Technology and Applications of metal cabinet drawers

Metal cabinet drawers are essential components in various applications due to their durability, versatility, and efficient storage capabilities. These drawers are commonly made from materials like steel or aluminum, providing robustness and resistance to wear and tear.

In office settings, metal cabinet drawers offer secure storage for documents, stationery, and other essentials, ensuring organization and easy access. They contribute to space optimization by fitting neatly under desks or alongside workstations, enhancing productivity through efficient storage solutions.

In industrial environments, metal cabinet drawers are used to store tools, parts, and equipment. Their sturdy construction allows them to withstand heavy loads and frequent use, making them ideal for manufacturing facilities and workshops. They facilitate inventory management and contribute to workplace safety by keeping tools and materials organized and easily accessible.

In healthcare facilities, metal cabinet drawers are crucial for storing medical supplies, medications, and patient records securely. Their design often includes locking mechanisms to ensure confidentiality and prevent unauthorized access, adhering to strict regulatory requirements for patient privacy and safety.

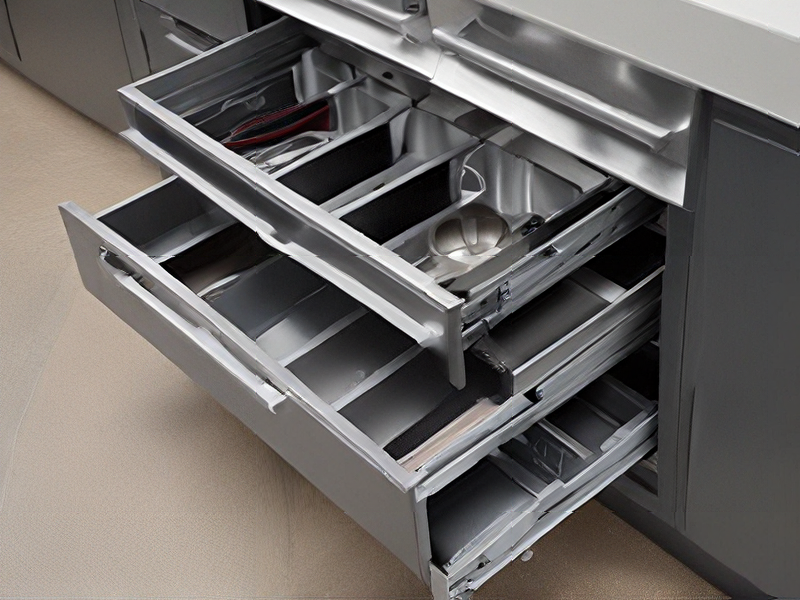

In residential settings, metal cabinet drawers find use in kitchens, garages, and workshops, providing durable storage solutions for household items, tools, and hobby materials. They contribute to maintaining order and efficiency within living spaces, enhancing overall functionality and convenience.

Overall, the technology behind metal cabinet drawers continues to evolve with advancements in materials and design, catering to diverse applications across various sectors. Their enduring popularity stems from their ability to combine strength, reliability, and organizational efficiency, making them indispensable in both professional and domestic environments.

Quality Testing Methods for metal cabinet drawers and how to control quality

Quality testing for metal cabinet drawers involves several key methods to ensure durability, functionality, and safety. Here are common methods and controls used:

Testing Methods

1. Load Testing:

– Static Load Test: Verifies the drawer’s ability to hold weight without deformation or failure. Drawers are loaded to their maximum rated capacity and observed for structural integrity.

– Dynamic Load Test: Involves repeatedly opening and closing drawers while loaded to simulate long-term use. This tests the durability of the slides and the drawer’s overall construction.

2. Cycle Testing:

– Drawers are opened and closed thousands of times to simulate years of use. This assesses the longevity of components like slides, handles, and latches.

3. Material Testing:

– Tensile Strength: Measures the material’s resistance to breaking under tension.

– Corrosion Resistance: Metal parts are exposed to salt spray or other corrosive environments to test their resistance to rust and corrosion.

4. Finish Testing:

– Adhesion Tests: Ensure paint or coatings properly adhere to the metal surface.

– Scratch and Abrasion Resistance: Tests how well the finish withstands wear and tear.

5. Functional Testing:

– Fit and Finish: Ensures all parts fit together properly without gaps or misalignments.

– Smooth Operation: Tests the ease of opening and closing, ensuring no sticking or excessive resistance.

Quality Control

1. Incoming Material Inspection:

– Raw materials are inspected for compliance with specifications before production begins.

2. In-Process Inspection:

– Regular checks during manufacturing to ensure components meet quality standards. This includes verifying dimensions, alignment, and assembly integrity.

