Technology and Applications of laser cutting acrylic sheets

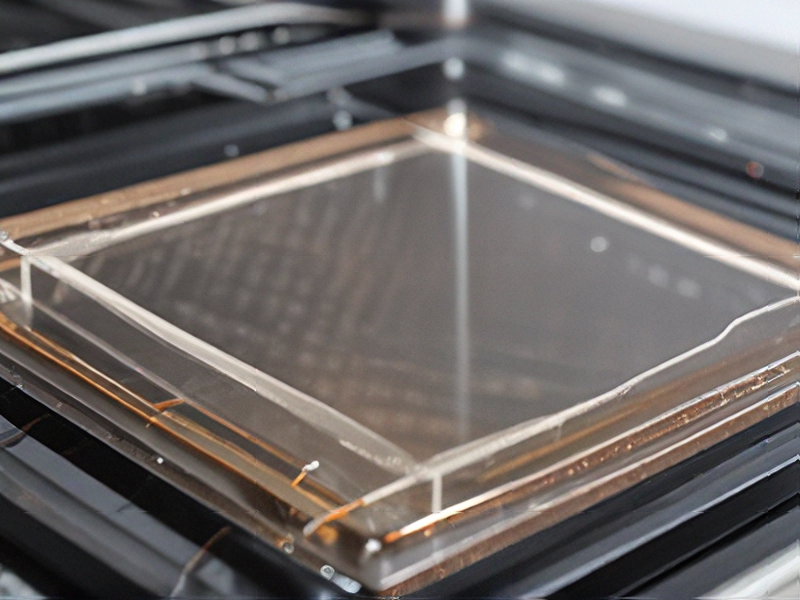

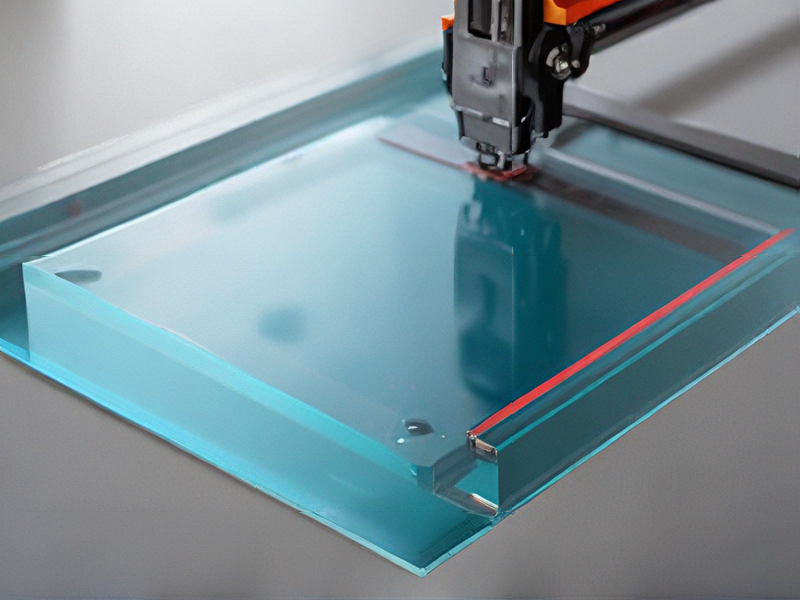

Laser cutting acrylic sheets is widely used across industries due to its precision and versatility. A laser beam, guided by CAD software, melts or vaporizes the acrylic along the cutting path, resulting in smooth edges without physical contact. This method allows for intricate designs and shapes, making it ideal for signage, displays, and intricate parts in industries such as automotive, electronics, and crafts.

Key advantages include high precision (up to 0.1 mm), minimal material wastage, and the ability to cut complex shapes quickly. The process is also non-contact, reducing the risk of material deformation. Different types of lasers (CO2 and fiber) are used depending on thickness and required edge finish.

Applications range from architectural models to intricate jewelry due to the clean finish and ability to create small details. In electronics, acrylic parts can be precisely cut for prototypes or housings. In signage and displays, laser cutting allows for custom logos and lettering with polished edges that enhance visual appeal.

However, considerations such as laser power settings and material thickness affect cutting quality. Safety measures for handling acrylic fumes are also crucial. Overall, laser cutting acrylic sheets combines precision, versatility, and speed, making it indispensable across various manufacturing and design sectors.

