Technology and Applications of g codes of cnc

G-codes are essential in computer numerical control (CNC) machines for controlling tool movement and operations. They consist of letter-addressed commands followed by numerical values, directing CNC machines on how to perform tasks such as cutting, drilling, and shaping materials like metal, wood, or plastic.

Key Applications:

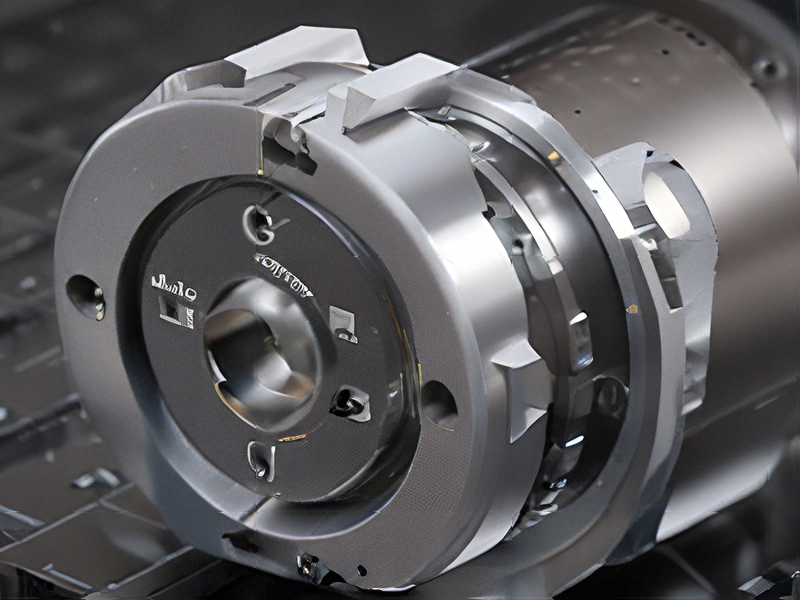

1. Tool Path Control: G-codes dictate tool movement along axes (X, Y, Z), specifying coordinates and speeds. This ensures precise cutting or shaping of workpieces as per design specifications.

2. Speed and Feed Control: Commands like G00 (rapid move) and G01 (linear interpolation) regulate tool speed and material feed rate. This prevents tool wear and enhances machining efficiency.

3. Tool Changes: G-codes manage tool changes (e.g., G43 for tool length compensation), optimizing machining continuity and accuracy during complex operations.

4. Cycle Control: G-codes facilitate repetitive operations (e.g., drilling cycles with G81), automating tasks and reducing manual intervention.

5. Coordinate System Management: Commands like G54-G59 set workpiece coordinate origins, allowing machines to reference different points on the workpiece for varied machining operations.

Technological Impact:

– Precision: G-codes ensure high accuracy and repeatability, critical for manufacturing components with tight tolerances.

– Automation: CNC machines execute complex operations autonomously based on programmed G-code sequences, reducing labor-intensive tasks.

