Technology and Applications of tools for grinding metal

Grinding metal involves various tools and technologies designed for precision and efficiency in shaping and finishing metal surfaces. Key tools include:

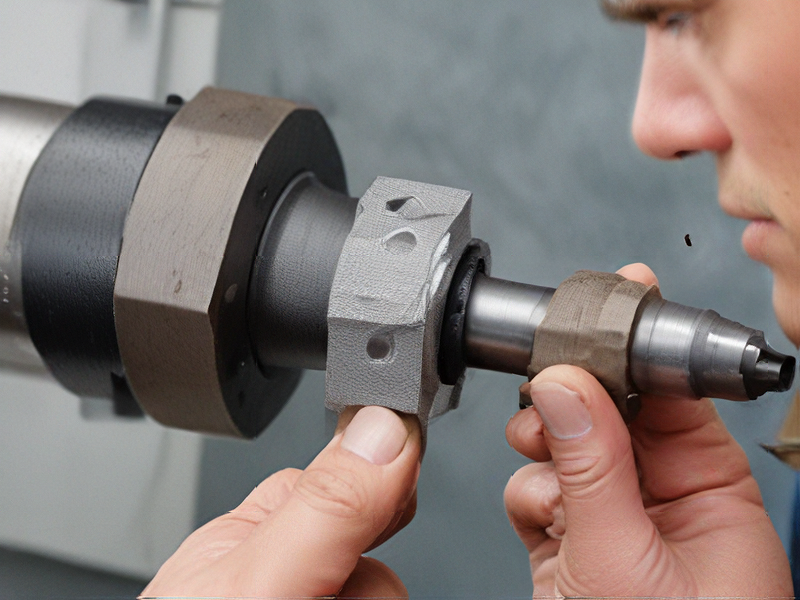

1. Grinding Machines: These range from bench grinders for rough work to precision surface grinders for fine finishing. They use abrasive wheels or belts to remove material and achieve desired surface quality.

2. Abrasive Wheels: Made of abrasive particles bonded together, wheels like aluminum oxide and silicon carbide vary in hardness and grit size for different applications. Diamond and cubic boron nitride wheels are used for harder metals.

3. Coolants and Lubricants: Essential for cooling workpieces and preventing overheating and thermal damage during grinding, coolants also aid in flushing away swarf (metallic debris) for cleaner finishes.

4. Safety Gear: Personal protective equipment such as goggles, gloves, and face shields protect operators from sparks, debris, and coolant splashes.

Applications of metal grinding tools include:

– Deburring: Removing sharp edges and burrs from metal components.

– Surface Preparation: Achieving smooth, even surfaces before coating or further processing.

– Precision Grinding: Fine-tuning dimensions and achieving tight tolerances in manufacturing.

– Sharpening: Refurbishing cutting tools like drills and lathe bits for extended use.

Innovations in grinding technology continue to enhance efficiency and precision, such as computer numerical control (CNC) integration for automated and repeatable processes, and advancements in abrasive materials for longer tool life and enhanced performance. These tools and technologies play crucial roles across industries from automotive to aerospace, enabling the production of high-quality metal components.

Quality Testing Methods for tools for grinding metal and how to control quality

Quality testing methods for tools used for grinding metal typically involve several key approaches to ensure performance and durability:

1. Dimensional Accuracy: Tools must meet precise dimensional specifications. This is verified using calipers, micrometers, or coordinate measuring machines (CMMs) to ensure the tool’s dimensions match design requirements.

2. Hardness Testing: Metal grinding tools require specific hardness levels to perform effectively. Rockwell or Brinell hardness tests are commonly used to verify the hardness of the tool material.

3. Surface Roughness Measurement: The surface finish of grinding tools affects the quality of the finished metal surface. Profilometers or surface roughness testers measure the roughness parameters to ensure they meet specified limits.

4. Microstructural Analysis: Tools undergo microscopic examination to assess their internal structure and ensure uniformity. This can reveal defects such as voids or inclusions that may compromise tool integrity.

5. Performance Testing: Tools are tested under operational conditions to evaluate performance metrics such as material removal rate, wear resistance, and stability. This can involve grinding tests on standardized workpieces.

Quality Control Measures:

1. Supplier Assessment: Ensure suppliers adhere to quality standards and provide certifications for raw materials.

2. In-process Inspections: Regular checks during manufacturing to catch defects early and prevent them from propagating.

3. Statistical Process Control (SPC): Monitor key process parameters using control charts to ensure consistency and predictability.

