Technology and Applications of properties of copper metal

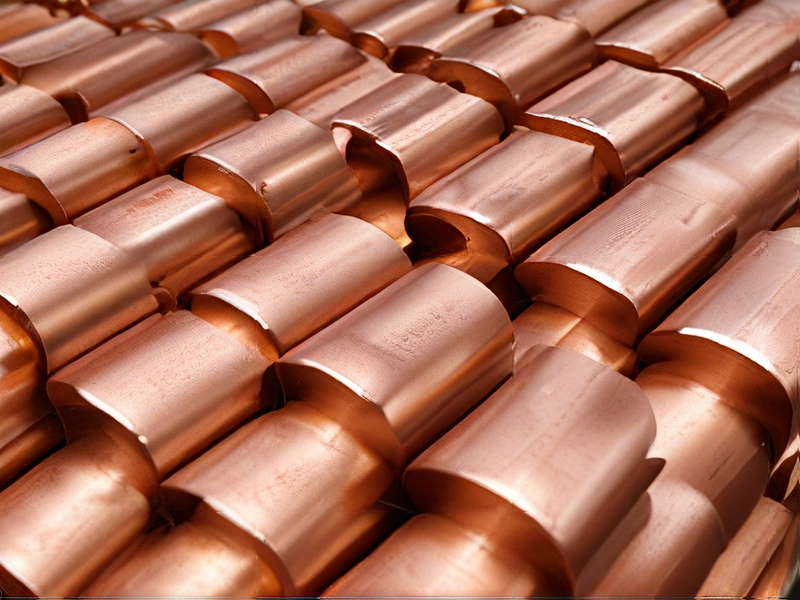

Copper, known for its excellent electrical conductivity and corrosion resistance, finds extensive applications in various technologies. In electrical wiring and electronics, copper’s conductivity allows for efficient transmission of electricity with minimal energy loss, making it indispensable in power cables, transformers, and printed circuit boards. Its ductility enables easy shaping into wires and intricate components, crucial for miniaturized electronics.

In construction, copper’s durability and aesthetic appeal make it ideal for roofing, gutters, and architectural detailing. Its antimicrobial properties also find use in healthcare settings, where copper surfaces inhibit bacterial growth, contributing to improved hygiene.

In industrial applications, copper’s heat conductivity supports its use in heat exchangers, boilers, and radiators. Additionally, its malleability facilitates forming into pipes and fittings for plumbing systems.

In renewable energy technologies, such as solar panels and wind turbines, copper’s conductivity supports efficient energy generation and transmission. Its reliability in harsh environments ensures longevity and performance sustainability.

In conclusion, copper’s blend of electrical, mechanical, and antimicrobial properties makes it indispensable across diverse industries, supporting technological advancements in energy, construction, and healthcare sectors.

Quality Testing Methods for properties of copper metal and how to control quality

Quality testing methods for copper metal typically include both destructive and non-destructive techniques to ensure various properties are within specified limits.

1. Chemical Composition Analysis: This involves spectroscopic methods such as ICP-OES (Inductively Coupled Plasma – Optical Emission Spectroscopy) or XRF (X-ray Fluorescence) to determine elemental composition, ensuring copper purity and alloy consistency.

2. Mechanical Properties Testing: Methods like tensile testing assess strength, ductility, and elasticity. Hardness testing (e.g., Brinell, Rockwell) measures resistance to deformation under controlled conditions.

3. Microstructural Analysis: Microscopy techniques (optical or electron microscopy) examine grain size, phase distribution, and inclusion content, crucial for assessing material integrity and processing effects.

4. Dimensional Inspection: Precision tools ensure components meet dimensional specifications, crucial for parts compatibility and assembly.

5. Non-Destructive Testing (NDT): Techniques like ultrasonic testing (UT) and eddy current testing (ECT) detect surface and subsurface defects without damaging the material, ensuring structural integrity.

Quality Control Measures:

– Process Control: Implementing standardized procedures and protocols to minimize variations in manufacturing.

