Technology and Applications of how do you cut sheet metal

Cutting sheet metal involves several technologies and methods tailored to different thicknesses and precision requirements. Here are some common techniques:

1. Shearing: Suitable for straight cuts in thinner sheets, shearing uses blades to slice through metal, producing clean edges. It’s efficient for mass production.

2. Laser Cutting: Utilizes a focused laser beam to melt, burn, or vaporize metal along a programmed path. It’s highly precise, suitable for intricate designs, and works well with various metals.

3. Plasma Cutting: Involves ionizing gas passing through a nozzle to create a plasma arc that melts metal. It’s versatile for both thin and thick sheets, offering high cutting speeds.

4. Water Jet Cutting: Uses a high-pressure stream of water (sometimes with abrasive particles) to cut metal. It’s cold cutting, meaning no heat-affected zone, and is effective for reflective materials.

5. Electrical Discharge Machining (EDM): Uses electrical discharges to erode conductive materials like metal. It’s precise but slower than other methods, ideal for complex shapes.

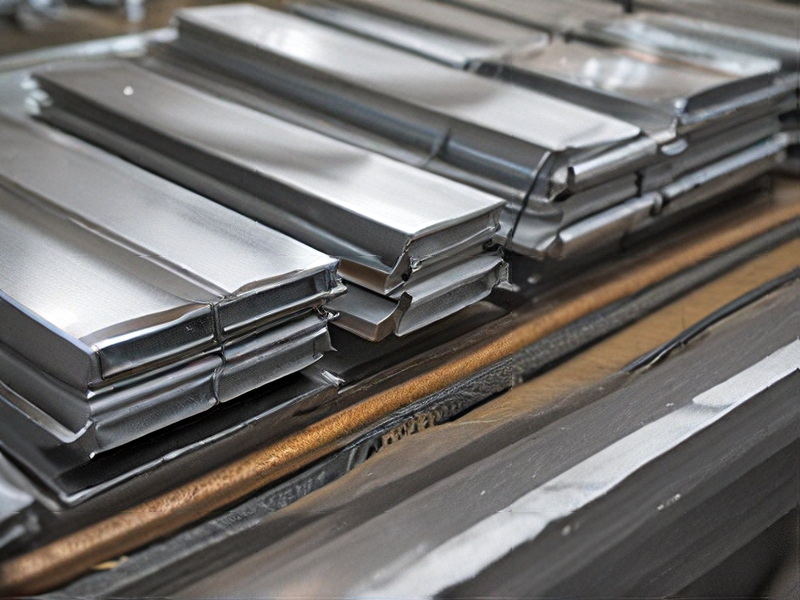

Applications span various industries: automotive (for chassis and panels), aerospace (for components), construction (for HVAC ducts), and electronics (for enclosures). Choosing the right method depends on material type, thickness, tolerance requirements, and production volume, ensuring efficiency and quality in sheet metal fabrication.

Quality Testing Methods for how do you cut sheet metal and how to control quality

When cutting sheet metal, ensuring quality involves several key methods:

1. Precision Cutting Tools: Use tools like laser cutters, water jets, or CNC machines for accurate cuts, minimizing material deformation and burrs.

2. Measurement and Alignment: Prioritize precise measurements and alignment to avoid errors in cutting dimensions. Utilize tools such as calipers and alignment jigs.

3. Quality Control Checks: Implement frequent checks during and after cutting to verify dimensions, angles, and surface quality. This ensures adherence to specifications.

4. Operator Training: Train operators thoroughly on equipment operation, safety protocols, and quality standards to reduce errors and improve consistency.

5. Material Handling: Handle sheet metal carefully to prevent scratches, dents, or warping that can affect cut quality and appearance.

6. Workflow Optimization: Streamline workflow to minimize handling and processing times, reducing the likelihood of errors and material waste.

7. Documentation and Traceability: Maintain detailed records of cutting parameters, inspection results, and material sources for traceability and quality assurance purposes.

8. Continuous Improvement: Regularly review processes and seek feedback from operators to identify areas for improvement in cutting techniques and quality control measures.

By integrating these methods, manufacturers can effectively cut sheet metal with high precision and consistency while maintaining stringent quality standards throughout the production process.

Tips for Procurement and Considerations when Purchasing from how do you cut sheet metal

When purchasing equipment for cutting sheet metal, consider the following tips and factors:

1. Type of Cutting Required: Decide whether you need straight cuts, curves, or intricate designs. Different tools like shears, nibblers, or laser cutters are suitable for different cutting needs.

