Technology and Applications of machining bolts

Machining bolts involves precision engineering to create fasteners with exact specifications for use in various applications. The primary technologies used in machining bolts include:

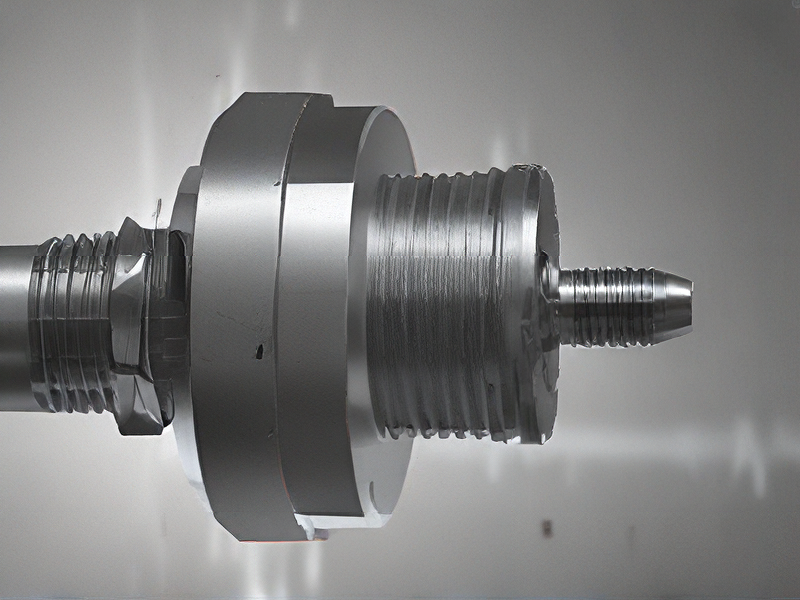

1. CNC Machining: Computer Numerical Control (CNC) machines are widely used for bolt manufacturing. These automated machines provide high precision and repeatability. CNC lathes and milling machines are commonly employed to cut threads, shape bolt heads, and form intricate designs.

2. Thread Rolling: This process involves deforming the bolt’s material using dies to create threads. Unlike cutting, thread rolling compresses and strengthens the material, resulting in a stronger thread profile.

3. Heat Treatment: Bolts often undergo heat treatment to enhance their mechanical properties. Processes such as quenching and tempering improve hardness, strength, and durability, making bolts suitable for high-stress applications.

4. Surface Finishing: Various surface treatments, including coating and plating, are applied to bolts to enhance corrosion resistance and improve aesthetic appeal. Common methods include galvanizing, anodizing, and applying anti-corrosive coatings.

Applications of machined bolts span numerous industries:

– Automotive: Bolts are essential in assembling engine components, chassis, and body parts. High-strength bolts are crucial for safety-critical applications.

– Construction: Structural bolts are used in building frameworks, bridges, and other infrastructure. They ensure stability and safety in construction projects.

– Aerospace: Precision-machined bolts are vital for aircraft assembly, ensuring components are securely fastened in high-stress environments.

– Manufacturing: Machinery and equipment rely on bolts for assembly and maintenance. Custom bolts are often used in specialized machinery.

– Marine: Corrosion-resistant bolts are used in shipbuilding and offshore structures, where exposure to saltwater demands high durability.

In summary, the machining of bolts involves advanced technologies like CNC machining, thread rolling, heat treatment, and surface finishing, making them integral to various high-performance applications across industries.

Quality Testing Methods for machining bolts and how to control quality

Quality testing methods for machining bolts typically involve both dimensional checks and performance evaluations. Here are key methods:

1. Dimensional Inspection: Using calipers, micrometers, and gauges to measure critical dimensions like length, diameter, thread pitch, and head dimensions.

2. Surface Finish Analysis: Utilizing profilometers to ensure surface roughness meets specifications, crucial for functionality and appearance.

3. Thread Verification: Gauge measurement to confirm accurate thread pitch, depth, and profile conform to standards (e.g., ISO metric threads).

