Technology and Applications of fabrication in steel structure

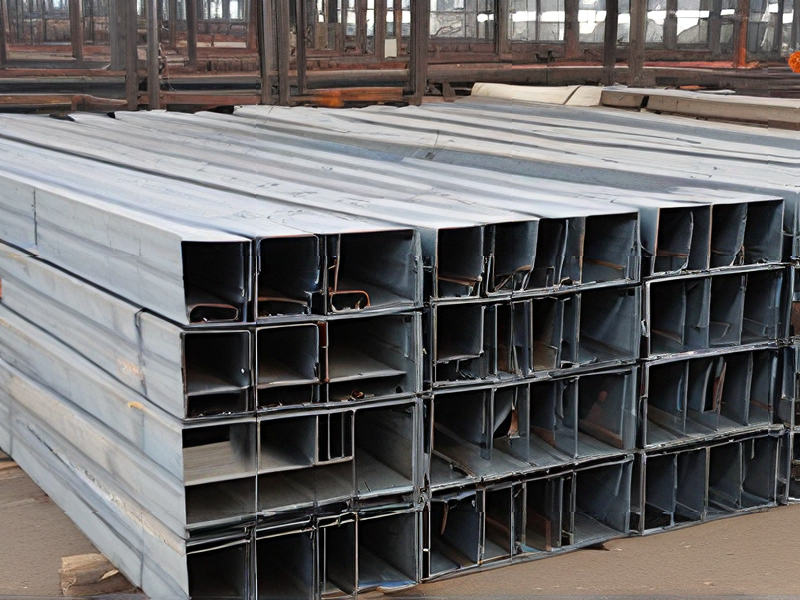

Fabrication in steel structures involves the process of transforming raw materials into predefined shapes and sizes, typically involving cutting, bending, and assembling structural components. This technology finds extensive applications across various industries due to steel’s strength, durability, and versatility.

In construction, steel fabrication enables the creation of complex frameworks for buildings, bridges, and industrial facilities. Prefabricated steel components are fabricated off-site, ensuring precision and efficiency during assembly, reducing construction time and costs. This method also supports sustainable construction practices by minimizing waste and enhancing recyclability.

In manufacturing, steel fabrication plays a crucial role in producing machinery, equipment, and transportation vehicles. The ability to fabricate steel into custom shapes allows for the creation of specialized components that meet specific operational requirements. This flexibility extends to sectors such as aerospace, automotive, and shipbuilding, where steel’s high strength-to-weight ratio is particularly advantageous.

Moreover, advancements in fabrication technology, including computer-aided design (CAD), automated cutting systems, and robotic welding, have revolutionized the precision and efficiency of steel fabrication processes. These technologies improve accuracy, reduce human error, and increase productivity, thereby enhancing overall quality and consistency in the fabrication of steel structures.

Overall, steel fabrication technology continues to evolve, driven by innovation and demand for robust, cost-effective, and sustainable solutions across diverse industrial applications.

Quality Testing Methods for fabrication in steel structure and how to control quality

Quality testing for steel structures involves several methods to ensure the integrity and safety of the construction. Key testing methods include:

1. Visual Inspection: The most basic form of quality control, visual inspection involves checking for surface defects such as cracks, welding flaws, and deformations.

2. Ultrasonic Testing (UT): This non-destructive test uses high-frequency sound waves to detect internal defects like voids or inclusions within the steel. It provides accurate depth and size of the flaw.

3. Radiographic Testing (RT): Utilizing X-rays or gamma rays, this method inspects the internal structure of the steel for defects. It’s highly effective for identifying weld quality and internal flaws.

4. Magnetic Particle Testing (MT): This method detects surface and near-surface discontinuities in ferromagnetic materials. It involves magnetizing the steel and applying iron particles to reveal any defects.

5. Dye Penetrant Testing (PT): Suitable for non-porous materials, this test involves applying a dye to the surface, which penetrates any cracks or defects. After a developer is applied, defects become visible under ultraviolet light.

