Technology and Applications of hot rolled steel material

Technology and Applications of Hot Rolled Steel

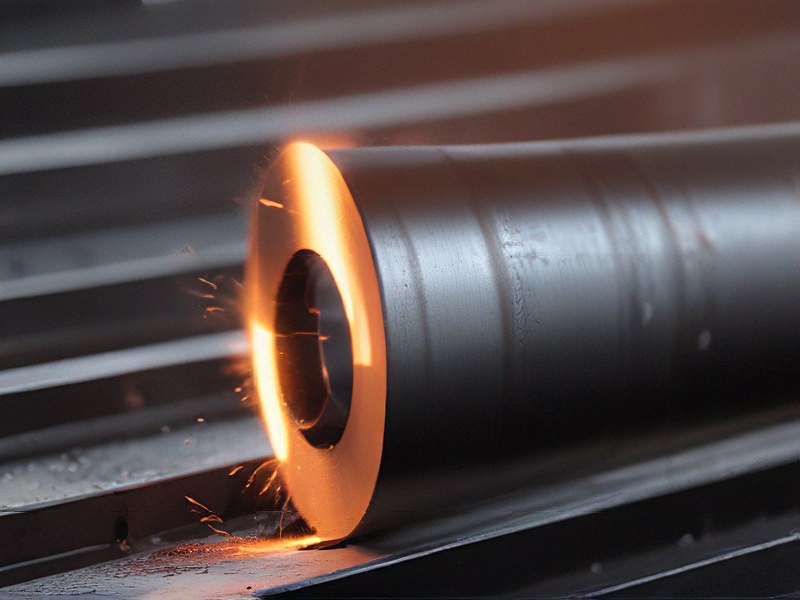

Hot rolled steel is manufactured by rolling steel at high temperatures, typically over 1700°F, which is above the recrystallization temperature of most steels. This process starts with a large, rectangular slab of metal that is heated and passed through a series of rollers to achieve the desired thickness. The high temperatures make the steel easier to shape and form, resulting in a more malleable product.

Technology:

1. Heating and Soaking: Steel slabs are heated in a furnace to the necessary temperature.

2. Roughing Mill: The heated slabs are passed through a roughing mill, reducing thickness and forming a rough shape.

3. Finishing Mill: The semi-finished slabs are further rolled to precise dimensions.

4. Cooling: The steel is cooled using laminar flow water sprays.

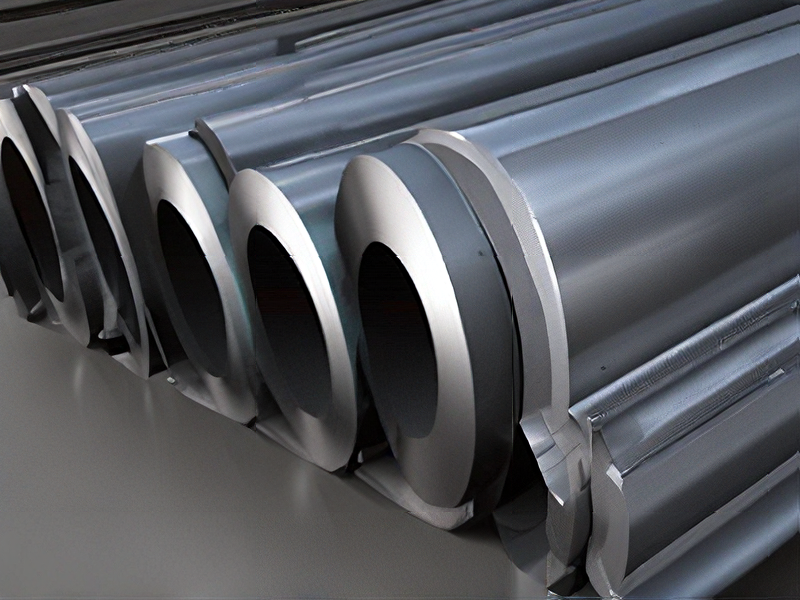

5. Coiling: The finished steel is wound into coils for transportation and further processing.

Applications:

1. Construction: Hot rolled steel is extensively used in construction for structural components like I-beams, H-beams, and columns due to its strength and durability.

2. Automotive: It’s used for manufacturing parts that require strength and wear resistance, such as frames and wheel rims.

3. Railroad Tracks: Its durability and ability to withstand high stress make it ideal for rails.

4. Agricultural Equipment: Components such as plows, harrows, and other machinery parts benefit from its robustness.

5. Pipes and Tubing: Hot rolled steel is used for making large diameter pipes and tubes that need to withstand high pressures.

Hot rolled steel is valued for its affordability, high strength, and versatility, making it a fundamental material across various industries. Its technology ensures efficient production, while its wide range of applications underscores its importance in modern manufacturing and infrastructure.

Quality Testing Methods for hot rolled steel material and how to control quality

Quality testing methods for hot-rolled steel material typically include the following:

1. Visual Inspection: This initial test identifies surface defects like cracks, scales, and improper shapes.

2. Dimensional Inspection: Ensures the steel meets specific dimensional criteria using tools like calipers and micrometers.

3. Chemical Analysis: Determines the material’s composition using techniques such as spectroscopy to ensure it meets the specified standards.

4. Mechanical Testing:

– Tensile Test: Measures the steel’s strength and ductility.

– Hardness Test: Assesses resistance to deformation, usually using the Rockwell or Brinell methods.

– Impact Test: Evaluates toughness using a Charpy or Izod test.

