Technology and Applications of fibre optic laser cutting machines

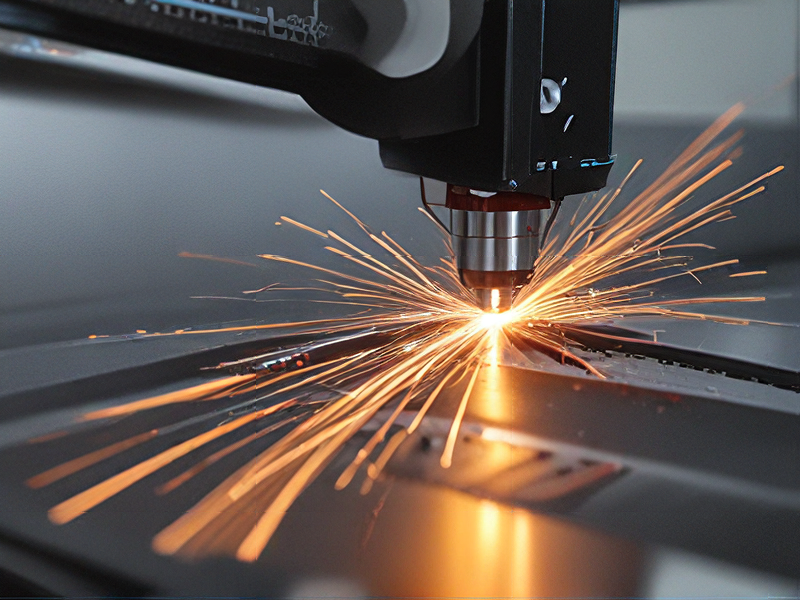

Fiber optic laser cutting machines utilize high-powered laser beams generated within optical fibers for precise cutting applications across various materials. These machines are highly efficient due to their ability to focus intense laser energy into a small spot size, enabling clean and accurate cuts with minimal heat-affected zones.

Key technologies involved include:

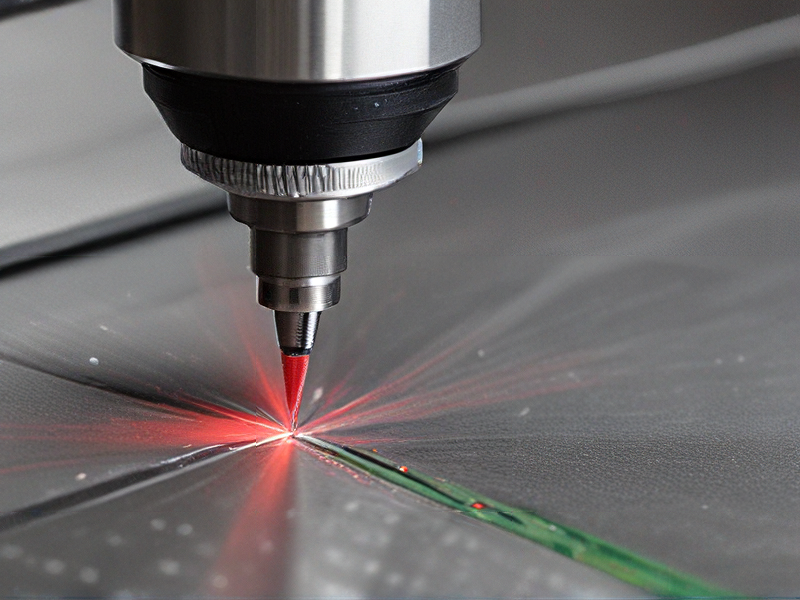

1. Fiber Optic Delivery System: Utilizes optical fibers to transmit laser energy from the source (laser resonator) to the cutting head. These fibers are flexible and can be routed over long distances without significant energy loss.

2. High-Powered Laser Source: Typically a fiber laser resonator, which generates the laser beam used for cutting. Fiber lasers are preferred due to their high electrical efficiency, reliability, and capability to produce high-quality beams suitable for precision cutting.

3. Cutting Head: Contains focusing optics that concentrate the laser beam to a small diameter at the material surface, ensuring precise and efficient cutting. Some cutting heads also incorporate automated height control and real-time monitoring systems to maintain optimal cutting conditions.

Applications of fiber optic laser cutting machines span various industries:

– Manufacturing: Used extensively in automotive, aerospace, and electronics industries for cutting metals (e.g., steel, aluminum) and other materials (e.g., plastics, composites).

– Fabrication: Ideal for creating complex shapes and intricate patterns in sheet metal fabrication, signage, and architectural components.

– Prototyping and Rapid Manufacturing: Enables quick iteration and production of prototypes and small batches with high accuracy and repeatability.

Benefits include:

– Precision and Speed: Capable of cutting intricate shapes with high precision at high cutting speeds, reducing production times.

– Flexibility: Can process a wide range of materials and thicknesses, adapting easily to changing production needs.

– Cost Efficiency: Lower operating costs due to reduced energy consumption and minimal material wastage compared to traditional cutting methods.

In conclusion, fiber optic laser cutting machines represent a technological leap in manufacturing and fabrication, offering unmatched precision, speed, and versatility across various industries while contributing to cost-effective and sustainable production processes.

Quality Testing Methods for fibre optic laser cutting machines and how to control quality

Quality testing methods for fiber optic laser cutting machines typically involve both in-process and post-process inspections to ensure consistent performance and output precision. Here are some key methods and strategies:

1. Dimensional Accuracy Checks: Utilizing precision measuring tools such as micrometers and calipers to verify the dimensions of cut parts against design specifications.

