Technology and Applications of plastic sheets hdpe

High-density polyethylene (HDPE) plastic sheets find widespread application across various industries due to their versatile properties. HDPE sheets are valued for their durability, lightweight nature, and resistance to chemicals and moisture. These characteristics make them suitable for both indoor and outdoor use.

In construction, HDPE sheets are employed as damp-proof membranes to prevent water penetration in foundations and roofs. Their flexibility allows for easy installation and adaptation to different surface contours. In agriculture, HDPE sheets are used for lining reservoirs, ponds, and canals due to their impermeability and ability to withstand harsh environmental conditions.

The packaging industry utilizes HDPE sheets for manufacturing crates, containers, and bottles. Their toughness ensures protection during transit, while their resistance to chemicals preserves the integrity of the packaged goods. In signage and advertising, HDPE sheets serve as durable substrates for outdoor signage, owing to their UV resistance and ability to maintain colorfastness over extended periods.

Furthermore, HDPE sheets are integral to the manufacturing of playground equipment, automotive components, and healthcare products like orthotics and prosthetics. Their lightweight nature contributes to fuel efficiency in vehicles, while their resilience enhances safety in recreational settings.

In summary, HDPE plastic sheets are prized for their durability, chemical resistance, and versatility across numerous applications including construction, agriculture, packaging, signage, automotive, and healthcare industries. Their ability to withstand environmental stresses while maintaining structural integrity makes them indispensable in modern manufacturing and everyday life.

Quality Testing Methods for plastic sheets hdpe and how to control quality

Quality testing of HDPE (High-Density Polyethylene) plastic sheets involves various methods to ensure the material meets required standards. Key testing methods and quality control techniques include:

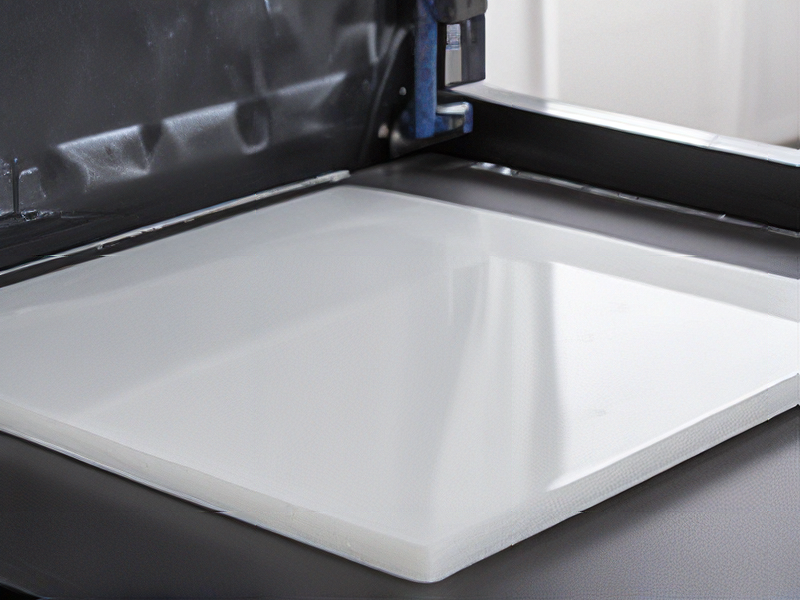

1. Visual Inspection: Initial examination for surface defects, color uniformity, and overall appearance to detect visible flaws.

2. Dimensional Accuracy: Measurement of length, width, and thickness using calipers or micrometers to ensure they meet specified tolerances.

3. Tensile Strength Testing: This evaluates the material’s resistance to being pulled apart, usually performed using a universal testing machine. It ensures the HDPE sheets can withstand specified stress levels.

4. Impact Resistance: This tests the material’s ability to absorb energy during impact without breaking. The Izod or Charpy impact test methods are commonly used.

5. Flexural Strength: This measures the sheet’s resistance to bending, ensuring it can withstand flexing forces during use.

6. Thermal Analysis: Differential Scanning Calorimetry (DSC) assesses melting temperature and crystallinity, which are critical for understanding the material’s thermal properties.

7. Chemical Resistance: Exposure to various chemicals to ensure the HDPE’s resistance to degradation or chemical reactions.

8. Environmental Stress Cracking Resistance (ESCR): Evaluates the material’s resistance to cracking under stress in the presence of certain chemicals, ensuring long-term durability.

Quality Control Techniques

1. Standard Operating Procedures (SOPs): Implementing SOPs for production processes to maintain consistency.

2. Batch Testing: Regularly testing samples from each production batch to ensure compliance with quality standards.

3. Statistical Process Control (SPC): Using statistical methods to monitor and control the manufacturing process, identifying any variations that could affect quality.

4. ISO Certification: Adhering to ISO standards (e.g., ISO 9001) ensures a structured quality management system is in place.

5. Regular Audits and Reviews: Conducting internal and external audits to continually assess and improve quality processes.

By integrating these testing methods and quality control techniques, manufacturers can ensure HDPE plastic sheets meet industry standards and customer requirements.