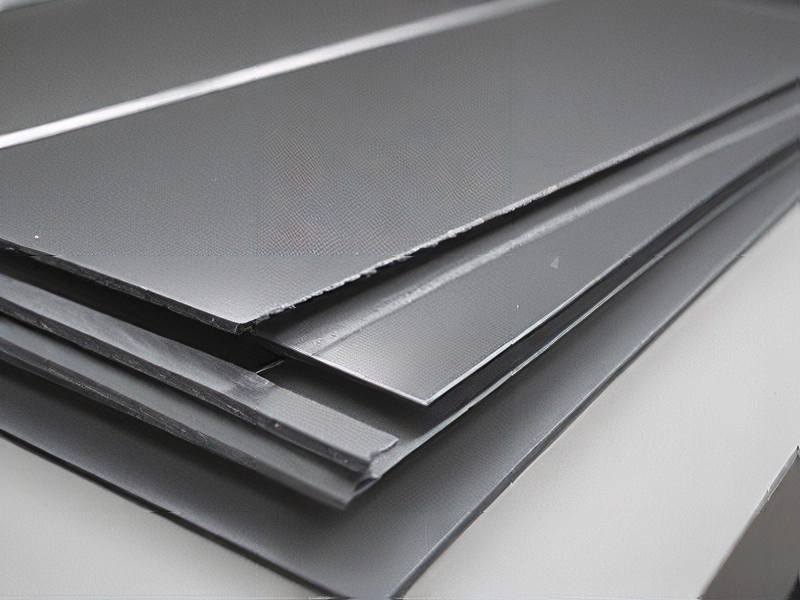

2. Material Thickness: Ensure the tool can handle the thickness of the sheet metal you work with. Thicker materials may require more powerful tools or different cutting methods.

3. Accuracy and Precision: Evaluate the tool’s ability to make precise cuts without excessive burrs or deformities. Laser cutters typically offer high precision compared to manual tools.

4. Speed and Efficiency: Consider the production volume and speed requirements. Laser cutters are fast but may be overkill for small-scale operations.

5. Cost and Budget: Balance the initial cost of the equipment with long-term savings and productivity gains. Cheaper tools might cost less upfront but could be less efficient or durable.

6. Ease of Use and Maintenance: Choose tools that are user-friendly and easy to maintain. Complex machinery may require specialized training and regular servicing.

7. Safety Features: Prioritize tools with safety features like blade guards, emergency stop buttons, and proper ventilation for laser cutters.

8. Space and Installation Requirements: Consider the size of the equipment and the space available in your workshop. Laser cutters, for instance, require adequate ventilation and space for operation.

9. Supplier Reputation and Support: Purchase from reputable suppliers who offer good customer support, warranties, and readily available spare parts.

10. Future Expansion: Anticipate future needs and whether the equipment can accommodate your growing business demands.

By carefully evaluating these factors and matching them to your specific requirements, you can make an informed decision when purchasing sheet metal cutting equipment.

FAQs on Sourcing and Manufacturing from how do you cut sheet metal in China

FAQs on Sourcing and Manufacturing in China

1. How do you cut sheet metal in China?

– Laser Cutting: Ideal for precision cutting of intricate designs and thin metals.

– Plasma Cutting: Suitable for thicker metals and high-speed applications.

– Water Jet Cutting: Utilizes high-pressure water mixed with abrasives for precise and heat-free cuts.

– Shearing: Mechanical process for straight-line cuts on sheet metal.

2. What are the main benefits of sourcing from China?

– Cost Efficiency: Lower labor and production costs.

– Diverse Suppliers: Wide range of manufacturers for various industries.

– Scalability: Ability to quickly scale production volumes.

3. How do I find reliable manufacturers in China?

– Online Platforms: Use sites like Alibaba, Global Sources, and Made-in-China.

– Trade Shows: Attend events like the Canton Fair for direct interaction with suppliers.

– Third-Party Agencies: Hire sourcing agents or companies specializing in vetting suppliers.

4. What are the common challenges when manufacturing in China?

– Quality Control: Ensuring consistent product quality.

– Communication Barriers: Language and cultural differences.

– Intellectual Property Risks: Protecting your designs and patents.

5. How can I ensure quality control?

– On-Site Inspections: Regular visits to the manufacturing site.

– Third-Party Audits: Hire inspection companies for unbiased quality checks.

– Clear Specifications: Provide detailed product requirements and standards.

6. What are the logistics considerations?

– Shipping Costs: Calculate costs for sea, air, or rail transport.

– Customs Regulations: Ensure compliance with import/export laws.

– Lead Times: Factor in production and shipping times to meet deadlines.

7. How can I protect my intellectual property?

– NDAs: Use Non-Disclosure Agreements with suppliers.

– Trademarks and Patents: Register your IP in China.

– Secure Contracts: Include IP protection clauses in manufacturing agreements.

For more detailed guidance, consider consulting with a sourcing expert or legal advisor familiar with Chinese manufacturing practices.