Quality Testing Methods for laser cutting acrylic sheets and how to control quality

Quality testing for laser-cut acrylic sheets involves several methods to ensure precision, accuracy, and overall quality. Here are some effective approaches:

1. Visual Inspection: Immediately after cutting, perform a visual inspection for any defects such as burns, cracks, or irregular edges. This is the simplest and quickest method to identify superficial flaws.

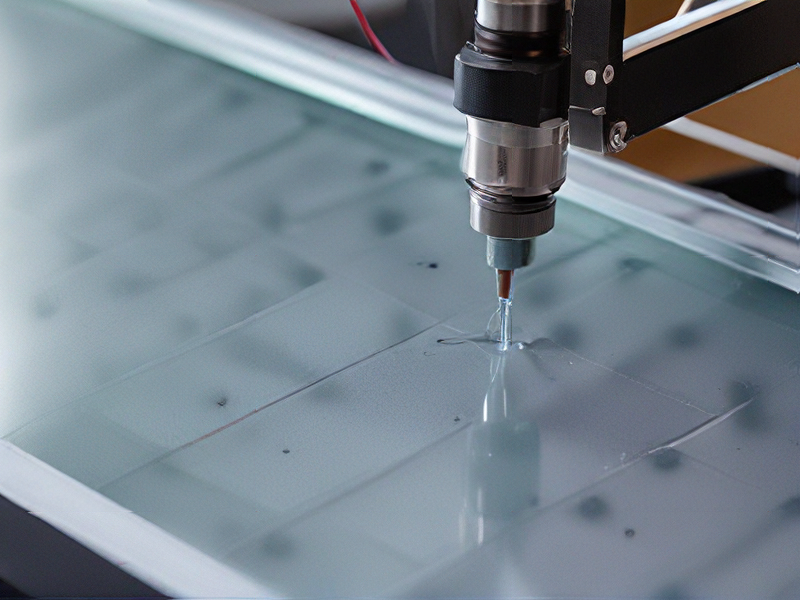

2. Dimensional Accuracy: Use digital calipers or micrometers to measure the dimensions of the acrylic pieces. Compare the measurements against the design specifications to ensure they are within acceptable tolerance levels.

3. Edge Quality Assessment: Assess the edge finish of the acrylic. A clean, polished edge indicates good cutting quality, while charred or melted edges may suggest overheating or improper settings during the cutting process.

4. Thickness Measurement: Use a micrometer to measure the thickness of the acrylic sheets in various spots. Consistency in thickness is crucial for applications where uniformity is required.

5. Mechanical Testing: Conduct stress tests or impact tests to evaluate the acrylic’s durability and resistance to breakage. This is particularly important for applications requiring structural integrity.

6. Environmental Testing: For applications exposed to varying conditions, test the acrylic sheets for UV resistance, moisture absorption, and temperature stability.

Quality Control Measures:

– Standard Operating Procedures (SOPs): Establish SOPs for the laser cutting process to minimize variability and ensure consistency.

– Calibration of Equipment: Regularly calibrate laser cutting equipment to maintain precision in cutting settings.

– Training: Provide training for operators on best practices for handling and cutting acrylic.

– Documentation: Maintain detailed records of inspections and measurements to identify patterns or recurring issues, facilitating continuous improvement.

By implementing these methods and controls, manufacturers can enhance the quality of laser-cut acrylic sheets and reduce waste.

Tips for Procurement and Considerations when Purchasing from laser cutting acrylic sheets

When procuring and purchasing laser-cut acrylic sheets, consider the following tips and considerations to ensure quality and efficiency:

