Technology and Applications of cnc g-code

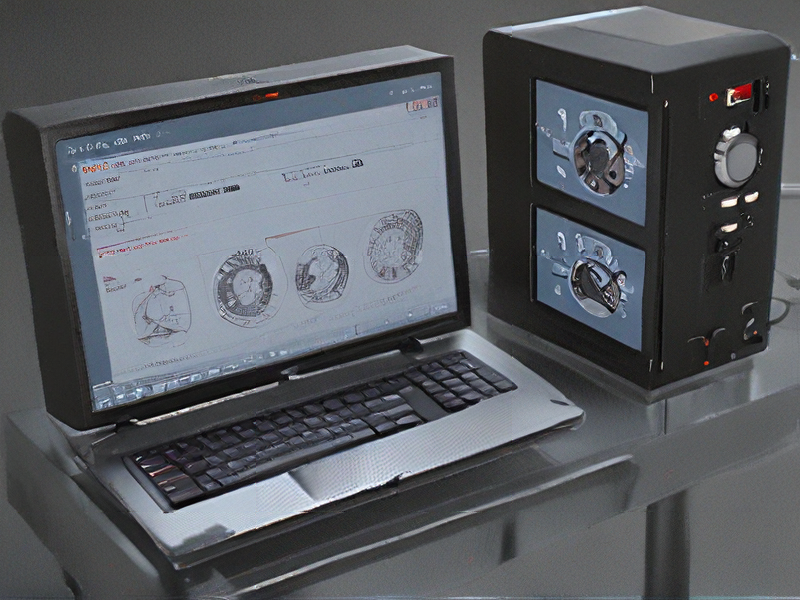

CNC (Computer Numerical Control) G-code is a programming language used to control CNC machines, which are automated tools that execute precise manufacturing tasks. G-code commands are alphanumeric instructions that dictate various operations such as cutting, drilling, and shaping materials like metal, wood, and plastics.

The technology behind G-code involves translating design specifications into a sequence of commands that CNC machines can understand and execute. These commands include movement coordinates, tool selection, speed, and other parameters essential for accurate machining. G-code files can be generated manually or by CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, which streamline the process by converting designs into machine-readable code.

Applications of G-code span across industries including manufacturing, aerospace, automotive, and prototyping. CNC machines equipped with G-code capabilities can produce complex geometries with high precision and repeatability, making them invaluable for mass production as well as rapid prototyping.

Key advantages of G-code programming include automation of repetitive tasks, reduced human error, and the ability to manufacture intricate parts that would be challenging or impossible with manual methods. Additionally, CNC machines can operate continuously, optimizing production efficiency and reducing lead times.

In summary, CNC G-code technology revolutionizes manufacturing by enabling precise control over automated machinery, facilitating diverse applications across industries while enhancing efficiency and accuracy in production processes.

Quality Testing Methods for cnc g-code and how to control quality

Testing CNC G-code for quality involves several methods to ensure accuracy and reliability:

1. Syntax Checking: Utilize software tools to verify G-code syntax adherence to standards like ISO 6983. This ensures commands are correctly formatted.

2. Simulation: Use CNC simulation software to visualize toolpaths and verify movements. This helps detect collisions, excessive tool wear, or improper cutting sequences.

3. Dimensional Verification: Measure physical parts produced by CNC machines using calibrated tools. Compare dimensions against CAD/CAM models to check for deviations.

4. Toolpath Analysis: Analyze the generated toolpath for smoothness and efficiency. Ensure it meets design requirements without unnecessary movements or abrupt changes.

5. Post-Processor Validation: Validate post-processed G-code output against expected machine-specific commands. Ensure correct tool selection, spindle speeds, and feed rates.

6. Material and Finish Inspection: Inspect finished parts for surface finish, accuracy, and overall quality. Identify defects or deviations from design specifications.

To control quality effectively:

– Establish clear quality standards and procedures.

– Train operators on G-code interpretation and quality assurance techniques.

– Implement regular maintenance and calibration schedules for CNC machines.

– Document and analyze quality data to identify trends and improvement opportunities.

By integrating these methods into your CNC workflow, you can enhance the quality and reliability of machined parts while minimizing errors and rework.

