Technology and Applications of discount steel

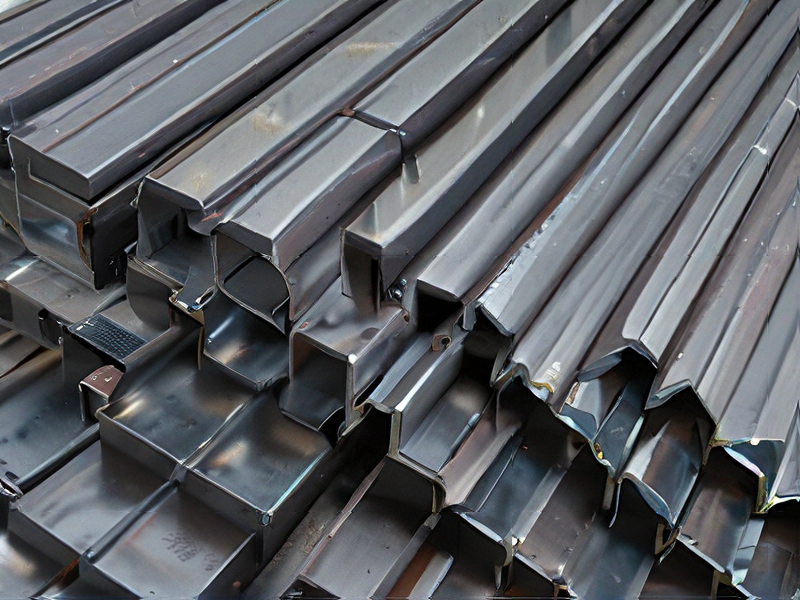

Technology and Applications of Discount Steel

Technology:

Discount steel is produced using advanced metallurgical techniques that optimize cost efficiency without compromising quality. These techniques include electric arc furnace (EAF) technology, which melts scrap steel with electricity, reducing raw material costs and environmental impact. Continuous casting processes improve yield and reduce waste by forming steel directly into shapes suitable for subsequent processing. Alloying and heat treatment technologies enhance specific properties, such as strength, ductility, and corrosion resistance, tailoring the steel for various applications.

Applications:

1. Construction:

Discount steel is extensively used in the construction industry for structural components such as beams, columns, and reinforcing bars. Its high strength-to-weight ratio makes it ideal for skyscrapers, bridges, and residential buildings.

2. Automotive:

In the automotive sector, discount steel is employed for chassis, body panels, and engine components. Its affordability and durability help manufacturers maintain cost-effective production while ensuring vehicle safety and performance.

3. Infrastructure:

Discount steel is vital in infrastructure projects, including railways, pipelines, and power plants. Its robustness and versatility support the construction of durable and reliable transportation and utility systems.

4. Manufacturing:

In manufacturing, discount steel is used to produce machinery, tools, and equipment. Its machinability and weldability make it suitable for fabricating a wide range of industrial products, from small tools to large industrial machines.

5. Energy Sector:

The energy sector benefits from discount steel in the construction of oil rigs, wind turbines, and solar panel supports. Its resilience and adaptability to harsh environments ensure the longevity and reliability of energy infrastructure.

In summary, discount steel leverages advanced production technologies to provide cost-effective, high-quality material suitable for diverse applications, from construction and automotive to infrastructure and energy sectors, driving economic growth and technological advancement.

Quality Testing Methods for discount steel and how to control quality

Quality testing for discount steel involves several methods to ensure the material meets required standards despite its lower cost. The key methods include:

1. Visual Inspection: Initial examination for obvious defects like cracks, surface irregularities, and rust.

2. Chemical Composition Analysis: Using spectrometers to verify the chemical makeup, ensuring it conforms to specifications.

3. Mechanical Testing:

– Tensile Testing: Measures the strength and ductility of the steel.

– Hardness Testing: Determines resistance to indentation using methods like Rockwell, Brinell, or Vickers.

– Impact Testing: Assesses the material’s toughness, typically through Charpy or Izod tests.

4. Non-Destructive Testing (NDT):

– Ultrasonic Testing (UT): Detects internal flaws using high-frequency sound waves.

– Radiographic Testing (RT): Uses X-rays or gamma rays to identify internal defects.

– Magnetic Particle Testing (MPT): Reveals surface and near-surface discontinuities in ferromagnetic materials.

– Dye Penetrant Testing (DPT): Highlights surface cracks by applying a liquid dye.

5. Dimensional Inspection: Ensures the steel’s dimensions are within tolerance using tools like calipers, micrometers, and coordinate measuring machines (CMM).