– Statistical Process Control (SPC): Monitoring key process parameters to detect deviations and ensure consistent quality.

– Certification and Standards Compliance: Adhering to international standards (e.g., ASTM, ISO) ensures product reliability and customer satisfaction.

By integrating these methods into quality assurance practices, manufacturers can maintain high standards for copper metal products, meeting stringent industry requirements and customer expectations effectively.

Tips for Procurement and Considerations when Purchasing from properties of copper metal

Tips for Procurement of Copper Metal

1. Supplier Selection:

– Reputation and Reliability: Choose suppliers with a strong track record and good reviews.

– Quality Assurance: Ensure they provide certifications like ISO 9001.

2. Pricing and Contracts:

– Market Analysis: Understand market trends to negotiate favorable terms.

– Long-term Contracts: Consider long-term contracts to lock in prices and ensure supply stability.

3. Specifications and Standards:

– Grade and Purity: Specify the required copper grade (e.g., C11000 for electrolytic tough pitch copper) and purity.

– Compliance: Ensure materials meet industry standards (e.g., ASTM, ISO).

4. Inventory Management:

– Demand Forecasting: Accurately predict usage to optimize inventory levels.

– Just-in-Time (JIT): Implement JIT procurement to reduce holding costs.

5. Sustainability:

– Recycled Copper: Consider using recycled copper to reduce environmental impact.

– Eco-friendly Suppliers: Partner with suppliers who follow sustainable practices.

Considerations When Purchasing Copper Metal

1. Physical Properties:

– Conductivity: Copper’s high electrical and thermal conductivity makes it ideal for electrical wiring and heat exchangers.

– Corrosion Resistance: Its resistance to corrosion ensures longevity in plumbing and roofing applications.

– Ductility and Malleability: Copper’s ability to be easily shaped is crucial for applications requiring intricate designs.

2. Mechanical Properties:

– Tensile Strength: Evaluate tensile strength for applications needing structural integrity.

– Fatigue Resistance: Important for components subjected to repeated stress.

3. Environmental Conditions:

– Oxidation: Copper can oxidize, forming a green patina. This can be protective or aesthetic, depending on the application.

– Temperature Variations: Copper retains its properties over a wide temperature range.

4. Economic Factors:

– Price Volatility: Copper prices can be volatile due to market demand and geopolitical factors.

– Life-cycle Costs: Consider total cost of ownership, including maintenance and longevity.

5. Regulatory Compliance:

– RoHS and REACH: Ensure compliance with regulations restricting hazardous substances.

By carefully considering these factors, you can make informed decisions and optimize the procurement process for copper metal.

FAQs on Sourcing and Manufacturing from properties of copper metal in China

Certainly! Here are some frequently asked questions (FAQs) on sourcing and manufacturing from properties of copper metal in China:

1. Why source copper from China?

China is a leading global producer of copper, offering competitive pricing and a robust supply chain. Its manufacturing infrastructure supports various industries, ensuring scalability and reliability.

2. What are the key properties of Chinese copper?

Chinese copper is known for its high conductivity, corrosion resistance, and malleability, making it ideal for electrical wiring, plumbing, and industrial applications.

3. How can I ensure quality when sourcing copper from China?

Choose suppliers with ISO certifications and a proven track record. Conduct factory audits and request samples for testing to verify compliance with international standards.

4. What are the typical manufacturing processes used in China for copper products?

Processes include smelting, refining, and extrusion. Advanced techniques like continuous casting ensure consistent quality and precise dimensions for various copper components.

5. Are there environmental considerations when sourcing copper from China?

Chinese regulations enforce strict environmental standards in copper production. Look for suppliers committed to sustainable practices and compliance with local laws.

6. How can I navigate logistical challenges when importing copper from China?

Work with experienced freight forwarders and customs brokers to manage shipping logistics efficiently. Plan for potential delays and ensure compliance with import regulations.

By addressing these FAQs, businesses can make informed decisions when sourcing and manufacturing copper products in China, ensuring both quality and efficiency in their operations.