6. Hardness Testing: Measuring the hardness of steel can indicate its strength and resistance to deformation. Common methods include the Brinell, Rockwell, and Vickers tests.

7. Tensile Testing: This destructive test measures the material’s response to applied tension, providing data on its strength and ductility.

To control quality, several strategies can be employed:

1. Standards and Specifications: Adhering to industry standards (e.g., ASTM, ISO) ensures materials and processes meet required specifications.

2. Regular Inspections: Scheduled inspections throughout the fabrication process help identify and address issues early.

3. Qualified Personnel: Employing skilled and certified inspectors and technicians ensures testing is performed correctly.

4. Documentation and Traceability: Keeping detailed records of materials, tests, and inspections allows for traceability and accountability.

5. Calibration of Equipment: Regular calibration of testing equipment ensures accurate and reliable results.

6. Training Programs: Ongoing training for staff on the latest testing methods and quality control practices helps maintain high standards.

These methods and controls collectively ensure the structural integrity and safety of steel structures.

Tips for Procurement and Considerations when Purchasing from fabrication in steel structure

When procuring steel structures from fabrication, consider these essential tips:

1. Vendor Selection: Choose fabricators with a proven track record in steel fabrication. Look for certifications (e.g., ISO 9001) and previous project experience.

2. Quality Standards: Ensure the fabricator adheres to relevant quality standards (e.g., ASTM, EN). Insist on material certifications and welding procedures.

3. Cost and Value: Evaluate quotes based on both cost and value. Cheaper isn’t always better if it compromises quality or delivery.

4. Capacity and Lead Times: Assess the fabricator’s capacity to handle your project size and their ability to meet your required delivery schedules.

5. Communication: Clear and continuous communication is crucial. Ensure the fabricator understands your specifications, timelines, and any customization requirements.

6. Quality Control: Discuss inspection and testing protocols. Inspect fabricated components during production to catch issues early.

7. Logistics and Shipping: Plan logistics for transportation and delivery. Consider packaging requirements and the fabricator’s experience in handling shipments.

8. Contractual Agreements: Have a robust contract covering scope, timelines, payment terms, and contingencies for delays or defects.

9. Environmental Considerations: Ensure the fabricator complies with environmental regulations and promotes sustainable practices where possible.

10. Feedback and Evaluation: After completion, review the project with the fabricator. Document lessons learned for future procurements.

By focusing on these aspects, you can enhance the efficiency and reliability of your procurement process for steel structures from fabrication.

FAQs on Sourcing and Manufacturing from fabrication in steel structure in China

When sourcing and manufacturing steel structures in China, several FAQs commonly arise:

1. Quality Assurance: How can I ensure the quality meets international standards? Engage with suppliers who have certifications like ISO 9001 and conduct regular inspections.

2. Communication: How do I overcome language barriers? Choose suppliers with English-speaking staff or employ translators to ensure clear communication.

3. Cost Management: How can I control costs effectively? Obtain detailed quotes, negotiate prices based on volume, and clarify what’s included (e.g., taxes, shipping).

4. Lead Times: What are typical lead times? Plan for longer lead times due to manufacturing schedules and shipping from China.

5. MOQs (Minimum Order Quantities): Are there MOQ requirements? Suppliers often have MOQs; negotiate based on your project needs.

6. Logistics: How do I handle shipping and customs? Work with freight forwarders experienced in shipping from China and ensure all customs requirements are met.

7. Intellectual Property: How can I protect my designs? Use legal agreements and non-disclosure agreements (NDAs) with suppliers.

8. Payment Terms: What payment terms are typical? Negotiate terms that balance supplier needs with your financial security (e.g., letters of credit, payment milestones).

9. Dispute Resolution: How are disputes handled? Establish clear protocols in contracts for dispute resolution, considering both Chinese and international legal frameworks.

10. Cultural Differences: How do I navigate cultural differences? Understand and respect Chinese business customs and etiquette to build stronger relationships.

By addressing these FAQs proactively, you can navigate sourcing and manufacturing steel structures in China more effectively, ensuring smoother operations and mitigating potential challenges.