantee the authenticity and quality of the materials.

3. Market Pricing and Trends: Stay updated on market prices and trends to negotiate fair prices and understand cost fluctuations. Consider hedging strategies for price stability if purchasing large quantities.

4. Supply Chain Transparency: Seek transparency in the supply chain to trace the material back to its source. This ensures compliance with regulations and ethical sourcing practices, which is increasingly important to consumers and regulatory bodies.

5. Legal and Regulatory Compliance: Understand and comply with legal requirements such as import/export regulations, taxes, tariffs, and environmental laws. Non-compliance can lead to fines or reputational damage.

6. Storage and Transportation: Plan for secure storage and transportation, especially for high-value metals. Consider insurance coverage and secure transport options to minimize the risk of loss or theft.

7. Environmental Impact: Assess the environmental impact of extracting and using legacy metals. Consider suppliers with sustainable practices or support initiatives for responsible mining and recycling.

8. Long-term Supply Agreements: Establish long-term supply agreements with reliable suppliers to ensure a stable supply chain. This can also provide leverage for negotiating favorable terms and pricing.

By addressing these considerations, businesses can effectively manage procurement risks and ensure the ethical and efficient sourcing of legacy metals for their operations.

FAQs on Sourcing and Manufacturing from legacy metals in China

Certainly! Sourcing and manufacturing with legacy metals in China often involves navigating several key considerations:

1. Regulatory Compliance: Ensure adherence to Chinese environmental regulations and international standards (e.g., REACH in Europe) to manage the impact of legacy metals like lead, mercury, and cadmium.

2. Supplier Assessment: Thoroughly vet suppliers for their capability to handle legacy metals safely, including certifications like ISO 14001 for environmental management and ISO 9001 for quality management.

3. Supply Chain Transparency: Establish clear communication with suppliers to trace the origins of materials and ensure ethical practices throughout the supply chain, addressing concerns of pollution and worker safety.

4. Quality Control: Implement stringent quality control measures to mitigate risks associated with legacy metals, such as contamination and durability issues.

5. Alternative Materials: Explore alternatives where feasible, such as using recycled metals or substituting with less harmful materials to reduce environmental impact.

6. Long-term Strategy: Develop a sustainable sourcing strategy that considers evolving regulations and consumer expectations regarding environmental sustainability.

Navigating these aspects requires collaboration between manufacturers, suppliers, and regulatory bodies to ensure responsible sourcing and manufacturing practices concerning legacy metals in China.