Technology and Applications of paper laminate sheets

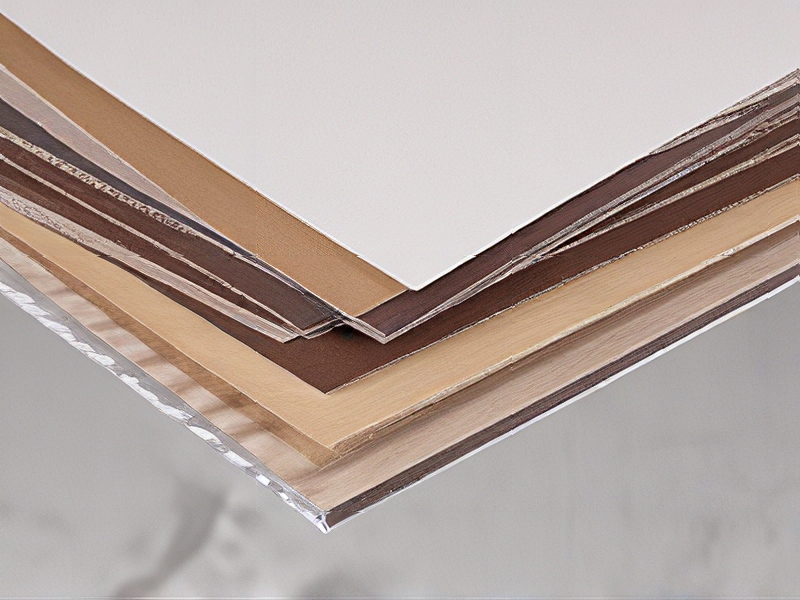

Paper laminate sheets, often referred to as laminates or decorative laminates, are versatile materials used extensively in various applications due to their durability, aesthetic appeal, and ease of maintenance. These sheets typically consist of multiple layers of paper soaked in resin, compressed under high pressure, and then cured to form a hard, durable surface.

Applications:

1. Furniture: One of the primary uses of paper laminate sheets is in furniture manufacturing. They are applied to surfaces such as tabletops, cabinets, and shelves to provide a decorative and protective layer. Laminates are preferred for their scratch resistance and ability to withstand wear and tear.

2. Interior Design: In interior design, laminates find use in wall panels, doors, and flooring. They offer a wide range of designs and textures, from wood grains to abstract patterns, making them suitable for both residential and commercial spaces.

3. Retail Fixtures: Laminates are commonly used in retail environments for displays, counters, and shelving units. Their durability and easy cleaning make them ideal for high-traffic areas where appearance matters.

4. Transportation: In the transportation sector, laminates are used in vehicle interiors for panels and trim. They provide a lightweight and decorative alternative to traditional materials while meeting safety and durability standards.

Technological Advancements:

Recent advancements in paper laminate technology include:

– Digital Printing: Improved digital printing techniques allow for more intricate designs and customization, expanding the aesthetic possibilities of laminates.

– Environmentally Friendly Options: Development of laminates using recycled materials or sustainable sources aligns with growing environmental concerns.

– Enhanced Durability: Innovations in resin formulations and production processes enhance the durability and scratch resistance of laminates, extending their lifespan.

In conclusion, paper laminate sheets combine aesthetic appeal with practical benefits, making them indispensable across diverse industries ranging from furniture and interior design to retail and transportation. Technological advancements continue to drive innovation in this versatile material, catering to evolving consumer preferences and sustainability demands.

