Technology and Applications of cnc m code g code

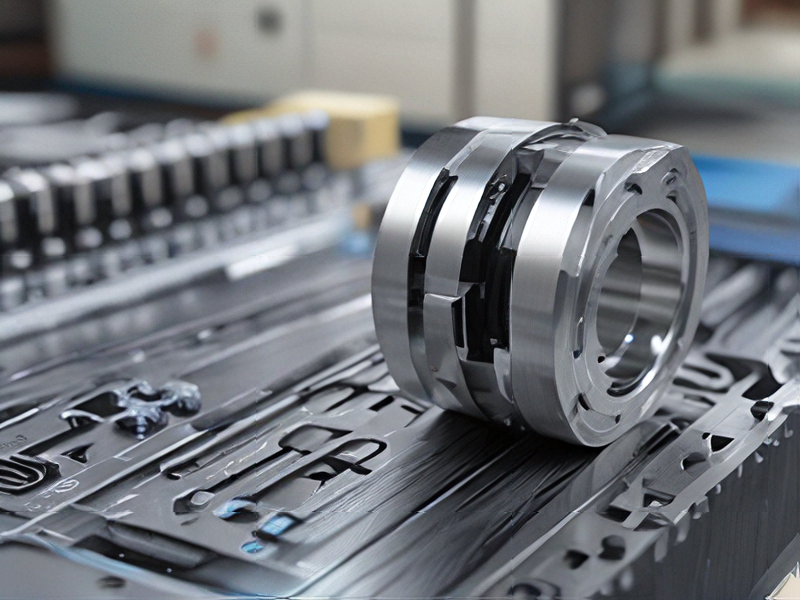

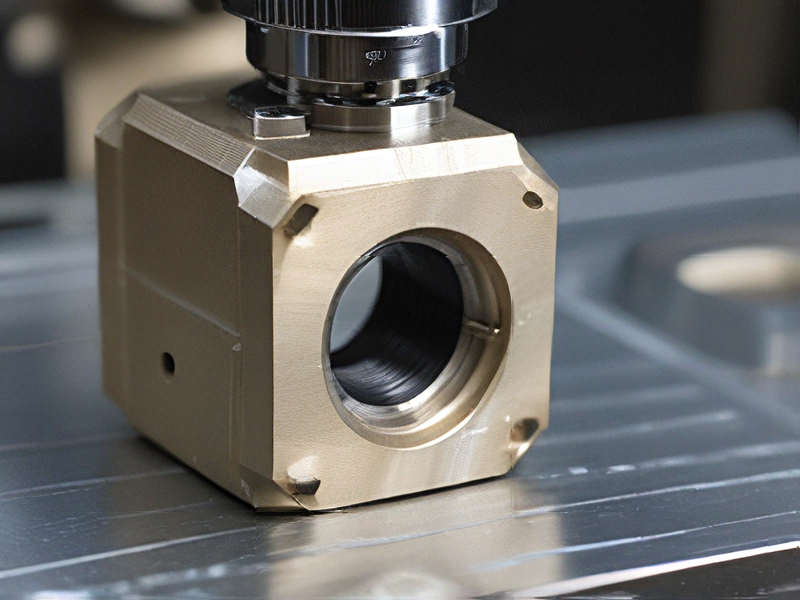

CNC (Computer Numerical Control) machines rely on G-code and M-code to operate and control their movements and functions. G-code, a programming language, dictates the precise movements, speeds, and positions of the machine’s tools and workpiece. It controls actions like linear and circular interpolation, tool changes, and coolant activation. Each command begins with a letter (G) followed by a numerical value.

Conversely, M-code commands manage auxiliary functions such as spindle rotation, coolant on/off, and tool changes. These commands begin with the letter M and are followed by a numerical code, specifying actions like starting or stopping the spindle, turning on coolant, or performing specific operations.

Applications span various industries, including manufacturing, aerospace, automotive, and electronics. CNC machines equipped with G-code and M-code capabilities offer unparalleled precision, efficiency, and flexibility in manufacturing processes. They enable complex machining operations like milling, turning, drilling, and grinding with consistent accuracy and repeatability.

