Technology and Applications of diy cnc router build

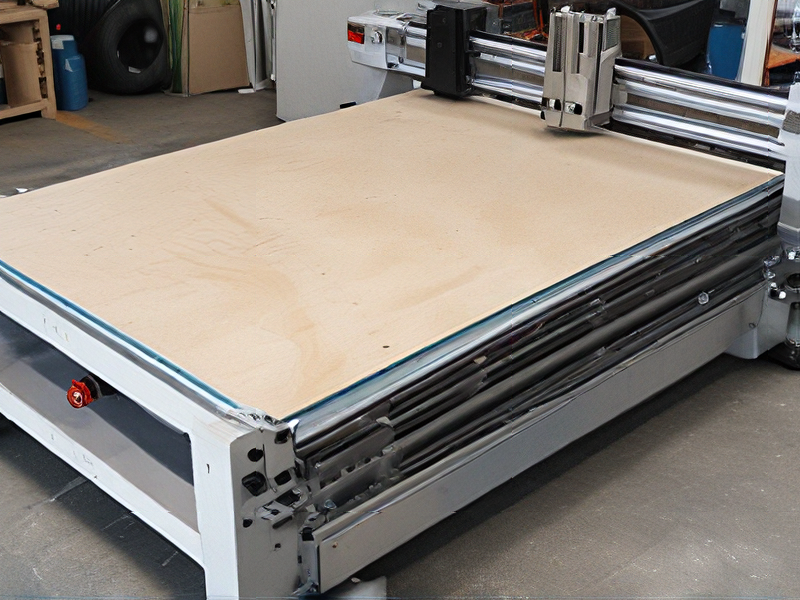

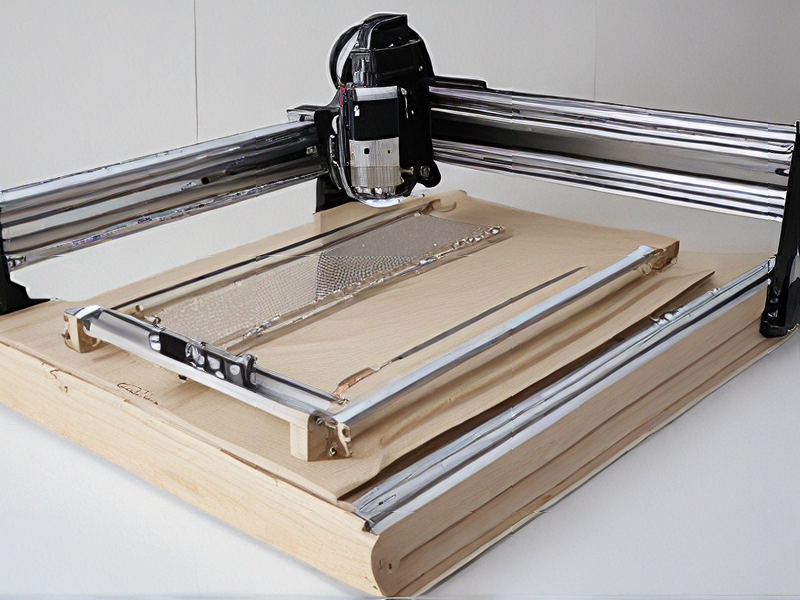

A DIY CNC (Computer Numerical Control) router is a versatile tool for precision cutting, milling, and engraving various materials such as wood, plastics, and metals. Building one yourself can be cost-effective and tailored to specific needs.

Technology:

1. Framework: Typically made from materials like aluminum, steel, or high-density plastics. A sturdy frame ensures accuracy and stability.

2. Motors: Stepper or servo motors drive the router along the X, Y, and Z axes, controlled by the CNC controller.

3. Controller: The brain of the CNC router, usually an Arduino, Raspberry Pi, or a dedicated CNC controller board. It interprets G-code from design software and sends commands to the motors.

4. Spindle: The cutting tool’s motor, which rotates at high speeds to cut or engrave the material.

5. Software: CAD (Computer-Aided Design) software for designing projects and CAM (Computer-Aided Manufacturing) software to convert designs into G-code.

Applications:

1. Woodworking: Precision cutting and engraving of wood for furniture, cabinetry, and decorative items.

2. Prototyping: Creating prototypes for mechanical parts, electronic housings, and custom components.

3. Sign Making: Crafting intricate signs and plaques from wood, plastic, or metal.

4. PCB Milling: Producing custom printed circuit boards for electronics projects.

5. Art and Design: Engraving detailed designs into various materials for art projects and custom decor.

Building Steps:

1. Design and Planning: Decide on the size, materials, and components based on your requirements.

2. Frame Assembly: Construct the frame, ensuring it is square and stable.

3. Motor and Spindle Installation: Mount the motors and spindle, and connect them to the CNC controller.

4. Wiring: Connect all electronic components, including limit switches and power supplies.

5. Software Setup: Install and configure the CNC control software and test the machine.

Building a DIY CNC router requires basic knowledge of electronics, mechanics, and software. It offers a rewarding project with broad applications, allowing for creative and precise fabrication.