Quality Testing Methods for paper laminate sheets and how to control quality

For quality testing of paper laminate sheets, several methods ensure adherence to standards:

1. Visual Inspection: Check for defects like bubbles, wrinkles, or uneven lamination.

2. Thickness Measurement: Use calipers to verify consistent thickness across the sheet.

3. Peel Strength Test: Assess how well layers adhere by pulling them apart.

4. Abrasion Resistance: Determine durability against rubbing or scratching.

5. Moisture Resistance: Expose samples to humidity to test water resistance.

6. Print Adhesion: Evaluate how well ink adheres to the laminate.

7. Chemical Resistance: Test resistance to solvents or cleaning agents.

To control quality:

1. Establish Standards: Define acceptable limits for each test.

2. Regular Sampling: Test samples from each batch or production run.

3. Calibration: Ensure testing equipment is accurate and calibrated.

4. Training: Educate staff on testing procedures and quality criteria.

5. Feedback Loop: Use test results to improve processes and materials.

6. Documentation: Maintain records of tests and results for traceability.

By implementing these methods and controls, manufacturers can consistently produce high-quality paper laminate sheets that meet customer expectations and industry standards.

Tips for Procurement and Considerations when Purchasing from paper laminate sheets

When procuring paper laminate sheets, consider the following key tips and considerations:

1. Quality and Durability: Evaluate the thickness and composition of the laminate to ensure it meets your durability requirements. Higher GSM (Grams per Square Meter) typically indicates better quality.

2. Purpose and Application: Determine the intended use of the laminate sheets. Different applications may require specific features such as water resistance, heat resistance, or anti-static properties.

3. Size and Dimensions: Check the size options available and ensure they align with your project needs. Customizable sizing might be necessary for specific applications.

4. Environmental Impact: Assess the environmental credentials of the laminate sheets, including whether they are recyclable or made from sustainable materials.

5. Supplier Reliability: Choose a supplier with a track record of delivering quality products on time. Check reviews and testimonials from other customers if possible.

6. Cost and Budget: Compare prices from different suppliers while considering factors like shipping costs and bulk discounts. Balance cost-effectiveness with quality.

7. Compatibility: Ensure compatibility with other materials or processes involved in your project, such as printing methods or adhesive types.

8. Samples and Testing: Request samples from potential suppliers to test quality and compatibility before making a larger purchase.

9. Customer Support and Service: Opt for suppliers who offer good customer support and assistance, especially if you have specific questions or customization needs.

10. Long-term Availability: Consider the availability of the laminate sheets over time, especially if your project requires consistent supply.

By considering these factors, you can make a more informed decision when purchasing paper laminate sheets, ensuring they meet your project requirements effectively.

FAQs on Sourcing and Manufacturing from paper laminate sheets in China

When sourcing paper laminate sheets from China, consider the following FAQs:

1. What types of paper laminate sheets are available in China?

– China offers a wide range of paper laminate sheets including decorative laminates, industrial laminates, and specialty laminates for various applications.

2. How can I find reliable manufacturers in China?

– Utilize online platforms like Alibaba or Made-in-China to find manufacturers. It’s crucial to vet potential suppliers thoroughly, checking their certifications, customer reviews, and visiting their facilities if possible.

3. What are the typical MOQs (Minimum Order Quantities) when sourcing from China?

– MOQs can vary significantly depending on the manufacturer and the type of laminate. Generally, larger orders result in lower unit costs, so negotiate based on your specific needs.

4. What quality control measures should I consider?

– Implement stringent quality control protocols. This includes requesting samples, conducting factory audits, and establishing clear quality standards in your contract with the manufacturer.

5. How can I manage logistics and shipping from China?

– Work with freight forwarders who specialize in shipping goods from China. Consider factors like shipping costs, transit times, and import duties when planning your logistics.

6. What are the typical payment terms with Chinese manufacturers?

– Payment terms are negotiable but commonly include options like 30% deposit, 70% balance upon shipment. Use secure payment methods and consider using a letter of credit for larger orders.

7. Are there any regulatory considerations when importing paper laminate sheets from China?

– Ensure compliance with local regulations and standards in your country regarding product safety, environmental impact, and import duties.

By addressing these FAQs, you can navigate the process of sourcing and manufacturing paper laminate sheets from China effectively while minimizing risks and ensuring product quality.