5. Ultrasonic Testing (UT): Detects internal defects by transmitting ultrasonic waves through the steel.

6. Magnetic Particle Inspection (MPI): Identifies surface and near-surface defects in ferromagnetic materials.

7. Eddy Current Testing: Detects surface and sub-surface flaws by inducing electrical currents and observing changes in their flow.

Quality Control Measures:

1. Standard Operating Procedures (SOPs): Establish detailed SOPs for each testing and manufacturing process.

2. Process Control: Implement statistical process control (SPC) to monitor and control production processes.

3. Quality Management Systems (QMS): Utilize QMS frameworks like ISO 9001 to maintain consistent quality.

4. Training and Certification: Ensure personnel are well-trained and certified in testing and quality control methods.

5. Traceability: Maintain detailed records of raw materials, processing conditions, and test results for traceability.

6. Regular Audits and Reviews: Conduct regular internal and external audits to identify and address any deviations from quality standards.

7. Supplier Quality Management: Work closely with suppliers to ensure they provide materials that meet the required standards.

These methods and controls help ensure that hot-rolled steel meets the necessary specifications for its intended use, reducing the risk of failures and improving overall product reliability.

Tips for Procurement and Considerations when Purchasing from hot rolled steel material

Tips for Procurement of Hot Rolled Steel Material

1. Understand Specifications: Clearly define the material specifications required for your project. This includes the grade, dimensions, and mechanical properties like tensile strength and hardness.

2. Quality Standards: Ensure the hot rolled steel complies with relevant quality standards such as ASTM, EN, or JIS. This guarantees material consistency and performance.

3. Supplier Selection: Choose reputable suppliers with a track record of reliability and quality. Check for certifications, past performance, and customer reviews.

4. Price Comparison: Conduct a thorough market analysis to compare prices. While cost is a factor, prioritize quality and supplier reliability.

5. Bulk Purchasing: If feasible, buy in bulk to leverage volume discounts. However, balance this with your storage capabilities and cash flow considerations.

6. Lead Time and Delivery: Confirm lead times and ensure the supplier can meet your project timeline. Discuss delivery terms and logistics to avoid delays.

7. Sample Testing: Request material samples for testing before committing to large orders. This helps verify that the material meets your specifications.

8. Contract Terms: Negotiate favorable contract terms, including payment conditions, warranties, and dispute resolution mechanisms. Ensure all terms are documented.

Considerations When Purchasing Hot Rolled Steel

1. Material Properties: Hot rolled steel has distinct characteristics, including lower precision and a rougher surface compared to cold rolled steel. Ensure these properties are suitable for your application.

2. Dimensional Tolerances: Be aware of the broader dimensional tolerances of hot rolled steel. Specify tolerances if your application requires precision.

3. Surface Condition: The surface finish of hot rolled steel is typically less smooth. Consider if additional processing like pickling or grinding is necessary.

4. Scale Formation: Hot rolled steel often has a layer of scale. Evaluate if descaling is required for your project.

5. Mechanical Properties: Hot rolling affects the mechanical properties, making the steel more malleable but potentially less strong than cold rolled steel. Ensure the mechanical properties align with your project needs.

6. Environmental Impact: Consider the environmental impact of hot rolled steel production and the supplier’s sustainability practices.

By focusing on these tips and considerations, you can effectively procure hot rolled steel that meets your project’s requirements while ensuring quality and cost-effectiveness.

FAQs on Sourcing and Manufacturing from hot rolled steel material in China

FAQs on Sourcing and Manufacturing from Hot Rolled Steel Material in China

1. What is hot rolled steel?

Hot rolled steel is produced by rolling the steel at high temperatures, typically over 1700°F, which is above the steel’s recrystallization temperature. This process allows the steel to be shaped and formed easily, resulting in a product that is easier to work with for various manufacturing processes.

2. Why source hot rolled steel from China?

China is one of the largest producers of steel globally, offering competitive prices and a wide range of grades and sizes. Chinese manufacturers are known for their capacity to produce high volumes and meet diverse specifications, making it an attractive sourcing option for many industries.

3. What are the common applications of hot rolled steel?

Hot rolled steel is used in construction, automotive, shipbuilding, and industrial machinery due to its strength and versatility. It’s commonly used for structural components like beams, rail tracks, and sheet metal.

4. How to ensure the quality of hot rolled steel from China?

Quality assurance can be managed by:

– Selecting reputable suppliers with proven track records.

– Requesting material certifications and compliance with international standards (e.g., ASTM, EN).

– Conducting third-party inspections and tests.

5. What are the logistical considerations for importing hot rolled steel from China?

Consider the following:

– Shipping costs and lead times.

– Import duties and taxes.

– Proper handling and storage to prevent damage and rust.

6. Are there environmental considerations when sourcing steel from China?

Yes, it’s important to consider the environmental impact of steel production. Look for suppliers with sustainable practices and certifications like ISO 14001, which indicates a commitment to environmental management.

7. What is the typical lead time for manufacturing and delivery?

Lead times can vary based on order size, complexity, and current demand. Generally, it ranges from a few weeks to several months. Confirm with your supplier for precise timelines.

8. How to handle communication and cultural differences?

Effective communication can be maintained through:

– Clear and detailed specifications.

– Regular updates and follow-ups.

– Using bilingual staff or professional translators to bridge language gaps.

By addressing these FAQs, businesses can make informed decisions when sourcing and manufacturing hot rolled steel from China, ensuring quality, cost-effectiveness, and timely delivery.