Quality Testing Methods for diy cnc router build and how to control quality

For DIY CNC router builds, quality testing is crucial to ensure performance and reliability. Here are some effective methods to control quality:

1. Dimensional Accuracy Checks: Measure critical dimensions using calipers or micrometers against design specifications. Ensure that parts fit together correctly and move smoothly.

2. Alignment Verification: Check the alignment of linear guides, lead screws, and rails using precision levels or laser alignment tools. Proper alignment prevents binding and ensures accurate movement.

3. Runout and Flatness Testing: Use dial indicators to measure runout on rotating components like spindles and check flatness on work surfaces. This ensures that cuts are precise and consistent.

4. Electrical Testing: Verify electrical connections for continuity and proper voltage levels. Check motor wiring, limit switches, and emergency stop functionality.

5. Motion Testing: Run the CNC router through test programs to evaluate movement accuracy, backlash, and repeatability. Use test patterns to assess dimensional accuracy over various distances.

6. Heat and Stress Testing: Operate the CNC router under normal load conditions for extended periods to identify overheating issues or structural weaknesses.

7. Surface Finish Evaluation: Test cuts on different materials to assess surface finish quality and consistency. This helps fine-tune spindle speed, feed rates, and tooling.

8. Software Calibration: Calibrate CNC controller settings, such as steps per unit and acceleration parameters, to match mechanical capabilities and improve accuracy.

To control quality effectively, maintain detailed records of measurements and test results throughout the build process. Regularly iterate and adjust components or settings based on testing feedback to achieve optimal performance.

Tips for Procurement and Considerations when Purchasing from diy cnc router build

When embarking on a DIY CNC router build, procurement is crucial for ensuring project success and cost-effectiveness. Here are key considerations:

1. Components Quality: Opt for high-quality components like stepper motors, linear motion guides, and ball screws. These determine accuracy and durability.

2. Compatibility and Integration: Ensure all components are compatible with your design and each other. Check specifications such as motor torque requirements and voltage ratings.

3. Cost vs. Quality: Balance between cost and quality. Sometimes investing more upfront can save on maintenance and replacement costs later.

4. Supplier Reputation: Choose reputable suppliers known for reliability and customer support. Reviews and testimonials can help gauge their reputation.

5. Lead Times and Availability: Check lead times and availability, especially for specialized components. Delays can stall your project.

6. Support and Documentation: Opt for suppliers providing clear documentation and support. This includes assembly instructions, wiring diagrams, and troubleshooting guides.

7. Scalability: Consider future upgrades or modifications. Choosing components with scalability in mind can future-proof your CNC router.

8. Safety and Compliance: Ensure components meet safety standards and regulations, especially if using the router in a professional or commercial setting.

9. Tooling and Consumables: Don’t forget tooling such as end mills and lubricants. Include these in your procurement plan to avoid delays during assembly.

10. Budget Management: Keep a detailed budget to track expenses. Factor in shipping costs, taxes, and potential customs duties if ordering internationally.

By carefully considering these points during procurement, you can streamline your DIY CNC router build, minimize setbacks, and ensure a robust and reliable final product.

FAQs on Sourcing and Manufacturing from diy cnc router build in China

Certainly! Here are some FAQs on sourcing and manufacturing a DIY CNC router build in China:

1. Why should I consider sourcing from China for my DIY CNC router?

China offers a wide range of components at competitive prices, making it cost-effective for DIY projects. It also has a robust manufacturing ecosystem with suppliers specializing in CNC components.

2. How do I find reliable suppliers in China?

Research online platforms like Alibaba or Made-in-China for suppliers with good reviews and certifications. Direct communication and requesting samples can also help verify reliability.

3. What are common challenges when sourcing from China?

Quality control can be an issue. It’s crucial to specify exact requirements and conduct regular inspections. Language barriers and cultural differences may also require clear communication.

4. Can I customize components for my DIY CNC router build?

Yes, many Chinese suppliers offer customization options for components like stepper motors, linear rails, and controller boards. Ensure specifications are detailed to avoid misunderstandings.

5. How do I handle manufacturing logistics?

Plan ahead for lead times, shipping costs, and import duties. Using a freight forwarder can streamline logistics and ensure compliance with import regulations.

6. What about intellectual property protection?

While concerns exist, working with reputable suppliers and having clear contracts with non-disclosure agreements (NDAs) can mitigate risks.

7. Are there alternatives to sourcing from China?

Other countries like Taiwan and South Korea offer similar manufacturing capabilities but may have different cost structures and availability of components.

Navigating sourcing and manufacturing in China for your DIY CNC router requires careful planning and due diligence, but it can provide significant cost savings and access to a wide array of components suited to your project’s needs.