4. Hardness Testing: Rockwell or Brinell tests to verify material hardness, ensuring it meets strength requirements.

5. Torque-Tension Testing: Evaluating bolt performance under load to ensure it can achieve specified clamping force without failure.

To control quality:

– Statistical Process Control (SPC): Monitoring key dimensions during production to detect variations and maintain consistency.

– Quality Management Systems (QMS): Implementing ISO 9001 standards to ensure systematic quality control processes.

– Supplier Quality Assurance: Auditing and qualifying suppliers to ensure raw materials meet required standards.

– Employee Training: Continuous training to maintain skill levels and awareness of quality standards.

– Root Cause Analysis: Investigating defects to identify and eliminate underlying causes.

By implementing these methods and controls, manufacturers can ensure that machined bolts meet required specifications consistently, minimizing defects and ensuring customer satisfaction.

Tips for Procurement and Considerations when Purchasing from machining bolts

Tips for Procurement and Considerations when Purchasing Machined Bolts

1. Specification Clarity: Ensure that the specifications for the bolts, such as material grade, size, threading, and tolerances, are clear and well-documented. This reduces the risk of receiving incorrect or substandard parts.

2. Supplier Selection: Choose suppliers with a solid reputation and proven track record in producing high-quality machined bolts. Look for certifications like ISO 9001 to ensure quality management standards.

3. Quality Control: Implement stringent quality control measures. This includes requesting sample bolts for initial inspection, conducting random checks on batches, and ensuring that the supplier adheres to the agreed specifications.

4. Material Certification: Request material certifications to verify that the bolts are made from the specified materials. This is crucial for applications requiring high strength or corrosion resistance.

5. Cost vs. Quality: Balance cost with quality. Cheaper bolts may save money initially but could lead to higher costs if they fail prematurely. Consider the total cost of ownership rather than just the purchase price.

6. Lead Times: Account for lead times in your procurement planning. Machined bolts can have long production times, especially if they require custom specifications. Ensure your supplier can meet your timeline requirements.

7. Communication: Maintain clear and open communication with your supplier. Regular updates and check-ins can help address any issues promptly and keep the production on track.

8. Documentation: Ensure all agreements, specifications, and requirements are documented and signed off by both parties. This helps prevent misunderstandings and provides a clear reference in case of disputes.

9. Logistics and Packaging: Consider the logistics and packaging of the bolts. Proper packaging prevents damage during transit, and efficient logistics ensure timely delivery.

10. After-Sales Support: Choose suppliers that offer robust after-sales support, including handling any issues with defects or non-conformities promptly.

By following these tips, you can enhance the procurement process, ensuring you receive high-quality machined bolts that meet your requirements and support your operations effectively.

FAQs on Sourcing and Manufacturing from machining bolts in China

When sourcing and manufacturing machining bolts in China, several FAQs commonly arise:

1. Quality Assurance: How can I ensure the quality of bolts manufactured in China?

– Answer: Partner with suppliers who have certifications like ISO 9001 and conduct regular quality inspections.

2. Communication: How do I overcome language barriers when discussing specifications?

– Answer: Utilize clear, detailed technical drawings and consider hiring a translator or using translation services.

3. Lead Times: What are typical lead times for manufacturing machining bolts in China?

– Answer: Lead times vary but generally range from 4-8 weeks, depending on complexity and order volume.

4. Minimum Order Quantities (MOQs): What are the MOQs for machining bolts in China?

– Answer: MOQs also vary but are often negotiable. They can range from hundreds to thousands of units.

5. Costs: How do costs compare with other manufacturing regions?

– Answer: China often offers competitive pricing due to economies of scale and lower labor costs, but prices can fluctuate with material costs and market conditions.

6. Intellectual Property (IP) Protection: How can I protect my designs and IP when manufacturing in China?

– Answer: Use non-disclosure agreements (NDAs) and consider registering patents or designs in China.

7. Logistics and Shipping: What are the logistics considerations for importing bolts from China?

– Answer: Plan for shipping costs, customs duties, and transportation logistics which can impact overall costs and timelines.

Navigating these considerations with due diligence and clear communication will help ensure successful sourcing and manufacturing of machining bolts from China.