Tips for Procurement and Considerations when Purchasing from cnc g-code

When procuring CNC G-code, it’s essential to ensure you select the right supplier and follow best practices to avoid costly errors. Here are some key tips and considerations:

1. Supplier Reliability

– Reputation: Choose suppliers with a strong track record. Check reviews and testimonials.

– Experience: Prefer suppliers with extensive experience in your industry.

– Support: Ensure they offer robust customer support and technical assistance.

2. Quality Assurance

– Standards Compliance: Verify that the G-code adheres to industry standards.

– Testing: Request sample G-codes to test on your machines before bulk purchase.

– Certification: Opt for suppliers who provide certification of the code’s accuracy.

3. Customization and Flexibility

– Tailored Solutions: Ensure the supplier can customize G-code for your specific needs.

– Software Compatibility: Confirm compatibility with your CNC machines and software.

4. Cost Considerations

– Transparent Pricing: Look for suppliers with clear pricing structures.

– Value Over Cost: Avoid choosing based solely on the lowest price; consider the value provided.

– Bulk Discounts: Negotiate for discounts on bulk orders.

5. Security and Confidentiality

– Data Protection: Ensure the supplier has measures to protect your design files.

– Confidentiality Agreements: Use NDAs to safeguard your intellectual property.

6. Lead Times and Delivery

– Prompt Delivery: Confirm that the supplier can meet your delivery timelines.

– Flexibility: Assess their ability to handle urgent or unexpected orders.

7. After-Sales Service

– Support: Evaluate the availability of ongoing support and troubleshooting.

– Updates: Check if the supplier offers updates or modifications to the G-code post-purchase.

8. Regulatory Compliance

– Legal Compliance: Ensure the supplier complies with all relevant regulations and industry standards.

– Documentation: Require proper documentation for all transactions.

9. Technical Expertise

– Consultation: Engage with suppliers who offer technical consultation to optimize your G-code use.

– Training: Consider suppliers who provide training for your team on utilizing the G-code effectively.

By carefully evaluating these aspects, you can make informed decisions that enhance the efficiency and reliability of your CNC operations.

FAQs on Sourcing and Manufacturing from cnc g-code in China

FAQs on Sourcing and Manufacturing CNC G-Code in China

1. Why source CNC G-Code services from China?

China is a global leader in manufacturing, offering cost-effective solutions, advanced technology, and skilled labor. Many companies choose China for its ability to produce high-quality CNC G-Code at competitive prices.

2. What are CNC G-Code services?

CNC G-Code is a language used to control automated machine tools. These services involve programming machines to produce parts with precision, based on specific design requirements.

3. How do I find reliable CNC G-Code manufacturers in China?

Use platforms like Alibaba, Made-in-China, and Global Sources. Verify suppliers through customer reviews, certifications, and by requesting samples.

4. What should I consider when choosing a supplier?

Consider the supplier’s experience, production capacity, quality control measures, and communication skills. Also, check for industry certifications like ISO.

5. How can I ensure the quality of the CNC G-Code produced?

Request prototypes and sample runs. Conduct factory audits, either personally or through third-party inspection services. Ensure the supplier has robust quality control processes.

6. What are the common payment terms?

Common terms include 30% deposit upfront and 70% balance upon shipment. Letters of credit and escrow services are also used to secure transactions.

7. How can I protect my intellectual property (IP)?

Sign non-disclosure agreements (NDAs) and ensure the supplier is aware of IP laws. Register your patents and trademarks in China.

8. What is the typical lead time for CNC G-Code services?

Lead times vary depending on complexity and order size but generally range from 2 to 6 weeks. Confirm timelines with your supplier.

9. Are there language barriers?

English is widely spoken in the business community. However, having a translator or bilingual staff can help avoid misunderstandings.

10. What are the shipping options?

Options include air freight for smaller, urgent orders and sea freight for larger, cost-sensitive shipments. Work with a reliable logistics provider to handle customs and delivery.

By addressing these common questions, businesses can better navigate the process of sourcing and manufacturing CNC G-Code in China, ensuring a smooth and efficient operation.