Technology and Applications of cnc gcode

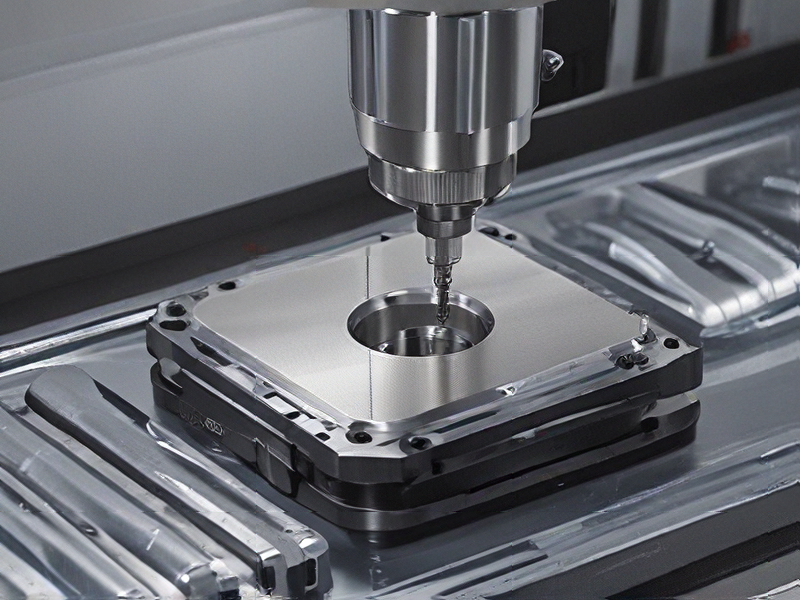

CNC (Computer Numerical Control) G-code is pivotal in modern manufacturing, automating the operation of machines like mills, lathes, and routers. It consists of a set of instructions that direct the precise movements and operations of these machines. Here are some key aspects and applications of CNC G-code:

1. Programming Language: G-code uses a standardized syntax to control CNC machines. It specifies commands for movements along the X, Y, and Z axes, spindle speed, tool changes, and coolant flow, among others.

2. Versatility: CNC G-code enables the production of complex parts with high accuracy and repeatability. It is used across various industries including aerospace, automotive, medical, and electronics.

3. Automation: By automating machine operations, G-code reduces manual intervention, minimizing errors and increasing productivity. Operators create G-code using CAM (Computer-Aided Manufacturing) software, which converts CAD (Computer-Aided Design) models into machine-readable instructions.

4. Precision Machining: CNC G-code facilitates intricate machining processes such as drilling, milling, turning, and grinding. It supports multi-axis machining, allowing machines to operate in 3, 4, or 5 axes for intricate part geometries.

5. Integration with CAD/CAM: G-code works closely with CAD models, translating design specifications into tangible products. CAM software generates G-code based on CAD designs, optimizing tool paths for efficiency and precision.

6. Customization: Manufacturers can tailor G-code to specific machine capabilities and material properties. This flexibility accommodates a wide range of production requirements and material types.

7. Continuous Advancements: The field of CNC machining continues to evolve with advancements in G-code programming, machine automation, and integration with IoT (Internet of Things) technologies for real-time monitoring and adaptive machining.

In essence, CNC G-code underpins the efficiency, accuracy, and flexibility of modern manufacturing processes, enabling industries to produce high-quality components and products at scale.

Quality Testing Methods for cnc gcode and how to control quality

To ensure the quality of CNC G-code, several methods can be employed:

1. Syntax and Structure Checking: Utilize software tools that verify the syntax and structure of the G-code for errors or inconsistencies. This ensures the commands are correctly formatted and interpreted by the CNC machine.

2. Simulation and Verification: Use CNC simulation software to visualize the toolpath and simulate the machining process. This helps identify potential collisions, toolpath inefficiencies, or errors in machining operations before actual production.

3. Dimensional Analysis: Perform dimensional checks on machined parts using metrology tools such as calipers, micrometers, or coordinate measuring machines (CMMs). Compare actual dimensions with the intended design specifications to ensure accuracy.

4. Run-off Testing: Conduct initial small-scale production runs (run-off tests) to validate the G-code’s performance in real-world conditions. Inspect the produced parts for dimensional accuracy, surface finish, and overall quality against set standards.

