Technology and Applications of 3d printing metal service

3D printing metal, also known as metal additive manufacturing, is a transformative technology that enables the creation of complex and precise metal parts directly from digital models. This process involves layer-by-layer deposition of metal powders or wires, which are melted using lasers, electron beams, or electric arcs, then solidified to form the final product.

Technology

1. Laser Powder Bed Fusion (LPBF): This technique uses a high-power laser to fuse metal powder particles layer by layer. Common metals used include titanium, aluminum, and stainless steel.

2. Electron Beam Melting (EBM): Similar to LPBF, but uses an electron beam as the heat source. It is highly suitable for high-temperature alloys.

3. Directed Energy Deposition (DED): This method involves melting metal feedstock (powder or wire) as it is deposited. It is used for larger structures and repairing existing components.

4. Binder Jetting: Involves depositing a binding agent onto a bed of metal powder, followed by a sintering process to fuse the particles. This method allows for high-speed production of complex parts.

Applications

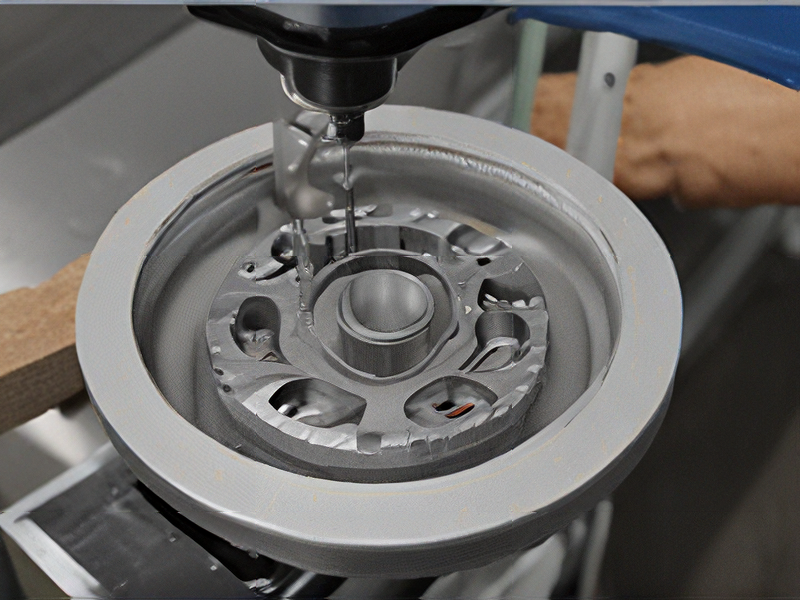

1. Aerospace: Metal 3D printing is used to produce lightweight, complex parts with high strength-to-weight ratios, such as engine components and airframe structures.

2. Medical: Custom implants and prosthetics, tailored to individual patients, are created using biocompatible metals.

3. Automotive: High-performance, custom parts like turbochargers, and lightweight structural components benefit from this technology.

4. Tooling: Rapid production of custom tools, molds, and dies is possible, reducing lead times and costs.

5. Energy: Components for turbines, heat exchangers, and oil and gas applications benefit from the ability to create intricate geometries and internal features.

Metal 3D printing continues to evolve, with ongoing advancements in materials, precision, and scalability, making it a pivotal technology in modern manufacturing.

Quality Testing Methods for 3d printing metal service and how to control quality

Quality testing methods for metal 3D printing services typically include several key approaches:

1. Dimensional Accuracy: Utilizing coordinate measuring machines (CMMs) to ensure printed parts match CAD specifications precisely.

2. Surface Roughness Analysis: Assessing surface finish using profilometers or optical scanners to meet required smoothness standards.

3. Microstructure Evaluation: Employing metallographic techniques such as microscopy and image analysis to inspect grain structure and ensure uniformity.

4. Mechanical Testing: Conducting tensile, compression, and hardness tests to verify mechanical properties and adherence to strength requirements.

5. Non-Destructive Testing (NDT): Employing methods like ultrasonic testing (UT) and X-ray computed tomography (CT) to detect internal defects without damaging parts.

To control quality effectively:

– Process Parameters Monitoring: Regularly monitor and adjust printing parameters (e.g., temperature, laser power) to maintain consistency.

