Technology and Applications of enamel paint metal

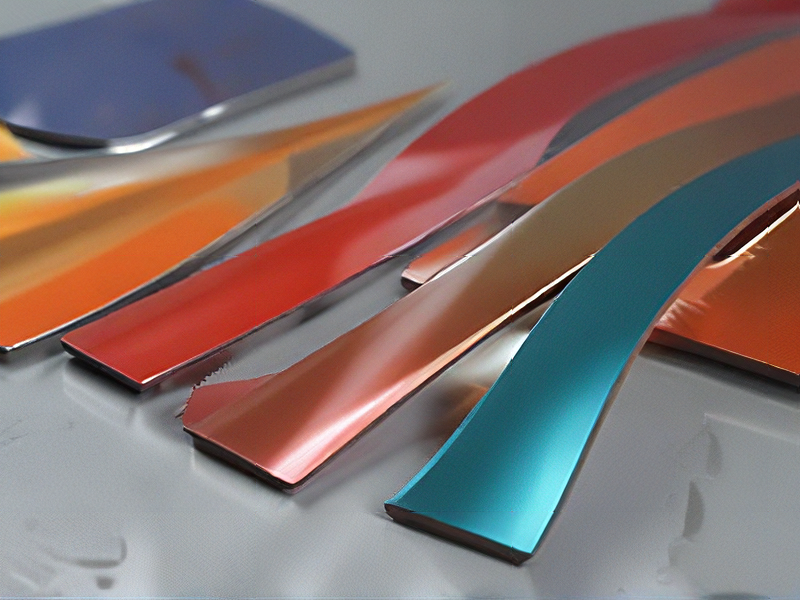

Enamel paint is a durable coating that provides a hard, glossy finish, making it ideal for various metal applications. Its formulation typically includes resins, pigments, and solvents, which create a tough, weather-resistant layer when cured. The primary technology behind enamel paints involves the use of alkyd or oil-based compositions, as well as newer water-based alternatives that combine environmental benefits with performance.

One of the most significant advantages of enamel paint on metal surfaces is its excellent adhesion, which prevents peeling and chipping. This makes it suitable for a range of applications, including home appliances, automotive finishes, and industrial equipment. The glossy finish not only enhances aesthetics but also simplifies cleaning, as dirt and grime do not cling easily to the smooth surface.

Enamel paints can be used for both indoor and outdoor applications. Outdoor products are often formulated with UV resistance, ensuring that the colors remain vibrant over time even when exposed to sunlight. Additionally, many enamel paints are resistant to moisture and chemicals, making them ideal for environments subject to harsh conditions.

Application methods for enamel paints vary, including spraying, brushing, and rolling, allowing for versatility based on the surface area and desired finish. Advanced formulations may also incorporate specialized additives that improve drying time and further enhance durability.

Overall, the technology and application of enamel paint on metal surfaces cater to industries and consumers seeking long-lasting, visually appealing, and protective finishes, making it a popular choice in diverse settings.

Quality Testing Methods for enamel paint metal and how to control quality

Quality testing methods for enamel paint on metal typically involve both visual inspections and various physical tests to ensure durability, appearance, and adherence to standards. Here are key methods and quality control measures:

1. Visual Inspection:

– Color Consistency: Compare paint color against a standard under controlled lighting conditions.

– Surface Finish: Check for smoothness, glossiness, and absence of defects like bubbles or brush marks.

– Uniformity: Ensure paint coverage is even without patches or thin spots.

2. Adhesion Testing:

– Cross-Hatch Test: Score the painted surface in a cross-hatch pattern and apply tape to check paint adhesion.

– Pull-off Test: Use a device to measure the force required to pull off the paint from the metal substrate.

3. Physical Property Tests:

– Hardness Test: Measure the resistance of the paint film to indentation or scratching.

– Impact Resistance: Evaluate the paint’s ability to withstand impact without cracking or chipping.

– Flexibility Test: Assess the paint’s ability to endure bending or flexing without flaking.

4. Chemical Resistance:

– Expose painted samples to chemicals like solvents or cleaners to assess resistance to staining or deterioration.