Tips for Procurement and Considerations when Purchasing from plastic sheets hdpe

When procuring HDPE (High-Density Polyethylene) plastic sheets, consider the following tips and factors:

Material Specifications

1. Quality and Grade: Ensure the HDPE sheets meet the required standards for your application, such as food-grade, UV resistant, or high molecular weight.

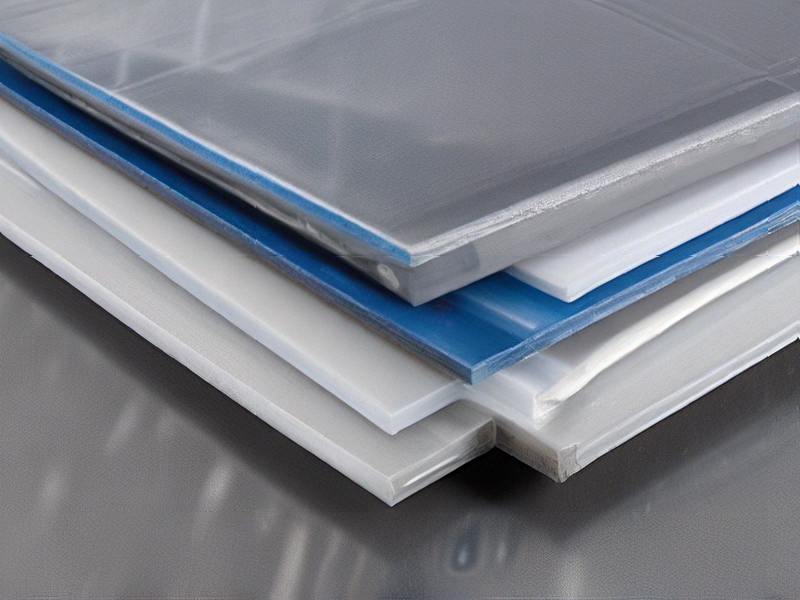

2. Thickness and Size: Specify the correct thickness and dimensions needed for your project to avoid waste and ensure structural integrity.

Supplier Evaluation

1. Reputation and Reliability: Choose suppliers with good reputations, positive reviews, and proven track records. Consistent supply and quality are critical.

2. Certifications: Verify that the supplier’s products are certified to meet industry standards and regulatory requirements.

Cost Considerations

1. Pricing: Compare prices from multiple suppliers to ensure competitiveness without compromising on quality. Consider bulk purchase discounts.

2. Total Cost of Ownership: Factor in shipping, handling, and any additional costs such as custom cutting or finishing.

Environmental Impact

1. Recyclability: Prefer HDPE sheets that are recyclable, as this reduces environmental impact and disposal costs.

2. Sustainability Practices: Check if the supplier follows sustainable manufacturing practices and uses recycled materials.

Technical Support and Service

1. Technical Assistance: Choose suppliers who offer technical support for product selection, application advice, and troubleshooting.

2. After-Sales Service: Ensure the supplier provides good after-sales support, including warranties and return policies.

Logistical Considerations

1. Delivery Times: Confirm the supplier’s delivery schedule aligns with your project timelines to avoid delays.

2. Inventory Management: Consider suppliers with strong inventory management capabilities to ensure product availability when needed.

Risk Management

1. Quality Control: Implement stringent quality checks upon receiving the HDPE sheets to ensure they meet specifications.

2. Contingency Planning: Have backup suppliers in place to mitigate risks of supply chain disruptions.

By considering these factors, you can ensure a cost-effective, high-quality, and reliable procurement process for HDPE plastic sheets.

FAQs on Sourcing and Manufacturing from plastic sheets hdpe in China

When sourcing and manufacturing HDPE (High-Density Polyethylene) plastic sheets from China, it’s essential to address key considerations to ensure quality and reliability:

1. Supplier Selection: Choose suppliers with proven experience in HDPE production and a track record of delivering consistent quality. Verify their certifications and conduct background checks to assess their reliability.

2. Quality Assurance: Insist on quality control measures throughout the manufacturing process. This includes raw material inspection, in-process checks, and final product testing to meet international standards (e.g., ASTM, ISO).

3. Customization Options: Clarify your customization needs upfront regarding thickness, color, dimensions, and additives (UV stabilizers, anti-static agents, etc.). Ensure the supplier can accommodate these specifications.

4. Production Capacity: Evaluate the supplier’s production capacity to meet your demand volume. Discuss lead times, production schedules, and their ability to scale production if needed.

5. Logistics and Shipping: Plan logistics carefully, considering shipping costs, transit times, and import/export regulations. Factor in packaging requirements to ensure the products arrive intact and undamaged.

6. Communication and Contracts: Establish clear communication channels and document all agreements in writing. Contracts should outline product specifications, pricing, payment terms, quality standards, and dispute resolution procedures.

7. Environmental and Ethical Standards: Inquire about the supplier’s environmental practices and adherence to labor laws. Ensure they comply with relevant regulations and ethical standards.

8. After-Sales Support: Discuss after-sales support, including warranty terms and provisions for returns or replacements in case of defects.

By addressing these points diligently, you can mitigate risks associated with sourcing HDPE plastic sheets from China and ensure a successful manufacturing process aligned with your business needs.