2. Surface Quality Inspection: Visual inspection or the use of optical profilometers to assess the smoothness and surface finish of cut edges.

3. Edge Quality Analysis: Testing for burrs, dross, or any irregularities along the edges of cut parts, often done through microscopic examination.

4. Accuracy of Cutting Path: Verifying the accuracy of the laser cutting path through alignment checks and geometric measurements using coordinate measuring machines (CMMs).

5. Material Integrity Testing: Ensuring that the heat-affected zone (HAZ) and overall material integrity meet required standards, possibly using non-destructive testing techniques like ultrasonic testing.

To control quality effectively:

– Calibration and Maintenance: Regular calibration of laser power, beam focus, and motion systems to maintain cutting precision.

– Process Monitoring: Real-time monitoring of key process parameters such as laser power, cutting speed, and assist gas pressure to detect deviations that could affect quality.

– Operator Training: Thorough training programs for operators to understand machine capabilities, optimal settings, and quality standards.

– Quality Management System (QMS): Implementing a QMS to document procedures, track non-conformances, and ensure continuous improvement.

By integrating these testing methods and quality control strategies, manufacturers can uphold high standards of quality and consistency in fiber optic laser cutting operations.

Tips for Procurement and Considerations when Purchasing from fibre optic laser cutting machines

When purchasing fiber optic laser cutting machines for procurement, several key considerations can ensure you make an informed decision:

1. Performance Specifications: Evaluate the machine’s cutting speed, accuracy, and power levels to match your specific production needs. Ensure it can handle the materials (such as metals, plastics) and thicknesses you intend to work with.

2. Laser Source and Technology: Understand the type of laser source (fiber, CO2) and its impact on efficiency, maintenance requirements, and operational costs. Fiber lasers are typically more energy-efficient and offer faster cutting speeds compared to CO2 lasers.

3. Cutting Area and Bed Size: Consider the size of the cutting bed in relation to your typical workpiece sizes. A larger bed accommodates bigger materials and allows for simultaneous processing of multiple smaller components.

4. Automation and Software Integration: Look for features like automatic material handling, nesting software capabilities, and compatibility with CAD/CAM systems. These streamline operations and improve productivity.

5. Maintenance and Support: Assess the ease of maintenance, availability of spare parts, and the reputation of the manufacturer or supplier for after-sales support and service.

6. Energy Efficiency and Operating Costs: Evaluate the machine’s power consumption and operational costs over its lifespan. Fiber lasers are generally more energy-efficient than CO2 lasers, contributing to lower operating costs.

7. Safety and Compliance: Ensure the machine meets safety standards and regulatory requirements applicable to your industry and region. This includes laser safety features and emissions compliance.

8. User Interface and Ergonomics: A user-friendly interface and ergonomic design contribute to operator efficiency and safety. Consider ease of programming, monitoring, and adjusting cutting parameters.

9. Reviews and References: Seek testimonials and reviews from other users or industry peers to gauge reliability, performance, and customer satisfaction with the machine and the supplier.

10. Cost and Return on Investment (ROI): Balance upfront costs with long-term ROI considerations, factoring in productivity gains, operational efficiencies, and potential revenue growth.

By carefully evaluating these factors, you can select a fiber optic laser cutting machine that aligns with your operational requirements, budget constraints, and growth objectives.

FAQs on Sourcing and Manufacturing from fibre optic laser cutting machines in China

FAQs on Sourcing and Manufacturing Fibre Optic Laser Cutting Machines in China

1. Why source fibre optic laser cutting machines from China?

China is a leading manufacturer of fibre optic laser cutting machines, offering high-quality products at competitive prices. The country has advanced manufacturing capabilities, a skilled workforce, and a well-developed supply chain.

2. How do I find reliable manufacturers?

Research online marketplaces like Alibaba and Global Sources, attend trade shows such as the Canton Fair, and consult industry associations. Look for manufacturers with positive reviews, certifications (ISO, CE), and a track record of exporting to your country.

3. What factors should I consider when choosing a manufacturer?

Evaluate the manufacturer’s experience, production capacity, quality control processes, after-sales service, and ability to provide customization. Request samples and visit factories if possible.

4. What are the common payment terms?

Typical payment terms include a 30% deposit upfront and 70% balance before shipment. Other options include letters of credit or escrow services to protect both parties.

5. How long does production and delivery take?

Production time varies but generally ranges from 30 to 60 days. Shipping can take an additional 20 to 40 days, depending on your location and shipping method.

6. What about quality control and inspections?

Ensure quality by requesting pre-shipment inspections and third-party quality control services. Many companies specialize in inspecting manufacturing facilities and products in China.

7. Are there any import regulations I should be aware of?

Check your country’s import regulations regarding certifications, tariffs, and duties. Ensure the machines comply with local safety and environmental standards.

8. How can I ensure good after-sales service and support?

Choose manufacturers that offer comprehensive after-sales support, including training, installation, maintenance, and spare parts supply. Verify their responsiveness and capability to address issues promptly.

9. What about warranties and guarantees?

Most manufacturers offer warranties ranging from one to two years. Clarify warranty terms, including coverage, duration, and the process for claiming repairs or replacements.

10. Can I customize the machines?

Many Chinese manufacturers offer customization to meet specific requirements. Discuss your needs upfront and ensure the manufacturer can accommodate them within reasonable timeframes and costs.

By carefully selecting a reputable manufacturer and understanding the sourcing process, you can efficiently procure high-quality fibre optic laser cutting machines from China.