5. Durability Testing:

– Weather Resistance: Subject samples to accelerated weathering tests (e.g., UV exposure, humidity cycles) to simulate long-term outdoor exposure.

– Corrosion Resistance: Evaluate the paint’s ability to protect the metal from corrosion.

6. Quality Control Measures:

– Standard Operating Procedures (SOPs): Establish detailed protocols for application, drying, and testing.

– Regular Inspections: Conduct frequent checks during production to catch defects early.

– Calibration of Equipment: Ensure testing instruments are calibrated regularly for accuracy.

By employing these methods and measures, manufacturers can maintain consistent quality in enamel paint for metal, ensuring it meets customer expectations and industry standards for durability, appearance, and performance.

Tips for Procurement and Considerations when Purchasing from enamel paint metal

When procuring enamel paint for metal surfaces, consider these key tips and factors to ensure a successful purchase:

1. Surface Compatibility: Verify that the enamel paint is specifically formulated for metal surfaces. Different types of enamel paints are designed for various materials, and using the correct type ensures adhesion and durability.

2. Durability and Resistance: Assess the paint’s resistance to weather conditions, chemicals, and abrasion. For outdoor applications or areas exposed to harsh environments, choose paints with high durability and UV resistance.

3. Application Method: Determine the application method suitable for your project—whether brushing, spraying, or dipping. Ensure the paint you select is compatible with your preferred application technique to achieve the desired finish.

4. Color and Finish Options: Enamel paints offer various color options and finishes (gloss, semi-gloss, matte). Consider the aesthetic requirements and functional needs of your project when selecting the color and finish of the paint.

5. Coverage and Yield: Check the coverage area and yield of the paint to estimate the quantity required for your project accurately. This helps in budgeting and preventing excess or shortage of paint.

6. Drying Time and Cure Time: Understand the drying time and cure time of the enamel paint. This information is crucial for scheduling subsequent coats and handling the painted metal without causing damage.

7. Environmental Considerations: Verify if the paint meets environmental standards and regulations, especially if you are working on projects with specific environmental requirements or certifications.

8. Brand Reputation and Reviews: Research the reputation of the paint brand and read reviews from other users to gauge performance, ease of application, and long-term durability.

9. Cost and Budget: Compare prices among different brands while considering the quality and performance factors. Balance cost-effectiveness with the desired quality and longevity of the paint.

10. Storage and Shelf Life: Check storage recommendations and the shelf life of the enamel paint. Proper storage ensures the paint remains usable and effective throughout its shelf life.

By considering these factors, you can make an informed decision when purchasing enamel paint for metal surfaces, ensuring that it meets your project’s requirements for durability, aesthetic appeal, and ease of application.

FAQs on Sourcing and Manufacturing from enamel paint metal in China

Certainly! When sourcing enamel paint for metal from China, consider these FAQs:

1. What are the key considerations when choosing a manufacturer in China?

– Look for manufacturers with experience in enamel paint production for metal.

– Ensure they adhere to quality standards and have certifications relevant to your market.

2. How can I verify the quality of enamel paint from Chinese manufacturers?

– Request samples for testing to ensure they meet your specifications.

– Conduct factory visits or audits to assess production processes and quality control measures.

3. What are the typical lead times and MOQs (Minimum Order Quantities)?

– Lead times can vary but typically range from a few weeks to a couple of months.

– MOQs depend on the manufacturer but are often negotiable based on your needs.

4. How can I ensure intellectual property protection when dealing with Chinese manufacturers?

– Use clear contracts that include clauses on IP protection and confidentiality.

– Consider working with manufacturers who have a reputation for respecting IP rights.

5. What are the common challenges when sourcing enamel paint from China?

– Language barriers and cultural differences may affect communication.

– Logistics and shipping can be complex; consider working with a freight forwarder.

6. Are there any environmental or regulatory considerations?

– Ensure manufacturers comply with local environmental regulations.

– Verify that the enamel paint formulations meet relevant safety standards.

By addressing these FAQs, you can navigate the sourcing and manufacturing process of enamel paint for metal in China more effectively while minimizing risks and ensuring product quality and compliance.