3. Final Inspection:

– Comprehensive testing of finished products to ensure they meet all quality criteria. This includes visual inspection, functional tests, and random sampling for load and cycle tests.

4. Statistical Process Control (SPC):

– Uses statistical methods to monitor and control the manufacturing process. SPC helps detect and correct deviations before they result in defective products.

5. Quality Management System (QMS):

– Implementing a QMS such as ISO 9001 ensures a systematic approach to quality, with documented processes and continuous improvement practices.

By combining rigorous testing methods with thorough quality control processes, manufacturers can ensure that metal cabinet drawers meet high standards of durability, functionality, and safety.

Tips for Procurement and Considerations when Purchasing from metal cabinet drawers

When procuring metal cabinet drawers, it’s essential to consider several key factors to ensure you make an informed purchase. Here are some tips and considerations to guide you through the process:

1. Material Quality: Check the type of metal used. Stainless steel and galvanized steel are known for their durability and resistance to corrosion, making them ideal for long-term use.

2. Construction and Design: Examine the construction quality. Welded joints are typically stronger than riveted ones. Look for smooth edges and a robust design to handle the intended load without deforming.

3. Load Capacity: Determine the maximum weight the drawers can handle. This is crucial for ensuring the drawers won’t fail under the weight of the items you plan to store.

4. Drawer Mechanism: Opt for drawers with high-quality glides and bearings to ensure smooth operation. Soft-close mechanisms can prevent slamming and extend the lifespan of the drawers.

5. Size and Configuration: Ensure the drawers fit the intended space and have the right dimensions to store your items efficiently. Consider adjustable dividers for better organization.

6. Locking System: For added security, especially in industrial or high-traffic environments, choose drawers with reliable locking mechanisms.

7. Finish and Coating: A good finish not only enhances appearance but also provides additional protection against rust and scratches. Powder-coated finishes are generally more durable.

8. Compliance and Standards: Ensure the cabinets meet relevant industry standards and certifications for safety and quality.

9. Vendor Reputation: Purchase from reputable suppliers with positive reviews and a track record of providing quality products. Check for warranties and after-sales support.

10. Cost vs. Value: While budget is important, prioritize value over the lowest price. Investing in higher quality may result in lower long-term costs due to reduced maintenance and replacement needs.

By focusing on these aspects, you can make a well-informed decision and select metal cabinet drawers that meet your specific needs and provide lasting value.

FAQs on Sourcing and Manufacturing from metal cabinet drawers in China

FAQs on Sourcing and Manufacturing Metal Cabinet Drawers in China

#### 1. Why source metal cabinet drawers from China?

China offers competitive pricing, a vast array of manufacturers, and advanced production capabilities. The country’s infrastructure supports large-scale manufacturing and efficient logistics.

#### 2. How do I find reliable manufacturers?

Utilize platforms like Alibaba, Made-in-China, and Global Sources. Look for suppliers with positive reviews, verified status, and strong communication skills. Visiting trade shows and factories can provide firsthand insight.

#### 3. What are the key considerations in selecting a supplier?

Consider the supplier’s production capacity, quality control processes, and compliance with international standards. Evaluate their experience with exporting and ability to meet your specifications and timelines.

#### 4. What is the typical production lead time?

Lead times can vary based on order size and complexity, typically ranging from 30 to 60 days. Ensure clear communication with your supplier to confirm timelines.

#### 5. How can I ensure product quality?

Implement a strict quality control plan, including pre-production samples, in-process inspections, and final inspections before shipment. Hiring a third-party inspection company can provide additional assurance.

#### 6. What are the common payment terms?

Standard terms include a 30% deposit upfront with the balance paid upon shipment. Letters of credit and escrow services can offer additional security.

#### 7. How do I handle logistics and shipping?

Work with a reputable freight forwarder to manage shipping. Understand the Incoterms (FOB, CIF, etc.) to clarify responsibilities and costs. Ensure proper packaging and documentation to avoid customs issues.

#### 8. Are there any import duties or taxes?

Import duties and taxes vary by country and product classification. Check your country’s customs regulations and consider consulting with a customs broker for accurate cost estimation.

#### 9. How do I address intellectual property (IP) concerns?

Protect your IP through patents and trademarks. Use non-disclosure agreements (NDAs) with suppliers and consider registering your IP in China to prevent unauthorized use.

#### 10. What should I do if there are issues with my order?

Maintain detailed records of all communications and agreements. If issues arise, try to resolve them directly with the supplier. If necessary, seek legal assistance or mediation services available through trade organizations.