1. Quality of Acrylic Sheets

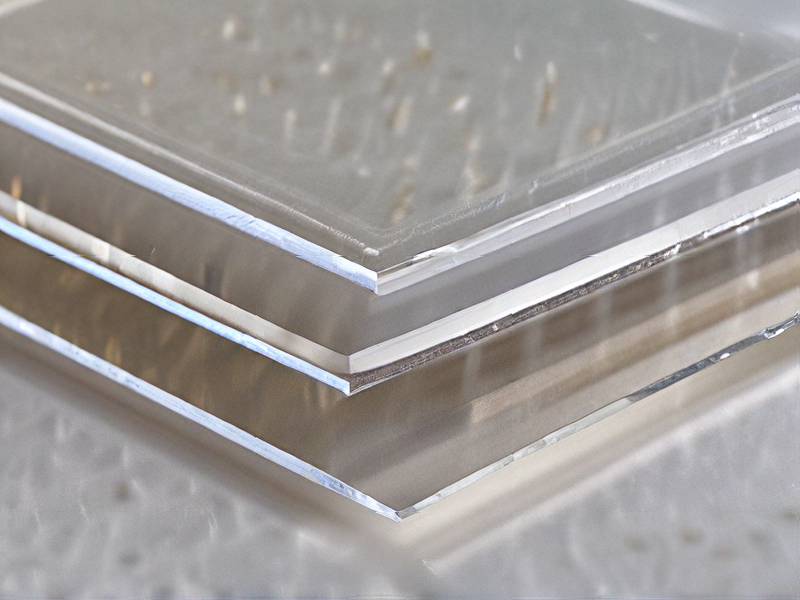

– Material Grade: Ensure the acrylic sheets are of high quality and suitable for laser cutting. Opt for cast acrylic rather than extruded acrylic for better results.

– Thickness Consistency: Verify the thickness uniformity across the sheets, as inconsistency can affect the precision of laser cuts.

2. Supplier Evaluation

– Reputation and Reviews: Choose suppliers with a strong reputation and positive customer reviews to guarantee reliable service and quality.

– Certifications: Look for suppliers with relevant certifications, such as ISO standards, indicating adherence to quality and safety guidelines.

3. Laser Cutting Specifications

– Machine Compatibility: Ensure the acrylic sheets are compatible with your laser cutting machine, considering factors like sheet size and material properties.

– Cutting Tolerances: Discuss the cutting tolerances with the supplier to meet your design requirements accurately.

4. Cost Considerations

– Bulk Purchasing: Negotiate for discounts on bulk purchases to reduce costs. However, ensure the large quantities meet your quality standards.

– Shipping and Handling: Consider shipping costs and ensure the supplier packages the acrylic sheets properly to avoid damage during transit.

5. Sustainability

– Eco-Friendly Options: Opt for suppliers offering eco-friendly acrylic options to align with sustainability goals.

– Waste Management: Plan for efficient waste management and recycling of acrylic offcuts to minimize environmental impact.

6. Customer Support

– Technical Assistance: Choose suppliers who offer robust customer support, including technical assistance for troubleshooting laser cutting issues.

– After-Sales Service: Ensure the supplier provides good after-sales service, including handling returns or replacements of defective sheets.

By considering these factors, you can optimize the procurement process, ensuring high-quality laser-cut acrylic sheets that meet your specific needs and contribute to the success of your projects.

FAQs on Sourcing and Manufacturing from laser cutting acrylic sheets in China

FAQs on Sourcing and Manufacturing Laser-Cut Acrylic Sheets in China

#### 1. Why Source Acrylic Sheets from China?

China offers competitive pricing, advanced manufacturing technology, and a wide range of suppliers. The extensive production capacity ensures efficient fulfillment of large orders.

#### 2. How to Find Reliable Suppliers?

Utilize platforms like Alibaba, Made-in-China, and Global Sources. Look for suppliers with positive reviews, verified status, and experience in exporting. Conduct thorough due diligence, including factory audits if possible.

#### 3. What are the Common Thicknesses and Sizes?

Acrylic sheets typically come in thicknesses ranging from 1mm to 25mm. Standard sizes include 4×8 feet (1220×2440 mm) and custom sizes can be requested.

#### 4. What Quality Standards Should Be Expected?

Look for suppliers that comply with ISO certifications and offer products adhering to international standards like ASTM and RoHS. Ensure the supplier provides quality assurance checks and sample testing.

#### 5. What Are the Typical Lead Times?

Lead times vary but generally range from 15 to 30 days depending on the order size and customization requirements. Always confirm with the supplier beforehand.

#### 6. How to Handle Shipping and Logistics?

Choose between shipping methods like FOB (Free On Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Engage a reliable freight forwarder to manage shipping logistics and customs clearance.

#### 7. What Are the Payment Terms?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and D/P (Documents Against Payment). Initial orders might require a 30% deposit, with the balance paid before shipment.

#### 8. How to Address Quality Issues?

Establish clear quality agreements and inspection protocols. Consider third-party inspections before shipment. Maintain open communication with the supplier to resolve any issues promptly.

#### 9. What Customization Options Are Available?

Suppliers can offer various customization options, including different colors, finishes (matte, glossy), and cutting shapes. Provide detailed specifications and drawings for precise customization.

#### 10. How to Ensure Sustainable and Ethical Sourcing?

Verify the supplier’s environmental and labor practices. Look for certifications like ISO 14001 for environmental management and SA8000 for social accountability.

By following these guidelines, you can effectively source high-quality laser-cut acrylic sheets from China while minimizing risks and ensuring smooth manufacturing processes.