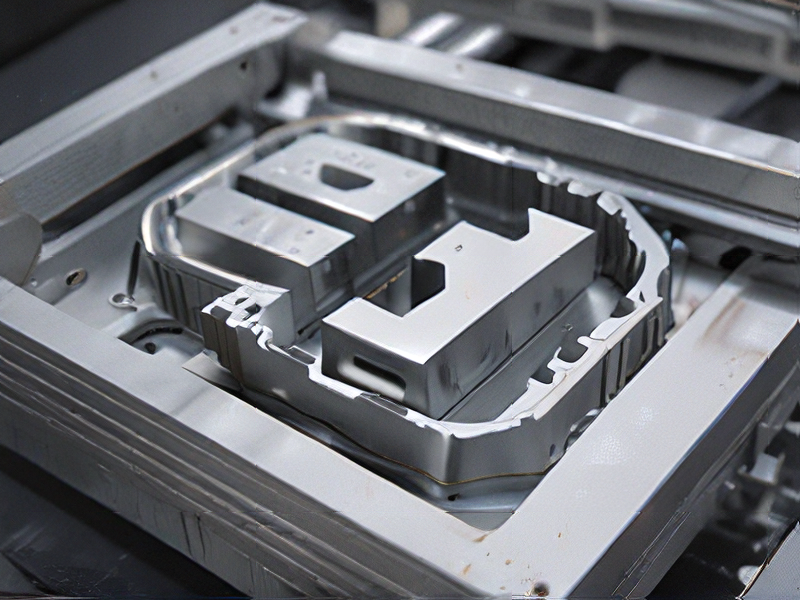

– Versatility: G-codes support various machining tasks across industries, from aerospace parts to intricate molds and prototypes.

Future Trends:

– Integration with CAD/CAM: Enhanced compatibility with design software streamlines production processes and improves machining accuracy.

– IoT and Connectivity: Integration with Internet of Things (IoT) enables real-time monitoring and data-driven optimization of CNC operations.

In conclusion, G-codes are pivotal in CNC machining, offering precise control over tool movements and operations, thereby driving efficiency, accuracy, and automation in modern manufacturing processes.

Quality Testing Methods for g codes of cnc and how to control quality

Quality Testing Methods for G Codes in CNC:

1. Simulation Software:

– Use simulation software (e.g., CIMCO, NCViewer) to visualize and verify the G-code before actual machining. This helps detect errors in tool paths, collisions, and unexpected movements.

2. Dry Run:

– Perform a dry run on the CNC machine without material. This allows observation of the machine’s behavior and ensures that the code executes as intended without causing damage.

3. Verification Programs:

– Utilize verification programs to compare the G-code with the original CAD model. These programs check for discrepancies and ensure the code produces the desired outcome.

4. Post-Processor Validation:

– Ensure that the post-processor generating the G-code from CAM software is correctly configured. This validation ensures the G-code is optimized and compatible with the specific CNC machine.

5. Toolpath Inspection:

– Manually inspect critical sections of the G-code for correctness, focusing on tool changes, feeds, speeds, and movement commands.

6. Automated Testing:

– Implement automated testing scripts that can run predefined scenarios to validate the G-code against common errors and best practices.

Quality Control Methods:

1. Documentation and Standards:

– Maintain detailed documentation of coding standards and best practices. Ensure all G-code adheres to these standards to minimize errors.

2. Peer Reviews:

– Conduct peer reviews where experienced CNC programmers review the G-code. This collaborative approach can identify potential issues that automated tools might miss.

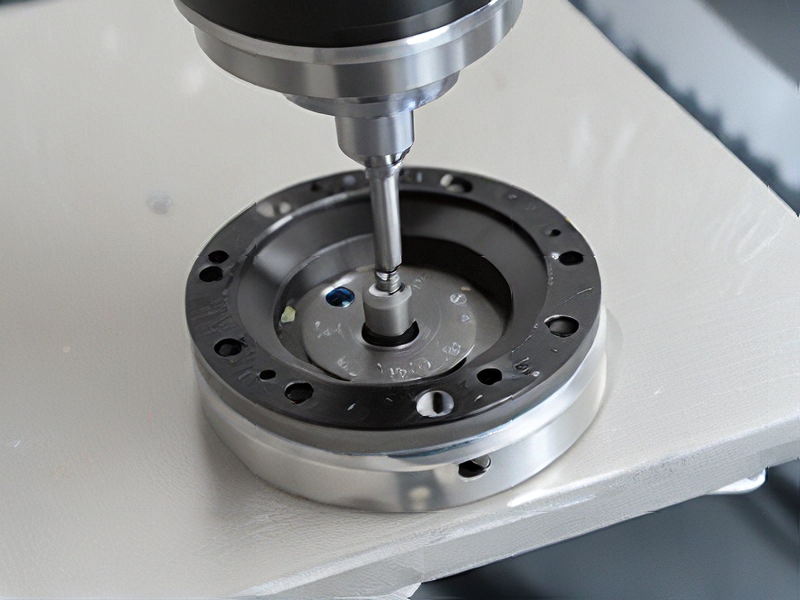

3. Regular Calibration:

– Regularly calibrate CNC machines to ensure they operate within specified tolerances. Calibration helps maintain the accuracy and reliability of the machine output.

