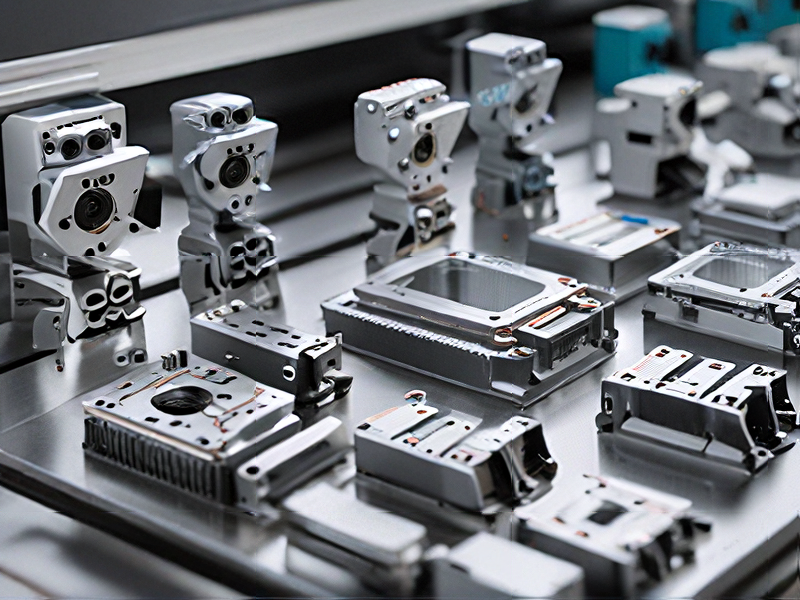

Technology and Applications of small cnc machines

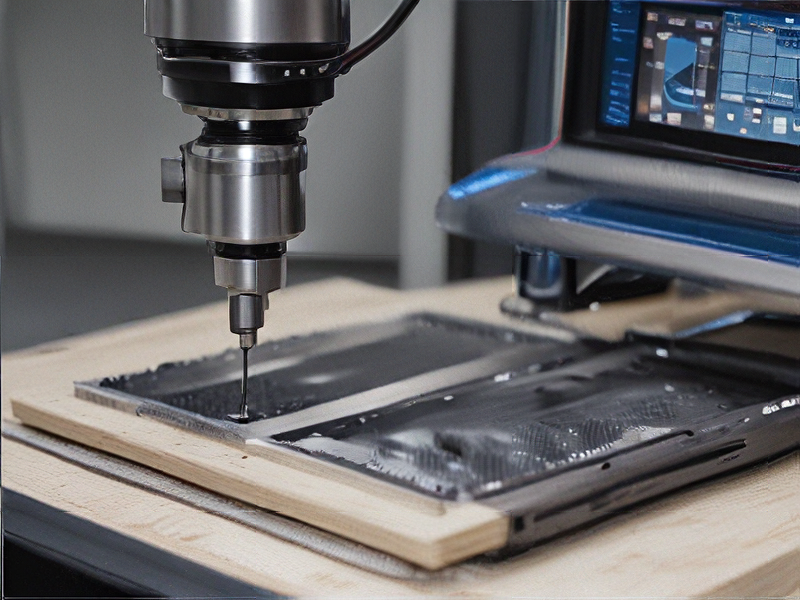

Small CNC (Computer Numerical Control) machines are highly versatile tools that have revolutionized manufacturing and prototyping across various industries. These compact machines, which can range from desktop models to slightly larger units, offer precision and automation in milling, routing, engraving, and cutting materials like wood, plastics, and metals.

Technology

Small CNC machines leverage advanced software to convert digital designs into precise physical parts. Key technological components include:

1. Controller: Acts as the brain of the CNC machine, interpreting G-code commands to control the movement of the machine.

2. Stepper/Servo Motors: Drive the machine’s axes, ensuring accurate positioning.

3. Spindle: The rotating component that cuts or engraves the material.

4. Bed/Table: Where the material is secured during machining.

5. Software: CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are used to create designs and generate toolpaths.

Applications

1. Prototyping: Engineers and designers use small CNC machines to quickly produce prototypes, testing form, fit, and function before mass production.

2. Jewelry Making: Jewelers create intricate designs and custom pieces with high precision.

3. Educational Purposes: Schools and universities use these machines to teach students about manufacturing, engineering, and design.

4. Hobbyists and DIYers: Individuals use CNC machines for personal projects, from custom furniture to model making.

5. Small-scale Manufacturing: Small businesses produce custom parts, signage, and other products without the need for large-scale machinery.

6. Art and Crafts: Artists use CNC machines to create detailed sculptures, engravings, and other artistic works.

Small CNC machines are celebrated for their ability to bring high-level manufacturing capabilities to smaller operations, enabling innovation and creativity in various fields. Their precision, automation, and versatility make them indispensable tools in both professional and personal settings.

Quality Testing Methods for small cnc machines and how to control quality

Quality testing for small CNC machines involves several key methods to ensure precision and reliability:

1. Dimensional Accuracy Checks: Utilize precision measuring tools such as calipers, micrometers, and height gauges to verify dimensions against design specifications.

