Technology and Applications of majestic steel service

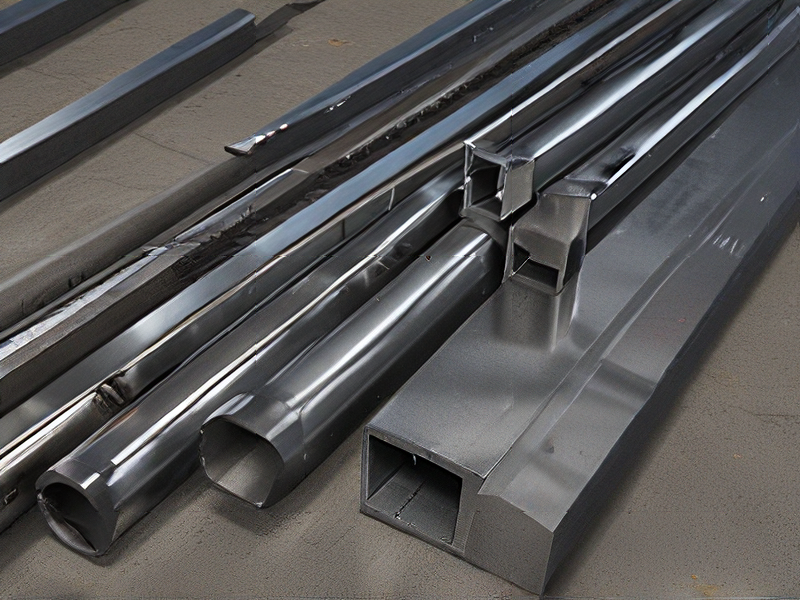

Majestic Steel USA is renowned for its expertise in steel processing and distribution. Specializing in flat-rolled products, they serve a wide range of industries including automotive, construction, agriculture, and appliance manufacturing. Their technological advancements and applications are pivotal in the steel industry.

Technological Innovations:

Majestic Steel employs advanced processing technologies such as slitting, blanking, and multi-blanking to meet precise customer specifications efficiently. Computer Numerical Control (CNC) equipment ensures accuracy in cutting and shaping steel sheets, enhancing productivity and minimizing waste.

Applications:

1. Automotive Industry: Majestic Steel supplies high-strength steel for vehicle components, contributing to lighter and more fuel-efficient cars while maintaining safety standards.

2. Construction: Steel from Majestic is used in structural beams, roofing, and cladding due to its durability and resistance to corrosion, ensuring longevity in buildings and infrastructure projects.

3. Appliance Manufacturing: Steel sheets are tailored for appliance panels and parts, offering aesthetic appeal, durability, and ease of maintenance.

4. Agricultural Equipment: Steel components provide strength and reliability in agricultural machinery, supporting efficient farm operations.

5. Energy Sector: Steel plays a crucial role in pipelines and infrastructure for oil, gas, and renewable energy projects, ensuring reliability and safety.

Environmental Commitment:

Majestic Steel prioritizes sustainability through efficient material usage and recycling initiatives, minimizing environmental impact across their operations.

In conclusion, Majestic Steel USA stands at the forefront of steel processing and distribution, leveraging advanced technology to deliver high-quality products across diverse industries while promoting sustainability in manufacturing practices.

Quality Testing Methods for majestic steel service and how to control quality

Quality testing methods for Majestic Steel Service involve several steps to ensure the steel meets required standards. These methods typically include:

1. Material Inspection: Initial inspection of raw materials for defects or inconsistencies. This involves visual inspection and sometimes chemical analysis.

2. Mechanical Testing: Evaluates the physical properties of steel such as tensile strength, hardness, and impact resistance. Common tests include:

– Tensile Test: Measures the force required to break a sample.

– Hardness Test: Determines the steel’s resistance to deformation.

– Impact Test: Assesses toughness by measuring the energy absorbed during fracture.

3. Dimensional Inspection: Ensures the steel products meet specified dimensions and tolerances using tools like calipers and micrometers.

4. Non-Destructive Testing (NDT): Identifies internal and surface defects without damaging the steel. Techniques include:

– Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal flaws.

– Magnetic Particle Testing (MPT): Identifies surface and near-surface discontinuities.

– Radiographic Testing (RT): Uses X-rays or gamma rays to reveal internal flaws.

5. Chemical Analysis: Determines the composition of the steel to ensure it meets specified chemical requirements. Methods include spectroscopy and wet chemical analysis.