4. Training and Skill Development:

– Continuously train CNC programmers and operators on the latest software tools, coding standards, and machine operations to reduce human error.

5. Feedback Loops:

– Establish a feedback loop where operators provide input on the performance of G-codes. Use this feedback to refine coding practices and improve future G-code quality.

By implementing these methods, the quality and reliability of G-codes for CNC machining can be significantly enhanced, leading to more accurate and efficient manufacturing processes.

Tips for Procurement and Considerations when Purchasing from g codes of cnc

When purchasing CNC equipment, especially focusing on G-codes, consider these tips:

1. Understanding G-codes: Familiarize yourself with commonly used G-codes relevant to your CNC operations. These codes dictate machine movements, tool changes, and other functions critical to machining processes.

2. Machine Compatibility: Ensure the G-codes you intend to use are compatible with your CNC machine’s controller. Different machines may interpret G-codes differently or have specific limitations.

3. Software Compatibility: Verify that your CAM (Computer-Aided Manufacturing) software generates G-codes compatible with your CNC machine. This ensures seamless operation and prevents errors during machining.

4. Training and Skill Requirements: Assess the skill level of your operators. Understanding G-codes requires training and experience in CNC programming and operation. Consider investing in training programs if needed.

5. Documentation and Support: Choose suppliers or manufacturers who provide comprehensive documentation on G-codes and offer reliable technical support. This ensures quick resolution of issues and efficient operation.

6. Cost and Value: Evaluate the cost of CNC equipment in relation to its features, including G-code compatibility. Opt for machines that offer the best value for your specific manufacturing needs.

7. Future Expansion: Consider future needs for your CNC operations. Ensure the equipment and G-codes you invest in can accommodate future growth and technological advancements.

By focusing on these considerations, you can make informed decisions when purchasing CNC equipment, specifically concerning G-codes, optimizing efficiency and productivity in your manufacturing processes.

FAQs on Sourcing and Manufacturing from g codes of cnc in China

Certainly! When sourcing and manufacturing CNC components in China, understanding G-codes is crucial. Here are FAQs to guide you:

1. What are G-codes in CNC machining?

G-codes are commands used to control CNC machines. They dictate tool movement, speed, and operations like drilling or cutting.

2. How do I ensure quality when sourcing from China?

Choose suppliers with ISO certifications and a track record of quality. Request samples and conduct inspections before full production.

3. What are common challenges in CNC manufacturing in China?

Communication barriers, cultural differences, and intellectual property protection are common challenges. Clear contracts and regular communication can mitigate risks.

4. How can I protect my designs and intellectual property?

Utilize non-disclosure agreements (NDAs), work with reputable manufacturers, and consider registering your designs and patents in China.

5. What are typical lead times for CNC manufacturing in China?

Lead times vary based on complexity and volume but typically range from a few weeks to several months. Clarify lead times and production schedules with your supplier.

6. What are the advantages of sourcing CNC components from China?

Lower production costs, access to advanced machining technologies, and a wide range of material options are key advantages.

7. How do I handle logistics and shipping?

Work with freight forwarders experienced in shipping from China. Plan for potential delays and customs procedures.

8. What are the payment terms usually negotiated?

Payment terms often include a deposit upfront with the balance paid upon completion or shipment. Negotiate terms that align with your cash flow and risk tolerance.

9. How can I stay updated on industry trends and regulations in China?

Engage with industry associations, attend trade shows, and stay informed through online resources and professional networks.

10. What steps should I take if issues arise during manufacturing?

Maintain open communication with your supplier, document issues, and work together to find solutions promptly.

Navigating sourcing and manufacturing in China requires diligence, clear communication, and a proactive approach to quality control and intellectual property protection.