2. Surface Finish Evaluation: Assess surface roughness using profilometers or surface roughness testers to ensure the machined parts meet required smoothness criteria.

3. Geometric Tolerances Verification: Employ coordinate measuring machines (CMMs) or optical comparators to check geometric tolerances like concentricity, perpendicularity, and parallelism.

4. Functionality Testing: Conduct functional tests to verify the CNC machine’s performance under simulated operational conditions, ensuring all axes move smoothly and accurately.

5. Material Verification: Use material testing methods such as spectroscopy or hardness testing to confirm material composition and mechanical properties.

To control quality effectively:

– Establish Clear Standards: Define precise quality standards and inspection criteria for each part and process.

– Regular Calibration: Ensure all measurement and testing equipment are regularly calibrated to maintain accuracy.

– In-process Inspection: Implement checkpoints during machining processes to catch deviations early.

– Document Control: Maintain comprehensive records of inspection results and any deviations found, enabling traceability and continuous improvement.

– Training and Skill Development: Train operators and quality inspectors on proper inspection techniques and the importance of quality standards.

By integrating these methods and controls, manufacturers can uphold high standards of quality in small CNC machine production, ensuring consistent performance and customer satisfaction.

Tips for Procurement and Considerations when Purchasing from small cnc machines

When purchasing small CNC machines, several considerations are crucial to ensure you make an informed procurement decision:

1. Machine Specifications: Understand the specific capabilities of the CNC machine, such as its axis configuration, spindle power, and work envelope. Ensure these specifications align with your intended use and production requirements.

2. Accuracy and Precision: Check the machine’s accuracy specifications, including positioning and repeatability. These factors are critical for achieving precise machining results consistently.

3. Ease of Use and Programming: Consider the user interface and programming capabilities. A user-friendly interface and compatibility with CAM software can streamline operations and reduce training time for operators.

4. Support and Maintenance: Evaluate the availability of technical support, training, and maintenance services from the manufacturer or supplier. Reliable support ensures minimal downtime and effective troubleshooting.

5. Build Quality and Durability: Assess the machine’s build quality and the materials used. A robust construction enhances durability and reliability over the machine’s lifespan.

6. Cost and Value: Compare pricing against the machine’s features, capabilities, and expected return on investment (ROI). While cost-effective options are appealing, prioritize value and long-term benefits.

7. Supplier Reputation: Research the reputation and track record of the supplier or manufacturer. Reviews, testimonials, and references can provide insights into their reliability and customer satisfaction.

8. Customization Options: Determine if the supplier offers customization options to tailor the machine to specific needs or industry requirements.

9. Safety Features: Ensure the machine complies with safety standards and incorporates necessary safety features to protect operators and minimize risks in the workplace.

10. Future Scalability: Consider how easily the machine can accommodate future upgrades or expansions in your production needs.

By carefully evaluating these factors and conducting thorough research, you can confidently select a small CNC machine that meets your operational needs, budget constraints, and growth objectives effectively.

FAQs on Sourcing and Manufacturing from small cnc machines in China

Certainly! Here are some frequently asked questions (FAQs) regarding sourcing and manufacturing from small CNC machines in China:

1. What are the advantages of sourcing small CNC machines from China?

Sourcing from China often offers cost savings due to lower labor and production costs. Additionally, China has a robust infrastructure for manufacturing CNC machines, providing a wide range of options and capabilities.

2. What should I consider when selecting a supplier in China?

It’s crucial to assess the supplier’s reputation, quality control measures, production capabilities, and their experience in manufacturing CNC machines. Requesting samples and visiting their facilities if possible can also provide insights into their operations.

3. How can I ensure quality when sourcing from China?

Quality assurance can be ensured through detailed specifications and rigorous testing protocols. It’s essential to communicate clearly with the supplier, conduct inspections during production, and possibly enlist a third-party inspection service to verify quality before shipment.

4. What are the typical lead times for small CNC machines from China?

Lead times can vary depending on factors such as customization requirements and production capacity. Generally, lead times range from a few weeks to several months. Clear communication with the supplier about timelines and expectations is crucial to avoid delays.

5. What are the potential challenges of sourcing from China?

Challenges may include language barriers, cultural differences, intellectual property concerns, and logistics. Working with experienced partners or consultants who understand both the Chinese market and international business practices can mitigate these challenges.

6. Are there any import regulations or tariffs I should be aware of?

Yes, it’s important to research and comply with import regulations and tariffs in your country. Tariffs can significantly impact the total cost of importing CNC machines from China.

7. How can I handle payments and ensure security in transactions?

Using secure payment methods and establishing clear terms in the contract are essential steps. Consider using letters of credit or payment platforms that offer buyer protection. Building a trusted relationship with your supplier over time can also enhance transaction security.

Navigating sourcing and manufacturing from small CNC machines in China requires careful planning, communication, and adherence to best practices to ensure a successful partnership and product delivery.