6. Coating Inspection: Ensures any protective coatings (e.g., galvanizing) meet thickness and adhesion standards.

To control quality, Majestic Steel Service can implement several strategies:

1. Standard Operating Procedures (SOPs): Documented processes for each testing method to ensure consistency.

2. Quality Management System (QMS): An overarching system, often ISO 9001 certified, that encompasses all quality control processes and continuous improvement practices.

3. Regular Audits: Both internal and external audits to verify compliance with standards and identify areas for improvement.

4. Employee Training: Regular training programs to ensure all staff are knowledgeable about quality standards and testing methods.

5. Supplier Quality Assurance: Working closely with suppliers to ensure raw materials meet required standards before they reach the production floor.

By integrating these testing methods and quality control measures, Majestic Steel Service can maintain high standards and consistently deliver quality steel products.

Tips for Procurement and Considerations when Purchasing from majestic steel service

When purchasing from Majestic Steel Service, it’s crucial to follow these tips and considerations to ensure a successful procurement process:

1. Research and Review: Investigate Majestic Steel Service’s reputation, customer reviews, and case studies. Positive feedback and testimonials can be indicators of reliability and quality.

2. Product Quality and Standards: Verify that their steel products meet the necessary industry standards and certifications. Request material test reports and quality assurance documentation.

3. Price and Value: Compare prices with other suppliers, but also consider the value added by Majestic Steel Service, such as customer service, delivery options, and technical support. Look for competitive pricing that doesn’t compromise quality.

4. Supply Chain Reliability: Assess their supply chain stability. Check their lead times, inventory levels, and ability to meet your project deadlines. Reliable delivery schedules are crucial to avoid project delays.

5. Customization and Services: Determine if they offer customization services for specific project needs, such as cutting, slitting, or coating. Additional services like these can be beneficial and cost-effective.

6. Sustainability Practices: Investigate their sustainability initiatives and environmental practices. Suppliers with green certifications or eco-friendly processes might be preferred if sustainability is a priority for your business.

7. Customer Support: Evaluate their customer support responsiveness and expertise. Effective communication channels and a dedicated account manager can enhance the procurement experience.

8. Payment Terms and Conditions: Review the payment terms, return policies, and warranty conditions. Clear and favorable terms can mitigate risks and ensure smooth financial transactions.

9. Contractual Agreements: Ensure all agreements are documented in a formal contract, specifying the product specifications, delivery schedules, and terms of service. This protects both parties and provides a reference in case of disputes.

10. Visit and Inspect: If possible, visit their facilities to inspect the production processes and meet the team. This firsthand experience can provide insights into their operational efficiency and commitment to quality.

By considering these factors, you can make an informed decision when purchasing from Majestic Steel Service, ensuring your procurement process is efficient, cost-effective, and meets your quality standards.

FAQs on Sourcing and Manufacturing from majestic steel service in China

Majestic Steel Service is known for its sourcing and manufacturing capabilities in China, focusing on steel products. Here are some frequently asked questions (FAQs) regarding their operations:

1. What types of steel products does Majestic Steel Service manufacture in China?

Majestic Steel Service produces a wide range of steel products including coils, sheets, and processed steel for various industries.

2. How does Majestic Steel ensure quality control in their Chinese manufacturing facilities?

Quality control at Majestic Steel includes stringent supplier audits, regular inspections, and adherence to international standards to maintain consistent product quality.

3. What are the typical lead times for orders placed with Majestic Steel Service?

Lead times vary depending on the product and specifications, but generally range from a few weeks to a couple of months, considering manufacturing and shipping logistics.

4. Does Majestic Steel Service handle logistics such as shipping and customs clearance for orders from China?

Yes, Majestic Steel Service provides comprehensive logistics support, including shipping arrangements and customs clearance, to ensure smooth delivery of orders.

5. Can Majestic Steel Service accommodate custom manufacturing requests or specific product requirements?

Yes, Majestic Steel Service works closely with clients to fulfill custom manufacturing needs, offering tailored solutions and product configurations as required.

6. What certifications or standards does Majestic Steel Service adhere to in their manufacturing processes?

Majestic Steel Service maintains certifications such as ISO 9001 for quality management and adheres to industry standards to meet regulatory and customer requirements.

7. How does Majestic Steel Service manage relationships with suppliers and ensure supply chain reliability?

The company cultivates long-term partnerships with reliable suppliers in China, fostering transparency and accountability throughout the supply chain to maintain consistent product availability.

These FAQs provide insights into Majestic Steel Service’s operations in China, emphasizing their commitment to quality, flexibility in manufacturing, and robust logistics support for clients worldwide.