4. Quality Audits: Periodic audits to verify adherence to quality procedures and standards.

5. Feedback and Continuous Improvement: Gather feedback from users and incorporate it into product redesign and improvement processes.

By implementing these testing methods and quality control measures, manufacturers can ensure that tools for grinding metal meet stringent quality standards, enhancing reliability and customer satisfaction.

Tips for Procurement and Considerations when Purchasing from tools for grinding metal

When procuring tools for grinding metal, several key considerations can ensure you get the best quality and value. Here are some tips and factors to consider:

1. Understand Your Needs

– Material Type: Different metals (e.g., stainless steel, aluminum) require specific grinding tools.

– Purpose: Determine whether the grinding tool is for heavy-duty industrial use or smaller-scale tasks.

2. Quality and Durability

– Brand Reputation: Opt for well-known brands with a track record of quality.

– Material Quality: Check the composition and build quality of the tool to ensure it can withstand rigorous use.

3. Types of Grinding Tools

– Angle Grinders: Versatile and commonly used for various metal grinding tasks.

– Bench Grinders: Ideal for sharpening and detailed work.

– Belt Grinders: Suitable for finishing and smoothing metal surfaces.

4. Safety Features

– Guard Adjustments: Ensure the grinder has adjustable guards for safety.

– Vibration Control: Look for tools with vibration control features to reduce user fatigue and improve precision.

5. Power and Performance

– Motor Power: Higher power motors (measured in watts or horsepower) provide more efficient grinding.

– Speed Control: Variable speed settings allow for greater control over the grinding process.

6. Ergonomics and Usability

– Handle Design: Comfortable, anti-slip handles reduce strain during prolonged use.

– Weight: A lighter tool can be easier to handle, but ensure it doesn’t compromise on power.

7. Cost vs. Value

– Budget: Balance between cost and the features offered. Cheaper tools may save money initially but might not last as long.

– Warranty: Check for warranties or guarantees that cover defects and long-term use.

8. Supplier Reliability

– Reputation: Purchase from reputable suppliers known for reliable products and good customer service.

– Support: Ensure that there is adequate customer support and availability of replacement parts.

By carefully considering these factors, you can select the right grinding tool for your needs, ensuring efficiency, safety, and value for your investment.

FAQs on Sourcing and Manufacturing from tools for grinding metal in China

FAQs on Sourcing and Manufacturing Tools for Grinding Metal in China

#### 1. Why source metal grinding tools from China?

China is known for its vast manufacturing capabilities, cost-effective production, and a wide variety of metal grinding tools. The country offers competitive pricing, high-quality standards, and a robust supply chain.

#### 2. What types of metal grinding tools are commonly sourced from China?

Common tools include angle grinders, bench grinders, die grinders, surface grinders, and various types of grinding wheels and discs. Chinese manufacturers also produce custom grinding tools tailored to specific industrial needs.

#### 3. How to find reliable suppliers?

Utilize platforms like Alibaba, Global Sources, and Made-in-China to search for suppliers. Verify their credentials through customer reviews, certifications, and visiting their factories if possible. Trade shows and exhibitions can also be a good opportunity to meet suppliers.

#### 4. What should I consider when selecting a supplier?

Consider the supplier’s experience, quality control processes, production capacity, and lead times. Check for certifications such as ISO, and request product samples to evaluate quality.

#### 5. How to ensure product quality?

Implement stringent quality control measures including pre-shipment inspections and factory audits. Use third-party inspection agencies like SGS or Bureau Veritas to conduct thorough checks.

#### 6. What are the typical payment terms?

Common payment terms include 30% deposit before production and 70% balance before shipment (T/T). Letters of Credit (L/C) are also widely accepted. Always negotiate terms that protect your interests.

#### 7. How to handle shipping and logistics?

Work with experienced freight forwarders to manage shipping logistics. Consider Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to clearly define responsibilities.

#### 8. What about intellectual property protection?

Register patents and trademarks in China. Use Non-Disclosure Agreements (NDAs) and Non-Compete Agreements (NCAs) with suppliers to safeguard your designs and technology.

#### 9. Are there any trade regulations to be aware of?

Familiarize yourself with import/export regulations, tariffs, and duties. Ensure compliance with both Chinese and your home country’s regulations to avoid legal issues.

#### 10. Can I visit the factories?

Yes, visiting factories is recommended. It provides an opportunity to inspect production facilities, meet with management, and ensure that manufacturing practices align with your standards.

Sourcing metal grinding tools from China can be highly beneficial if managed carefully with attention to quality, reliability, and regulatory compliance.