5. Documentation and Version Control: Maintain comprehensive documentation of G-code programs, revisions, and machining parameters. Implement version control practices to track changes and ensure consistency in production processes.

6. Operator Training and Feedback: Provide thorough training to CNC operators on interpreting and executing G-code programs. Encourage feedback from operators regarding any issues encountered during machining, which can inform improvements in G-code quality.

By integrating these methods into the manufacturing process, companies can effectively control the quality of CNC G-code programming and ensure that machined parts meet desired specifications reliably.

Tips for Procurement and Considerations when Purchasing from cnc gcode

When purchasing CNC G-code, several considerations can ensure a smooth procurement process:

1. Accuracy and Compatibility: Ensure the G-code is compatible with your specific CNC machine model and version. Verify accuracy to prevent errors during machining.

2. Source and Reliability: Purchase G-code from reputable sources to guarantee quality and reliability. Consider vendors who offer support and updates.

3. Customization and Adaptability: Opt for G-code that allows customization to suit your production needs. Flexible code enables adjustments for different materials and geometries.

4. Security and Integrity: Prioritize G-code security to prevent tampering or unauthorized modifications that could compromise machining operations or intellectual property.

5. Cost-effectiveness: Compare pricing among vendors, balancing cost with quality and features. Look for value-added services like training or technical support.

6. Legal and Licensing: Ensure compliance with licensing agreements and intellectual property rights when purchasing proprietary G-code or software.

7. Training and Support: Choose vendors who provide training resources or technical support to maximize efficiency and troubleshoot issues promptly.

8. Integration and Workflow: Consider how the G-code integrates into your existing workflow. Compatibility with CAM software and CNC controllers is crucial for seamless operations.

9. Updates and Maintenance: Check if the vendor provides regular updates and maintenance support for their G-code to stay current with industry standards and improvements.

10. Feedback and Reviews: Seek feedback from industry peers or reviews online to gauge the performance and reliability of the G-code vendor.

By prioritizing these considerations, you can make informed decisions when purchasing CNC G-code, ensuring it meets your operational requirements while enhancing productivity and minimizing risks.

FAQs on Sourcing and Manufacturing from cnc gcode in China

When sourcing and manufacturing from CNC G-code in China, consider these FAQs:

1. What should I look for in a CNC machining supplier in China?

Look for suppliers with proven experience in your industry, certifications like ISO 9001 for quality management, and capabilities that match your project requirements.

2. How can I ensure quality control?

Implement thorough supplier vetting, conduct inspections during production, and consider third-party quality assurance services. Clear communication and defining quality standards upfront are crucial.

3. What are common challenges when sourcing from China?

Language barriers, cultural differences, intellectual property protection, and logistics can be challenging. Choose suppliers with good communication skills and experience in international trade.

4. How can I protect my designs and intellectual property?

Use non-disclosure agreements (NDAs) and ensure your supplier respects intellectual property rights. Consider registering trademarks and patents where applicable.

5. What are typical lead times for CNC manufacturing in China?

Lead times vary based on complexity and volume. Generally, they range from a few days to several weeks. Clear communication and planning are key to meeting deadlines.

6. What are the advantages of sourcing CNC manufacturing from China?

Lower labor costs, a wide range of capabilities, and flexibility in production volumes are primary advantages. China has a vast supplier network offering competitive pricing.

7. How do I handle shipping and logistics?

Work closely with your supplier to determine shipping methods, costs, and timelines. Consider using a freight forwarder for smoother logistics management.

8. What payment terms are common?

Common terms include T/T (Telegraphic Transfer) and Alibaba’s trade assurance. Negotiate terms that balance security and flexibility for both parties.

9. What should I do if I encounter quality issues?

Address issues promptly with your supplier, supported by clear documentation and evidence. Having a contingency plan for rework or replacement is advisable.

10. How can I build a long-term relationship with a Chinese supplier?

Foster trust through consistent communication, fair treatment, and honoring commitments. Visit the supplier if feasible to strengthen relationships and understand their capabilities better.

Navigating sourcing and manufacturing from CNC G-code in China requires diligence, clear expectations, and proactive management to ensure successful outcomes.