In practice, CNC programmers input G-code and M-code instructions via software interfaces or directly into the machine’s control unit. This programming flexibility accommodates customized designs, rapid prototyping, and mass production of intricate components. Overall, G-code and M-code are fundamental to the functionality and versatility of CNC technology, driving advancements in manufacturing across diverse sectors worldwide.

Quality Testing Methods for cnc m code g code and how to control quality

Quality testing methods for CNC (Computer Numerical Control) programs written in M code and G code typically involve several approaches to ensure accuracy and reliability:

1. Syntax Checking: Utilize software tools that parse the code for syntax errors or inconsistencies. This ensures that the code follows the correct formatting and structure required by the CNC machine.

2. Simulation: Use CNC simulation software to visualize the toolpath and operations as defined by the code. This allows for virtual testing to detect collisions, improper tool movements, or other issues that could lead to errors during actual machining.

3. Code Verification: Perform code verification using CAM (Computer-Aided Manufacturing) software or dedicated verification tools. These tools analyze the G code and M code for logical errors, such as incorrect coordinate movements or toolpath deviations.

4. Post-Processor Validation: Validate the output of the post-processor that converts CAM-generated toolpaths into machine-specific G code and M code. Ensure that the post-processed code accurately reflects the intended machining operations.

5. Toolpath Analysis: Analyze the toolpath generated by the CNC program to verify that it matches the design specifications. Check for smooth transitions, correct cutting depths, and proper tool engagement throughout the machining process.

To control quality effectively, establish a comprehensive testing protocol that includes these methods. Regularly update and maintain the software tools used for syntax checking, simulation, and verification to keep pace with advancements in CNC technology and programming standards. Additionally, provide training for programmers and operators on quality assurance procedures to minimize errors and optimize machining efficiency.

Tips for Procurement and Considerations when Purchasing from cnc m code g code

Procuring and purchasing G-code from CNC m code providers requires careful consideration.

Tips for Procurement:

* Define your needs: Clearly outline the specific part geometry, tolerances, and required features.

* Seek reputable suppliers: Choose established providers with a proven track record and positive customer reviews.

* Request samples: Ask for sample G-code programs to evaluate the quality and accuracy of their work.

* Understand file formats: Confirm compatibility with your CNC machine’s controller and software.

* Discuss post-processing: Inquire about post-processing services, such as toolpath optimization and simulation.

Considerations:

* Price: Compare quotes from multiple suppliers while considering factors like complexity and turnaround time.

* Turnaround time: Determine the urgency of your project and ensure the supplier can meet your deadlines.

* Technical expertise: Verify the supplier’s understanding of your specific machining requirements.

* Support and revisions: Assess the level of support provided for troubleshooting and potential revisions.

Remember, clear communication and thorough vetting are crucial for a successful procurement experience.

FAQs on Sourcing and Manufacturing from cnc m code g code in China

When sourcing and manufacturing from China using CNC M-code and G-code, consider these FAQs:

1. What are CNC M-code and G-code?

CNC M-code (miscellaneous function) and G-code (geometric code) are standard programming languages used to control CNC machines. M-codes control auxiliary functions, while G-codes command specific movements and operations.

2. How can I find reliable suppliers in China proficient in CNC machining?

Utilize online platforms like Alibaba, Made-in-China, or attend trade shows such as Canton Fair. Verify supplier credentials, request samples, and conduct due diligence on their CNC capabilities and quality control processes.

3. What should I consider when choosing a manufacturer for CNC machining in China?

Evaluate their CNC equipment, expertise with M-code and G-code programming, production capacity, quality assurance protocols (like ISO certification), and their ability to meet your specific manufacturing requirements.

4. How can I ensure quality control during manufacturing?

Specify detailed technical drawings with tolerances, conduct regular inspections during production, and consider third-party quality inspections. Clear communication regarding tolerances, surface finishes, and material specifications is crucial.

5. What are common challenges in CNC manufacturing from China?

Potential issues include language barriers, cultural differences in business practices, intellectual property protection, and logistics. Address these by using clear contracts, protecting designs, and establishing transparent communication channels.

6. How do I manage logistics and shipping from China?

Partner with freight forwarders experienced in shipping industrial goods. Understand incoterms, customs duties, and packaging requirements to ensure smooth delivery.

By understanding these key aspects and addressing potential challenges proactively, you can effectively navigate sourcing and manufacturing using CNC M-code and G-code in China.