To control quality, the following practices are essential:

– Supplier Certification: Work with certified suppliers who provide documentation and evidence of quality.

– In-Process Inspections: Regular checks during manufacturing to catch defects early.

– Quality Management Systems (QMS): Implement standards such as ISO 9001 to maintain consistent quality control processes.

– Traceability: Maintain records of the steel’s origin, processing, and testing results to ensure accountability and trace back any issues.

– Regular Audits: Conduct internal and external audits to verify compliance with quality standards.

These methods and controls help ensure that discount steel meets necessary performance and safety standards, mitigating risks associated with lower-cost materials.

Tips for Procurement and Considerations when Purchasing from discount steel

When procuring steel, especially from discount sources, several key tips and considerations can help ensure a successful purchase:

1. Quality Verification:

– Specifications: Ensure the steel meets required specifications, such as ASTM standards.

– Certifications: Request material certifications or mill test reports to verify the quality.

– Reputation: Purchase from reputable suppliers with positive reviews and a track record of reliability.

2. Supplier Evaluation:

– Experience: Check the supplier’s experience in the industry and their ability to meet your demands.

– Customer Service: Assess their responsiveness and willingness to address concerns.

– References: Ask for references or case studies of previous clients.

3. Cost Considerations:

– Total Cost of Ownership: Consider all costs, including shipping, handling, and potential hidden fees.

– Price Comparison: Compare prices from multiple suppliers to ensure you are getting a competitive rate.

– Bulk Discounts: Inquire about discounts for bulk purchases to optimize cost savings.

4. Logistics and Delivery:

– Lead Times: Confirm delivery lead times and ensure they align with your project schedule.

– Shipping Conditions: Understand the shipping conditions and who is responsible for freight costs.

– Storage Requirements: Ensure you have appropriate storage conditions to maintain the steel’s integrity upon arrival.

5. Risk Management:

– Inspection: Implement a robust inspection process upon receipt to catch any discrepancies early.

– Return Policies: Understand the supplier’s return policies and procedures in case the material is not as expected.

– Contractual Terms: Have clear contractual terms that protect your interests and outline the supplier’s responsibilities.

6. Sustainability and Compliance:

– Environmental Impact: Consider the environmental impact of the steel and opt for suppliers who prioritize sustainable practices.

– Regulatory Compliance: Ensure the steel complies with relevant local and international regulations.

By following these tips, you can mitigate risks, ensure quality, and achieve cost-effective procurement of discount steel.

FAQs on Sourcing and Manufacturing from discount steel in China

FAQs on Sourcing and Manufacturing from Discount Steel in China

1. Why source steel from China?

China is a global leader in steel production, offering competitive prices due to large-scale production and lower labor costs. This makes Chinese steel attractive for cost-sensitive projects.

2. Is the quality of Chinese steel reliable?

The quality varies by manufacturer. Reputable suppliers adhere to international standards like ISO and ASTM. Always request certifications and perform due diligence, including third-party inspections.

3. How can I find a reliable steel supplier in China?

Use online platforms like Alibaba or Made-in-China, and consider recommendations from industry peers. Conduct thorough background checks and visit factories if possible.

4. What are the common types of steel available?

Chinese suppliers offer a wide range of steel types, including carbon steel, stainless steel, alloy steel, and galvanized steel, suitable for various industrial applications.

5. How do I ensure the steel meets my specifications?

Provide detailed specifications and standards in your contract. Arrange for pre-shipment inspections and quality control tests by independent agencies.

6. What are the common payment terms?

Typical terms include T/T (telegraphic transfer), L/C (letter of credit), and D/P (documents against payment). Negotiate favorable terms and consider using escrow services for added security.

7. How do I handle shipping and logistics?

Most suppliers offer FOB (free on board) terms. You’ll need to arrange shipping through a freight forwarder. Ensure all customs documentation is accurate to avoid delays.

8. What about tariffs and import duties?

Check with your local customs office for applicable tariffs and duties on steel imports from China. These can impact overall cost savings.

9. How do I manage communication and potential language barriers?

Many Chinese suppliers have English-speaking representatives. Use clear, simple language, and confirm all details in writing to avoid misunderstandings.

10. What are the risks involved?

Risks include quality discrepancies, delays, and increased costs from tariffs. Mitigate these by choosing reputable suppliers, conducting regular audits, and having contingency plans.

By understanding these key aspects, businesses can effectively source and manufacture discount steel from China, balancing cost savings with quality assurance.