– Material Inspection: Conduct rigorous inspection of metal powders for purity, particle size distribution, and flowability.

– Post-Processing Validation: Validate heat treatments, surface treatments, and machining steps to ensure they meet specified standards.

– Documentation and Traceability: Maintain detailed records of each step in the printing process and material history for traceability and accountability.

Implementing these methods ensures that metal 3D printing services deliver parts with high precision, reliability, and performance, meeting stringent quality standards.

Tips for Procurement and Considerations when Purchasing from 3d printing metal service

When procuring from a 3D printing metal service, it’s crucial to consider several factors to ensure quality and cost-efficiency. Here are key tips and considerations:

1. Material Selection

– Type of Metal: Different metals (e.g., stainless steel, titanium, aluminum) have varied properties. Choose based on your project’s requirements for strength, durability, and weight.

– Quality Standards: Ensure the service adheres to relevant quality standards (e.g., ASTM, ISO) to guarantee material integrity.

2. Printing Technology

– Method: Understand the type of 3D printing technology used (e.g., Direct Metal Laser Sintering, Electron Beam Melting). Each has specific applications and limitations.

– Accuracy and Resolution: Verify the printer’s resolution and tolerance levels to ensure they meet your design specifications.

3. Design and Prototyping

– Design for Additive Manufacturing (DfAM): Optimize designs for 3D printing to reduce material waste and improve strength. Consult with the service for design adjustments.

– Prototyping: Request prototypes to evaluate the final product’s quality before mass production.

4. Cost Considerations

– Quotation and Pricing Models: Obtain detailed quotes, including material costs, printing time, and post-processing. Compare different services for cost-effectiveness.

– Volume Discounts: Inquire about discounts for larger quantities or repeat orders.

5. Post-Processing and Finishing

– Surface Finish: Determine the type of post-processing required (e.g., polishing, heat treatment) to achieve the desired surface finish and mechanical properties.

– Inspection and Testing: Ensure thorough inspection and testing processes are in place to verify the quality and performance of the final product.

6. Lead Time and Scalability

– Production Time: Clarify lead times for both prototypes and full-scale production runs. Consider services that offer scalable solutions for future needs.

– Supply Chain Integration: Assess the service’s ability to integrate with your supply chain for seamless order fulfillment.

7. Vendor Reputation and Support

– Reputation: Check reviews, case studies, and references to gauge the service’s reliability and quality.

– Customer Support: Ensure the vendor provides robust customer support for troubleshooting and consultation throughout the project lifecycle.

By meticulously evaluating these aspects, you can make informed decisions and optimize the benefits of using a 3D printing metal service.

FAQs on Sourcing and Manufacturing from 3d printing metal service in China

When sourcing and manufacturing through a 3D printing metal service in China, consider these FAQs:

1. What materials are available for 3D printing metal in China?

– Common materials include stainless steel, titanium, aluminum, and nickel alloys. Verify specific material capabilities with your chosen service provider.

2. What are typical lead times for 3D printed metal parts?

– Lead times vary based on complexity, part size, and quantity. Expect anywhere from a few days to several weeks, depending on these factors.

3. What quality standards do Chinese 3D printing metal services adhere to?

– Reputable services adhere to international standards such as ISO 9001 for quality management and AS9100 for aerospace applications. Ensure your provider meets your industry-specific requirements.

4. Can I get prototypes and large-scale production from the same service?

– Yes, many providers offer both rapid prototyping and production capabilities. Confirm their capacity to scale production as per your needs.

5. What are the cost considerations when manufacturing in China?

– Costs are influenced by material choice, part complexity, finishing requirements, and quantity. Request detailed quotes and compare with other providers to ensure competitiveness.

6. How can I ensure intellectual property (IP) protection?

– Discuss confidentiality agreements and IP protection measures with your service provider. Consider legal advice and understand Chinese IP laws if necessary.

7. What post-processing options are available?

– Services typically offer machining, polishing, heat treatment, and surface finishing options. Specify your requirements to achieve desired part properties.

8. What communication and support can I expect during the manufacturing process?

– Ensure clear communication channels and support in English or your preferred language. Clarify project milestones and expectations upfront.

Choosing a reputable 3D printing metal service in China involves thorough research, clear communication, and understanding of your specific project needs and expectations.